Distinctive features

Cast iron heats up more slowly than steel, but its properties are superior to all materials . During the operation of the furnace, burnout occurs more slowly. The case retains heat for up to seven hours. Cast iron is an alloy of iron and carbon, making it resistant to corrosion and resistant to high temperatures.

Silicon and manganese in the composition make cast iron more durable and ductile.

The structural elements of the furnace are combined into a single structure by welding . All joints are treated with sealant. The operating principle of cast iron stoves is the same. It comes down to heat transfer indicators and heat retention time. This is what distinguishes cast iron from other materials.

The stones are placed on top, and the water tank goes around the pipe and the stones. This ensures minimal heat loss.

Firewood is thrown into the firebox. When they burn, a hall is formed. It pours into a special compartment. Next, the hot air rises, and the stones are heated by the stove and pipe. The temperature in the pipe reaches 250 degrees Celsius . The stones give off heat to the room, thereby creating a comfortable environment.

How to heat properly?

To make it comfortable to steam in a black sauna, you need to follow a number of rules:

- Use birch wood for kindling. Solid fuel with chemical elements is prohibited.

- Before heating, you need to open the doors and windows in the bathhouse and check how the vent is positioned.

- Before adding firewood to the firebox for the second time, you need to fill a bucket with cold water and pour it over the walls and shelves.

- You can start steaming after a crimson tint appears on the surface of the stones.

- Before you start steaming, you need to remove the coals and ash from the bathhouse.

Before starting bath procedures, it is recommended to splash 2-3 cups of herbal infusions on the stones.

Black baths have long lost popularity, giving way to modern buildings with chimneys. Sometimes people want to feel how their ancestors steamed, but they don’t know how to assemble a stove according to the old model or carry out the procedures. To do this, just follow simple rules and assemble homemade oven equipment. The procedure itself is no different from modern soaring. The main thing is to wait until the smoke comes out of the steam room.

Advantages and disadvantages

Cast iron stoves are considered the standard. They are much more practical than stone, steel and other units. This is due to the optimal composition, design features and build quality.

Advantages:

- simple installation;

- cheap fuel (firewood);

- compact dimensions - usually the stoves are small, so they can be installed even in a small room;

- installation does not need to be coordinated with interested organizations, unlike gas boilers;

- the oven reaches the desired temperature much faster compared to electric and gas appliances;

- the housing is highly sealed;

- products are resistant to high temperatures (steel deforms over time);

- the water in the tank remains hot for up to 4 hours;

- service life is more than 30 years, which is not typical for stoves made of other materials.

Flaws:

- you need a stronger foundation than when installing a steel stove;

- unlike an electric boiler, it is necessary to make a chimney;

- despite the massiveness, the material is fragile, so you need to be careful when installing;

- the price of cast iron stoves is higher compared to steel and other units;

- Sudden cooling is not allowed, otherwise the cast iron will crack.

Hot water tank requirements

If you have to wait a long time for the water to heat up, or add it so that there is enough for everyone, this reduces the comfort of staying in the bathhouse. It is also very unpleasant if the water takes on a rusty color. The reliability and durability of the tank also matters a lot, since the prices for tanks are very high, and replacement will be expensive.

Stainless Steel Oven Mounting Tank

Based on this, we can highlight the main requirements for a hot water tank:

- it should heat up quickly;

- have high resistance to corrosion;

- withstand high temperatures;

- easy to clean;

- have sufficient capacity.

What to choose and which one is better?

Stoves for baths and saunas are made of cast iron, heat-resistant steel or alloyed stainless steel . Materials differ in carbon content. The ductility and strength of steel and cast iron is due to the low carbon content (2%). Each option has its own characteristics and disadvantages.

The main advantages of a cast iron stove:

- Thermal conductivity . The indicator is much better than that of structures made of brick and steel, which deform due to temperature changes. The efficiency of a cast iron stove is 82%. After one load of firewood it works up to 7-9 hours. The weight is up to 300 kg, which eliminates the need to install a foundation on it.

- Easy care . If you install a cast iron stove, you don't have to spend a lot of time maintaining it. The product does not rust and does not require special paint. Due to the absence of cladding, the unit is easy to install and, if necessary, dismantled for transfer to another location. Steel products need to be treated with heat-resistant paint, and this should be done once a year.

