I made a homemade product from an ordinary teapot. Now I'm the "master of steam"

I recently took apart a kettle for 300 rubles from Svetofor and found out why it was so cheap.

After disassembly, a brilliant idea came to me. Why not make a steam generator out of it for household needs. The fact is that a ready-made, factory-made device costs more than five thousand. Therefore, I decided to start assembling a homemade product from a cheap teapot. The first step is to remove the spout by stripping off the contact solder. But that's not the problem. The wall of the kettle is only 0.2 mm and when a piece of “foil” was removed, holes formed in the place of the welding pins.

Scroll through the galleries, bright photos await you there.

These holes need to be sealed somehow. They are of no use to us. By the way, we should kiss the hands of the person who invented cold welding. She is not replaceable in this place at all

. We sculpt it, making a welding pancake, according to the instructions. After sealing on both sides, I left the welding process alone for a day.

The next technological process is to drill 20mm holes with a step drill. One "hole" will be used to connect the oxygen hose. And the second is for filling water and monitoring the pressure inside the generator.

The next stage is the assembly of fittings onto the mounted threads. I use FUM tape. Because the working medium is gas. In our case, par.

Some attentive readers are wondering: “How did you make the lid? Did you attach it to the kettle?” Everything is very simple. But somehow the photos were not saved on the phone. Precisely at this moment. I promise to get to the garage and take rosary photos of the cover. Look for them in the comments.

Next, I need to find out during the installation process whether I damaged the main function of the kettle, boiling water. I pour water and close the lid. I turn it on. It's boiling.

All that remains is to connect the oxygen hose, put on the goggles and test our “hirabora”.

Tests have shown that sufficient steam is produced. You can watch the work process in the video.

Why is it needed?

- Steam difficult stains.

- Heat something explosive without fire, steam a tank for example.

- Steam for baths, hammam.

- Remove ice

This is the first thing that came to my mind. There are probably thousands of uses.

Attention

The author of this text is not responsible for your actions when converting an electric kettle into a steam generator or other homemade products. Working with electricity and high steam temperatures can lead to unexpected situations. Be prudent and do not repeat these actions.

Do you think this is a good homemade product? Waiting for your comments. If you have any questions, ask, I will answer.

With uv. Timofey Mikhailov.

Article: “Electric kettle for 351 rubles in the “Svetofor” -

Link .

Source

Purpose of the device

A steam generator is a product that works by supplying a high-power steam jet. In the container of the device, water is converted into hot steam as a result of high temperature. Due to the high pressure, steam passes through a large number of small holes at once.

Thanks to high pressure, the device performs the following functions:

- Cleaning. Cleans carpets and upholstered furniture.

- Ironing. Quickly smooths out wrinkles without leaving marks on the surface.

- Cleaning hard surfaces. Cleansing fatty residues, plaque and other contaminants.

- Disinfection. Materials that are difficult to wash can be disinfected.

- Car washing and cleaning. Cleaning and disinfection are carried out using a steam generator.

Steam washing is an effective alternative to car cleaning. For example, if there is persistent contamination on the surface, then after washing with heated water the quality of cleaning will be lower than with steam. In a steam device, high temperature acts in conjunction with high pressure. The device is used in the following cases:

- cleaning the interior or for washing ventilation or the engine, where there is unwanted moisture ingress;

- when careful cleaning is necessary, without consequences, or when there is not a lot of free space for a full wash;

- removing grease stains from the car interior;

- disinfection of a car, its interior or air conditioner.

Technical capabilities

Heat exchangers used in cedar barrels to create heated moist air are highly efficient and economical. These qualities are directly related to the low power rating - 2 kW, which is quite enough to quickly heat the air and maintain a stable temperature inside the phyto-barrel without the risk of overloading the electrical wiring.

The safety of the device is another pleasant point, confirmed by a special certificate. The reliability of operation of the steam generator is also due to the grounding of all components of the structure and the protection of the heating elements by equipping them with a level sensor, which allows the device to be automatically turned off if there is insufficient water in the tank. The inability to break down if the device is damaged or clogged is ensured by an overpressure valve.

Along with all the listed advantages, it is possible to control the device using a stand-alone remote control, which is placed on the wall of the steam room in any convenient place.

Types of device

Thanks to this device, you can make your life much easier. There are 5 types of devices, the principles of operation of which differ significantly from each other:

- Electric ones that operate from the network. If this is a non-industrial model, then you will need a 220 V outlet, and if it is an industrial model - 380 V.

- Induction steam generators. During operation, the electromagnetic field is transformed.

- Stoves. They use solid fuel such as coal or wood for heating.

