What is a ventilation diffuser

The diffuser is small in size, but an important design element of the ventilation system. Externally, it is a housing with a ventilation grille of complex design. What is air stagnation, drafts will have to be forgotten when the diffuser is installed in the ventilation.

The air passing through a conventional grille of a ventilation system ends up at the same point. In this case, zones of air with different temperatures are formed in the room. Its function is to protect the air duct from the accumulation of dust and debris.

The functionality of the diffuser is superior to that of a conventional grille. A diffuser is a structural unit located at the inlet or outlet of an air duct. It has special impellers and blades, thanks to which the air volume is taken in evenly and distributed optimally in the room. Makes it possible to use a static pressure chamber in ventilation with small dispersion holes, to change the direction of air movement and its shape.

A ventilation grille should be preferred over a diffuser in old high-rise buildings. The ventilation ducts there operate on the principle of pressure difference. The system outputs are located in the walls. Installing a diffuser won't change anything. However, if under these conditions you make an air duct and hide it in the gap between the false ceiling and the real ceiling, the diffuser will contribute to the rapid movement of air flows.

What is a diffuser?

A diffuser for a ventilation system is a device that has the shape of a lattice on the outside. The purpose of this unit is to uniformly distribute the incoming and outgoing air masses of the room. There are three types of devices that help dissipate air flows:

- Supply;

- Exhaust;

- Supply and exhaust (universal);

Diffusers in air conditioning

The purpose of such devices is to uniformly distribute air flows from an air conditioner or fan through air ducts into the room.

Difference between diffuser and vent grille

The difference between these devices is only in the design and intensity of air movement.

During the calculation and design of air flow dispersion equipment, air circulation is taken into account. Therefore, the arrangement of the blades and partitions of the structure is carried out so that the air flows are mixed as efficiently as possible and evenly distributed throughout the space of the room.

A diffuser, like ventilation grilles, promotes a more intense flow of air to the air ducts from the air conditioner, but does so in a slower and smoother manner.

Operating principle and purpose

Unlike the ventilation grille of outdated designs, the ventilation diffuser is designed in such a way that air flows do not just pass through it, but are mixed as efficiently as possible and distributed evenly in the room.

This is facilitated by the special design of partitions and blades. The principle operates both when air flow enters the system and when it is removed. The main purpose of the device is the effective distribution of air flows in space. Exhaust diffusers guarantee the absence of drafts, uneven ventilation, and air zones where fresh air does not reach.

An exhaust diffuser modernizes the exhaust system. Without the presence of an air distributor, exhaust air is extracted in the form of jets. The atmosphere of the room suffers. In addition, the amount of exhaust air passing through the exhaust system depends on the change in the direction of its flow. An air diffuser helps solve the problem.

Effective ventilation of the room where the ventilation diffuser is used. If the air masses are not dispersed, the ventilation system ventilates only the area where the air circulates. Using a diffuser, fresh air is distributed according to the vortex principle.

Air flow control is another purpose of the design. You can eliminate the noise of air moving around the room.

The ventilation air diffuser protects the entrance to the air duct and performs a decorative function.

Thread distribution

Each manufacturer produces devices of different shapes and air distributor designs. There is no strict classification of diffusers according to air flow characteristics, but they can be divided into the following types:

- Slotted - flow distribution passes through several slits, as in gratings.

- Jet - air is supplied in one or more jets of high speed and over long distances.

- Perforated - their surface has a large number of small holes through which air enters or is removed from the room evenly and at low speed.

- Vortex - the slots in them are located in such a way that air enters the room, twisting in the form of a funnel.

- Linear – elongated in shape with a small number of slots.

We recommend that you read: How to select and install a fan in an exhaust ventilation duct

There are other types for narrow applications or for specific systems.

Perforated diffuser

Advantages and disadvantages of diffusers

The use of the device in the air exchange system of warehouses, technical, industrial, and retail facilities is extremely significant. For air exchange in residential premises, ventilation diffusers perform the function of regulating the supply of fresh air from the street and its distribution in different directions.

A ventilation system equipped with a diffuser eliminates the presence of places with stagnant air. The advantage of the design is ease of operation and installation. The devices fit well into the interior of the room thanks to the decorative finish and the choice of the model in the desired color. The only disadvantage we can mention is the possibility of draft formation, but this problem is solved with the help of a static pressure chamber.

Classification

The ventilation equipment market offers various diffusers for ventilation.

