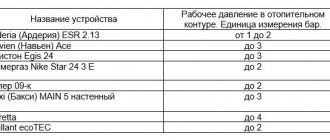

One of the most popular models in the Baxi line is the Baxi Eco Four 24 gas boiler. The equipment can be with a closed or open combustion chamber. The power of the unit is 24 kW. The name indicates the letter “F” if the gas boiler has a closed combustion chamber and forced smoke removal. In apartments, turbocharged boilers from Baxi are most often used. Let's look at the design of the expansion tank, breakdowns, pressure drop and how to fill the Baxi expansion tank with air.

Coolant in the heating system

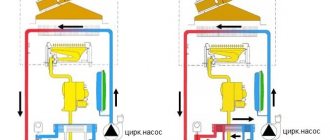

When installing a heating system, different options can be used. The most optimal is a closed heating system, in which the movement of the coolant is carried out using a circulation pump. In the primary heat exchanger, antifreeze is heated with a gas burner, and with the help of a pump it is pumped through a radiator system, thus transferring heat into the room.

The heating system must be filled with water for normal circulation. When heated, the liquid begins to expand, so the increase in volume must be compensated. For this reason, expansion tanks are installed in the heating system.

In this scheme, the gas boiler is only a heater. In Baxi Eco Four, the circulation pump and expansion tank are already built-in, so such equipment can be easily installed in small apartments.

Filling closed heating with a pump

If the circuit is not connected to the water supply, the only option left to fill the heating system is a pressure test pump. This is a small rectangular metal reservoir into which liquid is collected. From the reservoir, the coolant is supplied to the pipes thanks to a pump-action hand pump on which a pressure gauge is installed.

Hand pump for pressure testing.

There is nothing complicated about how to fill a closed heating system. Work algorithm:

- connect the hose from the pump to the circuit;

- pour coolant into the pump reservoir;

- manually pump fluid into the system.

If there is no pipe for draining water from the circuit, then you can connect the pump hose to one of the ends of the battery. To do this, you need to unscrew the plug and put the adapter in its place. Before starting work, be sure to open all air vents so that air can leave the circuit.

There is no point in gluing roll insulation under the wallpaper. A thin layer of thermal insulation will not give the desired result.

When working with thermal insulation in sheets and rolls, you need to use an insulation dowel or nail to fix the material.

Watch the pressure gauge reading carefully. Using such a pump, pressure testing of the heating system is carried out. They can pump up pressure to 10 atmospheres (if you have enough strength). When filling the system, such pressure is not necessary, otherwise the boiler will break.

Baxi expansion tank device

In the Baxi Eco Four 24 gas boiler, the expansion tank is located on the back wall of the equipment and is a red round container. The built-in expansion tank has a volume of 6 liters and is divided into 2 parts using a membrane. 1 part is inflated with air, and the second is connected to the heating system. When the system heats up, the volume of liquid increases and the resistance of the membrane is overcome, then the free volume of the tank is filled. After cooling, the membrane returns to the reverse position and pushes the liquid into the heating system. Consequently, the pressure during operation remains unchanged.

Causes of pressure drop and solutions

A drop in pressure can adversely affect the normal operation of the heating system. In this situation, water stops flowing into the unit and it automatically turns off. Therefore, it is important to provide for timely maintenance, inspection and repair.

The reasons for a drop in pressure can be different, let's look at the most common ones.

The pressure in the system drops when hot water is turned on

This problem is quite common. This phenomenon is explained by the special design of boiler units.

According to experts, in reality it is just a pressure gauge that reflects an incorrect value. The pressure drop may be caused by air leaks into the circuit or improper operation of the three-way valve.

For information! If, when you open a hot water tap, normal operation of the system is not restored over time, it means that the pressure is decreasing, and the problem really exists.

Pressure drops due to leaks

To eliminate this type of problem, the owner needs to diagnose and inspect the entire heating system, since liquid can escape through any component.

The cause of the leak may be a loose connection, worn-out heat exchangers, cracks in pipes and batteries. Most often, the level of tightness is checked when the circuit is put into operation, however, the tightness can be compromised during operation itself.

Nodes that need to be inspected and checked first:

- connecting fittings;

- radiators;

- expansion tanks;

- double-circuit boilers.

Detected problems must be corrected, after which the system will be recharged with liquid until the normal pressure level is restored.

