There are probably no owners who do not understand how important it is to use a heat-resistant cable in a steam room or sauna. The safety of visitors and the reliability of the building as a whole depend on this. You can, of course, try to save money and route the wiring in most rooms with regular VVG, and lay a real heat-resistant cable in the steam room. Or whether all the elements are made with heat-resistant wire, this is already decided by the owner or customer of the steam room construction. But in any case, it would be right to first understand the characteristics of the wire, and not try to buy and install in the steam room the first high-temperature cable you come across.

Classic heat-resistant high-temperature cable for a steam room in one core, there should be no metal or plastic braiding

Electrical wiring for baths and saunas

The main condition when choosing an energy cable is its thermal stability. It is also very important to remember that it is prohibited to install sockets in steam rooms. As for the installation of wiring in the bathhouse and steam room, due to high humidity it is necessary to create grounding.

When choosing wiring, you need to know about the main categories of premises available in the buildings in question:

- rooms with standard temperature conditions, in which you can get by with simple wiring, like in residential buildings;

- rooms where it is permissible to use only a heat-resistant cable for a bath, since the temperature in them reaches almost 170 degrees Celsius. The same cable should be used to operate an electric oven.

Heat resistant cable

The choice of cable products allows you not to experiment with homemade wiring and not once again risk your own health and the construction of the bathhouse itself. Moreover, 80% of all cases of fires in steam rooms and baths equipped with electric heaters are associated precisely with burnout of wiring insulation.

Special heat-resistant cable MMV

A fairly expensive type of wiring, it is actively used in industrial production for connecting electrical equipment to heaters and furnaces. It is believed that the cable can withstand short-term heating to a temperature of 500-700 ° C. The central core is made of nickel, so the wire will not burn out even if in contact with an open flame. The shell is three-layer, made of mica, fiberglass and a special fiber braid with impregnation.

MMV models have one significant drawback. This is a true heat resistant cable, but was designed to be permanently connected to a load. In a bathhouse or steam room, the heater is turned on and off periodically. With each cycle, the mica insulation wears away due to thermal expansion of the metal. In addition, low flexibility will require special installation techniques in the steam room, and adapters and sleeves are needed to connect the nickel core to copper wires.

Heat-resistant PAL wiring with a special type of insulation

This is a special type of cable designed to connect power to ovens and high temperature heating systems. Heat-resistant insulation is made of asbestos wound yarn covered with a film of fluoroplastic-4. Next, asbestos yarn is laid and silicone varnish is applied.

One of the most successful options for heat-resistant wire for a steam bath

The positive qualities of the cable include the fact that it can withstand heating up to 300°C for several thousand hours. The wiring easily withstands prolonged contact with gasoline, toluene, and any types of polar solvents.

The disadvantages include weak mechanical strength, so the connectors on the electric heater or boiler inside the bath must be fixed firmly. Able to withstand no more than 20 flexion-extension cycles.

This type of cable is inserted into the steam room through the wall directly to the terminal box. Ideal for a bathhouse if the wire is laid inside the wall.

Cable products PRKS and PRKA

Both cable models are made of stranded copper, coated with a heat-resistant silicone sheath that can withstand heating up to 250°C. It is believed that even with prolonged heating, the wiring does not melt and does not emit toxic gaseous products of polymer decomposition.

In addition, heat-resistant PVKV wire from the series can be used for steam bath equipment. Unlike the first two, the cable is designed for an increased supply voltage of 660V or 1140V. It is considered the most preferable option for laying heat-resistant wiring in places with extremely high levels of air humidity.

Heat-resistant wire RKGM

The classic version of a heat-resistant cable is a stranded copper core lined with silicone insulation and a fiberglass braided sheath. The disadvantages of the wire include a slightly lower level of maximum heating temperature; it cannot exceed 180°C. The advantages of heat-resistant wire include high resistance to mold and mildew.

A high-quality heat-resistant cable should only be copper, with silicon-silicone insulation and fiberglass braided

The attitude of bathhouse owners towards the RKGM cable is not always clear. Many people consider the wire to be too weak for the conditions required for heat-resistant circuits. The presence of fiberglass braiding is also not welcome, since it often “dusts” with glass microparticles.

