The use of gas boilers for heating private houses or apartments is becoming common.

Homeowners do not want to indulge the appetites of the owners of resource companies, who are constantly increasing housing and communal services tariffs.

Some villages are located in remote areas, their networks are not able to provide new subscribers.

These reasons have caused an increased demand for heating equipment, which is represented not only by European, but also by domestic manufacturers.

Consider gas boilers from Ochag.

Gas boilers from Ochag

, which is the owner of the Ochag brand, is located in Ulyanovsk. The beginning of its activities is considered to be 1993.

Today the company produces a wide range of heating equipment and individual components for it of its own design . There are many standard sizes and designs of gas boilers in production, capable of heating rooms from 70 to 1000 V. m.

The company carries out its activities based on the principles of simplicity, reliability, and stability of its equipment. The main advantage of Ochag boilers is their low cost, which makes them preferable and accessible to the mass buyer.

At the same time, the functionality and quality of the boilers are at a high level, which confirms the high demand and positive user ratings.

The boilers are non-volatile, which for the Russian user is a guarantee of reliability and continuous operation of the heating system.

About the manufacturer

The ServiceGaz company began its activities in 1993 in the city of Ulyanovsk. Today, this manufacturer supplies the domestic market with more than 60 modifications of gas boilers.

Domestic gas boilers and their manufacturers are presented here

The products are in wide demand among users due to their good technical characteristics and reasonable price. Currently, the average cost of units operating on gas is 14,000-17,000 rubles. Boilers are capable of heating rooms from 70 to 1000 m², it all depends on the specific model.

Kinds

The Ochag company produces different structural types of boilers:

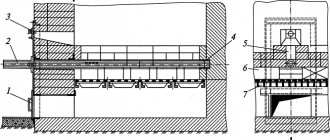

- Floor-standing . They do not require any special installation as they can be placed directly on the floor. This expands installation options compared to wall-mounted models.

- Wall mounted . They require hanging installation on strong, preferably load-bearing walls. Temporary or plasterboard partitions are not suitable for this. The specifics of the installation require reducing the weight and reducing the size of the boiler, which affects power and performance.

- Parapet . They can be used both as part of a heating circuit and as an independent heat source.

By functionality:

- Single-circuit . Designed only to supply the heating circuit with hot coolant.

- Dual-circuit . Capable of simultaneous heating of coolant and preparation of hot water (DHW) for domestic needs.

By type of combustion chamber:

- Atmospheric (open) . Smoke removal occurs through a common house chimney using a stove-type draft, and combustion air is taken directly from the room.

- Turbocharged (closed) . Smoke removal and air supply are carried out by a special turbocharging fan. Possible only on energy-dependent models, but independent ones can also be modified using an external turbo nozzle.

There are many design options for Ochag boilers; the user can choose the most suitable option for his or her purposes.

Series and models

The Ochag company produces several model lines:

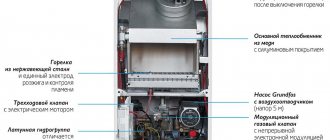

- Premium . The series is represented by single- and double-circuit floor-standing models AOGV and AKGV with a power from 8 to 29 kW. There are models with different types of automation - Italian SIT or the company’s own development.

- Standard . A series of floor-standing single- and double-circuit gas boilers. The power of the models is in the range of 7-20 kW. EUROSIT or SABK-AT automation was used.

The most common models are KSG 7, 10 and 15.

They have a power of 7, 10 and 15 kW, respectively, which makes it possible to provide thermal energy to rooms with an area of 70, 100 and 150 m2, which allows heating private houses of the most common sizes.

These are non-volatile floor-standing boilers, designed in a modern compact style and fit perfectly into the interior of any room . There is a possibility of conversion to liquefied gas.

A durable stainless steel burner is used.

IMPORTANT!

All models of Ochag boilers are manufactured in accordance with the requirements of the European standard ISO 9001-2011.

The lineup

Conord gas floor-standing boilers go on sale in several series. Each of them has its own characteristics.

- Conord single-circuit boiler with SIT automation:

- power – from 9 to 27 kW;

- temperature adjustment ranges from 60 to 90 C;

- system pressure – from 0.3 to 1.8 BAR;

- approximate cost – 12,000 rubles.

