Types of solid fuel boilers for heating a private home

Differences in solid fuel boilers are associated with:

- Resource supply technology.

- Existing combustion system.

Pellet

Automatic loading is done from the hopper. Depending on its volume, one bookmark is enough for a period of from a week to a month. Since the solid fuel boiler works independently, it is possible to adjust heating modes depending on the time of day and day of the week.

Photo 1. Solid fuel pellet boiler. On the right side of the device there is a hopper for loading pellets.

Automatic models of solid fuel boilers operate only on pellets. These are wood pellets that are obtained by pressing sawdust, shavings, bark, husks and other similar wood waste. Pellets do not burn, but smolder for a long time, releasing a significant amount of heat. Therefore, they provide a fairly high efficiency, up to 90-95%.

Important! Due to automation, a constant source of electricity will be required. In case of outages, it is advisable to purchase a UPS

With manual loading

Other types of solid fuel boilers are loaded only manually. The heat source is:

- firewood;

- coal;

- piece;

- coke;

- briquettes;

- peat.

The service life of one fill depends on the volume of the fuel chamber and the combustion technologies used. For convenience, the boiler door is tilted. This makes loading and further maintenance of the device easier.

The disadvantage of such models of solid fuel boilers is the impossibility of automatic operation. Periodic human effort is required to maintain the process.

But dependence on electricity is reduced. In addition, different types of resources are used and it is easier to select the most available ones in a given area.

Reference. There are models of solid fuel boilers with automatic and mechanical temperature control. In the latter case, a mechanical draft regulator (damper) is used. It does not depend on the availability of electricity.

Solid fuel boilers with manual loading are divided into types depending on their design features. The following technologies are distinguished:

- classical;

- pyrolysis;

- long burning.

Classic

Such solid fuel boilers do not use technologies that increase the duration and efficiency of combustion. Therefore, the wood in them burns out quickly, within a few hours.

The efficiency of such boilers is low, since a significant part of the heat escapes through the chimney.

The advantages of such models of solid fuel boilers include low cost due to the fact that the internal design is simple.

Pyrolysis

As the name suggests, pyrolysis combustion technology is used. During primary combustion with a lack of oxygen, pyrolysis gases are formed, which are also capable of burning, releasing a significant amount of heat.

The design is more complicated compared to the classic version of solid fuel boilers. An additional combustion chamber is located above the main combustion chamber, where gases are collected and burned.

Thanks to this, the following increases:

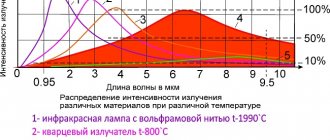

- efficiency (up to 85-95% depending on the type of raw material);

- duration of one bookmark.

Other advantages of such solid fuel boilers include precise temperature control and less soot and slag. The disadvantages of boilers are:

- High price (pays off during operation).

- The need to use only dry fuel (otherwise the pyrolysis process will not begin).

Photo 2. The internal structure of a solid fuel pyrolysis boiler and the principles of its operation at different stages.

Long burning

Solid fuel boilers of this type use a different technology. Firewood does not burn from bottom to top, as in the classic version, but from top to bottom. Burning becomes slow and efficient. Therefore, adding firewood to the boiler lasts for up to a day or more, and coal for up to a week. Like pyrolysis boilers, these solid fuel boilers operate on all types of wood resources.

Video description

The operation of a coal boiler is shown in the video:

Wood

In addition to firewood, solid fuel boilers can operate on wood waste: bark, wood chips, sawdust. But firewood remains the most popular and affordable type of solid fuel. And if the house also has a fireplace, then in this case the choice is clear. In addition, most models of modern energy-efficient boilers, such as pyrolysis or long-burning, are aimed at burning wood.

The calorific value of firewood is on average 10-20% lower than that of coal, but they have their own advantages that have a “beneficial” effect on the service life of the equipment:

- low content of unburned solid residues (especially in long-burning and gas-generating boilers);

- relatively low combustion temperature;

- high yield of pyrolysis gases, the afterburning of which increases the efficiency of the boiler;

- almost complete absence of sulfur in flue gases (there are no conditions for the appearance of acid when combined with water vapor);

- low temperature of exhaust combustion products compared to coal.

It’s not for nothing that birch firewood is considered the best Source projject.ru

Peat

This type is rarely used in its natural form - more often as part of briquettes. Perhaps one of the most “gentle” fuel options for boilers. But it has a rather low calorific value if we compare “volume units” - on average two times lower than that of firewood, and three times lower than that of coal. Although a kilogram of peat in briquettes gives the same heat as wood pellets and 20-25% more than firewood with a humidity of 20%.

