To heat a private home, it is customary to create your own, autonomous heating system.

Network resources are expensive and not available everywhere, but a private system allows you to independently regulate the heating mode and make decisions about the beginning and end of the heating season.

Heating systems powered by gas boilers are considered the most efficient.

They are not demanding, do not require constant user attention, and can provide a home not only with thermal energy, but also with hot water.

Let's consider a series of wall-mounted gas boilers produced by the world famous company Bosch.

Gas boiler Bosch 6000 24 kW

The Bosch 6000 series is the first series of boilers manufactured in Russia for the domestic user. Production was opened in the Saratov region, in the city of Engels.

The products are adapted to local technological and climatic conditions; the location of the plant in the country made it possible to significantly reduce the price and speed up the delivery of equipment to any point.

Gas boilers Bosch 6000 24 kW are wall-mounted convection units. The assembly is made from imported parts, the design is adapted to low gas pressure and low water quality.

Separate heat exchangers are used (copper primary and steel secondary plate type). The units are fully functional, but belong to the budget group of equipment available to a wide range of buyers.

Review of the wall-mounted double-circuit boiler Bosch Gaz 6000 W WBN 6000-24 C

The wall-mounted double-circuit boiler Bosch Gaz 6000 W WBN 6000-24 C is designed not only for heating rooms, but also for quickly preparing hot water. The thermal power of the model is 24 kW, which corresponds to a maximum heated area of up to 240 sq. m. However, taking into account the required reserve, it may be less. Other equipment characteristics:

- Combustion chamber type – closed;

- The installed heat exchanger is plate;

- Number of circuits – 2 (heating and hot water supply);

- DHW circuit capacity – 11.4 l/min;

- Chimney diameter – 60/100 mm.

Having received the Bosch Gaz 6000 W WBN 6000-24 C heating boiler, you should familiarize yourself with the information printed on the box. Here we will see a tag that says that it is made in Russia and is powered by natural gas with a nominal pressure of 13 mbar. The tag also indicates the model name and thermal power of the equipment. Currently, the equipment is produced at a plant in Engels, Saratov region. The boiler comes in very good packaging, which prevents possible damage to the equipment.

Today, according to information from the BOSCH company, a huge amount of equipment imported illegally from the territory of Ukraine has been recorded on the market of the Russian Federation. The cost of such equipment is comparatively lower (from 24 to 26 thousand rubles) due to the complete lack of warranty from the manufacturer. Externally, this boiler is no different, but the product serial number is not found in the BOSCH database

Having opened the box with the boiler, we will find a set of documentation for installation and connection of equipment. Everything is described in as much detail and clearly as possible, which will help to avoid confusion and errors during installation of the boiler. In addition to the technical data sheet and installation and maintenance instructions, inside there is an instruction manual for consumers. In order to protect the equipment from damage during transportation, it is encased in foam plastic that surrounds the device on all sides at once.

The delivery set includes a template to facilitate installation of the boiler on the wall.

Operating instructions for consumers and a Technical Data Sheet and installation and maintenance instructions for a specialist in Russian; previously there were instructions in Ukrainian.

A set of gaskets for the heating and hot water circuit, a set of dowel brackets.

Instructions for starting the pump during initial installation.

The Bosch Gaz 6000 W WBN 6000-24 C boiler is designed for wall mounting and connection to a coaxial chimney. It features flame presence control, automatic burner ignition, electronic protection and an adjustable fan. Also inside we will find a three-stage pump and a built-in expansion tank.

The fan, as for many other boilers, is manufactured in Poland, at the FIME plant

Thus, the boiler is delivered in a state completely ready for installation.

The Bosch Gaz 6000 W WBN 6000-24 C boiler itself is hidden under the foam, the body of which has a regular rectangular shape. On its front panel there is a control panel with a liquid crystal display and buttons, a pressure gauge, the Bosch logo and brief graphic instructions for setting the temperature in the heating and hot water circuits.

In the lower left corner there is another tag with the name of the model and its serial number - this makes it easier to find it during warranty service or repair work.

In order to protect the control panel from accidental scratches and roughness, it is covered with a blue technological film - they are removed after installation.

The control panel itself is removable, behind it there is access to the internal equipment of the double-circuit boiler.

Having laid down the boiler, we will find pipes for connecting elements of the water supply and heating system, a make-up tap and a discharge pipe. Their purpose is indicated in the documentation supplied with the kit.

