Home / Commissioning

Back

Published: 05/26/2019

Reading time: 4 min

1

3305

Carrying out commissioning (commissioning) work for hot water and steam heating boilers is the most effective means of energy saving, allowing you to avoid unnecessary costs. During the work, deficiencies in the condition of the unit are identified that can affect the operation of the heating system.

Only after all the necessary settings have been made and the functionality of individual segments of the heating system has been checked, the unit can be put into operation. Only specialists who have been certified at the manufacturer’s production base and who also have permission from Rostekhnadzor to perform gas-hazardous work have the right to carry out routine adjustment of boilers.

- 1 PDP program

- 2 PPR methodology

- 3 Mode map

- 4 Periods of commissioning

- 5 Equipment required for commissioning

- 6 Cautions

PPR program

In order to understand the purpose for which the official regime adjustment of heating boilers is carried out, it is necessary to take a brief excursion into the goals and objectives that this procedure pursues. So, before carrying out work, you need to draw up an adjustment program, methodology and work schedule.

The PNR program includes:

- selection of the optimal mode for the installed equipment;

- choice of duration and number of experiments performed;

- selection of equipment characteristics at the design points at which measurements are taken;

- carrying out commissioning work involves calculating a measurement scheme;

- Using the total thermal data of the fuel, the losses of thermal energy not obtained from unrealized residues due to the lack of complete chemical combustion are calculated.

Calculations carried out during operational adjustments demonstrate that as a result of the work, it is possible to reduce fuel consumption by up to 5% and increase the service life of the unit. The program is coordinated with the customer and Rostekhnadzor.

You can find a standard PNR program from me. Let me also remind you that before commissioning, you need to agree on the work methodology, and upon completion, provide the customer with operating mode maps. More on this later.

Operational and adjustment tests (RIT), operational adjustments of boilers

Conducting operational and adjustment tests of boilers is one of the effective low-cost methods of energy saving. Setting up boilers allows you to identify shortcomings in their condition and operation, outline and implement a set of measures that increase efficiency: optimize the levels of excess air in different parts of the gas path, flue gas temperatures, etc.

Operational adjustment works and tests are carried out

certified personnel with certified equipment.

What is commissioning work?

Regime and adjustment work is a set of works that includes the adjustment of fuel-using equipment in order to achieve the design (certified) volume of fuel consumption in the range of operating loads, the adjustment of means for automatically regulating fuel combustion processes, and auxiliary equipment. Boiler adjustments are carried out by specialized organizations.

Result of commissioning work

Based on the results of the commissioning, a technical report and boiler performance maps are drawn up. As practice shows, the costs of performing routine adjustments pay off within 3-6 months.

Fuel savings after routine adjustment of the boiler Comparative tests and calculations show that as a result of adjustment work, fuel savings of 3-5% are achieved. Carrying out routine adjustment work is provided for by the relevant instructions once every 3-5 years. This is explained by the fact that usually during this period the initial parameters at which the boiler operating maps were compiled change. In addition, individual parts of the boiler unit and auxiliary equipment may be subject to changes: cracks appear in the lining, scale on heat exchange surfaces, design changes after various repair and restoration work, especially the combustion part. As a result, the combustion mode becomes ineffective: the total volume of flue gases and their temperature changes, the efficiency of the equipment decreases, fuel consumption and harmful emissions increase. Boiler adjustment allows all this to be identified and eliminated. Correct the old regime map or draw up a new one.

Boiler operating map

Boiler operating chart is a document drawn up on the basis of operating and adjustment and balance tests, containing the main operational and control parameters of the furnace and boiler operation, efficiency value, specific fuel consumption at various capacities, limit values of parameters controlled by automatic safety and regulation. The boiler operating map helps to operate it correctly.

