In order to maintain optimal temperature conditions and steam generation in the bathhouse during health procedures, comprehensive insulation of the building should be ensured.

If the insulation of the ceiling in the bathhouse is done correctly, the consumption of fuel material will be reduced, the heating time of the premises will be reduced and the internal microclimate will be preserved. In addition, insulating the ceiling base will solve another serious problem - preventing the formation of condensation.

Is it necessary to organize ceiling insulation?

Heated air masses rise upward. The lack of a good thermal insulation system allows moist air to:

- Settle in drops on the ceiling. If the question of how to insulate the bathhouse ceiling was not resolved in time, the drops formed at the top will periodically fall down, spoiling all the pleasure of the bath procedures.

- Reach the roof, attic and ceilings, damaging them.

- Increase resource consumption for heating.

Organizing a functional and comfortable space Source stroyfora.ru

Having decided how to insulate the ceiling in a bathhouse, it is possible to cope with the following difficulties:

- Uncomfortable stay due to falling drops from the ceiling.

- Destruction of the structure itself.

- Unreasonably large consumption of resources to maintain the required temperature.

Advice! In order to solve the problem in the optimal way, you need to know the technological qualities of the materials and the procedure for performing the necessary work.

Popular methods of insulation

Based on the experience of professionals, mineral wool, clay, expanded clay and earth can be distinguished from all materials. A bathhouse, steam room and washing room can be insulated in several ways and various materials suitable for such a procedure can be used in the work.

Traditional methods are known for their inexpensive components, environmental friendliness and fire safety, but their implementation will require more time and effort. Modern methods, on the contrary, are simpler in terms of installation, but the materials will entail certain costs.

What should not be used?

If you decide to opt for modern materials, it is worth remembering that foam plastic should never be used in such work. This affordable and popular thermal insulation, when heated, emits chemicals that poison the air in the room, and in places where it touches a hot pipe it can even melt.

It is also not recommended to lay a layer of glass wool on the ceiling of the bathhouse, since it requires high precautions during operation and, due to small particles, often provokes irritation of the respiratory system and skin.

Main stages: everything you need

To understand how to properly insulate the ceiling in a bathhouse, you need to understand that the work being carried out must resolve the following issues:

- Vapor barriers.

- Thermal insulation.

- Waterproofing.

Only high-quality materials Source banya-ili-sauna.ru

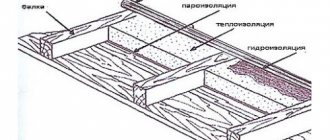

With proper organization, several layers are created. The bottom one is vapor barrier, the second one is thermal insulation and the final one is protection from water. All multilayers must be securely fastened in such a way as to prevent deformation.

Choosing the type of thermal insulation: all options

The specifics of the building must be taken into account when carrying out hydro-, heat- and vapor barrier work. Based on this, it is much easier to choose a ceiling in a bathhouse - what is best made of will depend on the following characteristics of the materials:

- Moisture resistance.

- Fire safety.

- Resistant to various temperatures, even high.

- Ease of installation.

- Weight.

Carrying out work from the attic side Source stroytorg.zp.ua

Mineral wool is the most popular option

In the process of solving the problem of how to insulate the ceiling in a bathhouse from the attic side, the choice often falls on mineral wool. This term itself combines several of the following types.

| Name of mineral wool type | What is it made from? |

| Slag | Blast furnace slag |

| Stone | Rocks that have undergone special treatment, including basalt |

| Glass wool | Glass fibers |

The advantages of using this material to solve the question of how to insulate the ceiling of a bathhouse:

- low thermal conductivity;

- no flammability;

- low weight;

- ease of installation;

- preservation of parameters during temperature changes.

Work must be carried out with the protection of the skin Source www.garrityinsulation.com

In addition to the listed advantages, it is important that mineral wool does not attract mice and does not serve as a favorable environment for the development of mold. It is sold in two release forms:

- Rolls.

- Separate panels.

