Installing heat meters will allow our clients to know exactly their actual heat consumption, which makes it possible to pay based on the heat energy consumed, and this will significantly reduce the cost of paying bills. After installing a commercial coolant metering unit at your facility, all costs for energy-saving measures will bring real savings. Installing a heat metering unit will reduce heat supply costs by 30%. In the absence of commercial metering of thermal energy, payment for heat is made according to calculated loads.

- Purchase of equipment

- Installation of a standard heat metering unit

- Delivery of heat metering unit

- Popular questions

- UUTE installation process

- Operation and maintenance of the metering unit after installation

- Our contacts

I. Development of design documentation for a heat metering unit

| No. | Name of works | Deadline | Cost, rub) |

| 1 | Development and approval of design documentation for a heat metering unit in a heat supply organization (PJSC MOEK) | from 7 days | from 30,000 – 40,000 |

| 2 | Development of design documentation for a heat metering unit for a sub-subscriber | from 3 days | from 10 000 |

II. Purchase of equipment

| No. | Name of works | Delivery time | Cost, rub) |

| 1 | Heat meter kit (the price of the heat meter kit includes a heat calculator, flow converters, sensors, printer, printer cabinet, installation kit) The cost is calculated specifically for each object, taking into account thermal loads and the number of systems (heating, hot water supply, ventilation, cold water supply, make-up) | from 10 days | from 40 000 |

| 2 | Additional equipment: (cable, metal hose, wires, electrical boxes, trays, flanges, transitions, bends, bends) | from 3 days | from 10 000 |

We have been cooperating with NPO Teplovizor since the founding of the manufacturing plant; when purchasing thermal energy metering devices, NPO Teplovizor provides us with a 50% discount.

Rights and obligations of the parties

6.1. The user has the right:

6.1.1. Make a free decision to provide your personal data necessary to use the TeploProekt website, and consent to their processing.

6.1.2. Update, supplement the provided information about personal data if this information changes.

6.1.3. The user has the right to receive from the Administration information regarding the processing of his personal data, unless such right is limited in accordance with federal laws. The user has the right to demand from the Administration clarification of his personal data, blocking or destruction of it if the personal data is incomplete, outdated, inaccurate, illegally obtained or is not necessary for the stated purpose of processing, as well as take measures provided by law to protect his rights.

6.2. The administration is obliged:

6.2.1. Use the information received solely for the purposes specified in clause 4 of this Privacy Policy.

6.2.2. Ensure that confidential information is kept secret, not disclosed without the prior written permission of the User, and also not sell, exchange, publish, or disclose in other possible ways the transferred personal data of the User, with the exception of paragraphs. 5.2 and 5.3. of this Privacy Policy.

6.2.3. Take precautions to protect the confidentiality of the User's personal data in accordance with the procedure usually used to protect this type of information in existing business transactions.

6.2.4. Block personal data relating to the relevant User from the moment of application or request from the User, or his legal representative or the authorized body for the protection of the rights of personal data subjects for the period of verification, in the event of detection of unreliable personal data or unlawful actions.

IV. Delivery of heat metering unit

| No. | Name of works | Deadline | Cost, rub) |

| 1 | Delivery of the metering unit to the customer and representative of the heat supply organization with the execution of a Certificate of Admission to Operation of Heat Energy Metering Devices (PJSC MOEK) | from 7 days | 15 000 |

| 2 | Delivery of the metering unit to the customer and representative of the heat supply organization (sub-subscriber) | from 3 days | — |

LLC specialists have extensive practical experience, will perform plumbing, electrical installation and commissioning work, and hand over metering units to the heat supply organization.

Our company carries out turnkey installation and carries out a full cycle of work - from surveying the facility to putting it into operation:

- coordination with the customer of upcoming work;

- performing plumbing and welding work with the coolant turned off for a period of no more than 3.5 hours;

- electrical installation and commissioning work from 1-3 days;

- preparation for delivery and delivery of the facility to the heat supply organization (7 days);

- registration of an admission certificate and a certificate of completion of work (7 days);

- reduction of work completion time through the use of new technologies.

Warranty for installation work – 1.5 years;

Equipment warranty from the manufacturer is 1.5 years.

