The need to install control units

Supply ventilation system installations, in accordance with the basic requirements of regulatory documents, must supply fresh outside air, preheated to a certain temperature. The supply air temperature must correspond to the type of ventilated room in the case of general ventilation or the technological process in the case of any production cycle.

The principle of operation of the supply and exhaust ventilation system.

In addition, the air temperature must be constant regardless of the outside air temperature and adjustments to the coolant temperature schedule. That is, when it gets colder and the temperature outside decreases, heating networks, as a rule, increase the temperature of the coolant, and the air temperature at the outlet of the air handling unit must remain at a given level.

Consequently, the heat load during the heating period is not a constant value, and the coolant must be regulated. Otherwise, there will be excessive consumption of thermal energy, an increase in temperature and excessive overheating of the premises, which can adversely affect the well-being of people or the technological process.

The air is heated in air supply air heaters, the number of which may vary depending on the adopted heat supply scheme. The most common option is installations with one heater, but there can be two or more.

Heaters are designed to heat air in the supply and supply and exhaust ventilation systems.

For some institutions where air heating is also necessary during the transitional season, two separate circuits of the heat supply system are provided. One heater operates in spring and autumn, the second circuit in winter. In the event of extreme frosts, when the main heater cannot cope with the load, the second one can heat the air to a predetermined temperature.

Supply installation of ventilation system.

Also, one of the main advantages of this scheme is almost 100% redundancy of the heat transfer surface. In case of emergency situations when one heater fails or defrosts, the second heater will be connected to operation and will fully cope with the main function. Therefore, when calculating the installation, it is advisable to provide two identical heaters, with a surface corresponding to the maximum power of the two operating modes.

When calculating the air handling unit, you may encounter a situation where the selected heater in maximum mode will produce thermal power many times greater than the required one. This is due to the limited number of heater sizes available from the manufacturer. Therefore, in order to have a constant supply air temperature, it is necessary to install control units of the heat supply system on each heating circuit and at each installation. These units will be controlled by the automation system of all ventilation systems of the complex.

Calculation

In order to buy a mixing unit or determine its price that is suitable for your air handling unit or air handling unit, you need to select it correctly. Before this, you need to calculate it. To calculate and select a mixing unit for ventilation, you need to know the following initial data:

- 1. Power of the heat exchanger (heater, heater or cooler). If it is not known, then it can be calculated using the formula:

- Q=L*(t2-t1)*0.335, kW

- Where

- L - productivity (air flow) of your air supply in m3/h (for example L=3000 m3/h)

- t1 is the temperature of the outside (street air) entering the heat exchanger, deg. C, (for example t1= -28 C)

- t2 is the temperature to which the air must be heated or cooled, degrees. C (for example t2=18 C)

- Q=3000*(18+28) *0.335=46.2 kW

- 3. Temperature of the coolant (water or antifreeze) at the inlet and outlet of the heat exchanger Deg. C (for example 90 and 70 C)

- 4. Hydraulic resistance of the heat exchanger, kPa. (for example 5.5 kPa)

- We calculate the coolant flow (water or antifreeze) in the heat exchanger using the formula:

- G=3.6*Q/(4.2*(T1-T2)), m3/h

- Where

- Q—heat exchanger power, kW. (in our case Q=46.2 kW)

- T1 - coolant temperature at the inlet to the heat exchanger, deg. C (for example T1= 90C)

- T2 is the temperature of the coolant at the outlet of the heat exchanger, deg. C (for example T2= 70C)

- G=3.6*46.2/(4.2*(90-70))=2.0 m3/h

We select the required standard size of the mixing unit from the catalog. According to the graphs, we find a control unit for the air supply unit, with a coolant flow rate slightly greater than what was calculated, and we check whether the hydraulic resistance of the heat exchanger and the static pressure of the mixing unit are higher. The blue dot should lie below the top red line. That. This size is suitable for your air handling unit.

Classification of power control options for installations

Scheme No. 1

The supply ventilation heat supply system can operate in several fundamentally different control modes:

- If during the operation of ventilation systems there is a smooth or stepwise change in water temperature at a constant flow rate, then it is customary to say that high-quality regulation is used at this unit. It is used in boiler houses or in individual heating points, that is, changes in coolant parameters will occur directly throughout the entire heat supply system. The hot water temperature is adjusted according to a special schedule of the heat supply organization depending on changes in the outside air temperature.