The models differ from each other in terms of installation location, shape, material, and purpose. Depending on the material used in the production of the product, there are:

- Metal diffusers for ventilation, the body of which is made of ordinary or stainless steel or aluminum. Steel ventilation diffuser models are not recommended for use in air conditioning systems. The formation of condensation is incompatible with the longevity of the air conditioner. In other cases, the metal housings of the diffuser guarantee its strength and durability. The models are significantly superior to their plastic counterparts in weight and price.

- The plastic version of the case is the most common. It is light in weight and has an affordable price. The choice is varied in design, shape and color, and is not inferior to metal analogues in its consumer characteristics. Does not corrode.

- External wooden grating is in demand and fits the design of baths and saunas.

For private households, plastic structures are more often purchased. Metal models are always placed in production areas.

Ventilation system diffusers are round, square, and rectangular.

Depending on whether diffusers introduce or remove air, they are of the following types:

- Supply diffusers. Attached to the opening of the air duct supplying fresh air from outside;

- Exhaust models operate in the opposite way to their supply counterparts and are accordingly connected to the exhaust hood system;

- A universal option is a supply and exhaust ventilation diffuser. It can work for air inflow and outflow. But, as a rule, universal models perform a little worse than those designed specifically for supply or removal.

- Combined devices have two holes in the housing for simultaneous connection to the exhaust and supply air ducts.

Types of diffusers

In a store or company that sells ventilation equipment, you will be offered a large number of diffusers of different appearance and materials to choose from. Deciding on materials is more or less simple - choose what you like best or what is best suited for the operating conditions. If the ventilation ducts are made of metal, it is logical (although not necessary) to use metal grilles. They are galvanized, made of stainless steel, or made of ordinary steel, but painted with powder paint.

If the ventilation ducts are made of plastic pipes, they are better connected to plastic diffusers. Everything seems to be clear here. The rest of the parameters are a little more complicated, let's figure it out.

All these are diffusers

Place of use

According to their purpose, diffusers are divided into:

- inlet;

- exhaust;

- universal (supply and exhaust);

- combined.

The names speak for themselves: they are used in different parts of the ventilation system. Supply and exhaust differ in the direction and position of the lamellas and partitions. There is not too much of a difference, it’s just that some work better for air output, others for air input. In principle, you can put the supply air on the hood or vice versa. A disaster will not happen, but the performance of the ventilation system may drop slightly. In private houses and apartments, the difference, due to low productivity, is impossible to notice. Noticeable changes can only occur in high-capacity ventilation.

Universal diffusers allow air to flow equally in both directions. So you can install them without hesitation. But, as usual, “station wagons” perform a little worse than specially designed models.

This is how an adjustable supply diffuser works - it changes the direction and shape of the air flow

Explanations are needed only, perhaps, with combined models. They differ in that part of the device works for inflow, and part for outflow. Accordingly, they are connected to different parts of the ventilation system. That is, you can install only one universal diffuser on the ceiling, and it will need to be connected to two branches - supply and exhaust. The connection method is described in each specific model; in general there is no point in talking about it.

Materials

Diffusers are made from:

- plastics;

- aluminum;

- steel (regular or stainless).

In private houses and apartments, plastic ones are most often used. For this situation this is the best option. At a relatively low price, they have excellent performance characteristics, a long service life, are easy to maintain, and are not subject to corrosion. They easily fit into plastic air ducts, which are increasingly used in private homes.

Ceiling diffuser can be made of plastic, metal, with wooden elements

Metal diffusers are used in industrial premises where only non-combustible materials can be used. They cost significantly more, weigh more, which complicates installation.

There are also diffusers whose outer part (grille) is made of wood. Such devices will fit perfectly into the interior of a wooden house.

Location

Depending on their location, diffusers are:

- ceiling;

- wall-mounted;

- floor-mounted

Depending on the installation method, diffusers can be ceiling (most), wall and floor

The most commonly seen type is a ceiling diffuser. They are used in 95% of ventilation systems, both in supply and exhaust systems. Mainly because the air is mixed in the upper part of the room, without causing much discomfort to the person. And also because with the installation of false ceilings it is easier to create a ventilation system if it simply did not exist before. Most often, the devices are attached to the main ceiling, and a hole is cut out in the suspended/suspended ceiling, which is covered by a grille.

Sometimes supply ventilation is done through the basement. Then they install floor diffusers. This phenomenon is very rare.

Wall diffusers are used even less frequently. There are not many situations. For example, in apartments after replacing windows with plastic ones. In this case, an influx of fresh air is needed and this can only be provided by making a hole in the wall and installing a diffuser. Or if there is a lack of fresh air and there is no desire to build/reconstruct the supply system.

