I think that the topic of ventilation in the bathhouse has been and will be very relevant. Therefore, I propose to discuss this particular problem today. Quite often you can encounter fungus, rot and an unpleasant odor not only in the steam room, but throughout the entire bathhouse. The reason is simple - poor ventilation, air stagnation and high humidity.

Such negative aspects cannot be allowed, and if they arise, they must be resolved as quickly as possible. Let's look at what Bastu ventilation is, why they talk a lot about it, and whether you can do it yourself. Ready? Then let's go...

Bathhouse projects

Number of projects 681

- 1 room

- 1 bathroom

Project of log bathhouse 4x6 m

- To favorites

- 60² Total area

- 6 x 4m Construction area

from 225,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Project Baths 5B-B

- To favorites

- 18.55² Total area

- 5 x 5m Building area

from RUB 300,159

Construction period 17 days

- 1 room

- 2 bathrooms

Project Baths Mercury

- To favorites

- 37² Total area

- 8 x 7m Construction area

from 499,500 rub.

Construction period 27 days

- 1 room

- 2 bathrooms

Bath Rafaella project

- To favorites

- 84² Total area

- 10 x 7m Construction area

from 1,134,000 rub.

Construction period 40 days

- 2 rooms

- 2 bathrooms

Project AS-2272

- To favorites

- 79² Total area

from 1,066,500 rub.

Construction time individually

Project of Log House Baths 4x5 m

- To favorites

- 20² Total area

- 4 x 5m Building area

from 245,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bani Anapa-5 project

- To favorites

- 30² Total area

- 6 x 6m Construction area

from 405,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Antalya Baths Project

- To favorites

- 74.5² Total area

- 11 x 11m Construction area

from 1,005,750 rub.

Construction period 40 days

- 1 bathroom

Sanduny Baths-2 project

- To favorites

- 48² Total area

- 6 x 9m Construction area

from 587,012 rub.

Construction time individually

- 5 rooms

- 3 bathrooms

Bani Opus Project

- To favorites

- 159² Total area

- 13 x 10m Construction area

from 2,146,500 rub.

Construction time 82 days

Quad bathhouse project "Mega-2"

- To favorites

- 2 x 5m Building area

from 244,900 rub.

Construction time 1 day

- 1 room

- 1 bathroom

Bathhouse project No. 25-11

- To favorites

- 19.26² Total area

- 4 x 5m Building area

from 260,010 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project "Anthea"

- To favorites

- 43.2² Total area

- 8 x 7m Construction area

from 1,030,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bathhouse Ivanovo project

- To favorites

- 93² Total area

- 9 x 9m Construction area

from 1,255,500 rub.

Construction period 52 days

- 1 bathroom

Barrel sauna project 6m

- To favorites

- 13.2² Total area

- 6 x 2m Building area

from 259,000 rub.

Construction time individually

- 3 rooms

- 2 bathrooms

Bathhouse Parkhochevo project

- To favorites

- 146² Total area

- 9 x 12m Construction area

from 3,500,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Project of a garden house-bath "Sanduny"

- To favorites

- 24.2² Total area

- 6 x 5m Construction area

from 326,700 rub.

Construction time individually

Project Hozblok made of timber “Light”

- To favorites

- 18² Total area

- 6 x 3m Building area

from RUB 143,550

Construction time 1 day

- 2 bathrooms

Bani South project

- To favorites

- 62² Total area

- 9 x 8m Construction area

from 994,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bani Cricket 2 project

- To favorites

- 62.68² Total area

- 6 x 9m Construction area

from 846,180 rub.

Construction period 38 days

View all projects

Air exchange is needed in any room, and especially in a bathhouse with its special microclimate. It is he who dictates how to make ventilation in the bathhouse, so that the influx of fresh air does not drive out the heat, but forces the air heated by the stove to circulate in the right direction. Without thinking through the design, you can get problems such as cold floors, a rapid decrease in temperature in the steam room, dampness with all its consequences, and the accumulation of carbon monoxide. You don’t have to invent anything: methods for ventilating baths have long been known, you just need to choose the most effective one in your case.