- If a change in the heat load occurs when the amount of coolant entering the installation changes, that is, at a constant temperature, the flow of hot water changes smoothly. Here we are dealing with quantitative regulation.

- With the qualitative-quantitative control method, temperature adjustments occur in the heating system (or from a heat source) and coolant flow changes zonally at each installation in its own mode. A rather complex control method, but most widely used in ventilation heat supply systems. It can only be implemented when installing an automation system.

Basic diagrams of control units

Scheme No. 2

There are at least several basic heater piping schemes, which have fundamental differences in terms of the chosen control scheme and heat supply source. There is no clear answer as to which of the schemes described below is correct; it all depends on a large number of factors (heat supply source and its capabilities and coolant requirements, already installed network equipment, the value of the free pressure drop at the entrance to the building, etc.).

a two-way linear control valve is installed as a control element , which absorbs the excess difference at the connection point and performs the main function of limiting the flow of water through heater. But in order to ensure protection against freezing of the air heater, a circulation pump is installed on the internal circuit of the air heater, which ensures constant flow through the installation through an additional jumper. This is a classic method of quantitative zonal control at each air supply unit.

Scheme No. 3

No less common are heat supply schemes for heaters with installed three-way valves . These circuits can operate in different control modes depending on the position of the valve and the location of the jumper insertion.

Scheme No. 4

Three-way valves can operate in water flow separation mode or as a mixing element (diagram No. 4). If the valve is installed in such a way that, depending on the heating demand of the installation, port A (from the heating network side) opens or closes, and the coolant circulates through the clan bypass (ports B and AB), then the most common quantitative control scheme takes place. Its use, as a rule, is limited by the maximum pressure drop in the central heating system, therefore it is most often used in autonomous heating systems. But when designing such a scheme, it is necessary to take into account that the flow rate in the heat supply system or at the heat source is not constant, therefore the network pumping equipment must be equipped with frequency converters.

Scheme No. 5

If it is necessary to ensure a constant flow rate from the heat source, then a jumper with an installed check valve and balancing valve should be added to the previous diagram in front of the valve (diagram No. 5).

If the jumper and valve are swapped in the circuit, and water is circulated in the internal circuit through the jumper, then the pressure of the circulation pump in this case will be less by the amount of hydraulic resistance of the valve. The coolant flow from the heating network will remain constant, and the valve will operate on a free pressure drop (diagram No. 6).

Scheme No. 6

Features of selecting a mixing unit

- When designing and installing the entire system, it becomes necessary to organize heat exchange in the air supply units. In order for the system to work correctly, it is necessary to select a mixing unit for each heat exchanger in such a way that its operating range corresponds to the throughput of the heat exchanger.

- The main problem in operating the entire system may arise due to the fact that the selected unit has too much or, conversely, too little cross-country ability.

- In the case of an underestimated cross-country ability, the system is unable to provide the required temperature parameters during periods of maximum load; In addition, the likelihood of breakdowns and malfunctions due to overloads sharply increases.

- If the permeability of the unit is too high, temperature regulation will occur with inertia. In this case, we get a large pipe cross-section with a small air or liquid flow rate. The valve will operate in the lower range, causing the coolant to be regulated unevenly.

Basic equipment of heat supply units. Selection and calculation

The heat supply units of air handling units made according to different schemes, as a rule, include identical equipment. Such units differ only in the installation location, the saturation of the reinforcement and the selection method.

When selecting equipment for heat supply units, there are several general rules and recommendations:

- When choosing a particular type of valve, you should carefully check the technical characteristics of both the maximum operating pressure and the maximum temperature.

- It is highly not recommended to purchase ready-made mixing units that are selected based on average conditions without taking into account important parameters such as free pressure drop in the system, type of coolant, flow rate, type of heat source, the need for frequency regulation, and so on.

- The diameter of shut-off valves, as well as check valves and mud traps must be no less than the diameter of the pipelines.

- The diameter of the heating system pipelines is determined as a result of hydraulic calculation based on the calculated (required) coolant flow rate, type of coolant (water or low-freezing liquids) and pipeline material. In no case should the diameter of the heating supply units be selected based on the connecting ports of the heater. It is selected ONLY BY CALCULATION!