Note : Some sources compare the calorific value of different types of fuel per 1 kg, which often misleads consumers. It is more correct to compare in volumetric units - they are the ones that appear as characteristics of the capacity of fireboxes and bunkers.

pros

Solid fuel heating boilers have the following advantages:

- the purchase and installation of such heating systems does not require a large budget;

- fuel is not in short supply and also has a low price;

- The equipment is presented in a wide range and it will not be difficult to choose the optimally suitable option.

- a solid fuel boiler is installed, as a rule, by specialists from the company that sells the equipment - there are no problems finding an installation specialist;

- Preparing the device for operation does not take much time.

In addition, combustion products are not harmful to the environment

This is very important in our time, when active work is being carried out to preserve nature in its original form. Solid fuel boilers can be used in remote areas where there is no gas pipeline or central heating system: residents of such settlements use this type of equipment

Advantages and disadvantages

The arsenal of long-burning solid fuel boilers has a number of positive qualities that make such an acquisition extremely profitable:

- High efficiency. Long-burning fuel boilers differ from conventional stoves in their fairly high efficiency, which for some models can reach 95% - and this figure is quite comparable to the operating efficiency of gas heating boilers. This efficiency is achieved through heat exchangers and the use of pyrolysis gas as the main fuel.

- Environmentally friendly. All models of long-burning solid fuel boilers emit only water vapor and carbon dioxide into the air, which do not cause any harm to the environment.

- Low cost of fuel, its availability and heating autonomy. Long-burning, wood-burning solid fuel boilers do not depend on the presence of gas mains, and some of them also depend on electricity. Solid fuel itself is not very expensive, and the absence of the need to coordinate heating equipment makes a solid fuel boiler a very profitable purchase.

- Possibility of providing hot water. Some boiler models have built-in circuits necessary to create hot water supply. Even if such a circuit is not available, you can always purchase a separate boiler and connect it to the boiler.

- Durable and easy to maintain. A properly installed long-burning solid fuel heating boiler, which is used in accordance with operating rules, can easily last for several decades without any complaints.

Among the disadvantages, the following qualities can be distinguished:

- The need to replenish fuel reserves. This is the most noticeable disadvantage of all solid fuel boilers - no matter how much time it takes to burn out one batch of fuel, sooner or later you will have to start the next one. In addition, for normal operation of the boiler, it is required to have a supply of fuel, which can only be stored in a specially equipped place.

- The need for regular cleaning. A mandatory item in any operating instructions for a solid fuel boiler is the periodic cleaning of the boiler from ash and soot.

- Requirements for the installation location. Solid fuel heating boilers need a separate room and a good foundation. In addition, the room must have normal ventilation.

Conclusion

Long-burning solid fuel boilers are one of the best options for autonomous heating devices for private and country houses. Knowing their advantages and taking into account the disadvantages, we can draw conclusions about the relevance of purchasing these devices and their operation.

Economics of heating equipment

To understand which boiler will be more economical and by how much, you need to take into account two important points: how much money you will need to spend on fuel and how quickly the boiler itself will pay for itself. Of course, it will be difficult to give absolute values in this article, since prices for everything change quickly. Therefore, it is best to consider everything in relative terms. Of course, the benefits of a solid fuel boiler will be determined relative to gas and electric boilers. True, here it will still be necessary to take into account whether purchasing a solid fuel boiler will be too expensive? This is a one-time expense, but for many it can be a deciding factor.

Types of solid fuel boilers

Today, domestic consumers have access to a large number of models of solid fuel boilers for heating, which can be represented in the following groups:

- classic solid fuel boilers;

- long-burning solid fuel boilers;

- pellet solid fuel boilers.

Traditional solid fuel boilers

True, it must be admitted that these devices have acquired a slightly different appearance and design. But all these changes were only beneficial, since modern models have increased efficiency and ease of use.

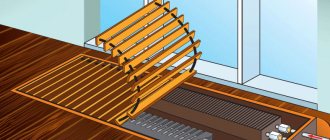

The following key elements can be distinguished in the design of a solid fuel boiler:

- The combustion chamber;

- Heat exchanger;

- Automation, which guarantees that the temperature is maintained at the required level.

For the manufacture of elements such as the combustion chamber and heat exchanger, steel or cast iron is used. However, none of these materials has serious advantages over the other. It is imperative to take into account additional parameters: quality of material, thickness, design.