Maintenance and repair of the heating unit

Maintenance of a heating unit (maintenance of ITP) is a set of measures that ensures uninterrupted operation of equipment, monitoring the functioning of units and elements of the facility during operation, carrying out seasonal and commissioning work, organizational and legal support of technical work, carrying out minor repair work, and checking instrumentation and control equipment.

All work on servicing heating units is carried out in accordance with current regulatory documents (PTE TE). Repair of thermal units with replacement of failed units is usually carried out by a specialized organization in accordance with an additional agreement.

questionnaire for thermal energy metering unit - go

Popular questions:

- Question: What savings will there be after installing a heat meter?

Answer: Before installing the heat meter, payment for heat consumption is made according to the contractual loads, which are specified in the heat supply contract, and after installing the heat meter, payment will be made for ACTUAL consumption, which, in our experience, is at least 30% lower. - Question: Does the heat meter count hot water and heating consumption?

Answer: The heat meter calculates the actual consumption of both hot water and heating in gigocalories (Gcal). - Question: What brand of printer is used to take readings from the heat meter?

Answer: Dot matrix printer. The heat meter manufacturer adapts the printer to his device. For example, Epson LX300+ printer, etc. - Question: Is it necessary to install valves before and after the heat meter?

Answer: Before and after the heat meter, it is necessary to install shut-off valves in order to be able to shut off the coolant and remove the flow converters, for example, for verification or repair. Shut-off valves can be either welded or flanged at the customer’s discretion. If the heating point is small, then the inlet valves can serve to shut off the coolant. - Question: How many channels should a heat meter have?

Answer: The number of channels is calculated depending on the number of systems. 2-channel is only for heating, heating and hot water is already 4 channels, heating + make-up is 3-channel, etc. - Question: How to calculate the diameter of the heat meter?

Answer: The diameter of the flow converters is calculated in the project for specific thermal loads. - Question: Does the heat meter require switching to winter or summer operating modes?

Answer: Some heat meters, for example SA94/2M, need to be switched to different operating modes: winter and summer. - Question: How often should readings be taken from the heat meter?

Answer: To submit to the heat supply organization, a report for heat energy consumption for the full month is taken. But the readings must be entered into the thermal energy logbook at approximately the same time every day. - Question: What are the stages of installing UUTE?

Answer: 1. Inspection of the facility and study of thermal loads; 2. Development and approval of design documentation for UTE in the heat supply organization; 3. Purchase of equipment: - Order a heat meter based on the agreed design documentation - Purchase of additional pipeline and electrical equipment for installation; 4. Installation and welding works; 5. Electrical installation and commissioning works; 6. The operating time of the heat meter is 3-7 days; 7. Delivery of the UUTE to a representative of the heat supply organization and execution of a certificate of admission to operation of UUTE devices. - Question: How is the commissioning act for commercial operation (initial) completed?

Answer: Putting the UTE into commercial operation is a procedure for checking the compliance of the UTE with the requirements of regulatory legal acts and design documentation, including drawing up an act of admitting the UTE into operation. Upon acceptance of the UUTE, the following package of documents is submitted: - Agreed design documentation for the UUTE (original); — Passports for installed measuring instruments and UUTE equipment (originals); — Certificates of verification of measuring instruments and UUTE equipment subject to verification, with valid verification marks (originals); — Records of continuous operation of the UTE for 3 (three) days (for objects with hot water supply - 7 (seven) days) preceding the date of putting the UTE into commercial operation. In the process of admitting the UUTE into commercial operation, the condition of the UUTE, the integrity of factory seals and marks, compliance with the measurement ranges of parameters, compliance of installation with project documentation, etc. are checked. Upon admission into operation, all measuring instruments as part of the UTE are sealed in accordance with the design documentation for the UTE, while the number of seals and their placement must exclude unauthorized interference in the operation of the UTE.

Thermal energy metering unit is equipment that records actual heat consumption and helps to save significantly.

The tariffs set by heat supply organizations are too high, so paying by the meter is much more profitable. Installing a heat metering unit allows you to reduce heating costs by 30%.