Shut-off valves

It is necessary to shut off the water flow in cases of emergency stops of the heating system, for example, to eliminate a leak, to carry out service or inspection work, etc. As shut-off valves, steel or brass ball valves (preferably full bore) or flanged valves are used.

For heat supply units with a pipeline diameter of up to 40 mm inclusive, it is customary to install threaded shut-off valves, and flanged valves over 50 mm.

To facilitate the installation or dismantling of assemblies, threaded fittings should be provided with union nuts, otherwise called “American or socket nuts”.

Check valves

Check valves are used in control units to prevent water from flowing back into the heating system if control valves are opened or closed. Or this is possible when the heating system is not balanced, a large number of units are installed in the system and when the coolant flow changes, pressure may occur on each other. Therefore, check valves are installed on the return pipeline and on the jumper of the heating supply unit.

Control Valves and Actuators

Two way valve.

A two-way or three-way control valve is the main actuator, which, by changing the flow rate or by mixing coolants, allows you to regulate the power of the air-handling unit heater depending on the heating demand of the installation. Another important function of the valve is to prevent the coolant from “freezing” when the units operate in winter. When the automation receives a signal about the critical temperatures of the coolant and air after the heater, the drive opens the control valve to the maximum flow.

Three-way valve.

The valve is selected based on the determination of the throughput coefficient Kv, which means how much coolant flow will pass through the valve in the open state with a loss of 10 meters of water column.

,

where G is the estimated water flow, m3/h; ∆p - actual pressure drop across the valve, bar Ƥ - coolant density.

The size of the control valve cannot be selected according to the diameter of the pipeline or heater ports. The smaller the Kv or valve diameter, the higher the speed of response to changes in air or heating network parameters will be, that is, the system will not be inertial.

In heat supply systems of air supply units, as a rule, two and three-way valves are used. Two-way valves work only in systems with changes in coolant flow, and three-way valves either act as mixing valves or work to separate heat flows.

Measuring fittings: pressure gauges and thermometers

Measuring equipment

Pressure gauges and thermometers are necessary tools for visual monitoring of the performance of the heating system. Thermometers are usually installed on the supply and return pipelines directly next to the heater. Pressure gauges are mounted on the pump group to monitor the operation of the pump and visually determine the difference created. Pressure gauges are also installed before and after the sump tank - to determine the degree of its clogging, and on the supply and return pipelines of the heating network in front of the piping unit - to control the free drop necessary for the full operation of the control valve.

Air bleed valves and system drain taps

Automatic air release valve

To bleed air after filling the system and during operation, it is recommended to install automatic air bleed valves in the piping units. They are conveniently mounted on special ports embedded in the heater coils in the upper part of the housing or at the highest point of the control unit pipelines.

Taps for emptying heaters and draining a section of the heating system should be installed at the lowest point of the control unit, or at the bottom of the heater.

Balancing valves

Balancing valve

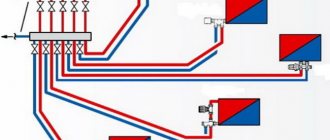

If the heat supply system has several air supply units operating in their own independent mode, then the heat flows in the pipelines will not be constant and may differ significantly from each other. To prevent pressure on each other from the coolant side, balancing valves are provided. Their main and main function is to throttle excess pressure and equalize the distribution of water flow between heaters in accordance with needs. Balancing valves installed on the return pipelines hydraulically link the heaters to each other.

The selection of valves is carried out by analogy with the selection of control valves, taking into account the Kv coefficient. The initial data for determining the valve size is the excess pressure drop that the balancing valve must absorb and the calculated flow rate in the network section.

Circulation pump

Circulation pump

The circulation pump of the internal circuit of the piping unit is designed to ensure constant circulation of water in the heater. This will minimize the risk of the heater “defrosting” at low outdoor temperatures. But the main purpose of the pumps is to overcome hydraulic resistance in the regulated area, that is, on all functional elements of the mixing unit, unloaded from the pressure of the heating network.