Next we will talk about ceiling diffusers, since they are the majority, and all the others still need to be looked for - they are usually delivered to order.

Application and principle of operation of a diffuser for ventilation

The air distributor can be used for ventilation systems for premises of any purpose - residential buildings, offices, production facilities. With these devices you can:

Eliminate drafts

Drafts have a negative impact on people's health. People with weak immune systems are especially susceptible to their influence. They arise as a result of the fact that air mass flows form a single stream. This phenomenon is eliminated by the supply air distributor. It promotes divergence and dispersion of air flow.

Effective ventilation

If the ventilation system does not have units that can be used to disperse the flow of air masses, only the area of the room in which the air circulates is ventilated, since the air flow is carried out using the jet method. When ventilating using an air diffuser, the jet air flow is evenly dispersed throughout the entire space of the room. Dispersion is mainly carried out according to the vortex principle. And ventilation deflectors help reduce the intensity of air movement through a flexible air duct, or speed up the movement of air masses entering the exhaust system.

Modernize the exhaust system

To modernize the exhaust system, outflow (exhaust) diffusers are used. They are installed in the ventilation system. Without an air distributor, although the exhaust structure discharges the air masses, jets of air flows are still formed. This factor negatively affects the atmosphere of the room. Plus, the volume of exhaust air entering the exhaust opening directly depends on changes in the direction of its flow - the greater the change, the lower the throughput. Using an air diffuser this problem can be solved.

Control air flow

You can control the inflow/outflow of air flow using a diffuser using a specially configured control panel. In this way, you can provide additional comfort and prevent the formation of drafts or poor ventilation. Another advantage of this device is sound insulation. Using this unit, you can eliminate the noise of air flows “walking” around the room.

How to choose a diffuser for ventilation

To choose the right diffuser for your ventilation system, you need to take into account some parameters.

Dimensions. The device must match the size of the duct.

Case material. Selected based on operating conditions. For rooms and air conditioning systems, a plastic option is suitable, and for outdoor ventilation you should purchase a metal product.

Diffuser model. With a large assortment, choosing a product model in accordance with the style of the room will not be difficult.

The volume and speed of air masses entering the room. It is important to know how much air the unit will work with. It is also important to consider the noise level it produces during operation.

If you take into account all the technical and desired parameters when choosing, then choosing a device will not be difficult.

Design features

Ceiling diffusers come in different designs. There are vortex and slot ones. These types can be made of any material, for any installation method. But, as agreed, we are talking about ceiling models.

Ceiling diffusers come in different designs

Vortex

In them, the grille partitions are located in such a way as to create turbulence in the air masses. This significantly increases the speed of air mixing and increases the performance of the system. They are easy to recognize - by the characteristic radial arrangement of the jumpers. A swirl ceiling diffuser is used where rapid air changes are required. It makes sense to install them in bathrooms and toilets to quickly restore a normal atmosphere, although they are usually used in rooms with a large area and high ceilings.

A swirl ceiling diffuser can be easily identified by its characteristic baffle arrangement

The internal part of a swirl ceiling diffuser is usually made in the form of a cylinder, and the grille can be anything - round or square, but the holes in it are located strictly along the circumference.

A swirl ceiling diffuser for supply ventilation may have an additional impeller, which is located behind the grille in the housing. The impeller can be movable or fixed. The movable impeller can be controlled - have several rotation speeds.

Another variety is with a static pressure chamber. It eliminates too active movement of air masses. When using ventilation diffusers with a static pressure chamber, even at high flow rates, there will be no drafts in the room.

Slotted

The slot ceiling diffuser is so called because of the characteristic shape of the holes - in the form of slits. The location of the cracks, the shape and dimensions of the partitions are specially designed and calculated. The distribution of air flows depends on their position and direction.

They are used in rooms with low or medium ventilation system performance. They are installed in living rooms and technical rooms with normal operating conditions (dressing rooms, pantries, built-in wardrobes).

Slot ceiling diffusers and air distribution direction

They have one important feature - they have adjustable slot diffusers that can change the direction of air supply (similar to the type of blinds on air conditioners). If we talk about types, they can be with or without a plenum.

Ceiling diffuser: installation

Gun for suspended ceilings: proper use and its types

There are two ways to connect diffusers to ventilation ducts: directly or through an adapter (static pressure chamber). The second option is more correct, but it requires a larger gap between the base and decorative ceilings.