In fact, the RKGM cable has a very thoughtful design:

- The fiberglass shell perfectly protects the silicone insulation from heat and mechanical stress;

- It does not absorb moisture and remains flexible even after 10-20 years of use.

Heat-resistant characteristics with a ceiling of 180°C are quite enough for a steam room, if the wiring in the bathhouse is laid and connected correctly. And most importantly, the cable is not subject to thermomechanical wear, which is often found in models with rigid insulation and varnish coating.

Wiring in rooms with standard temperature conditions

In such rooms it is recommended to use the following types of cables:

- AVVG;

- VVG;

- NYM;

- PVS.

Each of the above types of cables can be mounted surface-mounted or hidden. The only condition for their use is careful insulation of the cables, since the structure of the bathhouse or sauna itself is built from wood. Used for insulation: polyvinyl chloride, cross-linked polyethylene and other polymer materials.

Suitable for connecting lighting fixtures:

- PPGng-HF 3*1.5;

- VVGng-LS 3*1.5;

- NYM 3*1.5.

The cross-section of wires for connecting sockets should have an area of 2.3 square millimeters.

TECHNICAL PARAMETERS OF PRODUCTS - HPR PROTECTION

When protecting hoses, pipelines and cables from mechanical damage , various types of spiral protection are most often used: steel, plastic springs, wear-resistant textile protective sleeves for cables and hoses.

When protecting hose hoses, pipelines and cables from chemically active substances, it is best to use a protective sleeve for cables and hose hoses made of chemically resistant technical fabrics with sealed joints. For these purposes, sleeves made of Twaron fabric (DTG.90) and chemical-resistant fabrics with PTFE coating are offered.

The most common are protective sleeves for cables and high-pressure hoses from exposure to high temperatures - heat-resistant sleeves.

Types of protected equipment: high pressure hoses (high pressure hoses), cables, high pressure hoses, pipelines, wires, hoses, slings.

Table 1. Technical parameters of HVD Protection

| Product design type | Defence from: | Possibility of detachable connection | Features of production of HVD protection, size limits, mm | Average term batches of 100 linear meters. |

| Textile heat-resistant sleeve | Exposure to high temperature, particles of hot substances. | + | The internal diameter of the thermal sleeve is at least 20 mm. There are no restrictions on other parameters. | 5 working days |

| Textile protection of high pressure hoses and cables from abrasion | Abrasion, punctures, cuts and local abrasion | + | The inner diameter of the protective sleeve is at least 20 mm. There are no restrictions on other parameters. | 5 working days |

| Textile protection of high pressure hoses from chemicals. aggressive substances | Protection against acids and alkalis of various concentrations. | + | The inner diameter of the protective sleeve is at least 20 mm. There are no restrictions on other parameters. | 5-10 working days |

| Plastic spiral protection | Mechanical damage | — | from 13 mm to 110 mm (sectional diameter) | 10-20 working days |

* the data given in the table are statistical averages. For more detailed information on the issue you are interested in, please contact our specialists. Contact information is presented in the “ Contacts ” section.

MOST POPULAR RVD PROTECTION POSITIONS

Most often, textile protective heat-resistant sleeves, covers and casings with a double layer of material and multilayer are ordered from us (see below). This choice of customers is due to the high heat-resistant properties of such HPR Protection. As you know, one of the best heat insulators is air, and in the design of a heat-resistant hose with several layers, an air gap is formed - the temperature of the external environment cannot penetrate inside the hose and damage the hose, cable or hose located in the protective heat sleeve.

Production time 100 linear. meters of double textile protective sleeve is about 10 working days at an average production load.

Wiring in steam rooms

The steam compartments can only use heat-resistant sauna wire that can withstand elevated temperatures. If the cable insulation undergoes deformation under thermal influence, there will be a risk of fire.

The following types of cables can be purchased on the domestic market for steam rooms:

- RKGM 1*2.5;

- PVKV 1*2.5;

- PRKS 3*2.5;

- PMTK 3*2.5.