Mineral wool also has disadvantages:

- content of phenols harmful to health;

- small particles of material can damage the skin, mucous membranes, eyes, and respiratory tract;

- moisture absorption.

Material in the form of individual panels Source vsparket.ru

The weaknesses of mineral wool during operation can be circumvented if the work is carried out correctly in compliance with all insulation requirements. When working on insulation, safety precautions must be observed to avoid getting the material on open areas of the body, in the respiratory system, or in the eyes.

Foam plastic: there are more disadvantages than advantages

This material is rarely chosen due to significant disadvantages:

- flammability;

- release of acrid smoke during combustion;

- lack of resistance to high temperatures.

Foam plastic is not the best option Source www.beboss.pro

During operation in a bath, foam plastic will be exposed to high temperatures. Since this circumstance is enough for the material to begin to decompose, expanded polystyrene is not the best choice, despite its good thermal insulation properties.

See also: Catalog of companies that specialize in baths

Expanded clay: cheap and long-lasting

This thermal insulation material consists of small clay, porous and smooth pebbles. Expanded clay is a good choice in terms of thermal insulation, which has many advantages:

- Almost endless service life, as the material does not break down.

- Environmentally friendly.

- Non-flammability.

- Does not create a favorable environment for the development of microorganisms.

- Easy to install.

- Has a low price.

For your information! Expanded clay absorbs water, but much less than all types of mineral wool.

Expanded clay is a good option Source stavstroi26.ru

The oldest type of insulation: sawdust with cement

This type of insulation was especially relevant before the advent of modern building materials, for example, mineral wool and other materials that had already become familiar. However, even now it is quite possible to use this option.

The composition is collected in the following ratio (the quantity is determined by the area):

- 1 part cement;

- 10 parts well-dried straw;

- 1 part lime.

Another way to insulate the ceiling in a bathhouse from the attic side in the “old-fashioned” way:

- Dry ingredients are mixed.

- The required amount of water is added. The composition should be moderately thick so that it is well distributed over the surface and there are no voids left.

Advantages of the method:

- Environmentally friendly.

- Cheapness.

Mixing dry ingredients Source banya-ili-sauna.ru

Disadvantages:

- lower thermal insulation qualities compared to modern materials;

- labor intensity of the process;

- there is a high probability that additional treatment will be required to seal the cracks formed as a result of drying.

Important! The hay, sawdust or straw that is used must be very well dried.

Ecowool: is natural material always the best?

If you are looking for how to insulate the roof of a bathhouse so that the materials are as environmentally friendly and safe as possible, then ecowool will give many competitors a head start.

Cellulose is used in the manufacturing process of ecowool. To prevent natural fibrous material from serving as a breeding ground for pathological microorganisms and mice, it is subject to mandatory additional processing.

Advantages of ecowool:

- light weight;

- environmental friendliness;

- good adhesion to the surface;

- high thermal insulation.

Ecowool for insulation Source prouteplenie.com

See also: Catalog of companies that specialize in engineering systems

But the material also has disadvantages:

- ecowool has the property of absorbing moisture, which requires very reliable hydro- and vapor barrier;

- installation complexity, requiring special skills and equipment.

For your information! Ecowool is applied using the so-called “wet method” - spraying.

Mineral wool

Insulating a bathhouse ceiling with mineral wool is equally suitable for rooms with and without an attic. The main thing is to provide the ceiling with floor beams on which the insulation cake will be fixed.

This method is quite simple to implement and will not entail large financial costs. Before thermal insulation is installed, all wooden elements are treated with antiseptic agents. Further, all work consists of stages.

Installation of vapor barrier

Vapor barrier material is divided into several types: regular foil, aluminum foil and membrane film. For a bath room, insulation with aluminum coating or foil insulation is best suited. Along with protection from moisture, it provides heat reflection into the steam room, which allows you to save on heating by two or three times.