The regulated section usually means a heater, pipelines, shut-off and balancing valves, check valves and a sump. The control valve may be part of the regulated section, depending on the adopted heater piping scheme. If the control valve is installed in the piping unit in such a way that the coolant circulates in the internal circuit through the jumper of the valve itself with the direct port closed, then the valve is part of the circulation circuit. In such cases, the pump pressure is determined as the sum of the hydraulic resistance of all elements of the regulated section. It should be remembered that in the case when the coolant in the heating system is not water, the hydraulic resistance of all elements of the regulated section and the calculated flow rate should be adjusted depending on the viscosity and density of the coolant. Hydraulic losses on mud pits should be taken into account with a margin of 50% clogging.

If the control valve operates on a difference in the heating network (diagram No. 3), then the pressure loss on the valve is not taken into account when calculating the pump head.

When calculating the friction resistance of pipelines, it is imperative to take into account all pressure losses at branches, corners and turns. It is also necessary to take into account the roughness of the pipeline walls in accordance with the selected material.

All pressure losses on the elements of the piping unit should be determined only at the operating flow rate of the coolant, and not in accordance with the maximum flow rate of the heater that it is capable of passing.

The selection of circulation pumps is made according to the technical catalogs of manufacturers in accordance with operating points (calculated water flow and required pressure). The most common type of pump in units are three-speed glandless pumps. In cases where a smooth change in flow rate in the supply ventilation circuit is required, pumps with a built-in frequency converter are used.

Sump

Sump

Mud filters are filters for mechanical cleaning of coolant, usually with a mesh size of about 500 microns. In old heating systems, heating water contains a lot of suspended particles, sand or scale. All these contaminants can damage control valves and circulation pumps. Therefore, installing mud collectors directly in front of the equipment is a prerequisite for maintaining operability and warranty.

Protection of heaters from defrosting. Coolants in ventilation systems

The number and purpose of air heaters in supply ventilation installations may vary depending on the composition of the installation and the purpose of its operation. The heaters can be of first heating, second heating, with preheating in front of plate recuperators, separate for operation at different times of the year, or used for heating on separate branches of air ducts if the temperature conditions of the served premises are different.

Therefore, it is customary to say that preheating or 1st stage heaters always operate on “hot” air. That is, air with a very low temperature enters the heaters. In a continental climate, the danger of heaters defrosting is very high when starting up installations in winter or during new construction, when there are frequent interruptions in the power supply and interruptions in the supply of hot water.

There can be a huge number of reasons for water freezing in heaters in winter: from accidental closing of the valve at the inlet to a failure in the power supply and automation systems. Also, the most common cause of defrosting is the incorrect choice of circuit, low pressure drop in the heating system, incorrect selection of the control valve and a drive with a long response time.

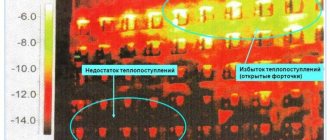

Defrosted heater of the supply ventilation system

You should also know that the ideal choice for controlling control valves is an actuator with analog control using a 0-10V signal. An equally rare cause of system defrosting is uncoordinated operation of the supply and exhaust ventilation systems. For example, it is a common case that during non-working hours the air supply units are switched off, but the exhaust units continue to operate for some reason, and a vacuum of air is created in the building. To replenish the air balance, air begins to be sucked in through all available leaks, including through a leaky air damper. Thus, when the system’s automation and insensitive sensors are turned off, the signal about low temperatures does not issue a command for the automation to turn on the heating of the heating system and the water in the heat exchanger freezes.

Video on defrosting the heater of the supply ventilation system:

Of course, heater piping units must also be equipped with the required number of sensors and protective thermostats complete with control cabinets, but in the event of power surges or lack of power supply, the automation system will not be able to protect the heaters. The only option to protect the system from defrosting with a 100% guarantee is to fill it with low-freezing coolants.

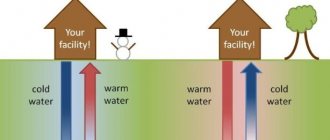

The main advantages of antifreeze include a low crystallization temperature and the absence of thermal expansion in a frozen state, which does not lead to rupture of the walls of air heaters. Low-freezing liquids include sets of additives that protect the pipeline system from corrosion, minimize cavitation and prevent sediment from forming when the system heats up or cools down.

The use of low-temperature coolants in some heat supply systems is limited by a maximum maximum temperature of 95-100°C, above which the chemical composition will decompose. Therefore, in an individual heating point, a temperature regulator or valve should be installed on the media separation heat exchanger (water-NZT), which will protect the heating system circuit from increasing the temperature above the critical one.