Air jams

The formation of cracks and depressurization of the heat supply system leads not only to leaks, but also to the opposite effect - the suction of air masses into the circuit. The result of this is the formation of air bubbles.

Bubbles also form when the circuit is not filled correctly, which is why air pockets appear in it, causing a significant drop in pressure.

Recommendation! This problem is solved by simply de-aerating the system, thanks to the installation of bleeders.

Problem with expansion tank

There are cases of problems with expansion tanks. A gap forms here or the nipple may leak air. The inside of the tank consists of two compartments separated by a membrane. One compartment contains air, and the other is filled with coolant. When the liquid working medium is heated, it expands and presses on the membrane with greater force. The membrane, in turn, affects the compression of the gas mixture.

When the equipment operates for a long time, the nipple wears out and begins to leak air, which leads to a decrease in pressure.

The only solution to this problem is to completely replace the tank, however, before doing this, you should make sure that the problem lies precisely in this, and not in leaking pipes, radiators and airing of the system.

Measuring equipment malfunction

Sometimes diagnosing a system for the integrity of its components may not yield results. If you have not been able to find a visible cause, then you should think about checking the proper operation of the boiler automation and control equipment. This equipment may break down and give incorrect readings.

It is quite difficult to determine this type of malfunction on your own, so it is better to seek help from specialists. The problem is solved by replacing control and measuring instruments.

Cracks in the heat exchanger in the boiler

Over time, microcracks can form on the walls of heat exchangers, allowing water to pass through from the heating system. Since the water in the boiler evaporates quickly, it is by no means easy to identify this breakdown yourself in the same way as in the previous situation. In addition, cracks can occur during washing, which is carried out for prevention or due to manufacturing defects. This problem is eliminated by sealing the detected area with a crack.

The coolant drain valve is not closed tightly

Sometimes the reason may lie in a completely simple issue, such as a faucet that is not clamped tightly enough, due to which the pressure level in the unit decreases. The problem can be fixed easily and quickly by tightening the tap.

What is the normal pressure in the expansion tank of a Baxi double-circuit boiler?

The instructions indicate the approximate pressure in the expansion tank - 0.5 bar. But this value is not entirely correct, since the pressure in the circuit should be 20% higher at room temperature of the coolant.

Many systems recommend a filling pressure of 1.2 to 1.5 bar. Thus, the required pressure in the air cavity of the tank should be from 0.8 to 1 bar. Qualified specialists usually recommend setting the pressure in the expansion tank to 1 bar.

Why an expansion tank in a Baxi wall-mounted boiler

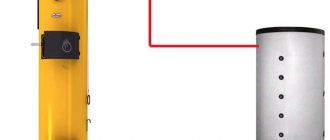

The Baxi Eco Four 24 gas boiler has a 6-liter expansion tank. Based on the total volume of the system, you can find out whether an expansion tank is needed.

It is not difficult to make the calculation, since the filling volume of the radiators and boiler is in the characteristics. If the diameter and total length are known, then the filling volume of the pipelines can be calculated.

If water is heated to 80 degrees, the volume will increase by about 5%. Thus, it is necessary to have an expansion tank with a volume of 8% of the total volume of the system when filled with water, and also 12% when using antifreeze as a heat carrier. The built-in expansion tank will be sufficient for a heating system with a volume of no more than 75 liters when using water, and up to 50 liters when using antifreeze.

These values are approximate. When choosing the volume of the expansion tank, you should make calculations for a specific system or use the manufacturer’s advice.

In many cases, the built-in tank in Baxi gas boilers is sufficient. If necessary, an additional tank is selected when designing the system.

How to fill the expansion tank of a Baxi gas boiler with air

Only an empty boiler can be filled with air into the expansion tank.

To do this you need to do the following:

- Close the heating system taps.

- Drain the water through the drain tap.

- Inflate the tank to the required pressure.

- Close the drain valve.

- Feed the heating system through the feed tap.

- Open the circuit taps.

In order to carry out maintenance, it is necessary to install a valve on the air cavity of the expansion tank. The valve is a regular car nipple, so you can pump the tank of a Baxi gas boiler using a tire pump (electric or manual). The electric pump is convenient because it has a pressure gauge to control the pressure. You can pump up the system with a hand pump and check the pressure with a car pressure gauge. If the need arises, you can bleed off the excess.