To access the internal equipment, lower the cover with the control panel down and tilt it towards you. The lid will not come off and will not hang - it is held in place by plastic clamps that look like clamps.

If necessary, they can be removed by unscrewing the retaining screws. In order to gain access to the combustion chamber, burner, blower fan and various sensors, you need to completely remove the metal front panel - to do this, unscrew the next two screws and move the cover to the side.

Now all the internal equipment of the boiler is ready for inspection and adjustment (or for maintenance).

The control module of the Bosch Gaz 6000 W WBN 6000-24 C boiler is located on a hinged lid and is covered with a plastic casing with warning signs. Multi-colored wires and cables go inside. You can familiarize yourself with their purpose using the instructions provided. The plastic cover is held in place by simple latches and can be removed without much difficulty. Inside we see a control module board with fuses. By the way, if the fuses become unusable, they can be quickly replaced - on the inside of the cover we will see two holders that hold spare fuses.

To connect diagnostic equipment, an external temperature sensor and a regulator, there is no need to remove the cover from the control module - just remove the small plastic cover behind which the necessary connectors are hidden.

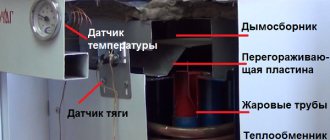

The wall-mounted double-circuit boiler Bosch Gaz 6000 W WBN 6000-24 C is easy to repair, and all its modules are located so as to provide easy access to them. For example, by removing the plastic cover with the control panel we will find a circulation pump with a speed switch, gas fittings, a plate heat exchanger for the DHW circuit, numerous sensors and connecting wires. Having removed the front metal one, we will find the combustion chamber, pressure switch, and exhaust pipe. For more convenient access to the internal equipment, we can remove the side covers.

Having unscrewed the front cover of the combustion chamber, we will find a powerful primary copper heat exchanger and a steel burner with an ignition system. The combustion chamber itself is closed on all sides with asbestos sheets. The thickness of the heat exchanger is 37 mm, width – 152 mm, length – 267 mm. Behind the combustion chamber there is a flat expansion tank, completely invisible at first glance. As for the heat exchanger of the DHW circuit, it is located in the lower part of the boiler, behind the gas fittings. Next to it you can see the hot water temperature sensor, filter and flow meter. To retain heat, we see thermal insulation on the housing covers.

Before carrying out installation work, it is recommended to read the relevant instructions. It is divided into several sections:

- General information about the boiler;

- Flue gas removal;

- Boiler installation;

- Electrical connections;

- Commissioning;

- Carrying out thermal disinfection.

It also describes the process of reconfiguring the Bosch Gaz 6000 W WBN 6000-24 C boiler to another type of gas - it can work not only from the gas main, but also from liquefied gas cylinders. No less important sections of the instructions are “Check/Maintenance” and “Failures”. With their help, you can understand the process of equipment maintenance and how to independently eliminate many malfunctions.

Wall-mounted heating boilers Bosch Gaz 6000 W WBN 6000-24 C are adapted to Russian operating conditions and are extremely simple. Control is carried out using several buttons, and in order to understand the operating modes, there is an informative liquid crystal display. It will also help you obtain diagnostic information - if any failures occur, an error code appears on the screen. All types of faults and their codes are described in the documentation for the boiler.

Bosch Gaz 6000 W WBN 6000-24 C boilers are economical and can operate at reduced gas pressure. The pressure spread can vary from 9 to 17 mbar. The supply voltage range is from 165 to 240 Volts, which is quite enough for domestic power grids. Despite their good equipment, the boilers are small in size, as can be seen in the photographs presented in the review. Consumers will also be pleased with the low noise level created by the equipment during operation.

This view provides overview information on all boilers of the Bosch WBN 6000 model range

Setting the parameters of the 1st service level:

Setting parameters of the 2nd and 3rd service levels:

Possible malfunctions of boilers of the Bosch WBN 6000-24C series

What models exist

The Bosch 6000 24 kW series consists of the following models:

- Bosch WBN 6000-24H . Single-circuit boilers designed only to power the heating system of the room.

- Bosch WBN 6000-24 C. Double-circuit units capable of heating the coolant for the heating system and at the same time preparing hot water for domestic hot water.

In addition, there are two options for completing the combustion chamber:

- Atmospheric. Air flow and smoke removal are carried out naturally, under the influence of stove-type draft.

- Turbocharged . The burner has a closed design; air supply for normal combustion and smoke exhaust are carried out under the action of a turbocharging fan.

