Specifics of using solar collectors

The main feature of solar collectors, which distinguishes them from heat generators of other types, is the cyclical nature of their operation. No sun - no thermal energy. As a result, such installations are passive at night.

The average daily heat production directly depends on the length of daylight hours. The latter is determined, firstly, by the geographical latitude of the area, and secondly, by the time of year. During the summer period, when insolation peaks in the northern hemisphere, the collector will work at maximum efficiency. In winter, its productivity decreases, reaching a minimum in December-January.

In winter, the efficiency of solar collectors decreases not only due to a decrease in daylight hours, but also due to a change in the angle of incidence of sunlight. Fluctuations in solar collector performance throughout the year should be taken into account when calculating its contribution to the heating system.

Another factor that can affect the productivity of a solar collector is the climatic characteristics of the region. There are many places in our country where for 200 or more days a year the sun is hidden behind a thick layer of clouds or a veil of fog. In cloudy weather, the performance of the solar collector does not drop to zero, since it is able to capture scattered solar rays, but it is significantly reduced.

General remarks

All of the above applies to expensive and high-quality solar collectors. Meanwhile, a large number of systems from different manufacturers have now appeared on the Russian market. What types of solar collectors are there and what is better to choose? How not to be deceived in expectations and choose the right option?

Flat solar collectors:

Flat-plate solar collectors are European, Russian and Chinese. Dimensions may vary, power is estimated standardly based on the collector area.

1. European. Usually supplied from Germany, less often from Italy or other European countries. Almost all manufacturers' collectors are distinguished by high quality workmanship and the highest possible efficiency for flat-plate collectors. The price is high.

2. Russian. Quality depends on the manufacturer. The best examples are still inferior to European models. The worst are comparable to cheap Chinese options. Efficiency also varies. Before installation, it is better to seek feedback on this type of collector and evaluate the applicability to your project. The price is average.

3. Chinese. Quality depends on the manufacturer. The best samples from well-known companies are inferior to European models and comparable to Russian ones. There are cheap flat collectors without a brand - the quality is usually low and the efficiency is also low, although it is possible to use them in water heating systems. The price is low.

Vacuum solar collectors:

Vacuum solar collectors are supplied almost exclusively from China and are not produced in Russia. They are produced in relatively small quantities in Europe, but are practically not supplied to Russia.

1. With heating tubes. The most common type of vacuum manifolds. Inside the glass vacuum tubes there are special copper tubes that transfer energy to the coolant. Quality varies from very high in the best factories in China to very low in small and handicraft industries. High-quality collectors are characterized by high glass strength and an increased level of solar energy absorption due to special selective nano-coatings. Low-quality tubes are fragile and have a low level of heat absorption. It is difficult to visually distinguish high-quality from low-quality ones, so you should focus on well-known brands. The largest manufacturer of vacuum manifolds in China is Himin Solar, whose products are of the highest quality.

2. With U-tubes. In these collectors, solar energy is transferred through mini copper loops (U-tubes) located inside each glass bulb. Compared to heating tubes, this increases efficiency by 10-15%. The production of such collectors is more technologically advanced, so they are usually high-quality solar collectors produced by well-known companies, the largest of which is Himin Solar.

Key Recommendation

If you only need hot water supply, you can choose either a flat or vacuum solar collector. A vacuum collector will only be more efficient in winter and in cloudy weather.

For heating in the Russian climate, only vacuum collectors should be used.

Remember that magic does not happen and, regardless of the type of collector, an additional source of energy is required in case of prolonged cloudy weather.

And most importantly, do not buy products of dubious manufacture and unknown quality, trust only well-known brands.

This article has been read 9159 times!

Operating principle and types of solar collectors

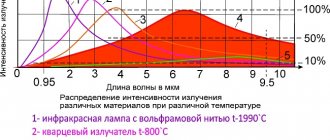

The time has come to say a few words about the design and operating principle of the solar collector. The main element of its design is the adsorber, which is a copper plate with a pipe welded to it. Absorbing the heat of the sun's rays falling on it, the plate (and along with it the pipe) quickly heats up. This heat is transferred to the liquid coolant circulating through the pipe, which in turn transports it further through the system.

The ability of a physical body to absorb or reflect solar rays depends, first of all, on the nature of its surface. For example, a mirror surface perfectly reflects light and heat, but a black surface, on the contrary, absorbs it. That is why a black coating is applied to the copper plate of the adsorber (the simplest option is black paint).