It’s easy to breathe in a properly equipped steam room Source i1.wp.com

Recommendations

For the ventilation device in the waiting room to be effective, you must adhere to the following recommendations:

- additional ventilation in the bathhouse using window vents is desirable;

- the waiting room itself must be insulated, since with a large temperature difference condensation (moisture, misty suspension under the ceiling) can accumulate here;

- ventilation openings are also necessary for the steam room so that high-quality circulation of air masses occurs;

- If possible, the waiting room should be made spacious at the rate of 1.3 m² per person, since smaller dimensions can create inconvenience and discomfort;

- the waiting area should be warm to provide comfortable conditions for relaxation after the steam room;

- there should be no sharp temperature differences between rooms, as well as between tiers of air space;

- The supply channel, which supplies fresh air to the furnace firebox, is recommended to be made of galvanized steel, with a built-in plug that can be used to regulate the supply flow.

The level of comfortable conditions inside the premises, the service life of the building, and the microclimate, which directly affects human health, depend on how well the ventilation of the bathhouse structure is organized.

Is ventilation necessary in a traditional Russian bath?

In the old days, Russian baths were not specially equipped with a ventilation system, and served well for many years. Air exchange in them occurred naturally. This was facilitated by log walls without insulation or cladding, between the crowns of which air leaked. As well as brick wood stoves with a blower, fired directly from the steam room, the chimney of which served as an exhaust hood.

Nobody thought about how to do ventilation in the bathhouse, and there was no need for it, since the bathhouses were small and consisted of a maximum of two rooms - a dressing room and a steam room, in which they steamed and washed. For such small buildings, the burst air exchange that occurs when the door is opened when entering and exiting the steam room was sufficient. And at the end of the procedures, it and the stove door were left ajar until the room was completely dry. Damp warm air was drawn into the chimney.

In the Russian bathhouse there was no special air exchange system Source dveribani.by

The possibility of burst ventilation can be provided in modern baths if you make an opening window on the wall opposite the door to the steam room, and diagonally from it. They are opened briefly before the next batch of steamers enter, only to freshen the air, but not to chill the room.

If you are building a Russian bathhouse without any frills, many separate rooms, with a traditional stove, you don’t have to think too much about how to make a hood in the bathhouse so that there is no dampness. A door, a small window, a good stove draft and mandatory ventilation after everyone has washed are enough.

An integrated approach to the condensate problem

When purchasing a ready-made sauna, you may encounter the problem of condensation in the dressing room. If an inspection of the ventilation system on site shows that everything is normal, you should look at the quality of the “pies” of the walls, floor, and ceiling.

Drawing of the placement of ventilation holes in the dressing room

Possible drafts and additional sources of moisture and cold from outside create problems inside the building. As a result, this method of solving the problem with condensation, like making ventilation in the dressing room, will not help. A whole range of work will be required to eliminate this deficiency.

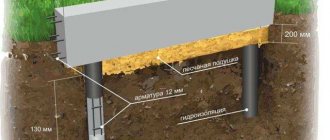

Floor insulation

The ideal flooring option is tiles. It seals all drafts from the underground space and also prevents the penetration of moisture. For greater comfort, you can lay a heated floor system underneath, but this will increase the costs of finishing and operation. Therefore, wooden coverings are most often installed. The correct floor should be installed in the following steps:

- Foundation ventilation. Before pouring, special holes (vents) are provided in the formwork along each wall of all rooms.

Scheme of floor ventilation in the dressing room

Ventilation of the underground space will ensure a healthy microclimate in the building and extend the service life of the floor covering; - The beams for the subfloor are packed onto the logs and covered with waterproofing;

- Insulation is installed between the beams. It should fit snugly against the wooden panels. Mineral wool, polystyrene foam, and expanded clay can be used as insulation. It all depends on the size of the budget;

- The next layer is waterproofing. The seams are sealed with metallized tape;

- The subfloor is installed.