The use of steel as a material for the combustion chamber and heat exchanger makes the product significantly lighter. At the same time, such devices cope better with mechanical stress during transportation and loading and unloading, in which they are superior to their cast iron counterparts. But a steel heat exchanger also has disadvantages. If its operation is carried out in violation of the rules, this will lead to its corrosion. Naturally, this situation rarely arises, since there is nothing difficult in preventing the temperature in the boiler from falling below the “dew point” temperature.

Among the advantages that cast iron has, mention should be made of its high durability. In this parameter, it is twice as good as steel. In addition, this material is better protected from corrosion.

Long-burning solid fuel boilers

ability to retain heat for a long time

The most common types of boilers are:

- pyrolysis (gas generator) boilers;

- boilers with top-down combustion.

Quite often, devices that use a pyrolysis combustion system are used. They are distinguished by the fact that heat is generated by burning gas generated during the combustion of solid fuel. This operating mode allows the fuel to burn longer than usual and ensures more efficient operation of the installation.

These devices can be used for heating small industrial facilities, cottages and country houses. At the same time, they can successfully serve as an independent heat source and be used in conjunction with other heating devices.

Pellet boilers

If a private house does not have a connection to the gas main, then among the possible solutions to the heating problem, its owner can choose pellet boilers. These devices are preferable to electric and liquid fuel devices, since the cost of pellets is lower than diesel fuel and electricity and at the same time they can be easily switched to automatic operation. The operation of these devices is less expensive, since one load of fuel is enough for 5-7 days of operation of such a boiler.

The design of these devices is represented by the following components: a boiler, a bunker and a system for supplying pellets from the bunker to the boiler.

Pellet boilers can be classified into two types:

- with built-in burners (volcano-type retort pellet burners);

- with mounted (pressurized) burners.

Pellet boilers with a mounted (pressurized) burner are distinguished by the fact that, if necessary, they can be converted to another type of fuel. To do this, you just need to change the burner.

Boilers that use a retort built-in burner do not have this feature, which limits their use.

Let's take a closer look at the process of feeding pellets from the bunker to the boiler. An external auger is used to load fuel into the burner hopper. The operation of the latter is controlled by a photosensor with which the burner is equipped. It is he who monitors how much the bunker is loaded with granules. When there is no free space left in the bunker for fuel, the external auger turns off. At this stage, the internal auger comes into operation, with the help of which the granules enter the combustion grate. There is an electric coil here that ignites the granules. Air access to the combustion zone is provided by a fan.

Long burning boilers

The operating principle of long-burning boilers is aimed at prolonged and economical combustion of fuel.

The period of operation of such boilers on one load is up to 5 days when using coal and up to 30 hours when using firewood. To increase the operating time and the amount of heat generated, the “top” or “top-bottom” combustion method is used. This method can be clearly seen using the example of the burning of an ordinary match, first turning it with the flame towards the floor, and then redirecting it upward - when the flame is directed upward, the combustion time will increase significantly. The air heating chamber is connected to the combustion chamber using a telescopic pipe with an air distributor, through which heated air is supplied. As the fuel burns, the pipe lowers under its own weight, which ensures uniform, optimal combustion of the thin top layer of fuel.

A distinctive feature of such boilers is the large volume of the combustion chamber, which allows loading up to 50 kg of fuel. Due to the limited air supply, fuel smoldering rather than combustion occurs. Due to the volume of the chamber and slow combustion, one load of fuel is enough to operate the boiler from 12 hours to 5 days. The efficiency of such boilers reaches 90%, they are easy to operate and maintain. A similar, but more advanced and economical technology is used in gas generator boilers.

Firebox

The process of kindling and adding firewood depends on the design of a particular boiler. In general terms, it includes kindling, the main mode of operation, and its completion.

- Before starting the fire, check the amount of water in the heating system and connect the shut-off valves.

- When kindling, open the damper and light the wood chips on a piece of paper. Small firewood is placed on the resulting fire. After they start the fire, add about 1/3 of the firebox with wood, after 5-7 minutes fill the firebox completely, and close the damper.

- Efficient heating is the main operating mode. When the fuel has burned 9/10 of the full load, you can wait for complete combustion by slightly opening the air supply control door, or add more fuel. If you add firewood less than half of the full load, then there is no need to regulate the further process. Otherwise, you will need to provide air flow so that smoke comes from the firewood.

- Completion of the firebox. When combustion stops, ash-like coals will remain and must be removed at least once every 10 days or when their level rises above the top of the air control door.