If the shape and dimensions of the ceiling diffusers and ventilation pipes match

To connect the ceiling diffuser directly to the ventilation pipes (branches), a tee/splitter is placed in the ventilation pipe at the installation site. The device is placed in the free third exit.

Cutting a hole directly in the pipe for its installation is the wrong decision. The housing protrudes beyond the pipe, impeding the movement of air, the performance of the system drops, and over time a dust plug forms, which can completely block the clearance. In general, this should be avoided.

The outlets from the main pipe must be selected so that they can be conveniently connected to the diffusers. It is not difficult to connect a round diffuser to a round outlet from the air duct, and a rectangular diffuser to a rectangular one

It is also important that their sizes match. This simple truth must be remembered when creating a system, choosing tees or making bends with the appropriate parameters

Diffusers of matching sizes are installed in ventilation ducts simply by inserting them. Models that are small in size and weight can be fixed to the box using sealant (neutral silicone). This is how models with a round base are usually attached.

For suspended ceilings of various types (plasterboard, plastic, Armstrong), a special fixation system has been developed - Clip in. It consists of spacers like those you see on recessed ceiling lights.

More massive square/rectangular models are attached to the walls of the box using self-tapping screws or on hangers from the ceiling. The first option is simpler, but it is better not to use it, since dust collects on the protruding self-tapping screw. Unless the design provides special protrusions for fasteners. Otherwise, over time, a solid plug will form in the place where the self-tapping screw sticks out, preventing the passage of air.

If the outlet is made of corrugated material or there is a desire to do everything “right,” heavy cases are suspended from the ceiling on studs or hangers.

Using adapters

Adapters or static pressure chambers help to avoid such unpleasant phenomena as drafts. In this tank there is a uniform redistribution of air, which flows in an even flow over the entire surface of the grille. But these devices have a significant drawback - they “steal” the ceiling height. Models with side connections are smaller in size, but still take up enough space.

Most often, the static pressure chamber is a parallelepiped, to the bottom of which a diffuser is attached. On the top or side there is an outlet for connecting a ventilation duct. It can be of any required shape: circle, square, rectangle, oval.

Adapters available:

- With built-in rotary valve. If the diffuser model does not provide for adjustment, this can be done using an adapter.

- With removable filter. They also allow you to clean the incoming air.

- With air flow divider. This is a sheet of metal with a small cell. Placed on powerful supply systems, it allows you to evenly distribute the air flow over the entire surface of the grille.

Static pressure chambers for ventilation diffusers are most often made from galvanized steel. Sheet thickness - 0.5-0.8 mm. There are companies that will make a device according to your parameters. There are also standard adapters on sale for standard solutions. They can be made of steel (galvanized, stainless) or plastic.

If necessary, the static pressure chamber is lined with insulation. This is necessary so that when the warm surface of the adapter interacts with cold air, condensation does not form on it.

class="figure-caption text-center">

If the diffuser is connected via an adapter, the main task is to secure this device. If it is a suspended ceiling, you can attach the camera to profiles. In the case of a suspended ceiling, you will have to hang it from the main ceiling. The methods are known: studs or perforated hangers.

Installation methods

There are three methods of connecting a diffuser to ventilation:

- Into an existing vent in the wall;

- To rigid or flexible duct material;

- Use as an intermediate link between the product and the internal ventilation outlet of the plenum chamber.

All air diffuser models are structurally equipped with means for fixation when attached. These are latches or holes for self-tapping screws.

When fastening to a rigid material, the design parameters and the input product must match so that the product can be installed in the opening. A tee splitter is used, which is inserted into the ventilation pipe. The device is connected to the third, free output. In this case, the tee outlet is selected to the size required for the device. To make it convenient to connect them. A secure fixation will be indicated by the latches, which make a characteristic sound when locked.

For suspended ceilings, fastening occurs according to the type of recessed lamps. Heavy weight models are installed using hangers or studs to a real ceiling or self-tapping screws.

When connecting the diffuser to a soft metal sleeve or corrugation, the flexible metal end is first pulled out of the ventilation duct. Next, the product is connected to it. Then the corrugation returns back to the hole, followed by a diffuser. The end of the input will end with a characteristic click, which means the latches are activated. The diffuser should connect to the hole in the ceiling or wall evenly. There should be no gaps left.

A static pressure chamber or adapter prevents excessive venting. But it is mounted in a fairly large gap between the real and suspended ceiling. The fact that they “steal” the ceiling height is a disadvantage of their use. The advantage is the absence of drafts. The principle of its beneficial action is the uniform mixing of air flows in the chamber tank and its even supply through the grate surface.