Natural cravings are unstable and unstable, depending on many external factors. If the chimney is located on the windward side of the house, any gust can extinguish the flame, causing immediate blockage of the boiler.

If no one is in the house, the system may become defrosted. For this reason, turbocharged boilers, which are independent of external factors and safer to operate, are in the highest demand.

Advantages and disadvantages

This model from this manufacturer has its advantages and disadvantages. The positive points include:

- High quality of materials used to create the device. Even despite the fact that not all components are produced at the company’s factories (for example, the pump is from the German manufacturer Wilo), the design components last a long time and reliably.

- Low noise level during heating system operation.

- Low cost in comparison with other models with similar characteristics.

- Their manufacturer is a well-known brand from Europe, which has proven itself in many other areas.

The disadvantages are:

- The company is not a full-fledged manufacturer of its boilers. The design uses a large number of parts from third-party brands.

- Too few service centers. If there is a malfunction, you will most likely have to fix it yourself or contact specialists from some private third-party companies.

- A small number of models, which makes it impossible to target large masses of people.

What functions do they have?

The list of available functions includes:

- Heating the coolant.

- Heating of hot water for domestic needs (double-circuit models).

- Self-diagnosis of problems.

- Monitoring water pressure, gas pressure, temperature of all systems (including flue gases).

- Availability of winter and summer operating modes.

- Possibility of connection to your own or common chimney of the house.

IMPORTANT!

All single-circuit models are equipped with appropriate adapters for connecting external indirect heating boilers, allowing the room to be supplied with large volumes of hot water.

Specifications

Let's look at the technical characteristics of boilers:

| Options | Values |

| Boiler type | Gas heating |

| Heat transfer method | Convection |

| Fuel type | Natural (mainline) gas, optionally liquefied gas |

| Combustion chamber type | Open or closed |

| Efficiency | 93,2 %, |

| Power | 24 kW |

| Installation method | Wall |

| Gas consumption | 2.8 m3/h |

| Heating circuit temperature | 40-82° |

| DHW temperature | 35-60° |

| Coolant pressure (maximum) | 3 Bar |

| Power supply | 220 V 50 Hz |

Advantages and disadvantages

The advantages of Bosch 6000 series boilers with a power of 24 kW include:

- Reliability, high efficiency and stable operation.

- Ability to efficiently heat coolant and hot water.

- Low noise level.

- Adaptation to Russian technological conditions.

- Economical gas consumption.

- Availability of a self-diagnosis system that detects malfunctions and critical errors of unit components.

The disadvantages of the units are:

- Energy dependence. The boiler needs a properly connected, stabilized and reliably grounded power supply, otherwise it will either not start at all or will constantly show an error.

- Demanding on water quality. For hard and medium water, it is recommended to use filters.

- Weak service organization.

- High cost of spare parts.

The disadvantages of Bosch 6000 boilers are common to all gas boilers of European design and are, rather, a feature of these units.

Model range, recommendations for selecting boilers

On our website, from a variety of gas double-circuit boilers mounted on the wall, a series of wall-mounted Bosch units is presented. The series starts with the lowest power device Bosch GAZ 6000 W WBN6000-12C RN S5700. Next come models with increasing power - 18 - 35 kW.

The choice of heating unit is made according to different criteria:

1. By the number of water heating circuits. Double-circuit systems heat the room with one circuit and provide hot water with the second.

2. By thermal power. In the model designation it is indicated before the letter “C” and has the form of a two-digit number. For example, the Bosch GAZ 6000 W WBN6000-18C RN S5700 wall-mounted boiler has a power of 18 kW, and the Bosch GAZ 6000 W WBN6000-24C RN S5700 has a power of 24 kW.

When selecting, you need to multiply the power in kW by 10. As a result, you will get the approximate total area of the room heated by a unit of this power.

But if your house has modern energy-efficient windows, double external doors with a thermal break, the external walls are thermally insulated, the interfloor floors are insulated, and supply and exhaust ventilation with recovery, then you can choose a boiler with a power that is one step lower.

For example, in a house with such ideal conditions, the Bosch GAZ 6000 W WBN6000-28C RN S5700 device can heat a room of 300 - 350 square meters. m. And in a house that does not have such conditions, you need to use the Bosch GAZ 6000 W WBN6000-35C RN S5700 unit.

For which rooms is it best suited?

The boiler power is 24 kW, which is optimal for rooms up to 240 m2.