In heat supply systems, as a rule, ethylene glycol or propylene-glycol mixtures are used, which differ in both price and scope. Ethylene glycol is the cheapest coolant, therefore it is most widely used in engineering systems. Propylene-glycol mixtures are used in safe industries, where in the event of system depressurization, a toxic coolant can pose a potential threat to life or disrupt the technological cycle. Such requirements are found mainly in the food industry or in medical institutions.

A low-freezing coolant with a crystallization temperature of -30°C contains 40% ethylene glycol mixed with distilled water. The main feature of all ethylene glycol-based coolants is the formation of a plastic gel at low temperatures, which does not cause rupture of heater tubes or the formation of cracks in welded joints.

It is not recommended to use a low-freezing coolant with a crystallization temperature of _65 degrees in heat supply systems, but it should be diluted with water to the required concentration.

After filling the networks with ethylene glycol solutions, the system should be carefully pressurized, since it is most likely that small coolant leaks or leaks may occur at the threaded connections. This is due to the low surface tension of all coolants and the ability to penetrate into all cracks and leaks in the system.

When carrying out a hydraulic calculation of a heating system that will be filled with an ethylene glycol solution, it should be taken into account that the coolant flow rate will be 8% higher than the water flow rate, and the pressure of the pumping equipment should be increased on average by 54%. When selecting the diameters of pipeline sections, it is necessary to take into account the increased viscosity of coolants and introduce a correction for an increase in diameter, where necessary.

Description of heat exchangers and mixing units

Often, a supply and exhaust system is provided in non-residential buildings to ensure standardized characteristics of the air environment. This type of ventilation brings outside air into the building and removes pollutants such as gases, vapors, dust, excess heat and moisture.

To preserve and maintain optimal conditions inside the building, in the ventilation system combined with a heater, the supply air is heated.

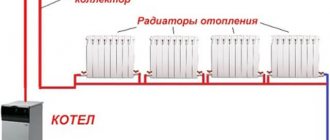

Mixing unit (MU) is a multicomponent engineering system installed as a piping of a water heater to control air heating parameters. The mixing unit changes the degree of heating of the working fluid entering the heat exchanger.

Types of heaters

Heaters, or duct heaters, differ in the types of working media circulating in the heat exchanger.

Mermen

Due to their affordable price and easy maintenance, water heaters are the most common type of heat exchange equipment.

A special feature of installing a ventilation system with a water heater is the installation of water supply pipes. This design makes it impossible to install a water duct heater in a comfortable apartment. But it is optimally suited for installing ventilation systems in warehouses, production facilities, etc.

Steam

In such heaters, the working medium is water vapor, which is ventilated inside the ventilation unit.

These installations show high efficiency due to the heating rate and the frequency of air exchange cycles. Steam duct heaters are used at industrial facilities where existing steam pipeline communications can be used.

Electrical

In this type of heating equipment, heating occurs using heating elements. From an installation point of view, this is the most convenient duct heater - there is no need to install complex engineering communications, it is enough to lay the electrical wiring and connect the socket.

Types of tie knots

Installation of an air exchange system with a water duct heater requires the selection of a mixing unit and installation diagram. There are 2 types of thermostatic blocks based on the type of valves - with two-way regulation and a three-way shut-off and control component.

Essential elements

The design solution of the mixing unit is one-piece, prefabricated complex equipment, which includes a combination of the following components:

- pipeline circuits;

- filters - to remove solid impurities and contaminants from the coolant;

- two or three-way valves - the main control elements that regulate the temperature of the working fluid;

- reverse shut-off and control element - to prevent the flow of coolant from the direct pipeline to the return one;

- circulation pump - responsible for the forced flow of liquid in the system;

- ball valves - to stop the intake of liquid from the heat supply system and start the working medium into the heat exchanger;

- pressure gauges and thermometers - to monitor system parameters;

- drain shut-off valves - for removing coolant when the unit is stopped for repair, maintenance and preservation of the air heating system.

If necessary, a “dry running” sensor is installed to monitor the presence of water in the heat exchanger.

Trim assembly for heater

An integral part of the mixing structure for the heater is a pump for forced circulation of water masses. Temperature regulation occurs through the input of hot water.