Causes of pressure drop and solutions

A drop in pressure can adversely affect the normal operation of the heating system. In this situation, water stops flowing into the unit and it automatically turns off. Therefore, it is important to provide for timely maintenance, inspection and repair.

The reasons for a drop in pressure can be different, let's look at the most common ones.

The pressure in the system drops when hot water is turned on

This problem is quite common. This phenomenon is explained by the special design of boiler units.

According to experts, in reality it is just a pressure gauge that reflects an incorrect value. The pressure drop may be caused by air leaks into the circuit or improper operation of the three-way valve.

For information! If, when you open a hot water tap, normal operation of the system is not restored over time, it means that the pressure is decreasing, and the problem really exists.

Pressure drops due to leaks

To eliminate this type of problem, the owner needs to diagnose and inspect the entire heating system, since liquid can escape through any component.

The cause of the leak may be a loose connection, worn-out heat exchangers, cracks in pipes and batteries. Most often, the level of tightness is checked when the circuit is put into operation, however, the tightness can be compromised during operation itself.

Nodes that need to be inspected and checked first:

- connecting fittings;

- radiators;

- expansion tanks;

- double-circuit boilers.

Detected problems must be corrected, after which the system will be recharged with liquid until the normal pressure level is restored.

Air jams

The formation of cracks and depressurization of the heat supply system leads not only to leaks, but also to the opposite effect - the suction of air masses into the circuit. The result of this is the formation of air bubbles.

Bubbles also form when the circuit is not filled correctly, which is why air pockets appear in it, causing a significant drop in pressure.

Recommendation! This problem is solved by simply de-aerating the system, thanks to the installation of bleeders.

Problem with expansion tank

There are cases of problems with expansion tanks. A gap forms here or the nipple may leak air. The inside of the tank consists of two compartments separated by a membrane. One compartment contains air, and the other is filled with coolant. When the liquid working medium is heated, it expands and presses on the membrane with greater force. The membrane, in turn, affects the compression of the gas mixture.

When the equipment operates for a long time, the nipple wears out and begins to leak air, which leads to a decrease in pressure.

The only solution to this problem is to completely replace the tank, however, before doing this, you should make sure that the problem lies precisely in this, and not in leaking pipes, radiators and airing of the system.

Measuring equipment malfunction

Sometimes diagnosing a system for the integrity of its components may not yield results. If you have not been able to find a visible cause, then you should think about checking the proper operation of the boiler automation and control equipment. This equipment may break down and give incorrect readings.

It is quite difficult to determine this type of malfunction on your own, so it is better to seek help from specialists. The problem is solved by replacing control and measuring instruments.

Cracks in the heat exchanger in the boiler

Over time, microcracks can form on the walls of heat exchangers, allowing water to pass through from the heating system. Since the water in the boiler evaporates quickly, it is by no means easy to identify this breakdown yourself in the same way as in the previous situation. In addition, cracks can occur during washing, which is carried out for prevention or due to manufacturing defects. This problem is eliminated by sealing the detected area with a crack.

The coolant drain valve is not closed tightly

Sometimes the reason may lie in a completely simple issue, such as a faucet that is not clamped tightly enough, due to which the pressure level in the unit decreases. The problem can be fixed easily and quickly by tightening the tap.

Breakdowns of expansion tanks

Gas boiler maintenance must be carried out annually. Checking the pressure is included in the list of works. If you carry out all checks in a timely manner, then no problems should arise. But if maintenance is not carried out, some problems may appear:

- The expansion tank has not been serviced and there is no pressure in it; the circuit pressure is at its maximum permissible value. After the system cools down, the volume of liquid begins to decrease, and the decrease in pressure is not compensated for by anything, therefore, the boiler stops working. This problem often occurs due to a long operation of a gas boiler in DHW mode or during a power outage.

- The pressure in the air chamber decreases, and with each refill of the gas boiler, the tank fills with water and eventually stops working. In addition, the membrane is pressed against the wall of the air part of the tank and can be damaged by the valve spool. In such a situation, you will have to replace the expansion tank.

- For no particular reason, some owners of gas boilers top up. For example, when using hot water, the pressure on the pressure gauge decreases and the boiler stops working by mistake. Since thermal expansion is not compensated, the next time the coolant is heated, the excess pressure is released using a safety valve. Some people withdraw the reset and do not pay attention to this situation. But frequent replenishment with untreated water can lead to malfunction of the heat exchanger.