- Ultrasonic, the principle of which is to evaporate steam using sound vibrations.

- Electrode steam furnace. The heating element is the electrodes.

At home, it is best to make an electric model yourself. To make it you will not need many parts and time. Moreover, if you search well in the garage or barn, you can easily find all the suitable elements.

DIY steam generator

It’s not difficult to make a structure yourself; the main thing is to prepare the necessary elements and tools, and also divide the whole process into stages. First of all, a container is selected, then heating elements are installed, water inflow and steam are taken out. Upon completion of installation of the structure, the equipment is tested.

Selection of capacity

The performance and mobility of the equipment depends on this parameter. It is best to choose a metal container that has good thermal insulation. This will reduce the likelihood of burns due to accidental contact. You can make a structure from a canister, a bucket or an electric kettle. The main rule is the tightness of the lid. The dimensions of the tank are selected depending on the planned steam.

A homemade steam generator of maximum power is made from a gas cylinder or an old fire extinguisher. They are first cleaned of residues and a pipeline is constructed through which steam will be supplied.

Heating elements

Heating parts are an important step in making a steam washer with your own hands. First, determine how the water will be heated: using a gas or electric stove, or through an electric heating element. The latter method is safer and simpler. You can use an element from an old electric kettle. If the tank is large, then two or more heating elements are used. If you use a gas cylinder, then a heating element for boilers is suitable for it.

Install the part at a height of 1 cm from the bottom of the container. Carefully drill holes with the required diameter and insert a bolt into them, which is secured on both sides with washers and nuts. Using gaskets made of heat-resistant silicone, they provide a tight seal so that water does not leak out of the cracks. Gaskets are fixed on both sides. Then install the heating element and draw water to check for leaks.

Generator installation

Before starting to assemble the structure, it is necessary to develop drawings of the device in advance and prepare additional parts and elements. These are pipes, control system and fittings. For large containers, it is better to make the water supply automatic. Then the heating element will not burn out. For these purposes, the pipeline is made with a check valve and a shut-off valve. If necessary, attach a cleaning filter. Do-it-yourself steam washing is installed in several stages:

- Preparing the tank. First, open the valve to allow the remaining gas to escape. Then the valve is removed and the inside of the container is washed well with warm water and detergent. The procedure is carried out several times until foreign odors are completely removed.

- Attaching heating elements. It is not recommended to use welding when attaching the heating element, since if the element burns out, it will be very difficult to replace it. Fasteners must be able to withstand high pressure in the tank, as well as high temperature and moisture.

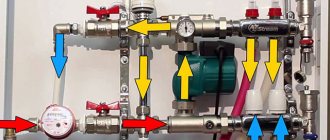

- Installation of fittings. At the top of the cylinder there are 4 branches: a pressure control valve is installed on one of them, the second is for supplying liquid to the tank, a pressure gauge and a temperature sensor are installed on the third branch, which monitor the heating temperature and pressure, and the fourth is for monitoring the water level in the tank. The last branch is placed below all the others.

- Additional installation points. This includes legs, a stand for the structure, or wheels for ease of movement. You can additionally make a protective casing to avoid accidental contact with the hot body.

- Steam supply system. It has the form of a pipeline, where the nozzle is taken with a smaller diameter.

It is important to think about the security system in advance. It is necessary to think about it so that when the maximum temperature or pressure is reached, the system itself turns off the heating.

Automatic shut-off sensors are sold at hardware stores. Therefore, there is no need to develop them yourself.

The main reasons for the breakdown of steam generators

A steam generator is a device, and like any unit, it fails. Among the most common malfunctions are: overheating of heating elements, burnout of the housing, as well as loss of integrity of the hoses supplying water.

Important! When assembling the device yourself, it is important to consider the sequence of installation of the elements and their exact location. Despite the simple design of the unit, it is a powerful tool associated with a risk to life.

Working with the unit requires great care. During work, your habit should be to monitor the pressure in the container. If the permissible values are exceeded, it must be vented. In addition, do not leave the device switched on in a room where children are present. Is it dangerous. When working with equipment, do not allow it to idle without water. The process of supply of cooled liquid must be continuous. This will protect the heating elements from overheating, and the device from overheating.

Before operating and turning on the device, check the tightness of both the tank itself (there may be one or two), as well as connecting and control valves, hoses and supply systems. Sometimes a simple lack of water in the network can lead to damage to the device. Check the serviceability of the supply and restrictive equipment and the self-shutdown unit. Other causes of failure include:

- Poor water quality.

- Incorrectly selected heating element power.

- Scale on heating elements.