Externally, the structure is a parallelepiped, the hole for the diffuser is located at the bottom. On the side or top there is a hole for a ventilation pipe of various sizes.

Adapters come in different models: with a removable filter, with a rotary valve, with an air mass divider. Standard adapters are made of plastic or steel.

In the ventilation system, diffusers perform a certain important function. They are often considered unimportant elements of the system. But this opinion is erroneous, because the correct organization of air flow, for which this element of the system is responsible, determines the functionality of the system as a whole.

Installing a diffuser in a soft channel

- First you need to remove the sleeve from the hole in the wall and attach a device to it for dispersing air flow.

- Then, the sleeve is placed in the channel, followed by the unit.

- When the system begins to come into contact with the wall surface, you need to fix the device. To do this, you will need to slowly, without making much effort, press on the diffuser until the fastening mechanisms work.

- Make sure there are no installation defects (protrusions, irregularities above the wall surface).

Installing a diffuser in ductless exhaust ventilation (hole in the wall)

- Initially, you need to prepare a hole in which the unit will be installed to dissipate air flows. For these purposes, it is recommended to use a pipe whose parameters will correspond to the size of the diffuser.

- The opening in the wall itself can be made from a pipe. To do this, you need to measure the length of the hole from the outer wall to the inner one, then adjust the pipe to these dimensions.

- Insert the fitted pipe into the hole and install the device into it according to the principle described above.

- The pipe can be secured to the hole using mounting foam.

If the diffuser components do not include latches for fastening, they can be replaced with glue, anchors, sealant or self-tapping screws.

Methods for installing a ventilation diffuser

To avoid any difficulties when installing the device in ventilation, you must remember: the air duct must clearly match the shape and cross-section of the diffuser.

For ease of installation, the device is equipped with holes for fastening, and some models come with special fasteners.

Installation of the air distributor in a rigid duct

The unit selected for size is carefully inserted into the channel until a characteristic click appears.

You must make sure that all latches are actuated and there are no gaps between the device body and the channel opening.

To avoid breaking the case, it is recommended to press it carefully.

Features of installation in a flexible air duct

A flexible air duct hose is pulled out of the channel, and a unit of the appropriate cross-section is attached to it. Next, the hose is retracted into the opening, followed by the air distributor.

The system is introduced smoothly until it stops. If you hear a click, it means everything is installed correctly. After installation is completed, it is necessary to check the quality of work.

A properly installed diffuser fits tightly to the ceiling or wall without gaps or protrusions.

Installation in a ventilation duct in the wall

The diffuser can be installed in an existing exhaust ventilation system, i.e. in a hole in the wall

The device is carefully mounted into the fixed pipe according to the previously indicated method.

If the kit does not include fixing latches, then the air distributor must be fixed using glue, self-tapping screws or any other method.

Diffusers Systemair Konika

Systemair Konika round ceiling diffuser with plenum chamber as an additional accessory. Konika is a supply and exhaust diffuser for ceiling installation. Konika can be used in offices, shops and similar premises. Konika can be connected directly to a round duct or connected to a plenum. Konika can be used for both cooled and heated air. Konika has a very high ejection, which makes possible a maximum temperature difference for cooled air ΔТ=12°C.

Diffusers Systemair Konika-A

Konika-A is a multi-cone ceiling diffuser. The air supply direction is adjustable from horizontal to vertical. The diffuser consists of an outer cone and an adjustable double central cone. By adjusting the double central cone, the direction of air supply is set from horizontal to vertical. The diffuser is made of steel with white powder coating (RAL 9010). Available in 6 standard sizes: from 160 to 500. To clean the air duct, the double internal cone must be removed.

Diffusers Systemair Kvadra

Systemair Kvadra 4-way distribution ceiling diffuser with KRC adapter connection and THOR plenum as accessories. Kvadra is a supply and exhaust diffuser for ceiling mounting. The diffuser can be used in offices, shops and similar premises. It can be connected to square or round ducts via a KRC adapter and connected to the plenum. The diffuser can be removed to clean the duct. Kvadra has very high ejection, which makes it suitable for supplying cooled air. The maximum temperature difference is ΔT 12 °C.

Systemair TSO diffusers

Systemair TSO perforated ceiling diffuser with plenum as an accessory. The TSO can be equipped with an SSO shielding device as an option. TSO is a supply and exhaust diffuser designed for ceiling mounting. The TSO has a perforated front plate and a coupling with a rubber seal that is leak-tested. TSO has a very high ejection, which allows a maximum permissible temperature difference dT of 10 °C. The air distribution pattern can be changed using the SSO shielding device to one-, two- and three-way distribution. The distribution device is adjustable.

