Is it possible to insulate the ceiling with polystyrene foam yourself?

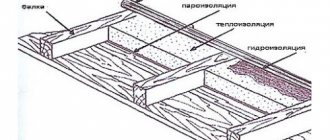

The standard scheme for attaching the foam layer is as follows:

- Waterproofing film.

- Reinforcing layer (ideally basalt mesh).

- Polystyrene foam (attached either with dowels or on a polyurethane layer).

- Plaster (applied on top to protect the foam from pests). What is needed is a soil base.

- Decorative finishing (plasterboard, plastic panels, suspended or suspended ceilings, whitewashing, painting).

The only difficulty that will arise after insulating the ceiling with foam plastic is the increasing humidity inside the room. The problem can be solved quite simply - by installing forced ventilation or an air conditioner that can regulate the humidity inside the room.

If this is not done, moisture condensation will begin to accumulate in the layer between the foam plastic and the waterproofing film (since it is warm inside the room in winter, and the wall itself is cool). Naturally, this will lead to the appearance of fungus and mold. Over time, it will spread not only along the ceiling, but also to the walls. Violation of this technology has repeatedly led to the fact that after repair the wallpaper had to be completely re-glued after 3-5 months, since they all turned black.

Ceiling insulation with foam plastic: advantages and disadvantages

Why should the ceiling be insulated with foam plastic from the outside of the house? Because in this case the ceiling part will not freeze. Accordingly, the interior of the room will be protected from the cold by both the thermal insulation material (in this case, foam plastic) and the roof covering itself (if we are talking specifically about the attic, that is, a residential attic). If you insulate from the inside, then the outer covering will freeze at a very low ambient temperature; accordingly, only that very layer of foam will protect the room from the cold.

Why is it recommended to use polystyrene foam?

Because he has:

- excellent soundproofing and thermal insulation qualities (a 10-centimeter layer corresponds to approximately a 1-meter layer of red brick);

- low weight;

- low cost;

- ease of installation.

The only drawback of polystyrene foam is its low resistance to moisture. If the material is moistened, it loses almost all of its thermal insulation qualities, and over time it can become moldy.

It is for this reason that insulation by simply gluing polystyrene foam onto the same polyurethane glue is not allowed.

Will a foam insulation layer protect against the cold if it is attached from the inside? Yes, and quite effectively. But before this, it is recommended that the ceiling itself be thoroughly treated with pesticide components, which will prevent the appearance of mold, rot, and fungus.

Ecowool as insulation for ceilings

The basis of ecowool is cellulose, an environmentally friendly material.

Advantages:

- Due to the content of lingin in the insulation, it becomes breathable, resilient and elastic.

- Fungus does not form in such insulation, and rodents will not infest it.

- Fire resistant.

- When working with metal surfaces, corrosion does not form.

Flaws:

- During operation, a lot of dust is generated.

- You won’t be able to insulate it yourself; the work must be done by specialists.

- You cannot heat the material because it will smolder.

Installation stages

- Installed in two ways: wet and dry. Dry is used to insulate the ceiling from the outside, and wet from the inside.

- Ecowool is wetted and glued to the surface.

- Bonding is carried out under pressure.

- When the material dries, the surface will become uniform.

- It can be treated with ecowool and adhesive, and then attached to the base of the upper part of the house.

Insulating the ceiling with polystyrene foam from the inside with your own hands

If we are talking about insulation in a private house, then the first thing you need to clarify is whether a layer of foam plastic will help retain heat inside the room. For example, this will be pointless on the ground floor of a two-story house, since it is already warm above (if heating is installed there). In fact, foam plastic in this case will only protect against noise, but it is much easier to replace it with the same acoustic panels or just mineral wool fiber, only a few centimeters thick - this will be enough.

If there is no second floor, and there is an unheated attic above, then a layer of polystyrene foam will be relevant. It is advisable to attach it from the outside, but if this is not possible, this is done from the inside (for example, if we are talking about an apartment in a multi-story building, which is located on the highest floor, and there is a roof immediately on top).

First of all, the ceiling is cleared of finishing to the capital level (concrete slab, brick, wooden beam). Next, pesticide treatment is performed. For this purpose, special solutions are used, which are filled with a regular sprayer and applied to the base under high pressure. You should not forget about the basic rules of protection from chemical reagents, since pesticides have a medium toxicity class.