Advice! Vinegar or citric acid will help fight scale. To do this, just dilute the water in the proportion of 1 teaspoon of powder per liter of water and boil it in a container.

- Lack of fluid supply during operation.

A wood-burning steam generator is an excellent alternative to electric ones if you have additional space

If you follow all the above recommendations, then the device, even if assembled with your own hands, will serve you faithfully for many years. And at the end of the article, we suggest watching a video about how the steam generator works.

Leave your questions and comments below the article. We will be glad to receive relevant advice that will be useful to our readers.

Most lovers of steam baths are accustomed to the need to heat the sauna and pour water on the stones to obtain steam. But modern technologies make it possible to speed up the production of steam using steam generators. A steam generator is a container filled with water for the purpose of evaporating it. Such devices are used mainly in baths, and also in car washes. Steam generators have a number of advantages:

- compactness;

- mobility;

- ease of operation.

In addition, such a device can be made with your own hands, since it has a simple design.

How to use a steam generator

The device is simple to use, somewhat reminiscent of an iron. Before work, you need to fill the tank with water, then connect the device to the electrical network and wait until the water boils and it can be used for work. Once ready, bring it to the surface that needs to be treated and press the steam button.

The liquid is refilled periodically. This is done carefully to avoid scalding from hot air. The steam in the container is under pressure, so when the lid is opened, hot air is released.

When working with a steam generator, you must adhere to safety precautions and follow simple rules:

- use the device indoors to avoid penetration of precipitation;

- Avoid letting hot steam come into contact with exposed areas of the body to avoid burning the skin;

- do not operate the device when your hands are wet;

- It is forbidden to clean the steam generator under running water;

- Regularly clean the heating element from scale.

Any heating element of the device must be insulated, and the circuit must be grounded.

It is recommended to use boiled, filtered or distilled water in the device. This will reduce the amount of scale formation and allow the device to work longer.

A steam generator made independently at home will greatly simplify cleaning and washing your car at home. Despite the fact that the homemade device is not as powerful as the factory installation, it does an excellent job of cleaning the car interior and some parts. During operation, it is important to control the timely supply of water and monitor the sensors to prevent damage to the device.

Source

Features of assembling a solid fuel steam generator for a home using wood or coal

To assemble a classic wood-burning boiler, metal pipes of different diameters are used. This is somewhat reminiscent of a layered cake with the widest layer at the bottom, this will be the loading chamber.

The device of a steam generator with a solid fuel combustion chamber

Some craftsmen say that the efficiency of a potbelly stove is much higher than the efficiency of electric steam generators. But that's not true. It’s just that assembling such a boiler is less expensive. The next layer is the water tank, it is located directly above the firebox. An adapter with a pipe is welded to it, through which steam will flow into the bathhouse. If you want to learn more about how to make a solid fuel steam generator with your own hands, watch this video.

Types of steam generators

With this device you can make your life much easier.

Steam generators perfectly disinfect and cleanse contaminants, help defrost pipes and a car engine in cold weather, and will also become an indispensable assistant for cleaning filters.

These devices operate differently, so it is customary to distinguish five types of design.

- Electric , powered from the network. Industrial models usually require connection to a regular 220 V outlet, while industrial models require a 380 V outlet.

- Oven steam generators use solid fuel (coal, wood) as heating.

- Electrode steam oven , which uses electrodes as the heating element.

- Induction steam generators, the operating principle of which is the transformation of the electromagnetic field.

- Ultrasonic steam generators evaporate steam using sound vibrations.

The easiest way to make an electric steam generator yourself is to use suitable elements. A steam generator for a car can be made from trash, which is easy to find in any home.

Design and principle of operation

The simplest products consist of:

- water tank;

- heating element

- supply tube.

Industrial units have many additional elements that provide expanded functionality of the device. For home use, such equipment will definitely come in handy, but the main disadvantage will be the high price. That is why you should pay attention to the possibility of making a steam generator for cars and other household needs with your own hands.

The essence of the steam generator:

- Water is supplied to the reservoir, preferably filtered and cleared of metal suspensions. This will increase the service life of the homemade device and help avoid frequent cleaning of the nozzle.

- When the heating element is turned on, the water begins to heat up and evaporate, entering the expansion tank, from where it exits through the pipeline through the nozzle.

The resulting steam can be directed to a contaminated surface, and can also be used for a sauna or Finnish bath.

Often, steam can remove oil stains or deeply ingrained dirt.

In most purchased models, you can adjust the temperature and intensity of evaporation. Despite the fact that home models do not have this advantage, they also cope well with their functions, and most importantly, they are affordable.