As for foreign manufacturers, it is best to use Olflex Heat 3*2.5 cable for installation. But its main disadvantage is its high cost, which significantly increases the demand for domestically produced products.

Heat-resistant shell

Cables designed for possible high thermal loads have a specific structure.

This allows security to be provided for a specified period of time. The non-flammable flexible cable contains single-component copper wire cores. The diameter of the basic solid wire can vary from 0.2 mm2 to 2.5 mm2.

The wire at the base is coated with a silicon-containing polymer material made of silicone. With a sharp increase in temperature and the action of a flame, the organic component of the insulating layer burns out, and the mineral component forms a dense monolithic layer.

The remaining inorganic coating of the electrical wiring is highly resistant to mechanical and vibration stress and allows the wire to conduct electricity under extreme conditions.

In some sources, polymer composites containing silicon are called ceramic-forming. Apparently, this is what the Russian translation refers to as a durable heat-resistant mineral coating. To some extent, it can be compared with ceramics, but the analogy is very conditional.

Some types of fire-resistant cables have a sheath made of composites based on magnesium oxides. This is a good solution due to the high heat-resistant properties of the insulator and absolute harmlessness.

Installation of electrical wiring and devices

Before installing a heat-resistant cable for baths and saunas, it is necessary to calculate the power that is required for the operation of all objects that consume electrical energy. Based on this, the heat-resistant cable for the sauna must have an appropriate cross-section that can withstand such a load.

A power of 1-2 kilowatts is enough to directly operate the lighting system. It will increase when installing additional accessories. Baths powered by an electric stove require at least 10 kilowatts of power to operate.

When installing any functional element that consumes electrical energy in a bathhouse or sauna, you must remember the safety rules and turn off the electricity supply.

The purchase of power cables, sockets, switches and lighting fixtures should be made in specialized stores to minimize the risk of purchasing defective products. There, sellers, taking into account the structural features of the bathhouse or sauna, can help draw up an installation diagram. It will be enough to provide high-quality photos of all premises.

Electrical voltage in the sauna

Bathhouse owners often have a question: what voltage to choose? You don’t have to rack your brains and use normal household voltage, i.e. 220v.

However, for this it is necessary to fulfill certain conditions:

- Electrical wiring lines must be protected with differential circuit breakers or RCDs.

- The power supply must be made with the TN-CS grounding system.

- The bathhouse must have a SUP potential equalization system.

If for some reason the conditions listed above are not met, then it is necessary to supply the voltage in the bath through a step-down transformer, for example, you can use YaTP-0.25 220/36V

A step-down transformer

Note! The step-down transformer must be located outside the sauna room.

Laying wiring

It was already mentioned above that cables in a bathhouse or sauna can be laid either openly or hidden under various protective elements. The closed method is preferable, but there are nuances here too.

According to GOST standards for working with electrical wiring, cables cannot be laid in metal tubes and corrugations. Also, metal sheathed cables must not be used. The reason for this ban is that the metal is susceptible to corrosive effects when exposed to moisture.

Cable for steam room in bathhouse

The steam room is considered the hottest and most thermally loaded room in the entire bathhouse. The walls of the steam room, depending on the design of the room, can heat up to 120°C, and next to an electric heater, up to 180-250°C. It is clear that in such conditions you should only use a heat-resistant sauna cable.

Advice! Before buying a cable for a steam room, it will be useful to familiarize yourself with the requirements of GOST R 50571.12-96, part 7. It is this document that describes the basic requirements for planning the wiring and installation of a heat-resistant cable for a bath.

Cold and hot zones in the steam room according to GOST

The document is useful and will certainly come in handy when drawing up a project for the future bathhouse as a whole, and when agreeing on a building permit.