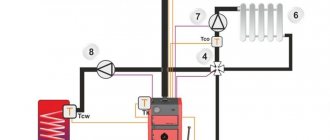

The principle of operation of the solar collector

1. Solar collector. 2. Buffer tank. 3. Hot water.

4. Cold water. 5. Controller. 6. Heat exchanger.

7. Pump. 8. Hot flow. 9. Cold flow.

You can also increase the amount of heat received from the sun by correctly selecting the glass covering the adsorber. Regular glass is not transparent enough. In addition, it glares, reflecting part of the sunlight falling on it. In solar collectors, as a rule, they try to use special glass with a low iron content, which increases its transparency. To reduce the proportion of light reflected by the surface, an anti-reflective coating is applied to the glass. And to prevent dust and moisture from getting inside the collector, which also reduce the throughput of the glass, the housing is made sealed, and sometimes even filled with inert gas.

Despite all these tricks, the efficiency of solar collectors is still far from 100%, which is due to the imperfection of their design. The heated adsorber plate radiates part of the received heat into the environment, heating the air in contact with it. To minimize heat loss, the adsorber must be insulated. The search for an effective way to thermally insulate an adsorber led engineers to the creation of several types of solar collectors, the most common of which are flat and tubular vacuum.

Flat-plate solar collectors

Flat solar collectors.

The design of a flat solar collector is extremely simple: it is a metal box covered with glass on top. Mineral wool is usually used to insulate the bottom and walls of the housing. This option is far from ideal, since heat transfer from the adsorber to the glass through the air inside the box cannot be ruled out. With a large temperature difference between inside and outside the collector, heat loss can be quite significant. As a result, a flat solar collector, which functions perfectly in spring and summer, becomes extremely ineffective in winter.

Design of a flat solar collector

1. Inlet pipe. 2. Protective glass.

3. Absorption layer. 4. Aluminum frame.

5. Copper tubes. 6. Heat insulator. 7. Outlet pipe.

Tubular vacuum solar collectors

Tubular vacuum solar collectors.

A vacuum solar collector is a panel consisting of a large number of relatively thin glass tubes. An adsorber is located inside each of them. To prevent heat transfer by gas (air), the tubes are evacuated. It is precisely due to the absence of gas near the adsorbers that vacuum collectors are characterized by low heat loss even in frosty weather.

Vacuum manifold device

1. Thermal insulation. 2. Heat exchanger housing. 3. Heat exchanger (collector)

4. Sealed plug. 5. Vacuum tube. 6. Capacitor.

7. Absorbing plate. 8. Heat pipe with working fluid.

Myth one: flat-plate collectors are stronger than vacuum ones

High-quality flat-plate collectors made in Germany are quite durable and can easily withstand hail and similar external influences. But, of course, you can break them if you want. The same can be said about quality vacuum manifolds. In practice, replacing glass tubes with installed vacuum manifolds is quite rare, since quality tubes are very durable and designed to last a long time. Pay attention to the video below, which shows a vacuum tube being tested for strength with a piece of ice, simulating hail. This is a case in point.

And here is the same example using a steel ball.

It is also worth remembering that if a flat plate collector becomes damaged, it usually needs to be replaced, which is an expensive and difficult task. If several glass tubes of the vacuum manifold are damaged, it will still continue to work, and the tubes can be replaced later. Typically, when installing vacuum manifolds, provision is made for how the tubes will be replaced if they are damaged and have reached the end of their normal service life (15 years).

Application areas of solar collectors

The main purpose of solar collectors, like any other heat generators, is to heat buildings and prepare water for a hot water supply system. It remains to find out which type of solar collectors is best suited to perform a particular function.

Flat-plate solar collectors, as we found out, have good performance in the spring and summer, but are ineffective in winter. It follows from this that using them for heating, the need for which appears precisely with the onset of cold weather, is inappropriate. This, however, does not mean that there is no use for this equipment at all.

Flat-plate collectors have one undeniable advantage - they are significantly cheaper than vacuum models, so in cases where you plan to use solar energy exclusively in the summer, it makes sense to purchase them. Flat solar collectors do an excellent job of preparing water for hot water supply in the summer. Even more often they are used to heat water in outdoor pools to a comfortable temperature.

Tubular vacuum manifolds are more versatile. With the arrival of winter cold, their performance does not decrease as significantly as in the case of flat models, which means they can be used all year round. This makes it possible to use such solar collectors not only for hot water supply, but also in the heating system.

Comparison of flat and vacuum solar collectors.

Solar collectors for heating water in winter

In our country, for objective and subjective reasons, solar power plants are not as widespread as in European countries and America.

One of the reasons is that in most parts of Russia, winter lasts quite a long time, and according to potential users, the economic effect of using solar power plants at this time is minimal. In addition, fallen snow reduces the efficiency of solar devices, and hail can damage them.

Nevertheless, solar collectors are in demand on the energy equipment market and there are several reasons for this, namely:

- As a result of use, the owner receives absolutely free thermal energy, which he can use at his own discretion.

- The energy conversion process is environmentally friendly for the environment and living organisms (people, animals, etc.).

