Home » Classification of gas boilers » Operating principles » Setting the modes of the Immergaz gas boiler

Heating equipment made in Italy by Immergas has long been known on the Russian market. It includes modern technologies and has the ability to connect other auxiliary devices, for example, a room thermostat or an outdoor programmer. Setting up a gas boiler Immergaz allows you to control the operation of the unit in two modes: via the remote control or using a panel located on the body.

…

- 1 Turning on the gas boiler

- 2 Setting the unit power

- 3 Programming settings

- 4 Other gas boiler settings

Turning on the gas boiler

Before turning on the gas boiler, you should check that the pressure in it is at the level of 1-1.2 bar and the gas supply valve is open. Then the Main handle must be moved to the “Remote control” or “DHW and heating” position. When one of the modes is activated, the top green indicator lights up.

If the unit is in the “Remote Control” mode and the remote control is connected to the boiler, the manual switches stop functioning. Setting up a gas boiler and turning on various functions is done from the remote control. When the remote control is activated, indicators 2 and 3 on the unit body are constantly lit, above which there are images of a water tap and a radiator. Indications of modes or failures are displayed on the remote control display.

If the knob is turned to the “Remote Control” position and the remote control is not connected, the heating knob will turn off, but the hot water knob will work.

When the “DHW and heating” mode , the heating knob is used to adjust the heating power, and the DHW knob is used to change the temperature of the water circuit.

…

If any light in the group, which includes 7 indicators located on the right, blinks, this indicates a malfunction.

How to properly set up a gas boiler?

Find out here the features of a wall-mounted gas boiler

Gas boiler temperature regulator - purpose and types

Gas boilers Immergas/Immergas boiler (Italy)

Immergas was founded in 1954 in the city of Brescello, which is located in the center of Italy . Immergas plant has been producing wall-mounted gas boilers for over thirty years . Today, the plant, with a total area of 40,000 m2, employs 550 highly qualified specialists.

The model range of wall-mounted gas boilers Immergas/Imergaz boilers consists of 78 models. The following models are supplied to Ukraine and the CIS countries: Star, Star KW, Mini, Maior, Zeus Maior , which are adapted to domestic operating conditions. The listed models are boilers with both forced emission of combustion products and natural draft.

Immergas brand is not limited to European countries. The products of the Italian plant are known even in China. Immergas products are exported to 32 countries around the world. Thus, in terms of sales of condensing wall-mounted gas boilers Immergas / Imergaz boilers , the company has become the absolute leader in sales of wall-mounted boilers in Europe.

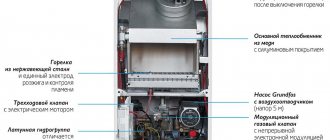

Many important components of Immergas boilers/Imergas boilers are manufactured directly at the company's plant. Among them are such key components as: a storage boiler with an original spiral heat exchanger made of high-grade stainless steel and internal copper turbo pipes of the boiler. The remaining components that are used to complete Immergas boilers/Imergaz boilers are supplied by leading European manufacturers.

To ensure stable and reliable operation of boilers, the company has established nearly 600 specialized service centers throughout Europe. To improve the skills of employees, training is provided on installation and maintenance of boilers.

boilers /Imergas boilers are produced on ten different plant assembly lines. Much attention is paid to maintaining high quality products, which is ensured by special tests. All Immergas boilers / Imergaz boilers undergo control checks at each stage of production. For this purpose, test benches are used, to which gas, water, electricity are supplied, and the removal of combustion products is also organized. Thus, all parts of the Immergas boiler/Imergaz boiler .

Over the history of its existence, Immergas have been able to combine into one coherent mechanism all the integral processes in the production of heating boilers: from product design to delivery to the client, from sales to technical support.

A client who has purchased an Immergas boiler / Imergas boiler receives a device that not only meets modern technical requirements, but also combines an ideal price-quality ratio. In addition, every Immergas gas boiler/Imergas boiler is provided with excellent after-sales service after purchase.

Boiler EOLO Mini 24 KW “IMMERGAS” turbo. Boiler EOLO Mini 28 KW “IMMERGAS” turbo. Boiler EOLO STAR 24 3E “IMMERGAS” turbo. Boiler NIKE Maior 28 KW E "IMMERGAS" atmospheric Boiler NIKE Mini 24 KW "IMMERGAS" atmospheric Boiler NIKE Mini 28 KW "IMMERGAS" atmospheric Boiler NIKE STAR 24 3E "IMMERGAS" atmospheric Immergas Zeus 28 kW Immergas Zeus 24 kW Nike Star 24 3 E Immergas Mini Nike 24 3 E Immergas Mini Eolo 28 3 E Immergas Mini Eolo 24 3 E Immergas Maior Eolo 32 4 E Immergas Maior Eolo 28 4 E Immergas Maior Eolo 24 4 E Immergas Eolo Star 24 3 E Immergas Avio 24 kW Immergas Nike Mini 28 kW Special Immergas Victrix 24 X 2 I Immergas Victrix 90 1 I Immergas Victrix 75 Immergas Victrix 26 2 I Immergas Victrix 50 Immergas Victrix Superior 32 KW Immergas Victrix Superior TOP 32 kW X ARES 150 Tec ARES 200 Tec ARES 250 Tec ARES 300 Tec ARES 350 Tec ARES 440 Tec ARES 550 Tec ARES 660 Tec ARES 770 Tec ARES 900 Tec Immergas Nike Mythos 24 2 E Immergas Eolo Mythos 24 2 E Immergas Victrix Zeus Superior 32 kW Immergas Hercules Сondensing 26 kW Immergas Hercules Сondensing 32 kW Immergas Hercules Condensing 32 kW ABT Immergas Hercules Solar 26 Immergas Mini Nike X 24 3 E Immergas Mini Eolo X 24 3 E

teplotek-ug.ru

Setting the unit power

You can adjust the optimal power of the Imeergas gas boiler using the gas valve. Setting the operating power of a gas boiler is carried out as follows:

- set the DHW switch to the desired position;

- open the hot water tap;

- adjust the required power using the adjustable nut on the gas valve;

- adjust the heat output by turning it clockwise to increase it, or counterclockwise to decrease it.