- Conord single-circuit boiler with thermo-hydraulic automation:

- power – from 11 to 27 kW;

- cylindrical heat exchanger;

- system pressure up to 5 BAR;

- approximate cost – 13,000 rubles.

- A unit with two thermal circuits, that is, it can be mounted inside a boiler system:

- power – from 12 to 30 kW;

- both natural and forced types of coolant circulation are acceptable;

- the average price is from 15,000 rubles.

- Double-circuit heating plant with SIT automation:

- power ranges from 11 to 29 kW;

- both natural and forced types of coolant circulation are acceptable;

- this model has a specialized sensor that can both turn off the gas supply if there is no traction, and restart the fuel supply when the process resumes;

- average cost – from 15,000 rubles.

You might be interested >> Description of the double-circuit gas wall-mounted boiler Baxi

Specifications

Let's consider the parameters of gas boilers Hearth:

| Options | Values | ||

| KSG-7AT | KSTG-16 | KNG 24 | |

| Boiler type | Gas heating convection | ||

| Fuel type | Natural gas with the possibility of conversion to liquefied gas | Natural gas with the possibility of using solid fuel | Natural gas with the ability to convert to liquefied gas |

| Functions | Heating | Heating | Heating and hot water supply |

| Installation method | Floor | Floor | Wall |

| Efficiency | 85 % | 75 % | 90 % |

| Power | 7 kW | 16 kW | 24 kW |

| Power supply | Absent | Absent | 220 V 50 Hz |

| Life time | 15 years | ||

| Guarantee | 36 months | ||

Consumer opinions about the technical characteristics of the model

The above-described floor-standing gas boiler “Ochag”, according to buyers, has outstanding technical characteristics. Among them, it is worth highlighting the heating capacity, which reaches 7 kW. The equipment can be installed on an area of up to 80 m2. This is true if the ceiling height is 2.7 m.

In an hour, natural gas will be consumed in a volume of 0.78 m3. As for liquefied gas, the installation will consume 0.64 kg within an hour. This type of fuel can be used when replacing burner nozzles. Before purchasing a gas boiler “Ochag”, you should definitely read reviews about it. From them you can find out that the working pressure of the coolant is 0.1 MPa.

Advantages and disadvantages

The advantages include:

- Durability, reliability, stable operation of boilers.

- A wide selection of models allows you to obtain the optimal design and power of the boiler.

- The energy independence of the units ensures uninterrupted operation of the heating system in all situations.

- High performance boilers.

- Simplicity of design, ease of management and maintenance.

- Low fuel consumption.

- Attractive appearance, compact size.

- Low price.

The disadvantages of Ochag boilers are::

- Difficulty igniting.

- The need to ensure a slope of the system to ensure coolant circulation.

- For more stable operation, the use of external devices is required - a circulation pump and a turbo nozzle.

For non-volatile boilers, these disadvantages are quite typical and are, rather, design features.

Operation and setup

Operation of gas boilers Hearth occurs practically without human intervention, in automatic mode.

The owner is only required to:

- Filling and draining water from the system.

- Switching the boiler to summer/winter mode.

- Periodically clean the housing from dust and dirt.

The operating mode is configured during installation and initial startup. Boilers are sold already configured and adjusted .

At startup, only adjustments are made to the factory settings for the most efficient operation under the given conditions.

The setup must be performed by a specialist from the service center with the appropriate approval and qualifications.

Any independent intervention in the boiler design automatically terminates the warranty agreement . In addition, an inexperienced user with his actions can permanently damage the boiler.

Reviews about the features and technical characteristics of the KSG-10 AT boiler

If you don’t know which model to choose, then it’s worth considering several options for gas heating equipment. Among other proposals, it is necessary to highlight the KSG-10 AT. You can purchase a gas boiler “Ochag” of this model for 11,000 rubles.

It has a floor-mounted design and provides maximum comfort to the consumer. Buyers note a heating output that reaches 10 kW. Heating capacity is 100 m2. Natural gas consumption per hour is 1.11 m3. As for liquefied gas, it can be used when replacing burner nozzles, and its consumption will be 0.88 kg/h. Consumers especially emphasize the rather compact overall dimensions of the installation; they are 250x470x750 mm.