- The energy of the sun is inexhaustible and renewable.

Of course, such devices also have disadvantages, and the most important of them is the high cost of the equipment, as well as the dependence of the performance (efficiency) of the units on external factors. External factors are weather conditions and the possibility of periodic maintenance of units (cleaning of dirt and snow, inspection of component connections, etc.).

Vacuum models are able to bring water to a boil even in severe frost

Different types of solar collectors, and among consumers the most popular are flat and vacuum models, behave differently in winter, which is due to their design, namely:

- Flat models are most susceptible to external factors (snow, low temperatures and strong winds, hail) and require more care.

- Vacuum ones are the most optimal for use in winter, which is due to their design, and they are also quite durable, because are made from high-strength materials.

Location of solar collectors

The efficiency of a solar collector directly depends on the amount of sunlight falling on the adsorber. It follows from this that the collector should be located in an open space, where shadows from neighboring buildings, trees located near mountains, etc. never (or at least for as long as possible) fall.

Not only the location of the collector is of great importance, but also its orientation. The “sunny” side in our northern hemisphere is the southern one, which means that ideally the collector “mirrors” should be turned strictly south. If it is technically impossible to do this, then you should choose a direction as close as possible to the south - southwest or southeast.

One should not lose sight of such a parameter as the angle of inclination of the solar collector. The magnitude of the angle depends on the deviation of the position of the Sun from the zenith, which in turn is determined by the geographic latitude of the area in which the equipment will be operated. If the tilt angle is set incorrectly, the optical energy loss will increase significantly, since a significant part of the sunlight will be reflected from the collector glass and, therefore, will not reach the absorber.

How to choose a solar collector of the required power

If you want the heating system of your home to cope with the task of maintaining a comfortable temperature in the rooms, and hot and not lukewarm water flows from the taps, and at the same time you plan to use a solar collector as a heat generator, you need to calculate the required power of the equipment in advance.

In this case, it will be necessary to take into account a fairly large number of parameters, including the purpose of the collector (DHW, heating or a combination of both), the heat needs of the facility (the total area of heated premises or the average daily consumption of hot water), the climatic features of the region, and the features of the collector installation.

In principle, making such calculations is not so difficult. The performance of each model is known, which means you can easily estimate the number of collectors required to provide heat to your home. Companies involved in the production of solar collectors have information (and can provide it to the consumer) about changes in the power of the equipment depending on the geographic latitude of the area, the angle of inclination of the “mirrors,” the deviation of their orientation from the south direction, etc., which allows making the necessary adjustments when calculating collector performance.

When selecting the required collector power, it is very important to achieve a balance between the shortage and excess of generated heat. Experts recommend focusing on the maximum possible capacity of the collector, i.e. using the indicator for the most productive summer season in the calculations. This goes against the desire of the average user to take equipment with a reserve (i.e., calculate according to the power of the coldest month) so that there is enough heat from the collector even on less sunny autumn and winter days.

However, if you follow the path of choosing a solar collector of increased power, then at the peak of its performance, i.e. in warm sunny weather, you will face a serious problem: more heat will be produced than consumed, and this threatens overheating of the circuit and other unpleasant consequences . There are two options for solving this problem: either install a low-power solar collector and connect backup heat sources in parallel in winter, or purchase a model with a large power reserve and provide ways to discharge excess heat in the spring-summer season.

We increase the efficiency of the solar collector in cold weather.

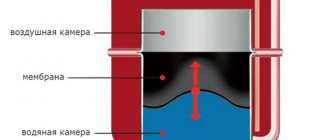

Using a simple system for heating and hot water supply in winter is possible if antifreeze is used as a coolant and the storage tank is supplemented with an auxiliary heating element (for example, a heating element). When using antifreeze, the design of the tank changes - a coil (most often copper) is installed in it, thanks to which the coolant circulates in the tank. The good conductivity of the metal allows the heat of the antifreeze to be transferred to the water in the tank.

It is recommended to include a circulation pump and an expansion tank in the design. Sometimes, to separate the water used for heating (technical) and personal use (drinking), an internal reservoir is installed in the tank. It is located at the top of the tank (where hot water collects) and is connected to the water supply system (hot water is drawn in using a valve, and the tank is filled with cold liquid). In this case, the heating system is connected to the main tank.

Depending on the external temperature, collector area, geographic location, time of year, type of collector, and many other factors, the efficiency of the system (i.e., the stability of the generated energy level) also fluctuates.

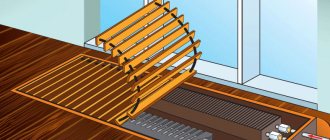

In addition to devices more familiar to users, there is also an air solar collector, the operating diagram of which assumes that the coolant in the system is air, which is heated from the absorber and supplied to the heated room using a fan.

