Installation and connection of equipment

One of the most difficult aspects is running a pipeline with a pump into a deep well. Here it is important to correctly connect the unit to the pipeline and securely fasten it to the cable. The installation technology is as follows:

- Unwind and spread the submersible section of the HDPE pipe on the ground. Connect its end to the pump connection via a compression fitting.

- Tie a cable to the eyes of the pump unit and secure it with a special clamp.

- Connect the cores of the power cables with crimp sleeves and perform hermetic insulation using heat-shrinkable tubes (they are put on the ends of the cut cable before joining).

- Tie the wiring to the pipe with plastic clamps along the entire vertical section.

Advice. Before lowering the pump into the well, it is advisable to check the functionality of the system, since in case of problems, it is much more difficult to remove a unit filled with water.

Having tied the second end of the cable to the eye of the well head, lower the pump to the required depth. Carry out the descent carefully, without jerking, so as not to drop the unit. When finished, place the head on the casing. How to do this job correctly is shown in the video:

It is somewhat easier to install an individual water supply from a well. To do this, it is enough to make a hole in the concrete ring at the level of the bottom of the trench and pass a pipe through it, then place a 90° elbow to connect the vertical section. To prevent the plastic from rubbing against the concrete edges of the hole, it is advisable to install an iron or plastic sleeve into it, sealing the opening with a building mixture for swimming pools. Water intake is organized in the same way as in a well.

Benefits of Well Water Supply

Water supply from a well is widely used for country private houses and cottages and here’s why:

- digging a well costs much less than drilling a well;

- Any person with the proper skills can dig a well with his own hands;

- a properly constructed well will provide water for many years, and completely free of charge (not counting, of course, the cost of supplying water to the house);

- You can dig a well without official permission.

It should be noted, however, that, compared to water from a well, well water, due to its close location to the surface of the earth, can contain quite a lot of impurities. It is quite suitable for technical needs and irrigation, but in order for it to be used for drinking, it is advisable to purify the water by installing a filter system. In addition, the well needs periodic cleaning (experts recommend doing it at least once a year).

Advantages of winter external water supply

When installing a surface-type pumping station in an insulated caisson (or basement of a house), it is more advisable to arrange an external water supply system according to the winter scheme. Even if the house is intended for seasonal living, and in winter it is visited “occasionally”, the water from the external part of the water supply system can not be drained, but only for the internal water supply. In this case, after the house is “heated”, it will be much easier to start the pump and water supply system.

A submersible well pump for water supply at home does not have the same starting difficulties as a suction pump. But the fact that the external part of the water distribution circuit in a private house from the well is in working order and is reliably protected from “defrosting” serves as an argument in favor of this choice.

For water supply in winter, it is necessary to insulate both the “top meter” of the well and the pipe entrance through the foundation Source dd-restaurant.ru

There is, of course, the option of installing a shallow winter water supply system with a heating cable, but it is better to dig a trench once for pipes deeper than the frost line than to purchase more expensive jacketed pipes (with insulation and a heating cable) and spend electricity heating the external pipeline. In addition, this option is suitable if people live in the house all the time - when leaving for more than a day (the time depends on the air temperature, depth and thickness of the insulation), the water from such a water supply must be drained.

Ready system on video:

Pump selection

A pump for supplying water to a private house from a well is the main element, and the consistency of the water delivery system depends on its correct choice. Pumps are :

- Superficial . The pump itself remains on the surface, and a special suction pipe is lowered into the water.

- Submersible . They are completely immersed in water to a depth, not reaching the bottom by about 1 meter, otherwise it will suck in sand, which will “kill” any, most modern equipment.

The first option ( surface pumps ) is convenient only in the spring and autumn, at summer cottages. The pumps are easy to install, raise water to a height of no more than 8-9 meters, are cheaper and have low efficiency. But they work well only at temperatures not lower than + 4C.

For wells with a depth of more than 9 meters, a submersible pump is best suited. If the water level changes, it is better to buy a pump model with a signal float. If the water level drops to a critical level, the pump automatically turns off.

Performance is an important selection criterion. It is calculated based on water consumption needs at all open water points.

But it’s not worth buying the most powerful pump if the water consumption is average. Running it “idling, dry” will increase the likelihood of a quick breakdown.

What types of pumps are there:

- Vibrating . Budget, not complicated, noisy. Not suitable for automatic water supply systems. They work poorly in dirty water, the pressure is good, low productivity, short-lived and burns well. Suitable for temporary, summer water supply options (Malysh-M BV 0.12-40 10m (240 W).

- Centrifugal . The best option, meets most of the characteristics required for wells. They work at great depths, have good performance, and are not noisy. Expensive and complicated.

- Vortex . They have high performance qualities, are simpler in design, cheaper than centrifugal ones, survive the ingress of air, but cannot tolerate even the slightest impurities in the water.