- Design . For this reason, both steel and cast iron stoves attract buyers. The range is represented by a variety of models, which allows you to find the right option. The ovens are equipped with doors made of heat-resistant glass. Various forged elements give the stoves a sophisticated look.

- Safety in operation . Compared to brick stoves, cast iron products are safer to use, as they are less likely to cause fire.

- Lifetime . One of the main features of cast iron stoves. With proper use, the service life exceeds 35 years.

The only disadvantage of a cast iron stove is the high price . But products from domestic manufacturers are cheaper. At this quality, it is no worse than that of Swedish and other manufacturers.

Popular furnaces with heat exchangers

Cast iron stoves are deservedly popular among lovers of Russian baths, but how are they combined with heat exchangers? As it turns out, they combine perfectly.

Cast iron stove

To get started, we recommend visiting the website of the Petrozavodsk stove manufacturer Karelia. Among the products offered to visitors are components, among which there is a disk-shaped heat exchanger, apparently attached to one of the walls of the furnace. Thus, you can purchase both a stove and an exchanger at once. As an option, they also sell mounted tanks for the chimney.

Cast iron stove with heat exchanger for a bath. Photo source

Vesuvius stove

Vesuvius stove with heat exchanger for a bath

The stove manufacturer Vesuvius also provides the opportunity to simultaneously purchase a stove (and in its catalog you will find both steel and cast iron stoves) and a heat exchanger . The buyer is given a choice of three models - two “samovars” for the chimney, differing in capacity, and one rectangular heat exchanger, which takes heat from the stove wall.

photo of heat exchangers on the Vesuvius website

Stoves for baths "Termofor"

There is a message on the Termofor website that the manufacturer took into account customer preferences and produces the most popular models - Tunguska 16 and Tunguska 24 - with already installed heat exchangers , which require an external location of the storage tank. The material of the exchangers is high-quality food grade stainless steel, 2 mm thick . Depending on the buyer’s choice, the placement can be varied by installing it either on the right or on the left wall of the stove.

Useful video

Termofor sauna stoves with a heat exchanger may be built well, but there are negative reviews. Watch the video and see what it looks like:

How to choose a cast iron stove and what to look for?

The range is represented by a huge selection of models . The buyer decides which one to choose based on individual needs and financial capabilities. To find a suitable option, you should read the recommendations.

Stove selection criteria:

- Placement of the firebox . It can be regular or extended. The latter is installed in the wall opening. This allows you to heat the stove not from the steam room or from the rest room.

- Tank type . The design can be built-in or wall-mounted. When choosing, you need to focus on the specifics of the bath.

- Productivity . This indicator is indicated in the product passport. It determines how quickly the room warms up.

- Door type . Models with a tempered glass door are more expensive, but simpler products are not inferior to them in quality.

- Material . Some manufacturers replace some of the elements with steel ones to reduce the cost of their products. The disadvantage is that the service life of the oven is significantly reduced.

- Heated volume . The indicator is indicated in the product characteristics. It is worth focusing on the area of the room.

- Ash box . Most modern models have a built-in box where combustion waste is collected.

Popular stove sets

To heat rooms measuring 6–14 cubic meters, the following kit for a steel stove is suitable:

Stove-heater

Chimney kit with ridge height 3 meters

Additional mesh of stones for 50 kilograms

Heat exchanger

Water tank 35 liters

Set for steel mesh oven:

Mesh oven

Chimney kit 3 meters high (3.5 or 4)

70 liter tank

Heat exchanger

Cast iron stove kit:

Stove-heater

Chimney kit 3 meters high (3.5 or 4)

Closed heater module

Mesh heater

60 liter tank

Heat exchanger

To accommodate a different volume, you can assemble the kit yourself on the website or ask a consultant.

TOP 7 best cast iron stoves for baths and saunas

When choosing a product, you should take time to study the characteristics of different models. When comparing, it is easier to understand which oven will be most suitable. The rating includes seven stoves from different manufacturers. Each of them has its own characteristics, advantages and disadvantages.

Hephaestus PB-04 MS

The products are made of alloy cast iron. The thickness of the parts is 40 mm. Due to its unique shape, the oven heats up to 500 ⁰C in a short time. Convection fins on the side mounts increase heat transfer. Despite the thickness, the unit quickly distributes steam.

Characteristics:

- dimensions - 39.40x56x64.50 cm;

- weight - 130 kg;

- heated volume - 15 m³;

- power - 8 kW;

- type - closed;

- Efficiency - 87%;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 11.5 cm.

