Repair and maintenance of electric boilers

The need for a service such as electric boiler repair can arise at almost any time.

This can be either a minor repair or a major one, including its replacement. But our company’s specialists will be able to successfully repair electric heating boilers of any model and from any manufacturer. After all, they are familiar with all the nuances of this equipment, and they have a specialized set of tools at their disposal.

All repair work is carried out in full compliance with approved regulations and rules:

- the first stage is carrying out diagnostic measures;

- the second is the actual repair of the electric heating boiler;

- the third is configuration and debugging.

All this requires experience and qualifications, which our craftsmen fully possess.

We will repair electric heating boilers from any manufacturer and any degree of complexity. A complete list of all works can be found on the price page. The cost of repairs of electric boilers is also indicated there. So, if you contact us, you are guaranteed not to encounter any hidden overpayments.

We offer both repair and maintenance services for electric boilers. We can provide qualified support to you at all stages - from drafting the project to commissioning.

We invite you to familiarize yourself with our prices -

It is important that all work is carried out by real professionals. After all, as our extensive practice shows, most often electric boilers fail not because of manufacturing defects, but because of design errors and low-quality installation.

Basic problems and repair methods

When starting to repair a heating boiler unit, regardless of the type of failure, it is necessary to begin by establishing the operating parameters of the power supply system and the medium pressure in the water supply system. Among the most common problems typical for the repair of electric boilers are the malfunction of heating elements, automatic control and internal thermal boiler.

heating element

Eliminating malfunctions in the operation of an electric boiler by changing heating elements requires compliance with strict rules specified by the manufacturer. If the Protherm boiler is under warranty, any repair work can only be performed by a service center.

First of all, the boiler unit is disconnected from the electrical network, which is the main condition for its own safety, since it eliminates the possibility of electric shock.

The next mandatory action of the repair personnel is to drain the liquid from the internal circuit of the boiler. At the same time, there is no need to drain the water in the in-house heating system, since it is turned off by shut-off valves at the inlet and outlet of the boiler.

If heating elements are located in hard-to-reach places, disassemble the internal equipment of the boiler. Next, the wires are disconnected from the heating elements. The initial connection system is pre-fixed: phase and zero.

After this, the mounting parts of the electric heating elements are unscrewed. The specially designed waterproof gasket is replaced. The use of old packing will likely lead to rapid leaks during operation of the newly installed heating element.

A working heating element is mounted and fixed. The procedures indicated for the disassembly process are performed in the opposite order. The electric boiler is connected to the electrical network. The performance of the equipment and the safety of the heating system are monitored.

Repair work on electrode type boilers is carried out by changing the electrodes, following a similar procedure for disassembling the boiler. At the same time, electrode boilers are the most demanding in terms of assembly punctuality.

Regarding the resumption of operation of induction boilers, due to the fact that such heating devices do not have heating elements, it is not possible to repair them on your own.

Security automation

The most popular causes of malfunctions in the control unit of electric boilers are:

- Failure of the remote control for boiler modes.

- Program failure, which could happen during transportation or installation.

- Board fault.

- Incorrectly set program code mode after the build is completed.

Criteria for malfunction of the control unit:

- When electricity is present, the boiler unit does not heat the water, which indicates that the temperature conditions are incorrectly adjusted.

- Fuses blown and the network controller malfunctions.

- Electronic board failure.

The latest failure can only be corrected by service center specialists.

Heat exchanger

The reason that the internal boiler of the boiler does not heat up may be the incorrect operation of the coolant circulation pump or the presence of an air lock in the heating system. In addition, low heat transfer in the boiler indicates that the heating surfaces are clogged with scale.

It is better for specialists to disassemble and assemble the boiler

Air locks can be eliminated yourself using an air vent. Circulation pump malfunctions can only be repaired by service centers.

Features of electric heating boilers

Today, electric heating boilers are installed as often in homes and institutions as often as solid fuel systems, as well as gas and liquid fuel systems. Indeed, they are easy to operate, have a fairly high efficiency, and are even safer in many ways than their other “colleagues.”

But at the same time, electric heating boilers also have a lot of design features that simply must be taken into account during their installation and, of course, during repairs.

Today, electric boilers are offered in wall-mounted or floor-mounted versions. The first is less powerful, but more compact and lightweight. Its installation can be carried out even in a fairly cramped room.

But floor-mounted electric boilers have great power and can serve spacious homes and institutions. At the same time, such models are larger in size and have greater weight, and require preliminary hardening of the floor.

Electric boilers can be powered from a conventional single-phase network, or from a more powerful three-phase one. The coolant can be water, oil and similar substances provided by the manufacturer.

Accordingly, all this will need to be taken into account if repair of electric heating boilers of a particular model is required.

When repairing electric boilers, the method of supplying heat energy must also be taken into account:

- with indirect heating. In this case, the heat transfer element is a heating element placed inside the heat exchange device. This option is the most common today;

- with direct heating - here the electrode is placed directly inside the coolant;

- induction models are an effective modern solution based on the principles of electromagnetic induction.