Preparing for work

Before you take on such important work, you need to think carefully about a few things:

- in what mode do you want to supply water - winter or summer, only for irrigation or also for drinking;

- what are the possible volumes of water consumption - how large is the area, how much water is needed daily for irrigation, are there any greenhouses and how much moisture will they require for irrigation;

- what source of water supply can you choose - your own well, a centralized one or a well that is on your site or not far from it. To do this, it’s a good idea to take a map of the area or ask your neighbors where they get water for irrigation and other purposes;

what are the features of your climate - is there a risk that the water in the well will dry up in especially hot months, is a backup source needed in these cases; what are the features of the internal structure of the site, where it is necessary to stretch pipes, and where you can use a regular hose; is it possible to supplying clean drinking water to the house and utility rooms; finally, the budget for all work - how much do you have.

IMPORTANT. The price factor, of course, is important, but not decisive. The fact is that such an important job as making your own water supply system at your dacha from a well is not done for 1 year. You are making an investment for a very long time, and if you skimp on the quality of materials and mechanisms, you can later overpay on their repair and replacement with others.

Which pipes are suitable?

Just 20 years ago, steel pipes were indispensable. Today they are almost never used: too expensive and impractical. Iron pipes rust very badly. Therefore, they came up with an alternative - plastic pipes. But plastic is different. Let's look at products made from it.

HDPE products

The most popular material for pipes is low-density polyethylene. Their advantage is that they do not require additional installation. Fittings for HDPE assembly are threaded and hand-tightened.

The advantages of the material are as follows:

- The term of use is 50 years.

- They do not corrode and do not rot.

- If the water in them freezes, the pipes will not burst; when they thaw, they will return to their previous position.

- Smooth inner surface. This is necessary so that less pressure is lost during transportation and deposits do not accumulate on the walls.

- Convenient assembly.

HDPE, of course, has several disadvantages:

- Poor heat tolerance (except for cross-linked polyethylene pipes).

- Low strength - you cannot walk on them.

HDPE pipes are welded with an “iron” - a special apparatus; they can also be connected using fittings. Tees, adapters, pieces of pipes are connected using threaded connections. This connection may seem fragile, but it is not.

Pipes differ in operating pressure:

- L - light, up to 2.5 atm.

- SL - medium - light, can withstand up to 4 atm.

- Medium - C, up to 8 atm.

- Heavy - T, from 10 atm and above.

For the installation of water supply systems, classes SL and C are used. The diameter of the pipes is 32, 40 and 50 mm. Pipes also differ in density: 63, 80 and 100 PE.

PVC materials

Another type of pipe used for water supply is polyvinyl chloride. They are cheaper than HDPE pipes and are connected by welding with glue. The seam can withstand 12-15 atm. The service life is the same as that of HDPE.

Characteristics of the material:

- Used at temperatures from -15 degrees to +45.

- Does not tolerate freezing well.

- Moderately sensitive to ultraviolet.

PVC pipes have several very important advantages:

- Easy pipe installation, flexibility.

- Smooth inner surface.

- Not affected by corrosion.

- Low flammable.

Like any material, PVC pipes have their disadvantages:

- The upper limit is +45 degrees.

- Difficult to dispose of because it is harmful.

- Not durable.

Cracks and scratches greatly reduce the strength of PVC pipes; threaded connections are impractical. If laying pipes around a site is an easy task, then piping equipment is a difficult task. Because of this drawback, the use of the material for external water pipes is limited, so such pipes are used more often for internal wiring, where the risk of damaging the pipes is minimal.

Polypropylene products

Another material that can be used as pipes is polypropylene. It also belongs to a type of plastic. Pipes are connected using couplings and soldering - there are special soldering irons that are used to heat the plastic on two elements, then connect them. The result is a monolithic structure. You don’t even have to buy a soldering iron; you can rent it from a store that sells pipes and fittings for them.

Polypropylene pipes have one drawback - expensive fittings.

Summer water supply from a well

Price from 31,600 rub.

+ Convenient systems with full drainage for the winter

SUMMER water supply from a well

requires mandatory conservation of the system in the fall. The remaining water will damage equipment, pipes, taps, and plumbing if it freezes. Since pipes from the well are laid at a shallow depth before entering the house. Summer water supply from a well is the cheapest option for water supply to a dacha. No large excavation work is required, easy to install and maintain. Installation of a house water supply system from a well takes 1 day and you receive cold and hot water. 5 year labor guarantee.

An engineer’s visit to the Customer’s site for consultation and drawing up an estimate costs 1,000 rubles; when ordering a water supply system for a house from a well, the cost of the visit is included in the cost of the system.

View the estimate for summer water supply from a well >>

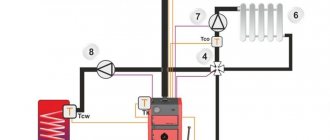

Detailed diagram of the water supply system of a country house

You can bring water into the building according to certain instructions.

- First, it is laid underground or on its surface.

- Then they are lowered into the well, where a deep pump is installed.

- When laying an external pipeline, it is advisable to use a small number of butt joints; in general, it is better to make a single thread from the well to the entrance to the house, and it must also be insulated.

- Pipeline insulation is made from various materials, the simplest is min. cotton wool

- After the deadwood is wound up, the equipment piping begins.

- If we talk about the pumping station, which will be located inside a residential building, then it is advisable to organize your own premises.

- Wiring around the house can be made from polypropylene pipes.

- It should start from appliances with greater consumption capacity (for example, a toilet or shower) to smaller ones (sink and sink).