The heat meter shows the actual consumption of thermal energy and hot water in gigacalories (Gcal).

UUTE installation process

Installation of a turnkey thermal energy metering unit is carried out according to the following scheme:

- Design of a heat metering unit

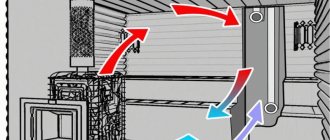

Installation of heat metering units is possible only according to a project agreed upon with the heat supply organization. In addition, we take into account the needs and wishes of the customer.

During design, the type of devices is determined. The heat meter may have several channels, depending on the number of engineering systems. A two-channel meter is used for heating, a four-channel meter is used for heating and hot water supply. In addition, the correct diameter of the heat meter is calculated based on the thermal loads.

By contacting us, you will not only receive a heating unit that fully complies with legal requirements and your wishes. undertakes project approval. In total, the design and approval of the heating unit will take up to 7 days.

- Purchasing the necessary equipment

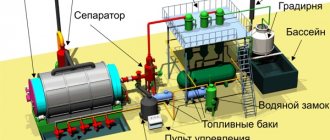

The heat metering unit requires various devices: a heat calculator, flow meters, various sensors, a printer and a cabinet for it, an installation kit. You will also need fasteners.

The cost of a set of equipment for installing a heat metering unit depends on the individual characteristics of the facility - thermal loads and the number of engineering systems. has been working with NPO Teplovizor since the founding of the plant, so equipment from this manufacturer will cost you 50% less.

It takes up to 10 days to select and purchase equipment. The equipment warranty is 1.5 years.

- Installation of a thermal energy metering unit

Our specialists have extensive experience in welding, electrical and plumbing work.

This allows you to quickly and efficiently install a heat metering unit at any facility. Thanks to the competent organization of installation, welding and plumbing work takes about 3.5 hours.

Upon completion of installation, the metering devices are commissioned and prepared for further operation.

The total period for installation and commissioning work, depending on the characteristics of the facility, is 1–3 days. We provide a 1.5 year warranty on installation work.

- Delivery of the metering unit to the client

Before handing over the heat metering unit to the customer, it is necessary to obtain an operating permit certificate for it. This procedure may take up to 7 days.

Contact us to install a heat metering unit - we work with residential apartment buildings and commercial properties, we carry out turnkey work, from inspection and design to installation and further maintenance of metering devices.

Operation and maintenance of the metering unit after installation

In order for the heat metering unit to serve for a long time, it is necessary not only to install it correctly, but also to comply with the main operating requirements:

- Use the meter correctly

To take readings from the meter, a matrix printer adapted for the device is used.

Readings must be taken daily and recorded in the log book. A full report on heat energy consumption is sent to the heat supply organization monthly. Correct metering of thermal energy will help you fully control utility costs.

Some heat metering devices are seasonally switched to summer/winter operating mode, which makes it possible to obtain more reliable and accurate readings.

- Maintenance and repair

To service the heat metering unit, shut-off valves are used, which shut off the system when the equipment needs to be removed. The type of shut-off valves is selected depending on the complexity of the system.

Every year it is necessary to obtain permission to operate the heat meter - only in this case its readings can be confidently considered reliable.

Scheduled verification of heat metering units is required once every 4 years. Unscheduled ones may be required if there is a suspicion of a breakdown of the meter, loss of documentation and other unforeseen circumstances. If the verification results reveal faults, the meter must be repaired or replaced.

A working meter guarantees accurate metering of thermal energy and saves you from disputes with the heat supply company, fines and other problems.

carries out not only the installation of heat metering units, but also provides affordable services for verification and repair of devices. We do everything to ensure that our customers' meters work smoothly and for a long time!

Cost of the heating unit project

The cost of designing a heating unit is usually determined individually in each specific case and depends on many factors: the type of heating unit being built; type of heating system; types, brands, types and quantities of equipment; the required power of the heating unit, volume and complexity of work and other indicators.

However, it is rightly noted that savings begin precisely at the stage of drawing up the project. With professional and high-quality design, the high price of modern, efficient equipment, the cost of the heating unit project, the cost of installation work and other expenses are recouped in the shortest possible time.