Selection of heat generator based on combustion duration

You can visually distinguish a real long-burning TT boiler from others by the following characteristics:

- The product data sheet indicates the operating time from 1 load is at least 8 hours.

- The increased volume of the firebox increases the overall height of the unit, which is why such boilers are taller than their “brothers” with the same thermal power. Another option is to increase the depth of the firebox, causing the body to “grow” in length.

- For tall models, the distance between the loading and ash door is about 500 mm, no less. Some manufacturers provide their products with a third intermediate door for ease of use.

Modern long-burning boiler Atmos D30

Note. Pyrolysis and pellet heaters do not belong to this category, as they operate on a different principle.

Example. A solid fuel hot water boiler operating according to the usual scheme has a firebox volume of 50-65 liters with a power of 22 kW and a rated combustion duration of 6 hours using wood. The total volume of the firebox of a long-burning heat generator is 100 liters or more, and the useful volume (up to the level of the loading door) is 80 liters with a power of 20 kW (for example, ATMOS D30 and VIESSMANN VITOLIGNO 250-S). If we consider boilers with top combustion of wood such as the Baltic Stropuva, then the chamber volume reaches 260 liters (power 20 kW).

Heaters with top combustion of fuel can operate for 12-15 hours on wood and up to 3 days on anthracite, but have a number of disadvantages:

- logs cannot be added “on the go”, but only after the previous portion of firewood has completely burned;

- it is difficult to do short-term heating of the house;

- Fine fuel like sawdust or debris sometimes hangs on the walls.

More details about these heat generators are described in the video:

TT coal fired boilers

Solid fuel heat generators using coal are extremely relevant for areas where there is no possibility of main gas supply.

In addition, there are regions where the use of coal is most economically feasible.

In this case, which boiler should you choose to run on coal? One for which you can find quality fuel in your region.

Some models, for example, are not designed to work on anthracite, and only work on brown coal.

Anthracite has a combustion temperature higher than brown coal. In theory, anthracite – up to 2000 degrees Celsius, brown coal – up to 1800 degrees Celsius.

And still, this is much higher than the burning temperature of wood (700-800 degrees Celsius). That’s why coal boilers have grates and doors made of cast iron.

Specifications

It should be noted that for all models of long-burning solid fuel boilers, average technical indicators are used.

- Working pressure within 1 atm.

- The efficiency is not higher than 89%.

- The coolant heats up to +80°C.

- In this case, you can start heating the coolant from +5°C.

- Boilers of this type belong to the “powerful” category. Their average productivity is 100 kW, this is an average value, there is more, there is less.

- Operating time from one load is 12 hours.

- Exhaust gas temperature – 270°С.

Attention! This list showed an efficiency of 89%. This is an average value that can vary depending on the type of solid fuel used (in this case, we mean firewood from different types of wood), and on the moisture content of the firewood used.

Types of solid fuel boilers

Classic solid fuel boilers

Modern classic units are an effective alternative to devices that run on other types of fuel, for example, gas, which, unlike firewood, coal, coke and briquettes, cannot always be used due to the lack of a nearby highway.

For the most part, they do not depend on electricity - they are loaded manually, operate in a natural circulation mode and have mechanical control. Some models provide automatic loading using feed hoppers - mainly for pellets, which are compressed wood pellets.

The units use several temperature control methods:

1. Using a damper that opens slightly to allow the required amount of air to pass through;

2. Using cold water added at the supply;

3. Using hot liquid supplied at the return.

Advantages:

- energy independence of many models;

- good efficiency - average efficiency is about 80%;

- versatility - in most cases;

- relatively high level of safety;

- cheap fuel - depending on the region;

- ease of operation.

Flaws:

- installation is possible only in a specially designated room;

- the need for a site for firewood, coal, briquettes;

- the need for regular maintenance, namely loading and cleaning;

- low comfort of use.

Such boilers are installed mainly in the countryside: in private houses, cottages, hotels, shops, warehouses.

Pyrolysis solid fuel boilers

A pyrolysis boiler, also called a gas generator, is an improved classic model.

It has 2 chambers connected to each other by ceramic nozzles:

1. One is intended for firewood, which at a temperature of +200 °C heats up, smolders and decomposes into coal and a volatile substance containing CO;

2. The other is used to accept pyrolysis gas generated by thermal exposure of wood.

The latter burns at a temperature of ≈ +1150 °C - preliminary ignition occurs after air supply. As a result, 2 different fuels are extracted and used from ordinary firewood - gas and charcoal, the total heat transfer of which is much higher than that of primary fuel.