The minimum heat output can be adjusted using a plastic screw located on the gas valve. The adjusting nut must remain motionless. It is recommended to turn off the power to the valve modulation coil and then turn the screw clockwise to increase the pressure or counterclockwise to decrease the pressure. After this, the power to the coil must be returned.

…

Note! The minimum power should not be less than that specified in the characteristics of the unit.

Immergas boiler what temperature to set

Home is a special value for a person. For some it is a fortress, for others it is a family nest, for others it is a symbol of independence. But whatever the mansion of your dreams, life in it is impossible without heat and hot water. Is it possible to get both benefits using one boiler? "Certainly!" – IMMERGAS specialists will confidently answer.

The matter of technology is afraid

For many, the issues of heating and hot water supply are still unclear and even scary. What is better: to buy one universal boiler or two devices - for heating and hot water? Which option is more economical and reliable? And does the “unified” system have any significant advantages? Don't panic! Everything is simpler than you think. A gas boiler that can simultaneously heat rooms and heat water for domestic needs is called “double-circuit”. This means that two independent systems operate in one device. Or, as the professionals say, “contours.” The first fills the radiators with hot water, and the second fills the taps in the kitchen and bathroom. That's all: a matter of technique, and no miracles!

__________________________________________________________________

Expert commentary Yuri Emelin, technical specialist at Immergas Russia:

“All IMMERGAS double-circuit boilers have separate controls for heating and hot water supply. Yes, this is exactly what you thought: the temperature in the radiators has no effect on the temperature of the water in the kitchen and bathroom! You can enjoy boiling water with cold radiators or have hot radiators with cold water in every tap. Moreover: IMMERGAS gas boilers perfectly heat the room with minimal burner power and provide you with hot water at low water pressure.”

Programming settings

Immergaz boilers of the Zeus series allow the user to program their own settings, each of which has its own indication.

To activate the programming mode, set the main control to the Reset position and hold for 15-20 seconds until the top indicator flashes. Then you need to switch the main regulator to the “DHW and heating” mode.

First, the first programming level is activated, which will allow you to adjust the parameters. You can determine the programmable parameter using 10 indicators, indicated by the corresponding icons:

- 1 – minimum heating power;

- 2 – maximum heating power;

- 3 – heating switch-on timer;

- 4 – parameter of smooth power control;

- 5 – pause time before ignition when working with a thermostat or remote control;

- 6 – thermostat of the DHW circuit;

- 7 – circulation pump;

- 8 – heating of the DHW circuit;

- 9 – gas;

- 10 – operation of relays and safety sensors.

The activated parameter will flash. At the same time, the upper sensor will also blink. You can adjust the required value using the DHW heat exchanger temperature switch.

After selecting a parameter, move the main switch to the Reset position and hold it until the indicator of the corresponding parameter goes out. After this, the mode switch is released.

A second level of programming is now available. Activation of parameters is indicated by blinking of the corresponding indicators. The values are changed using the heating temperature controller. The selection is confirmed by moving the main switch to the Reset position. After this, the mode indicator should go out. Programming mode will turn off if there is no activity for 30 seconds or the main switch is turned to the OFF position.

The automatic gas boiler provides power modulation depending on the room temperature. By setting the maximum and minimum performance values, the unit will operate within the set power range.

Other gas boiler settings

The gas boiler is equipped with an electronic timer that prevents frequent ignition of the burner. According to the factory settings, the timer is set to 180 seconds. It is possible to set the timer time from 30 seconds. up to 255 sec.

The gas boiler is equipped with a circulation pump, which has two operating modes:

- the first one turns the pump on and off based on a signal from the thermostat or remote control (the 1st light will be on);

- the second is designed to operate when the main switch is in heating mode (the last light will be on).

The user of the Immergaz gas boiler has the opportunity to activate “DHW heating”, which will constantly maintain the water temperature in the secondary circuit at 50°C. This allows you to quickly get hot water.

Wall-mounted gas boiler IMMERGAS. Model overview

Gas boilers IMMERGAS – two hundred heating horses, says the company slogan. The company located its production facilities in Italy and over 50 years they have gained trust, respect, and recognition of quality, predetermining exclusively positive feedback from their consumers.

The north of Italy has long been famous for technical innovation in all areas of industrial production. The largest company on the European market, specializing in the production of wall-mounted gas boilers under the world-famous Immergas brand, was no exception.

Using only the latest technologies and modern design in its developments, the Immergaz gas boiler is distinguished by its reliability and high quality. The company is so confident in its products that it provides an unprecedented extended warranty of 5 years!

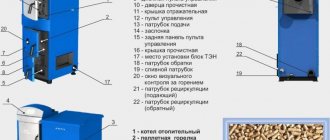

By offering the Immergaz gas boiler to the modern heating market, the company took care of expanding the range of equipment so that the boilers can be used not only in residential buildings, but also in industrial facilities, offering mini boiler rooms for large areas.

Our review is devoted to wall-mounted modifications of boilers called NIKE STAR 24 3 R, NIKE MYTHOS 24 3R, and EOLO STAR 24 3R - which have become bestsellers on the domestic market. Let's consider their features, principles of operation, technical characteristics. Let’s try to create our own opinion about the advantages of the engineering solutions of Immergaz specialists, talk and leave feedback on possible disadvantages.