What are suspended ceilings?

So, a suspended ceiling is understood as a decorative structure that is fixed on guide profiles and gives the room an aesthetic appearance, while masking all defects in the rough surface and placed communications or wires, if any. Moreover, the suspended ceiling plays the role of an insulating and sound-absorbing barrier, which is especially important in multi-story buildings.

To build a suspended ceiling with your own hands, you must first secure a special frame structure made of longitudinal and transverse profiles and hangers. The actual suspended ceiling material will subsequently be attached to them. This can be either drywall or special panels.

Please note that there are several types of suspended ceilings. In particular, mesh, lattice, rack, which are also called modular. If plasterboard is used to cover the frame, then such a ceiling is called solid. In cases where plasterboard is fixed directly to the rough ceiling without hangers, then we are talking about a false ceiling.

Cost of suspended ceiling

Depends on the choice of material, ceiling size and design complexity. The most expensive ceilings will be those with complex geometric designs. The type of cladding used also affects. Includes whether you will do the installation yourself or use the services of a professional.

Suspended ceilings can be selected to suit any room, requirements and budget. Installation can be done either by yourself or with the help of professionals. This design will last a long time and will look decent.

Advantages and disadvantages of a suspended ceiling

Naturally, any type of decorative finishing has both advantages and disadvantages.

Among the advantages of suspended ceilings are:

- The ability to hide any imperfections of the rough ceiling - the presence of gaps, cracks, chips and potholes, unevenness and level differences.

- Aesthetic appearance - thanks to this decor, the room can be transformed and decorated.

- There is plenty of room for imagination - you can vary the height and levels of ceilings, combine several types of material;

- It is possible to install any type of lighting - both main lamps and additional lighting, based on the initial project.

- Ensuring high-quality sound insulation and insulation.

- Convenient and easy maintenance - just wipe off the dust with dry cloths.

- Variety of ceiling surface finishes.

- It is easy to disguise all communications inside the suspended ceiling structure.

However, even such seemingly ideal suspended ceilings in all respects are not without a number of disadvantages.

The most significant among them are:

- The ceiling structure, as a rule, “steals” about 7-8 cm or more of the height of the room, since it is necessary to secure the frame for its installation.

- Depending on the complexity of the design and the size of the room, installation of a suspended ceiling can take quite a lot of time - usually several days.

- The costs of purchasing materials for suspended ceilings can be quite significant, especially if the materials purchased are not the simplest and cheapest.

- If any communication lines were installed above the ceiling, access to them must be provided by making a special window.

- Since plasterboard is not highly moisture resistant, it is not recommended to use this material in rooms with high humidity, for example, bathrooms, swimming pools or saunas.

Tools and materials

Before you make a suspended ceiling with your own hands, you will need to purchase a complete list of materials for the frame, plasterboard, as well as the finishing option chosen to your liking.

The first step in this case will be to assemble the suspended ceiling frame yourself. In this case, you need to decide what material it will be made of - wood or metal. If you decide to go with the wooden option, you will have to purchase bars that will be attached to the ceiling surface with hangers. If you choose a traditional metal frame option, then to create it you will need to purchase several types of metal profiles.

Please note that profiles and beams can be either main or load-bearing. In the case of the manufacture of a metal frame, previously only load-bearing profiles were used, but recently there has been a tendency to combine load-bearing and main profiles. As for the wooden blocks, they can also be combined so that the final structure does not turn out to be too heavy.

According to step-by-step instructions, a do-it-yourself suspended ceiling is assembled from galvanized metal profiles marked PP 60/27 and PNP 28/27. Foreign analogues can be labeled as CD and UD.

In addition, during the installation process you will need a set of hangers that are fixed to the ceiling and hold the suspended frame, anchors and dowel-nails, connecting “crabs” for joining jumpers, as well as two types of screws - small ones with a drill for metal products and for drywall.

The main material used for lining a solid suspended ceiling is plasterboard.

Depending on the characteristics, there are several types of drywall:

- gypsum board marking is assigned to standard material;

- GVKL is a designation for drywall with moisture-resistant qualities;

- GKLO - such drywall contains fiberglass in its composition, therefore it has fire-resistant properties;

- GKVLO marking is assigned to a material that combines both fire-resistant and moisture-resistant qualities;

- GVLV is plasterboard with the best performance characteristics, of the highest quality, sometimes it is also called “super sheet”.

The most affordable and optimal in weight is standard drywall marked with gypsum plasterboard. It is most often chosen for cladding ordinary residential premises, which are not subject to increased safety requirements.

The parameters of standard drywall sheets are usually as follows:

- length – 1500-2500 mm;

- width – 600-1200 mm;

- thickness – 9.5 mm.