Advantages:

- completely made of cast iron;

- spacious ash drawer;

- glass door;

- optimal size;

- convenient connection to the chimney;

- holds up to 180 kg of stones.

Flaws:

- high price;

- complex installation.

Hephaestus PB-04

High-quality stove made of alloy cast iron . Due to its unique design, it quickly warms up to the desired temperature, which ensures fast steam distribution. The side walls are equipped with convection fins, which increase heat transfer from burning wood.

Characteristics:

- dimensions - 39.40x56x64.50 cm;

- weight - 130 kg;

- heated volume - 15 m³;

- power - 8 kW;

- type - closed;

- Efficiency - 87%;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 11.5 cm.

Advantages:

- spacious compartment for stones and firewood;

- environmental friendliness;

- long service life;

- attractive appearance;

- high-quality case;

- built-in ash drawer.

Flaws:

- difficulties with installation (formation of a reinforced base);

- high price.

Vesuvius LEGEND STANDARD 16 (DT-4S)

The stove from the Russian manufacturer is extremely popular . The manufacturer uses high-quality materials to manufacture products. The stove heats a large room in a short time.

Characteristics:

- dimensions - 56x70x69 cm;

- weight - 117 kg;

- heated volume - 18 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 12 cm.

Advantages:

- weight of stones up to 120 kg;

- stylish design;

- glass door;

- high efficiency;

- fast heat transfer;

- easy care;

- glass self-cleaning system.

Flaws:

- some elements are made of steel;

- a protective coating must be applied.

Vesuvius LEGEND FORGING 16 (270)

When manufacturing furnaces, the manufacturer controls every stage: from the extraction of raw materials to packaging of products . Due to this, the stoves are of high quality. Model LEGEND FORGING 16 (270) has an attractive appearance.

It is characterized by high heat transfer. The thickness of the firebox walls is 1.2 cm.

Characteristics:

- dimensions - 56x70x69 cm;

- weight - 98 kg;

- heated volume - 18 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 12 cm.

Advantages:

- all-welded construction;

- spacious ash drawer;

- high efficiency;

- heat-resistant glass door;

- remote firebox.

Flaws:

- corrosion;

- the need for treatment with a special compound.

Vesuvius Sensation 16 Anthracite (270)

The manufacturer is constantly improving models. Cast iron stove Vesuvius Sensation 16 Anthracite (270) has optimal characteristics. Quickly warms up the room due to the dense walls.

Characteristics:

- dimensions - 41x64x69 cm;

- weight - 99 kg;

- heated volume - 18 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 12 cm.

Advantages:

- Beautiful design;

- capacity up to 60 kg of stones;

- convenient ash drawer;

- high efficiency;

- heat-resistant door;

- minimal load of stones on the collector;

- self-cooling and self-cleaning system;

- high quality coating.

Flaws:

- overcharge;

- installation difficulties.

Vesuvius RUSICH ANTHRACITE 22 (DT-4) 2016

High-quality model that meets European quality standards . A closed stove equipped with a chimney. The wall thickness is 0.8 cm, which ensures rapid distribution of heat and steam.

Characteristics:

- dimensions - 56x73x69.50 cm;

- weight - 99 kg;

- heated volume - 14 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 11.5 cm.

Advantages:

- quality material;

- durable cast iron door;

- optimal size;

- convenient connection to the chimney;

- it is heated from the next room;

- colorful appearance.

Flaws:

- holds 40 kg of stones;

- complex installation.

KASTOR Karhu-16 JK

Finnish stove made of alloy cast iron . Durable product. It warms up the room perfectly and maintains a high temperature for a long time.

It has a simple design, making it suitable for any room style.

Characteristics:

- dimensions - 43.50x71x49 cm;

- weight - 59 kg;

- heated volume - 16 m³;

- power - 16 kW;

- type - closed;

- secondary afterburning - yes;

- ash box - yes;

- chimney diameter - 10.4 cm.

Advantages:

- quality material;

- high level of productivity;

- compact size;

- beautiful design;

- high power;

- easy cleaning.

Flaws:

- high price;

- glass door.