After treatment, it is recommended to stop repairs for 2-3 days, while periodically ventilating the room. This should be done even if the pesticide manufacturer claims that it is not toxic to the human body in any way.

After all this, you can begin to insulate the ceiling with your own hands. The first step is to install the waterproofing film. This can be either ordinary polyethylene or combined multi-layer moisture protection. Of course, the second option will be preferable. Such panels are fastened with dowels, but it is better to use flea screws, which do not have caps as such and are screwed in to the end of their level. They leave no protruding parts, which will not damage the foam in the future.

The foam itself can be attached to the waterproofing on top. Its permissible thickness is in the range from 5 to 15 centimeters. There is no need for more for living space, and even insulation from the inside. It is also attached with dowels or polyurethane glue. Experts recommend performing a combination of these methods. That is, first strengthen it with glue, and then reinforce it all with dowels on top.

Next, a reinforcing mesh is pressed into the foam. Basalt fabric is best suited for this. It can be fastened over the entire plane using an ordinary construction stapler. The main thing is not to skimp on the staples.

Now all that remains is to apply a primer over the entire area of the insulated ceiling.

There are several options for it:

- primer paint;

- layer of plaster (1-2 centimeters);

- rough drywall (fixed with glue);

- special protective emulsions for ceilings.

The preferred option is ground plaster. It lasts the longest, is inexpensive, and will last for decades. Plus, it acts as additional reinforcement, which provides mechanical protection for the ceiling.

The top can be finished using any material. It is allowed to use plasterboard, suspended ceilings made of PVC film (with a glossy finish), simple whitewash, foam boards, and so on. You can even use facing siding if it looks attractive in terms of design.

What kind of material is this

The covering is a surface assembled from glued square tiles of polystyrene foam or polystyrene. The outer side of such parts may be uncoated, or may be laminated. The latter type lasts much longer and looks more attractive.

There are several types of such plates:

- Pressed

- Injection

- Extruded

They all differ in their manufacturing method.

The most inexpensive ones are pressed. They are made from polystyrene foam by pressing or stamping. She doesn't look the most beautiful. The grainy structure of the material is to blame. Strength also suffers from this - this type of finishing material will be the most fragile.

Tiles made by extrusion will be more expensive, but also more worthy looking. They are similar to regular stamped ones, but they have a finer grain and overall look much better. The front part is often laminated, which gives the material a more beautiful appearance and strength.

The most expensive stove is injection. Made by casting molten material into molds and heating it. The result is the most durable look of all. In addition, types of panels made using this method can form so-called “seamless” ceilings. They differ from the others in that after gluing, there are no visible joints between the individual elements of the coating.

The most popular size of such panels is 50 by 50 centimeters. Thickness varies depending on the manufacturing method. The pressed one will be the thinnest - 7-8 millimeters, the injection one has a thickness of 9-14 millimeters, and the most expensive, injection one, being the most durable, at the same time remains very thin - its thickness does not exceed the thickness of stamped products.

Insulating the ceiling with polystyrene foam: reviews from those who have already done it

Studying reviews on thematic forums, we can say that the effect of insulating the ceiling with foam plastic is generally positive. Of course, it is recommended to insulate the walls and even the floor, but then you will definitely have to install an additional ventilation system (forced type, that is, with an installed cooler and exchanger, which will also heat the air entering inside).

The only remark that was not taken into account by everyone was the need to use facade foam, which has a higher density (most often it is made in gray color, and the marking has the designation “F”, but not all manufacturers comply with these rules).

Tests have shown that installing foam plastic on the ceiling:

- increases the thermal insulation of the room by 15 percent;

- reduces the amount of noise by 3 times;

- visually levels the surface, regardless of bevels.

If foam plastic is also mounted on the walls and floor, and window openings are covered with modern PVC profiles with energy-saving double-glazed windows, then the thermal insulation of the room will be improved by 60-80 percent.

But what is better - polystyrene foam or basalt fiber (sold in rolls and is also considered good thermal insulation)? In terms of technical characteristics - glass wool, but in terms of cost and efficiency (taking into account the money spent), the favorite, without a doubt, is polystyrene foam. In addition, it is much easier to handle and install. And even if one of the plates needs to be replaced, it’s easy to do. But the glass wool layer will have to be changed completely.