Carrying out routine adjustment work on boiler units allows

- identify and eliminate shortcomings of the burner device;

- get fuel savings of up to 5%;

- reduce the volume of toxic emissions to a minimum for this type of equipment;

- optimize the operation of the boiler (ensure maximum efficiency), draw up a regime map;

- obtain the necessary experimental data for drawing up regime maps and graphs of recommended fuel-air ratios, allowing boiler room operators to select the most efficient operating modes of equipment with the appropriate settings for automatic control or manual control;

- extend the service life of equipment, increase its reliability and safety.

Frequency of routine adjustment work According to the “Rules for the technical operation of thermal power plants”, registered. Ministry of Justice of Russia No. 4358 dated 04/02/03: “Routine and adjustment tests are carried out at least once every 5 years for boilers using solid and liquid fuels and at least once every 3 years for boilers using gaseous fuels. For the latter, with stable operation, the frequency can be increased in agreement with the state energy supervision authority.”

Extraordinary operational testing of boilers

Extraordinary operational testing of boilers is carried out in the following cases:

- modernization and reconstruction of boilers;

- changes in the characteristics of the fuel burned;

- systematic deviations of actual boiler performance indicators from standard characteristics;

- after chemical flushing of the boiler to reduce gas consumption.

Certificate for carrying out maintenance and adjustment work

IP Nekrasov P.S. has a certificate for performing commissioning and operational adjustment work on gas-using equipment of enterprises and organizations of all forms of ownership by type:

- adjustment of fuel-using equipment;

- setting up automatic control means;

- setting up heat recovery units;

- adjustment of auxiliary equipment, including for boiler houses - chemical water treatment equipment.

tes-rk.ru

PPR technique

Before commissioning, it is imperative to draw up and approve with Rostechnadzor a methodology for carrying out commissioning of the boiler room. It is necessary to agree with the customer on the commissioning schedule.

I won’t tell you what should be in the methodology and graphics, but will simply post sample files here. You can download and watch. Link to the method here. The link to the schedule is here.

Advantages of commissioning work

Regime and adjustment work allows:

- identify problems in the operation of boilers and measures to eliminate them;

- save up to 5%;

- minimize the volume of harmful substances produced during the heating process;

- optimize the operation of boiler equipment;

- increase the service life of equipment, as well as improve its reliability and safety.

Testing of boiler equipment is divided into 2 accuracy classes. If high demands are placed on the results, then it is necessary to use tests of 1st accuracy class. They allow you to determine the efficiency with high accuracy - up to 1-1.5%. As for the tests for accuracy class 2, they are preliminary. The accuracy in determining equipment performance is from 2.5 to 3%.

Regime card

This document is drawn up for each heating boiler based on the results of commissioning tests. It contains basic control data of the boiler operation, efficiency value, specific fuel consumption under conditions of different productivity.

In addition, the maximum values of the parameters controlled by the safety control automation are entered here, which ensures stable operation of the boilers. The regime map is intended for organizing qualified operation of a gas boiler, taking into account all current changes and boiler safety. You can sample the regime map of the DKVR boiler

.

Boiler operating map

Boiler operating map is a document drawn up on the basis of operational, adjustment and balance tests, containing the main operational and control parameters of the boiler, efficiency value, specific fuel consumption at various capacities, etc.

A boiler operating map is required for its correct and competent operation; it must be re-drawn or adjusted every 3 years.

For questions regarding performance testing, please contact the head of the technical maintenance department: Minaev Sergey Aleksandrovich tel. 8-906-750-50-27

Periods of commissioning

Regular adjustment of boilers is regulated by relevant requirements and is carried out within a period of at least 3 to 5 years, depending on the type of unit. The reason for this is the fact that during a given period, changes occur in the operation of the equipment that affect the initial parameters. By the time the specified period expires, there is a discrepancy between the performance indicators of the solid fuel or gas boiler and the data indicated in the regime map.

Plus, certain segments of the unit, as well as auxiliary equipment, may be subject to changes:

- the appearance of cracks in the cladding;

- scale formed on heat exchangers;

- structural changes resulting from repair work.

The result of such changes may be a decrease in the efficiency of the fuel combustion mode:

- the temperature and amount of exhaust gases changes;

- Boiler efficiency decreases;

- Fuel consumption increases at different temperatures.