What is the difference between stoves of the Ermak 12 model?

| Year of issue | Power, kilowatts | Heater type | Door | Additional options | |

| Ermak 12 | 2012 | 12 | Open - stones are on top of the stove, water is poured on them | Without glass, steel | |

| Ermak 12 PS | 2012 | 12 | Open | With panoramic glass, steel | |

| Ermak 12 Standard | 2017 | 12 | Open | Without glass, steel | Oven material to choose from - steel or cast iron |

| Ermak 12 Premium | 2017 | 12 | Open | With panoramic glass, wide decorative stainless steel frame | Ash drawer with black glass top. Oven material to choose from - steel or cast iron |

| Ermak 12 Mesh Standard | 2017 | 12 | Mesh heater for 150–170 kg of stones | Without glass, steel | Oven material to choose from - steel or cast iron |

| Ermak 12 Mesh Premium | 2017 | 12 | Mesh heater for 150–170 kg of stones | With panoramic glass, wide decorative stainless steel frame | Ash drawer with black glass top. Oven material to choose from - steel or cast iron |

| Ermak 16 | 2012 | 16 | Open | ||

| Ermak 16 PS | 2012 | 16 | Open | ||

| Ermak 16 Standard | 2017 | 16 | Open | Oven material to choose from - steel or cast iron | |

| Ermak 16 Premium | 2017 | 16 | Open | With panoramic glass, wide decorative stainless steel frame | Ash drawer with black glass top. Oven material to choose from - steel or cast iron |

| Ermak 16 Mesh Standard | 2017 | 16 | Mesh heater for 150–200 kg of stones | Oven material to choose from - steel or cast iron | |

| Ermak 16 Mesh Premium | 2017 | 16 | Mesh heater for 150–200 kg of stones | Ash drawer with black glass top. Oven material to choose from - steel or cast iron | |

| Ermak 20 | 2012 | 21,5 | Open | ||

| Ermak 20 PS | 2012 | 21,5 | Open | ||

| Ermak 20 Standard | 2017 | 21,5 | Open | Oven material to choose from - steel or cast iron | |

| Ermak 20 Premium | 2017 | 21,5 | Open | With panoramic glass, wide decorative stainless steel frame | Ash drawer with black glass top. Oven material to choose from - steel or cast iron |

| Ermak 20 Mesh Standard | 2017 | 21,5 | Mesh heater for 180–240 kg of stones | Oven material to choose from - steel or cast iron | |

| Ermak 20 Mesh Premium | 2017 | 21,5 | Mesh heater for 180–240 kg of stones | With panoramic glass, wide decorative stainless steel frame | Ash drawer with black glass top. Oven material to choose from - steel or cast iron |

In 2020 appeared

— mesh ovens;

- the ability to choose the furnace material - steel or cast iron;

— in steel furnaces, the thickness of steel increased to 8 millimeters;

— the warranty has increased, for steel from 1 year to 3, for cast iron from 3 to 5;

— the ability to install a closed heater and steam generator.

Step 1. Determine the furnace power

Step 2: Select oven type

Step 3. Choose a stove with or without panoramic glass

Step 4. Select oven material

Step 5. Select oven accessories

Step 6. If you have chosen a stove-heater, then decide on the accessories for it

Popular stove sets

What is the difference between Ermak model stoves?

ROOMS VENTILATION SYSTEM

Since the stove takes air from the room where it is installed, it is necessary that a sufficient amount of air enters the room. This is especially true for rooms in which doors and windows are sealed, so the supply of fresh air cannot be guaranteed, which can negatively affect the draft power of the stove and the safety of people in the room. In such rooms, it is necessary to install an additional supply of fresh air through an external air intake or an air intake into an adjacent ventilated room, with the exception of the boiler room and garage, which is strictly prohibited.

The connecting pipe must be smooth, the minimum diameter is 120 mm, the length must not exceed 4 m, and the number of bends must not exceed 3. If the pipe is led directly outside, it must be equipped with a special windproof shield.

It is absolutely necessary that in rooms where stoves with natural chimney draft operate, as much air is supplied as required for combustion, that is, up to 20 m3/h. A constant air flow must be guaranteed by several external openings that are constantly open. The size of the holes is indicated in the fire safety regulations, information about which can be obtained from the relevant authorities. Openings should be protected with bars and never covered. It is important to remember that a suction hood installed in the same or adjacent room leads to a decrease in pressure in the room, which leads to the release of exhaust gases (smoke), so it is necessary to provide a greater supply of fresh air. Otherwise, a decrease in exhaust pressure can turn the stove flue into an air intake device, releasing exhaust gases into the room, with serious consequences for people.