These are private houses, cottages, public or commercial premises, workshops, etc. Not recommended for use in industrial premises, especially models with an atmospheric burner .

Constant drafts will extinguish the flame, causing the boiler to block and no heating.

User manual

Operation of Bosch 6000 24 kW gas wall-mounted boilers is simple and does not require any special actions from the user. Adjustment of the operating mode, heating circuit temperature or hot water temperature is simple and is carried out in operating mode.

Every year you should invite a specialist to carry out maintenance and cleaning of the unit. All problems or unusual behavior that arise are reasons to immediately call a technician and repair the boiler.

The user can only drain and refill the system independently after the summer period, which is done using a make-up tap or drain tap.

All attempts to independently interfere with the mechanics or electronics of boilers can cause destruction or failure of important components of the unit, which will require expensive repairs.

Download instructions

Download instructions for the gas boiler Bosch GAZ 6000 WBN 24 kW.

Basic boiler malfunctions

Let's look at the most common errors of Bosch 6000 24 kV boilers:

| Code | Decoding | Solution |

| A7 | Malfunction of the DHW thermistor | Check connection, replace sensor |

| A8 | The connection between the control board and the bus is interrupted | Check the condition of the contacts, clean and connect |

| A9 | The DHW thermistor is not installed correctly | Correct the position of the sensor, secure it more securely |

| EA | No flame | There is no gas in the line, the gas valve is closed, the ignition system has failed, the ionization electrode is not grounded |

| E2 | Failure of the direct line thermistor of the heating circuit | Check contacts, replace sensor |

| E9 | Triggering of the heating circuit flow limiter | Check for air pockets, pump operation, fuse |

| C6 | Differential pressure switch failure | Check the connection, remove condensate from the pipes, clean the smoke exhaust system |

| C7 | Fan doesn't work | Check the connection, lubricate the shaft, replace the device |

| F7 | The boiler is turned off, but the electronics see the flame | Clean the contacts, check the control board for the presence of condensate drops, ground the boiler body |

Boiler errors

A malfunction can occur at the most inopportune moment. You need to have at least a minimal understanding of errors and troubleshooting methods.

A7

The hot water t0 sensor has failed. It is necessary to identify any defects that have arisen. Check wiring for short circuit. Replace if necessary.

Ad

Problems with the t0 boiler sensor. It is necessary to check that the working wires are connected correctly.

C1

The fan is not running at full power. Find out what voltage is in the network. Pay attention to the exhaust of flue gases. If necessary, carry out unscheduled cleaning and/or repairs.

C4

The differential pressure switch does not open when the fan is not running. It will need to be checked.

C6

The differential pressure switch is not closed. The fan, wiring and plug should be checked. Perhaps this is where the problem lies. If necessary, replace the failed element. In addition, you should pay attention to the pipes responsible for removing exhaust gases and check the differential pressure switch.

C7

The fan has failed. Check connections and plug. Replace if necessary.

C.E.

When filling the heating system, the pressure is very low. Everything is simple here. You need to add water.

d7

Problems with gas fittings. The wiring should be checked. The gas fittings may need to be replaced.

E2

The t0 sensor has broken on the supply line. The sensor itself may be defective or a short circuit has occurred. Replace the problematic part.

E9

The heat exchanger limiter t0 is triggered. You should pay attention to the limiter and identify defects.

Maybe the element failed due to a short circuit in the wiring. Will need replacement. Also, check the operating pressure in the heating system and the t0 limiter. Change if necessary.

Perhaps technical failures are caused by a pump failure that does not start. If the pump does not work, you need to dismantle it and replace it.

It happens that there are problems with the fuse. If it is not in working condition, you will need to install a new one.

Often the water circuit fails. If the heat exchanger circuit is damaged, remove it and install a new one.

Problems may arise with the flue gas t0 limiter. Or there is a short circuit in the wiring: replace.

E.A.

There is no flame. Pay attention to the protective conductors and their connections. The gas valve may be closed: open it. Pay attention to the gas supply pressure. If any problems are found, correct the problem.

The electrical connection may be incorrect. Check and correct the fault.

There may be no flame due to slagging in the flue gas outlets. Clean or repair the structure.

If the gas supply is not set, eliminate the problem.

When using an air intake, exhaust gases enter the room and are not discharged outside. The draft and ventilation holes should be checked.

They may be clogged with dust and dirt; clean the heat exchanger. Inspect the gas fittings and replace if necessary.