Symptoms of broken expansion tanks

When the heating circuit indicators are constantly changing, consumers are wondering what pressure should be in the expansion tank of the Baxi boiler? Oscillations can occur for various reasons, including when the membrane container fails:

- When operating the tank, it is necessary to constantly monitor the condition of the nipple. A worn rubber band on the valve can cause air or nitrogen from the gas chamber to gradually escape into the atmosphere. If a worn valve is not replaced in time, liquid will constantly fill the tank, compressing the membrane. Ultimately, this will lead to the polymer shell being torn on the internal protrusions of the tank itself.

Nipple on the tank body https://eco-kotly.ru

- To operate the container in standard mode, you need to know what pressure should be in the Baksi gas boiler, and in no case exceed this figure. If you do not follow this advice, then, when the coolant cools, the membrane bulb will begin to stretch towards the empty wet chamber. This will inevitably lead to its plastic deformation, and, in the most unfavorable conditions, to rupture. This situation is quite real, for example, with a volatile system with forced circulation, if for some reason the electricity in the house is turned off.

The principle of operation of the membrane https://odstroy.ru

- When a Baxi double-circuit appliance is used in a house, with increased consumption during peak hours, the owner can completely turn off the heating circuit for this time, using all the energy of the gas unit to prepare water for DHW needs. In such cases, the boiler quickly empties, the protection against dry operation is activated, and it turns off. This situation requires you to constantly recharge the circuit from the water supply. If this procedure is done several times every day. The membrane of the expansion tank periodically stretches or contracts, which leads to fatigue deformations and cracks on its surface.

If any of the above situations occur, the pressure in the system constantly changes, and the membrane tank ceases to cope with its main function. If the membrane is damaged or physically worn out, this part cannot be repaired and the owner has to replace it. If a breakdown damages the valve, nipple and threaded connection, then an advisable solution would be to purchase a new tank and install it in the system.

Membrane damage https://rtpregion.ru

In the following video you can see the main reasons for the voltage drop on the membranes of expansion tanks:

Pressure drop in a Baxi gas boiler when hot water is turned on

Often the pressure drops when hot water is turned on in a Baxi gas boiler. This problem occurs due to low pressure in the expansion tank. This is due to the fact that when the equipment switches to water heating mode, the circulation pump begins pumping liquid in a small circle through the secondary heat exchanger. At this time, the heating circuit stops heating and the coolant cools down, the volume decreases and, in the absence of compensating pressure in the tank, the pressure of the heating system drops and error e10 appears on the boiler.

But with such a problem, the heat exchanger may be broken. In addition, water may enter the DHW system from the heating circuit. In order to perform the test, you need to stop the supply of cold water to the gas boiler and open the drain tap. If water comes out of the tap, then this is the coolant from the heating circuit and the heat exchanger must be replaced.

You should remember about timely maintenance of the gas boiler, as it helps to avoid serious breakdowns, therefore increasing the service life of the entire heating system.

How to increase the pressure in the boiler

If the pressure drops due to the expansion tank, it means that its volume is incorrectly calculated or the internal membrane is damaged. The situation can be corrected by more accurately calculating the required volume or by replacing the tank.

If the pressure in the heating system drops immediately after it is first started, then this is normal. The newly filled circuit, if it was filled with ordinary tap water, is full of air. As soon as it is converted into bubbles and removed from the pipes, the circuit parameters are normalized. You can also try removing the bubbles manually by using a manual air release.

The worst thing is if the pressure in the system laid inside the walls and floors has dropped - the pipes are often masked and completely recessed in building structures. If something happens to them, you will have to suffer thoroughly to localize the problem. The situation can be prevented by more careful selection of materials for the construction of the heating circuit.

Before increasing the pressure, it is necessary to check the tightness of the system. To do this you need to inspect:

- All heating devices - often leaks form where they connect to the pipes. Leaks between individual sections are also possible;

- Pipes - microcracks often lead to leakage of coolant, due to which the pressure gradually drops;

- Fittings are another common place for coolant leaks to occur;

- Boilers - double-circuit models have a complex internal structure; it is necessary to inspect the circulation pump, three-way valve and heat exchanger.