Areas of application

Steam generators have found their greatest application in:

- Food industry (heat treatment, sterilization, defrosting, pasteurization of food products; heat treatment of various units, parts and equipment used to produce and maintain the required temperature, disinfection of utensils). This equipment is in greatest demand in this industry.

- Transportation of various substances (food, chemicals). Thus, steam generators maintain the required temperature and heat the premises if transportation occurs in the cold season.

- Construction . Thanks to the steam generator, building materials (foam plastic, asphalt) are created and their required temperature is maintained. In winter, it helps clear ice from construction sites and massive materials.

- Woodworking industry . Used in the paper making process. Wood and materials made from it in large quantities can be dried using an industrial steam generator.

- Medicine and cosmetic industry . A steam generator is perfect as a disinfectant. It can be used to sterilize clothing, materials, instruments, and containers.

- Agriculture . The use is widespread in the manufacture of feed.

- The process of work of laundries and dry cleaners . Steam helps remove stubborn stains from clothes and shoes.

Also, these devices can often be found in rooms with dry air to maintain the required level of humidity. Almost no sewing workshop can do without such a device.

Baths and saunas often use steam generators in their work as equipment that can get rid of contaminants, as well as as disinfecting equipment. Power plants often use steam generators for their operation. They are also used to heat pipelines.

Each sphere uses steam at different pressures. When choosing a device, it is important to consider where it will be used and whether it will meet all the requirements of the industry.

DIY steam generator

Having decided on the main question - how the water will be heated, you can proceed directly to assembling the unit.

Selection of capacity

This parameter largely determines the performance and mobility of the equipment. To heat water, it is advisable to use a metal container with sufficient thermal insulation to reduce the risk of burns due to accidental contact during use. This could be a metal canister, a bucket, or even an old electric kettle. Depending on the required volume of steam and operating time, such a device requires periodic addition of water.

You can make a maximum power steam generator with your own hands from an old gas cylinder, after first cleaning it of possible residues and constructing a suitable pipeline for supplying steam.

It is on the example of using a gas cylinder (option - an old fire extinguisher) that our guide will be based.

Where it all begins

At one time, I had a desire to equip an individual microbath, or phyto-barrel as it is also called, in my city apartment; my wife really liked it.

There were no problems with the barrel itself; knocking down a wooden structure made of planed tongue-and-groove boards doesn’t require a lot of intelligence or special skill, but the steam room requires a steam generator. My first thought was to buy a production model.

A modern steam generator for a bath is a reliable and durable device, and most of these devices have many operating modes, they are equipped with sophisticated protection and control systems, but at that time I was not ready to pay that kind of money for them.

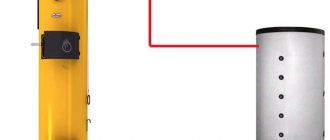

Wall-mounted steam generator "Harvia".

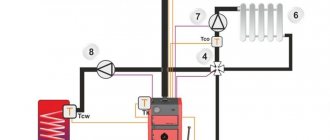

For those who are interested, below I have tabulated popular models and also placed a diagram that clearly shows the operating principle of an industrial steam generator.

| Serial models of steam generators | |||

| Model name | Power consumption | Dimensions | Price |

| Harvia Helix HGX11L | 10.8kW | 155x320x600 mm | 57 t/rub |

| Harvia Helix Pro HGP30 | 30kW | 320x490x560 mm | 166.5 t/rub |

| Helo HNS 60 T1 | 6kW | 160x380x520 mm | 60 t/rub |

| Helo HNS 140 T1 | 14kW | 160x380x520 mm | 70.5 t/rub |

| TYLO Steam 2/4/6 | 2 – 6kW | 445x130x415 mm | 74 t/rub |

| TYLO Steam 12 | 12kW | 570x224x485 mm | 135.5 t/rub |

Scheme of operation of one of the serial models of the steam generator.

Having studied the structure of the steam generator, I realized that it is not so difficult to make it with my own hands, moreover, such a device would not be superfluous in a real wood-burning sauna, plus in my case it could be useful in the apiary for melting wax out of frames.

Unfortunately, I was not able to make a universal homemade steam generator that would be suitable for all occasions; instead, I assembled several steam generators, each of which was “tailored” for a specific purpose.

Details of one of the serial models of the steam generator.

Testing and Troubleshooting

After assembly, the homemade steam generator must be properly tested. The tightness of the container and installed fittings, the speed of heating the water and the operation of the sensors are checked.

To connect to the network, it is preferable to install an RCD ( residual current device ) and a grounding circuit. After this, you can check the heating rate and the volume of steam released.

Possible operational problems are eliminated by adjusting the valves and debugging the automatic safety system.