Before making a suspended ceiling, you will need to calculate the amount of materials for repairs. Numerous online calculators can help with this, however, in practice, you can handle this task yourself. If you determine the surface area of the ceiling and the dimensions of the plasterboard sheets, you can easily calculate how many sheets will be needed to completely cover the area.

Please note that a plasterboard suspended ceiling will have a fairly large mass. Each 1 m2 of standard drywall weighs about 13-15 kg, so it’s worth calling a helper to equip the ceiling.

It is worth noting the fact that the seams between the sheets of drywall will be the weak points of the structure, again due to its significant mass. In these areas, the subsequently applied plaster may crack. Therefore, at the finishing stage, these places will need to be given special attention.

To work with suspended ceilings you will need the following tools:

- perforator;

- screwdriver;

- ladder;

- construction knife;

- level, preferably laser;

- roulette;

- pencil for marking.

If you plan to equip a complex lighting system, then all lamps and LED strip must be purchased in advance. In addition, it is important to outline the location of lighting fixtures and lay electrical wires for them even before covering the surface with plasterboard.

The outside of the plasterboard ceiling will need to be refined.

For this you will need:

- primer mixture;

- starting and finishing putty;

- putty knife;

- reinforcing mesh to strengthen joints and seams.

The approximate amount of materials for arranging a suspended ceiling per 1 m2 of plasterboard looks like this:

- anchor bolts – 1 piece;

- PP 60/27 or CD profiles – 2.9 m

- PP 28/27 or UD profiles – along the perimeter of the drywall;

- sealing tape - along the perimeter of the material;

- direct suspension, rods and suspensions - 1 piece each;

- metal screws – 2 pieces;

- self-tapping screws for drywall - 23 pieces;

- connecting crabs - 2 pieces;

- profile extensions – 0.2-0.5 units;

- dowels per 1 m of PP 28/27 profile – 2 pieces;

- reinforcing mesh – 1.2 m;

- separating tape – along the perimeter of the material.

Please note that before starting work, it is worth planning your actions in detail. Make a detailed step-by-step diagram that you will follow. It will also help in calculating the amount of materials.

Preparatory work

Before installing such a ceiling, preparatory work is carried out, which consists of the following:

- Initially, you need to finish leveling the walls in the room, and the installation locations of the frame must be ideal.

- Draw a sketch on the sheet to calculate the required amount of material. Additionally, the ceiling is drawn, or rather, a frame diagram is made in order to calculate all the points of contact of the sheets on the profiles. This step will allow you to avoid mistakes when fastening the sheets, since it is not always possible to secure the edge of the drywall into the profile.

Sketch of a suspended ceiling made of plasterboard

- Next, all defects that are on the ceiling are removed, even despite the fact that it will be closed. This will prevent the old finishing coating from crumbling onto the sheets. It is also recommended to seal all possible cracks and then open the surface with a primer.

Advice! Final finishing should be carried out when the drywall sheets have already been installed and securely fixed.

Installing a single-level ceiling step by step

We will describe the process of assembling a single-level suspended ceiling with your own hands in step-by-step instructions. If all materials and tools have already been purchased and prepared, then you can begin installing the ceiling. However, first you need to remove unnecessary pieces of furniture from the room or at least cover them if the first option is not possible. After this, you can begin marking the walls and ceiling, as well as install fasteners.

Stage 1. Take a tape measure and measure the height of the ceiling in each corner of the room. In this way we find the lowest point - we will start from there.

Stage 2. We put 5-8 cm down from the corner and put a point in this place. Please note that if there are additional lamps that require their own wiring, the indentation should be made a little larger.

Stage 3. In each corner we place dots that correspond to the level of the first mark.

Stage 4. We connect all the marks with straight lines using a pencil or paint cord.

Next, in the process of installing a suspended ceiling with your own hands, step-by-step instructions suggest moving on to assembling the frame structure.

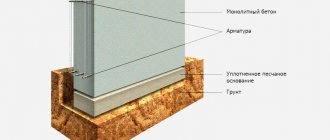

Stage 5. We take the supporting profiles PP 28/27 (UD) and attach them to the wall along the marked lines. First, we apply the profile with its lower edge above the marking line. Then we place points on the wall through the holes in the plank, marking the places for drilling. We drill holes in the wall. Pay attention to the profiles themselves. If they do not have prepared holes for fastening on the sides, you need to drill them yourself, stepping back from the edges by 10 cm.

Stage 6. We glue the prepared profiles with sealing tape and fix them to the wall with dowel nails.

Stage 7. The hangers will be at a distance of 40 cm from each other. Therefore, you need to draw lines on the ceiling with the indicated indentation.

Stage 8. Since connecting jumpers will be installed on the profiles approximately every 2.5 m, the hangers will be attached in increments of 50 cm. In this case, to install the first row of hangers, we retreat 25 cm from the wall, and the next one after another 50 cm, that is 75 cm from the walls. We fix all subsequent rows in increments of 60 cm.