Systemair TSR diffusers

TSR is a Systemair ceiling diffuser equipped with an air distribution chamber for surface installation. The air distribution chamber is equipped with a removable valve, measuring connections and sound insulation made of non-fibre material. TSR is a round diffuser for ceiling installation. The diffuser is equipped with an air distribution chamber. The air distribution chamber is equipped with an air valve and measuring pipes. The inner surface is covered with non-fibrous soundproofing material. TSR is designed for cooled air with a maximum temperature difference ΔТ = 12 °C.

Systemair TSP diffusers

TSP is a Systemair ceiling diffuser equipped with an air distribution chamber. Used for outdoor installation. TSP is a diffuser with a perforated front panel. The air distribution chamber is equipped with measuring pipes and sound insulation made of non-fibre material. TSP is a round perforated diffuser for ceiling installation. The diffuser is equipped with an air distribution chamber. The air distribution chamber is equipped with an air valve and measuring pipes. The inner surface is covered with non-fibrous soundproofing material. TSP is designed for cooled air with a maximum temperature difference ΔT = 12 °C.

Diffusers Systemair CAP-C

Ceiling diffusers CAP-C are designed for surface installation and are connected directly to the air duct using a coupling with a rubber seal tested for leaks. 360° rotating discs (nozzles) provide 100% adjustment of air distribution (air can be directed horizontally, vertically, to 1-2-3-4 sides). The side gap is adjustable within 0-20 mm, providing the possibility of increasing the supply air flow. The CAP-C diffuser design consists of a front panel with nozzles complete with a soundproof plenum and valve. The maximum temperature difference between the supply air and the room air temperature is ΔT=12 K. Applicable for both cooled and heated air. The diffuser is made of galvanized steel and painted white, the rotary discs are made of ABS plastic.

Installation of a fan in a suspended ceiling

Installation of ventilation equipment in a suspended ceiling is carried out after laying air ducts and electrical cables to the installation site of the device. It is equally important at the preparatory stage to correctly select the power of the diffuser so that after installation it copes with the tasks assigned to it.

Selecting a device by power

To select a fan based on power, you need to know the volume of the room and its purpose, as well as the air exchange rate, which indicates the number of air updates in the room over a certain period of time. The air exchange rate is determined according to SNiP 2.08.01-89. In this regulatory document there is a section “Ventilation”, in it we find paragraphs 4.1-4.17, which talks about the definition of this indicator.

The power of a bathroom fan is calculated in the following sequence:

- Find the volume of the room by multiplying its length, width and height. We take all parameters in meters. The result is obtained in cubic meters.

- In the specified section of SNiP we find a table indicating the maximum air exchange rate for premises for various purposes. We find a line with parameters for the bathroom. This number is 10.

- Now we calculate the fan power. To do this, multiply the volume of the bathroom by 10. We get a number that is measured in cubic meters per hour. We select a diffuser with a power equal to or slightly higher than this number.

The power of a bathroom diffuser is calculated taking into account the number of seats. One such place requires a ventilation equipment capacity of 40-50 m³/h. Moreover, if the ventilation ducts in the walls of the room are clogged or are not working at full capacity, then the capacity per seat is increased to 100-150 cubic meters per hour.

Attention! Bathrooms that have a common ventilation duct with another room (bathroom or kitchen) must be equipped with a check valve on the diffuser to prevent air from flowing into another room.

Installation sequence

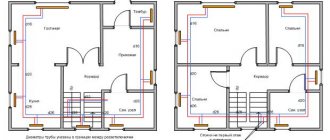

During the process of assembling the suspended ceiling, the installation location of the ceiling diffuser is marked on the base ceiling. An air duct is laid to this place. When assembling the frame of a suspended ceiling structure at the installation site of the device, the lathing is reinforced with additional wood slats or galvanized profiles.

After installing the suspended ceiling, a hole is drilled or cut to fit the dimensions of the device in the intended location for installing the diffuser. To drill a hole of a given diameter, use a drill or hammer drill. A pipe is installed in the hole, and then a fan is installed and connected to the power supply.

Self-tapping screws are used to attach the unit to the frame. After installation, check the functionality of the device. Now you can install the decorative trim. It will create an attractive appearance of the device from the outside of the room.

This is interesting: Pumping stations for the home - calculation, selection and installation