Vapor barrier film sheets are overlapped onto a wooden beam using a construction stapler. Using foil tape, carefully glue all joints. This is the most effective way to properly and efficiently provide a bathhouse with thermal insulation.

Installation of sheathing

On the inside of the room, perpendicular to the wooden beams, a sheathing is nailed, which fixes the insulation and is sheathed on top with facing material.

A gap is left at one edge between the vapor barrier layer and the decorative cladding, which will reflect heat, and the insulation layer will lie tightly on the foil insulation.

Installation of insulation

The selected type of insulation is pressed into the resulting space between the ceiling beams of the steam room. There should be no gaps between the sheets of mineral wool; to do this, the material is compressed and installed in the seats with little force.

In order for this process to proceed without difficulty, the beams are fixed from each other at a distance less than 1 - 1.5 cm from the width of the wool.

Laying waterproofing

To reliably protect the insulation from moisture and contaminants entering from the outside, it is covered with polyethylene or thermal film.

As in the case of vapor barrier, the film is fixed to the supporting structure using a construction stapler. For natural air circulation, a ventilation gap is provided between the thermal insulation and waterproofing layers.

Installation of decorative cladding

The insulation pie is completed with decorative finishing of the bathhouse ceiling. Cladding panels are nailed to the ceiling beams with finishing nails. A stainless steel screen is usually suspended above the heater (at a distance of 15 cm from the ceiling). This will protect the roof section from overheating and, as a result, deformation.

To protect the thermal insulation structure from mechanical damage, it is recommended to install a subfloor in bathhouses with an attic.

The most popular and high-quality cladding for the ceiling of a steam room is lining made of linden wood, larch or aspen.

These types of wood can withstand high temperatures and create a healthy indoor microclimate.

Selection of material for waterproofing and vapor barrier

Additional protection from steam and water is necessary, no matter what insulation is chosen. Without it, moisture will reach both the insulation and the supporting elements, damaging them.

Vapor barrier can be provided by the following coatings:

- aluminium foil;

- geosynthetics, etc.

Geosynthetics for waterproofing Source stroimsami.online

Advice! If there is a choice, it is recommended to give preference to those materials that have a layer of foil.

For waterproofing use:

- roofing felt;

- plastic film;

- special films.

Laying roofing felt in the attic Source sk-sota.ru

For your information! Dense polyethylene and roofing felt are a cheaper option compared to special types of coating.

Different types of ceilings: features of the work

Depending on the type of ceiling in the bathhouse, the list and nature of the work required to organize insulation is determined. Types of ceilings:

- Panel.

- Hemmed.

- Grazing.

Each type has its own nuances. If you decide to independently implement how to insulate the ceiling in a bathhouse with your own hands, then even a step-by-step guide will not help if you lack the skills and tools. Trusting professionals is the best solution. In this case, it is quite enough to have general information about the procedure for performing work and materials.

Briefly about the main thing

The choice of the type of insulation organization and the materials used should be based on the following main points:

- the established budget;

- bath area;

- structural features of the structure;

- planned frequency of use of the bathhouse.

By adhering to all the above recommendations, you can organize a functional and high-quality ceiling, which will reduce the cost of fuel for heating the room. And it will last for many years.

Ratings 0

Why insulate the ceiling in a bathhouse?

Heat leakage from a room can occur in three main ways:

- through cracks in the ceiling structure;

- when heat transfers to cold objects in the environment;

- when heated air masses pass through various types of monolithic/homogeneous barriers.

To eliminate all of these problems, a multi-layer ceiling structure is installed, which includes, among other things, a layer of heat-insulating material. If insulation is performed incorrectly or is completely absent, condensation will begin to form on the floors, warming up the room will require much more time and, therefore, more significant expenditure of energy resources.

A standard insulation scheme for a ceiling structure is shown in the following image.

Standard scheme for insulating a ceiling structure

Helpful advice! Try to lay each subsequent insulating layer perpendicular to the previous one. This will allow you to obtain the most reliable design with minimal deformation indicators.