When operating a pyrolysis unit, the moisture content of the wood must be taken into account - it should be no more than 20%.

Advantages:

- high efficiency – ≈ 90%;

- increased interval between downloads;

- almost complete burnout and low ash content;

- economical operation;

- compatibility with indirect heating boiler;

- possibility of automatic control, simplifying operation.

Flaws:

- the need for a special room, a platform for firewood and regular maintenance;

- dependence on power supply and log moisture;

- lack of combustion stability with incomplete filling;

- high price.

Pyrolysis boilers are distinguished by their high power; in addition, they are expensive, so they are usually installed in suburban residential and commercial buildings with a considerable square footage.

Long-burning solid fuel boilers

Among the competitors, the most expressive and efficient is the long-burning boiler called Stropuva - an innovative cylindrical unit with patented technology.

Firewood, briquettes or coal placed in the firebox are burned according to the principle of a candle, not a fire - from top to bottom, not from bottom to top. An essential role for the effectiveness of this method is played by an automatic valve - a draft regulator, which expands or contracts depending on the heating value.

There are practically no temperature surges in these units; as a result, excess heat is not discharged into storage tanks due to its absence.

One stack of firewood weighing 50 kg is enough for uninterrupted heating of a room of 130 m2 for 30 hours. In addition, the fuel burns virtually to a residue - after burning coal, cleaning is carried out weekly, in the case of logs - once every 14 days.

Advantages:

- energy independence of many models;

- optimal efficiency – approximately 85%;

- long burning interval;

- no impact of loading on efficiency;

- economical use;

- ease of use.

Flaws:

- the need for maintenance, premises and areas for storing fuel;

- inconvenient doors, regardless of model;

- high price.

Objects for using such devices are private households, as well as small-sized commercial and outbuildings. For large buildings and structures, the units are mounted in a cascade.

Additional equipment for automatic heating of a solid fuel boiler

In addition to the boiler itself, automatic installations have a number of devices that ensure simplicity and ease of operation of the heating system, these include:

- devices for controlling the microclimate in the house (they are special sensors that record the temperature level outside and inside the room, after which the flow of air and fuel into the boiler chamber is regulated);

- equipment responsible for igniting solid fuel (present only in pyrolysis boilers, which can initiate the combustion process, which greatly simplifies the process of starting heating equipment).

As for the self-cleaning system, it has not yet been invented. Therefore, it is necessary to independently clean the ash pan from accumulated dust and waste. Modern devices are unpretentious and require cleaning only once a week.

More technologically advanced models allow you to control the operation of the system and change modes from a distance, which provides additional convenience during the operation of the equipment.

Video: what you need to know when choosing an automatic solid fuel boiler

Features of working with solid fuel boilers

Heating a private house with solid fuel has a cyclical nature, which is due to the need to carry out a certain sequence: thus, fuel is added, it is ignited, it burns. Of course, such a cycling process negatively affects the durability of the heat exchanger. Temperature changes are also observed in the rooms.

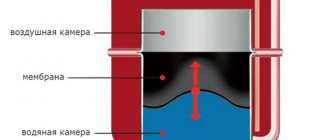

To solve this issue, heat accumulators are used - thermally insulated containers of 500-1000 liters. When the boiler burns, heat accumulates, energy is released when heat transfer decreases, and the boiler goes out. Thus, heating the house with solid fuel begins to work stably and the temperature evens out.

https://youtube.com/watch?v=QCyj_qUNWp4

But in this case, the power needs to be increased to 40%, since the quality of the fuel is unstable, the condition of the chimney will also affect the heat production.

When installing heating using solid fuel, the parameters of the chimney must clearly meet the requirements. It is also necessary to ensure that it is possible to clean the chimney and inspect it, because the soot that appears can ignite spontaneously and cause a fire.

Pellet boilers

Pellets are wood pellets. In other words, pressed wood waste, which is consumed by the heat generator as it is burned. As a rule, the volume of the pellet boiler bunker is sufficient for autonomous operation of the heating system from 1 to 6 days with an efficiency of up to 85%. Based on practicality and efficiency, a pellet boiler is the best choice for heating a private home. From a budget point of view, this is one of the most expensive types of boiler equipment.

In addition, when purchasing a pellet boiler, you should solve the problem of storing pellets. They cannot be stored outside, as they will have high humidity. For storage in the house you need to allocate a sufficiently large space with a good ventilation system.