Stagnation of the system

Let's talk a little more about the problems associated with an excess of generated heat. So, let’s assume that you have installed a sufficiently powerful solar collector that can completely provide heat to the heating system of your home. But summer came, and the need for heating disappeared. If you can turn off the power supply to an electric boiler, or turn off the fuel supply to a gas boiler, then we have no control over the sun - we cannot “turn off” it when it gets too hot.

System stagnation is one of the main potential problems of solar collectors. If not enough heat is taken from the collector circuit, the coolant overheats. At a certain moment, the latter may boil, which will lead to the cessation of its circulation along the circuit. When the coolant cools down and condenses, the system will resume operation. However, not all types of coolants easily tolerate the transition from liquid to gaseous state and back. Some, as a result of overheating, acquire a jelly-like consistency, which makes further operation of the circuit impossible.

Only stable removal of the heat produced by the collector will help to avoid stagnation. If the calculation of equipment power is done correctly, the likelihood of problems occurring is almost zero.

However, even in this case, the occurrence of force majeure cannot be ruled out, so methods of protection against overheating should be provided in advance:

1. Installation of a reserve tank for storing hot water. If the water in the main tank of the hot water supply system has reached the set maximum, and the solar collector continues to supply heat, a switch will occur automatically and the water will begin to heat up in the reserve tank. The created supply of warm water can be used for domestic needs later, in cloudy weather.

2. Heating the water in the pool. Owners of houses with a swimming pool (whether indoor or outdoor) have an excellent opportunity to remove excess heat energy. The volume of the pool is incomparably larger than the volume of any household storage tank, which means that the water in it will not heat up so much that it will no longer be able to absorb heat.

3. Drain hot water. If it is not possible to use excess heat profitably, you can simply drain heated water from the hot water storage tank into the sewer in small portions. The cold water entering the container will lower the temperature of the entire volume, which will continue to remove heat from the circuit.

4. External heat exchanger with fan. If the solar collector has a high productivity, the excess heat can also be very large. In this case, the system is equipped with an additional circuit filled with refrigerant. This additional circuit is connected to the system via a heat exchanger equipped with a fan and mounted outside the building. If there is a risk of overheating, excess heat enters the additional circuit and is “thrown out” into the air through the heat exchanger.

5. Discharge of heat into the ground. If, in addition to the solar collector, the house has a ground source heat pump, excess heat can be directed to the well. In this case, you solve two problems at once: on the one hand, you protect the collector circuit from overheating, on the other, you restore the heat reserve in the ground that has been depleted over the winter.

6. Isolation of the solar collector from direct sunlight. This method is one of the simplest from a technical point of view. Of course, you shouldn’t climb onto the roof and curtain the collector manually - it’s difficult and unsafe. It is much more rational to install a remotely controlled barrier, like a roller shutter. You can even connect the damper control unit to the controller - if the temperature in the circuit rises dangerously, the manifold will close automatically.

7. Drain the coolant. This method can be considered radical, but at the same time it is quite simple. If there is a risk of overheating, the coolant is drained through a pump into a special container integrated into the system circuit. When conditions become favorable again, the pump will return the coolant to the circuit and the operation of the collector will be restored.

Other system components

It is not enough to simply collect the heat emitted by the sun. It still needs to be transported, stored, transferred to consumers, all these processes need to be controlled, etc. This means that in addition to the collectors located on the roof, the system contains many other components, perhaps less noticeable, but no less important. Let's focus your attention on just a few of them.

Coolant

The coolant function in the collector circuit can be performed by either water or non-freezing liquid.

Water has a number of disadvantages that impose certain restrictions on its use as a coolant in solar collectors:

- Firstly, at negative temperatures it freezes. To prevent the frozen coolant from breaking the pipes of the circuit, it will have to be drained as cold weather approaches, which means that in winter you will not receive even small amounts of thermal energy from the collector.

- Secondly, the boiling point of water that is not too high can cause frequent stagnation in the summer.

Non-freezing liquid, unlike water, has a significantly lower freezing point and an incomparably higher boiling point, which makes it more convenient to use as a coolant. However, at high temperatures, the anti-freeze may undergo irreversible changes, so it should be protected from excessive overheating.

Pump adapted for solar systems

To ensure forced circulation of the coolant along the collector circuit, a pump adapted for solar systems is required.

Heat exchanger for hot water supply

Heat is transferred from the solar collector circuit to the water used in the hot water supply or to the coolant of the heating system via a heat exchanger. As a rule, a large volume tank with a built-in heat exchanger is used to accumulate hot water. It is rational to use tanks with two or more heat exchangers: this will allow you to take heat not only from the solar collector, but also from other sources (gas or electric boiler, heat pump, etc.).