According to GOST, the internal space of the steam room inside the bathhouse is divided into four zones:

- The first one is the hottest. Its boundaries extend at a distance of half a meter around the electric heater. The air temperature is maximum, so you can connect electrical appliances only with a cable that maintains temperatures up to 250°C;

- The coldest zone No. 2 is the space between the floor and the shelf at a height of 50 cm. Normally, the cable located in this part of the steam room can be anything, since the documents do not establish a requirement for heat resistance;

- The third zone is actually the space where visitors are located; the requirements for insulation of wires and cables are such that the shell must withstand heating of at least 170 ° C;

- The fourth zone is located almost under the ceiling of the steam room; this is the most humid and hot place, except for the electric heater. The cable must be heat-resistant with a limit of 170°C and at the same time withstand the aggressive effects of hot water vapor inside the steam room.

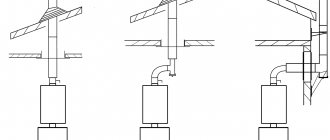

In addition, electrical wiring laid inside the steam room should not have a metal braid; accordingly, it cannot be laid inside metal cable ducts or pipes. The most common method of installing cables inside a sauna is external wiring on ceramic chips. Despite being somewhat archaic, this is a reliable and very convenient way to install a heat-resistant cable in a steam room, which will provide visual control of the insulation and protection from hot bath walls and condensation.

It is better to install wiring in a steam bath on insulators

If the appearance of the external wiring does not fit into the interior of the room, then the cable can be routed through the wall of the steam room from the cable entrance in the bathhouse directly, using ceramic sleeves or liners.

Installation of sockets and switches

After the heat-resistant cable for the sauna has been laid, you can begin installing sockets and switches. It was said above that these elements of the electrical network can be used throughout the entire building except the steam room itself.

It is also unacceptable to install distribution panels in rooms with high humidity. In addition to steam rooms, the same ban applies to showers. All other rooms in the house can be equipped with electrical network components without any restrictions.

Specifications

A heat-resistant cable is an electrical conductor enclosed in a sheath of heat-resistant material. This insulation is specially made for the operation of wires and cables in rooms with high temperatures. The insulation is halogen-free, resulting in low smoke emissions. The sheath of these cables and wires is environmentally friendly.

Technical indicator of the product

The RKGM wire has the following characteristics:

- Rated alternating voltage - up to 660 V.

- The cross-section of the stranded core is from 0.75 to 120 square millimeters.

- Flexibility class - from 4 and more.

- The smallest bending radius during installation work is double.

- The operating temperature range is from minus 60 to plus 180 degrees Celsius. The gasket temperature should not be less than 15 degrees below zero.

- The warranty period is 8 years.

- Resistant to fire.

Kinds

Installation of lighting system

Also, when the heat-resistant wire for the sauna is laid, you can begin installing lighting fixtures. It is unacceptable to use standard lamps and light bulbs for the same reason as with an energy cable. Increased importance and temperature will lead to rapid failure of these elements.

The luminaires used must be sealed so that moisture and steam entering do not increase the risk of short circuiting and, as a result, fire. Also, if the lamp is heated unevenly, if steam gets under the lampshade, it may burst, which can lead to injury to visitors (read: “Which lamps for saunas and baths are the most practical and safe”).

When installing the lighting system, it is necessary to take into account that the lighting of the steam rooms should not be too bright. Usually matte lampshades with screwed-in 60-watt light bulbs are used.

International designations

In the international market of heat-resistant wires, certain abbreviations have been adopted for each type of product. For example, the abbreviation SID denotes a conventional solid single-component core; SIF – fine-wire modification; SIFF – products with super thin cores. Non-flammable flexible wire is marked SIZ in the international professional community.

The presence of the combination of letters GL in the designation indicates the presence of a braid made of heat-resistant glass fibers. In practice, a significant number of abbreviations are used.

When purchasing products, pay attention to the designations. If necessary, all suppliers can provide clarifications and provide a fire safety certificate. According to international standards, the document indicates:

- fire resistance;

- tendency to spread fire;

- the amount of halogen-containing gases released;

- volume of acid gases indicating pH and conductivity values;

- the value of the smoke density values when the sample burns under specific specified conditions.

After reading the information provided about the heat-resistant properties and other characteristics of the wires, buyers’ doubts will disappear.