Stage 9. To ensure that the holes for the hangers are in the right places, we apply them to the markings on the ceiling and re-mark the points for drilling the holes. We place anchors in the finished recesses and secure the hangers with them so that they do not sag, otherwise the work will be ruined.

Stage 10. We begin the installation of suspensions. If their length does not fit into the parameters of the room, they can either be shortened or lengthened. To increase the length of the profile, you can connect two strips with special devices. It is worth checking that the joints in adjacent rows are spaced apart and close to the hangers, otherwise the frame may not support the weight of the drywall. The total length of the profiles in one row should be 1-2 cm less than the size of the ceiling. In this case, each plank must be attached to the hangers and guides from the corner of the room, using self-tapping screws. Lastly, profiles are installed in the central part of the room.

Stage 11. First, we attach two rows of profiles to one side of the ceiling. Then we move to the opposite wall, where we also fix two rows of profiles. After this, you can move on to the central bars.

Stage 12. Using crabs and self-tapping screws, we install jumpers in increments of 2.5 m. They are located in places where the joints between adjacent sheets of drywall will pass.

Stage 13. Finally, we move on to fixing the drywall. We cut the edges with a knife so that we get a small corner. This will improve adhesion to the putty. If the ends are pasted over from the factory, then leave them as is.

Stage 14. Screw the sheet, starting from the corner. We apply the sheet to the profiles with a distance of 0.5 cm from the wall. We screw in the screws every 20 cm. At the seams between adjacent sheets, we place the screws staggered. We slightly deepen the heads of the screws into the surface of the drywall so that they do not peek out. We also lay the plasterboard sheets themselves offset so that the 4 pieces do not converge at one point.

Finishing

The process of assembling a suspended ceiling does not end with the installation of drywall. After this, the entire surface of the ceiling still needs to be refined. You can choose any type of finishing to suit your taste - simple or textured plaster, painting, wallpapering or other options. However, in any case, it is necessary to treat the surface - putty the seams, joints and recesses from self-tapping screws. First, the surface is primed and then covered with putty.

After the first layer of starting putty has dried, a reinforcing mesh (serpyanka) is laid on the joints and seams and another layer of the mixture is applied. If the seams between the sheets are too wide, they are filled with putty mixture. In addition, during the grouting process, you will probably notice any flaws on the drywall - scratches, peeling paper, etc. These defects also need to be laid with sickle and putty.

In order for the putty to better adhere to the material, it is better to make the edges of the drywall at the joints slightly rounded. Then the mixture will penetrate as deeply as possible into the space between the sheets. The reinforcing tape and putty layer must be aligned with the thickness of the drywall. This is possible because the edges of the sheets are slightly narrowed in thickness so that the reinforcing mesh can be recessed.

If you cut the drywall yourself for mounting on the ceiling, then first the cut edge must be cleaned with a plane or knife at 45 ℃. This will create a wedge-shaped groove into which the putty and reinforcing tape will fit freely. In this case, the putty will adhere well to the drywall.

Once the entire surface of the drywall has been covered with the starting putty and dried, you can apply the final layer of finishing putty mixture.

Thus, the technology of how suspended ceilings are made includes preparing the surface, laying electrical wiring for lighting, assembling the frame, attaching drywall, installing lighting and finishing the surface.

A few recommendations

Here are a few more short recommendations for installing suspended ceilings with your own hands:

- Use only good quality materials. This way you will ensure yourself a reliable and durable ceiling covering.

- Take your time while working. Make a plan, spend more time on surface markings and calculations so as not to make mistakes and not run to the shops for missing materials.

- GKL brand drywall should only be used in dry rooms.

- Level is your best assistant.

- To further soundproof the room, use mineral wool, placing it above the frame.

- Before you begin attaching the drywall, leave it lying flat for a few days.

Installing suspended plasterboard ceilings is not such a difficult task. These instructions will help you make a suspended ceiling with your own hands and avoid mistakes and shortcomings.

Types of ceilings

The main difference between a suspended ceiling is the material used for cladding, because you can use tiles, panels and other materials. Among the types used, the following should be highlighted:

- Tiled ceiling. Typically used in shops, offices and other places where many people gather. By analogy, you can use other, more affordable materials MDF, drywall.

Ceiling with Armstrong tiles

- Panel ceiling. Plastic is often used. Easy to install yourself; sometimes plastic is replaced with wood. Connects through grooves, leaving no gaps.

- Slatted ceiling. This includes metal panels that are easy to install yourself, without special hardware.

Slat ceilings

- Cellular and slatted ceiling. The main covering of this type is a panel made of aluminum or steel.

The most difficult thing is to install plasterboard on the ceiling, since it will require not only a frame, but also finishing work. Therefore, below we will describe how to create a plasterboard ceiling yourself.