Popular stove sets

To heat rooms measuring 6–14 cubic meters, the following kit for a steel stove is suitable:

Stove-heater

Chimney kit with ridge height 3 meters

Additional mesh of stones for 50 kilograms

Heat exchanger

Water tank 35 liters

Set for steel mesh oven:

Mesh oven

Chimney kit 3 meters high (3.5 or 4)

70 liter tank

Heat exchanger

Cast iron stove kit:

Stove-heater

Chimney kit 3 meters high (3.5 or 4)

Closed heater module

Mesh heater

60 liter tank

Heat exchanger

To accommodate a different volume, you can assemble the kit yourself on the website or ask a consultant.

Homemade stove made of cast iron pipe

Given the high cost of ready-made devices, some craftsmen are building homemade heating tanks for bathhouses. In addition to the stove itself, you need to take care of a durable surface for it. It is not necessary to build a full-fledged foundation, but it is necessary to lay a metal sheet on the floor and secure it. Place flat slate on top. Both sheets should protrude 5 centimeters from all sides of the structure.

The easiest way to make a sauna stove yourself is from a large cast-iron pipe half a meter in diameter and a meter long.

A finished boiler of such volumes will be able to heat a steam room measuring 12–15 square meters. You will also need a sheet of cast iron with a thickness of 5 to 10 mm. The only tools you need are a welding machine with electrodes and a grinder with discs for working on metal. Visually, the finished oven may look something like this.

Finished oven dimensions

First of all, take care of the bottom of the future oven. Cut a circle with a diameter of 50 cm (equal to the diameter of the pipe) from a cast iron sheet. Then weld it to one end of the pipe - this will be the bottom of the future boiler for the bath. After this, cut a small rectangular hole in the pipe at the bottom to create an ash pan there. We turn the cut piece of metal into a door for the ash pit by simply welding metal hinges to the pipe and to this element. For the handle of the ash door, weld a small piece of metal or pre-purchased steel fittings to it.

Install a grate immediately above the ash pan. You need to buy it in a specialized department of a construction or hardware store. It is better to use standard grates, as they are easier to change if necessary than to create them yourself. To place the grate above the ash pan, weld small supports inside the pipe, on which you place the grate bars. Sections of thick reinforcement can be used as supporting elements.

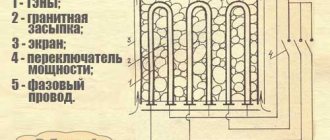

On top of the grates, cut a rectangular hole intended for the firebox. Make the door with the handle in the same way as was described in the case of organizing the door for the ash pan. And on top of the firebox you need to make a container for stones. Cut another circle from the cast iron sheet. Make a hole on the side for the chimney pipe (standard size is 120 mm). Install this circle inside the structure and weld it. It should be located 20 centimeters below the upper end of the pipe. This recess will be the compartment for stones. Weld a pipe to the chimney opening, and weld legs from sections of thick reinforcement or other suitable material to the bottom of the stove.

Disadvantages of cast iron stoves

The main disadvantage of the unit is its high cost, which not every person can afford. In addition, it is important to choose the model wisely so as not to make a mistake with the quality of the alloy. And, unfortunately, it can be different. Many experienced stove makers do not trust Russian cast iron, considering it to be of lower quality. But Swedish-made stoves with solid cast iron fireboxes are called the standard of strength. In these models, the doors are adjusted manually without the use of a seal. At the same time, the level of work of the craftsmen is so high that in the end the oven chamber is completely sealed.

If you do not make gross mistakes during operation, such a boiler will never burst, despite temperature changes. The same cannot be said about low-quality cast iron, which is terribly afraid of temperature changes, when in two adjacent places the temperature difference is more than 80 degrees. And such an incident can easily happen if, for example, cold water is accidentally spilled on the stove, which happens in a bathhouse. Therefore, many Russian leading manufacturers of bath equipment do not make cast iron stoves. And those companies that do create sauna boilers from cast iron strongly recommend that buyers of their products treat it very carefully.

General information

A device for heating a bath made of cast iron is versatile because it can warm the water and air inside the steam room at the same time.