Official adjustment work on repair, installation and commissioning of gas boilers and water heaters allows us to identify and eliminate errors that reduce the efficiency of the equipment. Based on the results of periodic work, the regime map is corrected or the document is drawn up anew.

Regime tests

Regime tests of water heating units are carried out to install an energy saving method that does not require large financial expenses.

These measures are also called environmental-heat-technical. During setup, shortcomings in the operation of the entire water heating system are identified.

After receiving all the necessary data, a comprehensive system is developed to improve the efficiency of device operation.

The need for routine adjustment of boilers:

- identifying and eliminating defects in all equipment;

- reducing to a minimum the emission of toxic gases into the atmosphere;

- increasing the efficiency of the heating device;

- increasing the service life of system mechanisms and units;

- checking the operational characteristics of the entire water heating installation as stated in the manufacturer’s documentation and technical data sheet of the equipment.

Regular tests of solid fuel boilers are carried out once every 5 years, and for gas boilers - once every 3 years.

The advantages and benefits of a hot water heating boiler are beyond doubt, but like any technical means, boilers periodically require maintenance.

How to correctly calculate the power of a gas boiler, read here.

Equipment required for commissioning

In order to carry out qualified commissioning of the boiler, it is necessary to use special equipment from the following list:

- gas analyzer - a device that allows you to monitor the smoke removal system; the set parameters allow you to make corrections for combustion modes;

- leak detector configured for flammable gases - monitors the tightness of gas connections for leaks;

- electronic differential pressure gauge – monitors response parameters for gas equipment safety automation;

- a set of pressure gauges – monitors the operation of safety automatics for units;

- pyrometer – sets the accuracy of thermometers, duplicating the parameters of heating water or steam.

You should know that commissioning of boilers cannot be carried out without a gas analyzer, because data on the tightness of the chimney, as well as the composition of the exhaust gases, ensure the safety of the residents of this living space. After all, the concentration of CO2 and O2 are values demonstrating the efficiency of fuel combustion.

The concentration of CO determines the composition of carbon monoxide, which is odorless and poses a real danger of suffocation, especially during sleep. Errors in settings, as well as depressurization of the chimney can lead to serious consequences. At a CO concentration of 400 ppm, which is unacceptable by safety rules, death is possible within 3-4 hours.

Why is boiler adjustment necessary?

Home > Useful information > Why is boiler adjustment necessary?

The main goal pursued by the regime adjustment of boilers is to determine and establish optimal operating modes of heat-generating equipment, which allow minimizing emissions of combustion products into the atmosphere.

Regular adjustment of boilers is essentially one of the most effective and inexpensive techniques that ensure energy saving. This set of measures is aimed at identifying deficiencies in the operation of equipment, as well as identifying basic measures to improve the efficiency of the system as a whole. In particular, the levels of excess air volumes in one or another part of the gas path, temperature indicators of exhaust gases, etc. can be optimized. A boiler operation map must be drawn up.

The set of works that includes routine adjustment of boilers is, first of all, measures taken to achieve the equipment’s design fuel consumption. In addition, this is the adjustment of automation, responsible for adjusting fuel combustion modes, and other auxiliary systems. Regular adjustment of boilers must be entrusted to qualified specialists. Based on the results obtained during the commissioning process, a report and performance maps of the heat-generating equipment are compiled. The cost of work in this case is incomparably small in comparison with the resulting economic effect. Typically, all costs are recouped after a period of time from 3 months to six months. Comparative calculations and practical tests invariably demonstrate the fact that regime adjustment of boilers allows achieving energy savings of up to 5%.

In accordance with existing instructions, operational adjustment work must be carried out at least once every 3-5 years. As a rule, during this period of time, the technical parameters of the main and auxiliary equipment (on the basis of which previous performance maps were compiled) change. Accordingly, the efficiency of the combustion mode decreases: the volume and temperature of the flue gases changes, the efficiency decreases, and energy consumption increases. Regular adjustment of boilers provides the opportunity to detect and eliminate such deficiencies by drawing up a new map, which will take into account all the operating characteristics of the equipment for its subsequent correct operation.