Each of the listed boiler options has its own characteristics, pros and cons. Thus, models equipped with heating elements are among the most expensive in terms of electricity consumption. However, they themselves are quite inexpensive. At the same time, the heating element can collect all the scale from the water - especially if it is placed directly into the liquid. Typically, repairing electric boilers of this model comes down to replacing the heating element.

Induction-type models are economical and efficient. But at the same time they are offered more expensive. And repairing electric boilers of these models is quite labor-intensive and complicated.

What is an electric boiler

An electric boiler is a special high-tech equipment designed for heating various types of premises. A distinctive feature of such a unit is the use of a special type of fuel - electrical energy. In many respects, the boiler is superior to equipment operating on other types of fuel: liquid, solid, gas.

Electrical equipment is considered the safest to use. But in order for it to function well, it is necessary to strictly follow the rules of its operation and perform timely technological maintenance.

Watch the video about the operating principle and design of the Protherm Skat electric boiler.

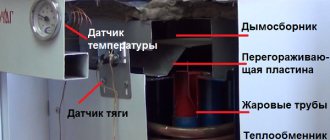

Device

Despite the wide variety of boilers with different operating principles, the design of all models is approximately the same. The main place in the structure is given to the heating element. Depending on the type of heater used and the principle of its operation, there are several types of boiler units.

All heating elements are located in heat exchangers, which are considered the main structural elements of the boiler unit. If they malfunction, heating of the coolant is impossible.

Depending on the design and manufacturer, the equipment may have different configurations.

List of elements:

- Electronic control unit. Regulates temperature conditions by turning equipment on and off at the right time.

- Circulation pump (heat pump). It is a mandatory component of the system and maintains a stable speed of coolant movement in the circuit. It produces forced circulation of liquid and creates the necessary pressure in the system, while ensuring the most effective heat exchange and heating of the room.

- Expansion tank. Not all types of electric boilers with a pump are equipped with an expansion tank. Therefore, if you purchase equipment without a tank, you will need to purchase this part separately and install it by cutting it into the pipe heating circuit.

- Filters. They purify and remove various impurities from water.

- Safety valves. Protect the system from unwanted deviations in operation.

- Safety valve. Connected to the return pipe. Performs emergency water release when the pressure rises above the established norm.

- Pressure gauge. This device determines the pressure of liquids and gases inside the boiler and pipes of heating systems; it is necessary for monitoring.

- Thermal switch . Shuts down equipment when it overheats. Connected to a temperature sensor located at the top of the electric boiler.

- Automatic air valve. It is located above the heating tank and produces an emergency release of air from the tank in case of excess pressure.

Types of electric boilers

Depending on the operating principle of the heater, all electric boilers are divided into three types.

Electric heating elements

The principle of operation is based on simple electrical heating of elements that give off their heat to the liquid. Heating element – heating element. Water or other approved liquids are used as a coolant, in accordance with the operating instructions.

Induction

Their action is based on the principle of electromagnetic induction. The heating element is a coil, inside of which there is a pipeline filled with water. When an electric current passes through the coil under the influence of an electromagnetic field, the coolant heats up.

Ionic

The working element in such structures are electrodes placed in a special aqueous medium, where the process of heating the coolant occurs when alternating current passes through it.

A feature of the use of this type of boiler is the mandatory monitoring of the electrical conductivity of the liquid and the adoption of measures to regulate it. The phenomenon of electrolysis and breakdown should not be allowed. Failure to comply with these requirements may result in equipment failure.

The liquid used cannot be used for domestic purposes. The heat carrier, which circulates through the pipes and enters the working tank of the boiler, comes into direct contact with the electric current. It is not recommended to carry out repair and commissioning work without the involvement of an experienced technician.

Repair work on electric heating boilers

Our company is often contacted by users faced with the following problematic situations:

- during operation, the boiler makes unusual noises;

- refuses to get involved in work;

- automatic shutdown is constantly activated;

- or vice versa – it doesn’t work;

- The boiler takes a very long time to heat up to the set temperature.

An ordinary user will not be able to independently determine the cause of the problem. To do this, you need to know all the technical features of the unit. Moreover, depending on the model, they can be individual. Sometimes the so-called “reboot” of the unit helps - that is, turning it off and then turning it on again after a quarter of an hour. However, this does not always happen, of course.

Quite often people come to us because their automatic security systems are constantly tripping. It is necessary to carefully inspect not only the boiler itself, but also the electrical wiring in the house. It is quite possible that the problem is hidden there. In any case, our specialist will check the error code being issued and carry out the appropriate repair measures.

Violation of the manufacturer's recommendations during operation of the electric boiler, the use of low-quality coolant, unqualified intervention in the equipment, power surges - all this and much more can lead to breakdowns.

We invite you to familiarize yourself with our prices -

What we recommend

As soon as there is a need to repair the electric boiler, under no circumstances should you try to fix the problem on your own. Modern electric boilers are very complex equipment. Inept actions can not only damage the device, but also cause irreparable damage to your health.

If your electric heating boiler starts to work “somehow wrong,” you should immediately disconnect it from the power supply and call our service specialists. The technician will arrive and conduct a thorough diagnosis of the equipment in order to identify the true cause of the problem. Then they will carry out qualified repairs of the electric boiler with a quality guarantee.