It is impossible not to mention its insignificant weight, it reaches 48 kg. The coolant temperature control range is from 50 to 90 °C. At the boiler outlet, the maximum temperature of the coolant should not exceed 95 °C. Buyers also like the rather impressive volume of water in the boiler; it is equivalent to 18 liters.

How to light a boiler

The procedure for igniting a gas boiler with automatic SABK-AT:

- Open the gas tap.

- Place the gas block handle in the “Ignition” position.

- Press the “Start” button, hold it for about 10 seconds, then press the piezo ignition button 2-3 times until it clicks (ignition is possible through the viewing window using a burning match).

- Hold the “Start” button for another 20-30 seconds to warm up the thermocouple. The gas valve can then be held open by a magnetic plug.

- Turn the gas block knob to position 5 and make sure the burner flame is stable.

- Set the desired temperature on the gas block.

To ignite the burner of boilers with automatic EUROSIT, the same steps are performed, only in step 5 the handle must be turned to position 7.

Download instructions

Download instructions for the gas boiler Ochag.

How to light a boiler?

In order to ignite the Hearth boiler, you need to turn the control knob clockwise until the point is opposite the pointer. Then press and hold the start button. Press the piezo ignition button until you hear a characteristic click. At this time, the igniter lights. We continue to hold the start button pressed while the thermocouple heats up. The gas block operates automatically on the igniter. Next, turn the knob counterclockwise to the required temperature.

The Hearth boiler achieves high efficiency due to efficient combustion of fuel and high heat transfer from flue gases through “flame” pipes to the coolant and a developed firebox. The manufacturer guarantees a service life of at least 15 years. Factory warranty for the product is 24 months.

Watch a video on how to light a gas boiler with Eurosit630 automation

Why does a gas boiler go out?

The extinction of a gas boiler flame can be caused by external or internal reasons.

External reasons include:

- The occurrence of reverse thrust . The most difficult case, practically impossible to eliminate by conventional means. Sometimes eliminating drafts and opening or closing some doors or windows helps.

- Strong gust of wind outside . Cases of flames being blown out by the wind are frequent; they are the result of an unsuccessfully located chimney or low height above the roof surface.

- Drafts in the room . This situation is completely solvable, the main thing is to determine the source of the draft and close it.

Internal problems may be:

- Stopping the gas supply to the mains.

- Gas valve failure, problems with gas equipment.

- Burner nozzles are clogged with soot and combustion products.

If such problems occur, you should call the gas service and clarify the reasons for the lack of gas. The fuel supply valve must be closed before doing this.

Call a specialist from the service center and entrust him with the repair of gas equipment.

It is prohibited to try to repair the gas block yourself; this can cause very dangerous and even fatal consequences.

Basic faults

The main malfunctions of gas boilers Hearth are problems with the burner - weak flame, extinction after a few seconds of burning, frequent flame failures for unknown reasons.

There can be many reasons for the malfunction of gas equipment; to eliminate possible problems, you need knowledge of the design and operating features of the equipment.

All work must be carried out by service technicians who are certified to work with gas equipment.

The only possible independent procedure may be to clean the burner nozzles from soot.

Reviews about the main features of the KSG-7 AT model

If you want to purchase a gas boiler, then you should pay attention to the KSG-7 AT from. The cost of the equipment is 10,600 rubles. This steel boiler is automatic and floor-standing. According to consumers, it is characterized by ease of use, provides maximum comfort and is easy to install.

Gas consumption during operation of the device is quite economical. The efficiency is high. According to users, these features are among the main ones inherent in the devices described.

The gas boiler "Ochag KSG" has a modern unique design. The unit does not require external sources of electricity and is energy independent. Buyers like that even with reduced gas pressure the device operates stably. It has a high efficiency, which is ensured by an increased heat exchange area.

Price range

The average prices of Ochag boilers are in the conventional range of 12-20 thousand rubles. Before purchasing, you should clarify what additional devices and accessories will be needed for the normal operation of the boiler itself and the entire system as a whole.

In addition, you will need to conclude a warranty agreement in order to be able to urgently restore the system’s functionality.