Cautions

Carrying out commissioning work by people who do not have the appropriate certification and permission can not only deprive users of the opportunities associated with warranty obligations, but also lead to tragic consequences.

In this case, there is a risk of the following situations:

- the possibility of an explosion cannot be ruled out;

- damage to adjustments in gas fittings;

- excessive fuel consumption can increase several times;

- contamination of the boiler with soot from unproductive combustion;

- failure of heat exchangers due to operation at extreme loads.

By using the services of unqualified specialists, each user risks facing premature repairs that involve replacing expensive components.

In addition, you will have to carry out re-commissioning work and lose the possibility of warranty service at the service center. A gas boiler is accepted for warranty service only after recording it in the warranty card, which can only be done by service technicians.

Operational and adjustment tests of boilers

According to the “Rules for the technical operation of thermal power plants,” operational and adjustment tests are carried out at least once every 5 years for boilers using solid and liquid fuels and at least once every 3 years for boilers using gaseous fuels. For the latter, with stable operation, the frequency can be increased in agreement with the state energy supervision authority.

The purpose of RNI is to establish standard operating characteristics of a boiler installation, to achieve maximum boiler efficiency under various operating loads.

- The objectives of operational testing are

- adjusting the operating mode of the boiler installation;

- determination of optimal excess air at various loads;

- determination of the main heat losses under various loads;

- determination of specific fuel consumption for supplied thermal energy;

- determination of gross boiler efficiency;

- drawing up operational maps of boilers at different loads;

- preparation of a technical report;

- Operational and adjustment tests are carried out according to group 2 of tests and the efficiency is determined with an accuracy of 1.5 - 2%

- Tests are carried out to determine efficiency using the reverse balance method.

Carrying out operational and adjustment tests on boiler units allows

- identify and eliminate the shortcomings of the burner device

- get fuel savings of up to 5%

- reduce toxic emissions to a minimum for this type of equipment

- optimize the operation of the boiler (ensure maximum efficiency), draw up a regime map

- obtain the necessary experimental data for drawing up operating maps and graphs of recommended fuel-air ratios, allowing boiler room operators to select the most efficient operating modes of equipment with appropriate settings for automatic control or manual control

- extend the service life of equipment, increase its reliability and safety

Organization of tests and preparatory work

- Familiarization with the technical documentation of the boiler installation (factory design).

- Checking the boiler's availability of draft and blast at rated load; checking the density of the gas-air path.

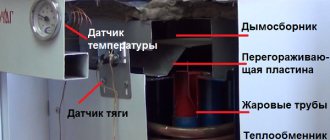

- Complete inspection of the boiler installation to assess its condition; equipped with control means: instrumentation and automation and readiness of the installation for testing.

- Drawing up and issuing to the customer a list of works to eliminate identified deficiencies, manufacturing the necessary selections, fittings and devices for testing (with the issuance of drawings and sketches for production).

- Drawing up a diagram of the arrangement of devices.

- Installation of devices, their wiring and connection according to the diagram.

- Technical supervision over the elimination of identified deficiencies, over the manufacture and installation of necessary devices and fixtures (bends, fittings, etc.).

- Preparation, testing and adjustment of devices and instruments for testing.

- Conducting safety and medical care briefings for test participants.

- Educational and training preparation of test participants with analysis and correction of the actions of individual performers, clarification of the sequence of entries in the observation log.

Stages of work (as a percentage of total volume)

- Drawing up a test program. Checking the readiness of the boiler installation for testing – 20%

- Installation of test instruments, instruction of boiler room operators – 10%

- Determination of optimal excess air with analysis of combustion products - 40%

- Processing test results, determining the main losses and boiler efficiency, drawing up a technical report - 30%

Total – 100%

The results of the tests are compiled operational maps and a technical report.