A cast iron stove fits perfectly into a sauna interior; you can choose a model that will harmonize with any type of design. Even compact types of stoves are distinguished by their considerable weight, more than 50 kilograms. At the same time, the device is quite easy to transport and install.

Wood-burning stoves are highly popular due to their simplicity of design, high reliability and ease of use.

According to your individual wishes, the stove can be lined with any suitable material.:

- ceramic bricks;

- tiles;

- natural stone.

Cladding is sometimes a necessary measure when the purchased stove turns out to be of low quality.

Low-grade cast iron can crack during operation, and the outer cladding will protect it from such problems. If the stove is made of high quality cast iron, it does not need to be sheathed with anything, since it itself will look natural in the steam room.

Device

Cast iron stoves operating on wood fuel differ in the following characteristics:

- Indicator of firebox volume.

- Determines the power level of the furnace, as well as the volume of stones needed. The power of the purchased stove should be selected based on the cubic capacity of the steam room. Experts do not recommend choosing a stove whose power level is higher than optimal. Otherwise, during the combustion of wood you will have to reduce the intensity of combustion. Then the oven will not be able to maintain the heating of the stones at the proper level, which means it will not be possible to create the optimal temperature and humidity conditions.

- Type and volume of container for laying stone. The container can be a metal mesh, a brick or all-stone box made of soapstone or soapstone. Stone or brick containers serve as excellent heat accumulators. In addition, the heater can be open or closed.

- Based on the type of tunnel, a distinction is made between external and non-external. In the first case, you can lay firewood from the room adjacent to the steam room. This could be a dressing room or a rest room. In the second - only from the steam room itself.

- Based on the type of oven doors, they are divided into: solid cast iron oven doors, with glazing, without glazing. When choosing a stove, it is necessary to take into account the fact that the presence of glazing elements in a sauna stove leads to a decrease in efficiency and an increase in the level of heat loss. To light a sauna stove equipped with a glass insert, you will need to consume more firewood and additional time. The main advantage of stoves decorated with glazing is their appearance, which allows you to admire the flames and creates a feeling of special comfort.

- The oven can be round in shape, or have a rectangular or square cross-section.

It is worth studying in more detail the main types of sauna stoves.

They are:

- With closed heater . Such models are considered the most economical in terms of the amount of firewood consumed and the mass of soot formed during their combustion. Such devices can efficiently heat a room with a volume of up to 45 cubic meters. The main design feature is that in such a stove the stones are located inside. Above the heater there is a hole through which water is supplied, which in the process turns into steam, dry and clean.

- With a non-removable firebox type . Such stoves are often modest in size and can perfectly complement the interior of any steam room. They are often installed inside small buildings that do not have utility rooms. It is only important not to store firewood in the same room where the stove is located, since this is unsafe from the point of view of the possibility of fire.

- Stationary furnaces with a remote firebox type . It involves installing an open heater in a steam room with removal of the firebox to a recreation room or utility room.

Operating principle

The general algorithm for operating a wood-burning cast-iron sauna stove is not very complicated:

- the basis of a wood-burning cast-iron stove is its firebox, where solid fragments of fuel are placed;

- when it burns, heat is released, which is accumulated by the stove body or heater;

- under the firebox there is an ash pit into which wood combustion waste falls;

- Smoke is removed through the chimney pipe.

In some models, the design involves equipping the oven with a water container, where it is heated, after which the water becomes suitable for washing.

IMPORTANT!

The heating element is the body of the device, which accumulates the thermal radiation of the furnace.

Peculiarities

The design of a cast-iron wood-burning stove may require the installation of various additional elements.

This may include the following components:

- water heater;

- pipe for removing smoke and other combustion products;

- container for water.

The fuel most often is firewood, but it is acceptable to use briquettes made from compressed peat or sawdust . It is important to know that coal should not be used to light cast iron stoves, since it has a higher combustion temperature than wood raw materials.

The characteristics of cast iron are such that high-temperature exposure can lead to cracks in the metal . In addition, a wood-burning sauna maintains an atmosphere that is more beneficial to human health and well-being. You can achieve significant heat transfer rates from a cast iron stove.

The process is facilitated by the presence of lining the unit with natural stone. In addition to the energy and aesthetic effect, this technique will protect the structure from moisture, which will significantly extend its service life.

The chimney in such stoves is equipped in one of the possible ways:

- on the reverse side of the structure;

- on the unit itself;

- by bringing it to the roof of the building.