Often, part of the heating and ventilation ducts are laid in the underground space. With this scheme, communications are insulated and waterproofed.

Ceiling insulation

Perhaps this is the weakest point in the waiting room. It is this area that is most negatively affected by the effects of steam.

Scheme of ceiling insulation in the dressing room

The warmer the ceiling, the less condensation will accumulate on it. The ideal filler option is expanded clay, which will replace both insulation and vapor barrier. But this is not always technically possible.

Therefore, false ceilings are most popular:

- The guide bars are filled, a vapor barrier is laid;

- Insulation is placed between the wooden profiles (mineral wool is recommended) and sewn with a reflector (foil film). The seams between the sheets are taped with metallized tape.

An important point is the ventilation gap between the insulation and the finishing lining of the ceiling.

Wall insulation

It is carried out according to the same principle as ceiling cladding. For a brick bathhouse, it is assumed that the facade will be insulated. And the inside is being waterproofed.

Scheme of wall insulation in the dressing room and waterproofing devices

Wood is recommended as the finishing material for wall cladding. At the same time, it is not painted, varnished, and treated with protective compounds: antiseptics and fire-fighting agents. Proper insulation with your own hands will significantly reduce the extent of condensation.

Another important point for saving heat and optimizing ventilation is doors. The size of the entrance group to the dressing room is recommended 1800*800.

In this case, the box must be insulated. The door to the steam room is made smaller than the entrance door. Thus, heat loss in both rooms is reduced.

Heating

The sharp difference between the steam room and the dressing room is the main reason for the appearance of condensation. Therefore, experienced craftsmen strive to create optimal temperature conditions in each room. For this purpose, the stove is used as a heat source.

There are several options:

- Related uses. When the stove with one wall opens into the dressing room. This option also includes when the firebox is located in the relaxation room, and the rest of the building is in the steam room;

- Construction of an additional partition between the steam room and the dressing room, or placement of a washing room between these rooms;

- The use of ventilation ducts coming from the steam room for heating adjacent rooms.

Arrangement of a ventilation duct for heating the dressing room

Which method to choose is determined individually.

The need for ventilation in modern baths

Modern baths have become completely different over the last century. Today they are built from different materials, not just logs. They are clad on the outside, insulated and clapboarded on the inside, literally sealing the building. They make several isolated rooms - a steam room, a washing room, a locker room, a relaxation room, a bathroom, and sometimes a swimming pool and a kitchen.

Plan of a modern bath complex Source remoo.ru

The principles of heating have also changed: stoves are often made with a firebox from a dressing room, and many people prefer electric heating devices, which do not require a chimney, to work with wood. And in order not to go outside in bad weather, such complexes are often attached to the house or placed directly in it.

The desire for convenience, comfort and beauty can lead to undesirable consequences and even harm your health if you do not think about how to properly ventilate a bathhouse. The most common consequences are carbon monoxide poisoning, rotting of wooden structures and the appearance of mold, the spores of which are not at all harmless.

The need for ventilation

Ventilation must be done during heating, as well as after completion of all procedures.

For heating and direct use:

- ventilation helps to establish air exchange so that the polluted air flow leaves the room, being replaced by a cleaner, but warmer one;

- fresh air supply is needed directly for the furnace;

- adjustment of the temperature and humidity indicators of the specific air environment of the bath;

- maintaining a more comfortable temperature inside the waiting room and relaxation area.

Ventilation after visiting:

- allows you to dry the bathhouse to prevent the appearance of mold and mildew on wooden finishing elements, accessories, etc. Excessive dampness in a poorly lit space can easily provoke mold and rotting of wood;

- long-term exposure to moisture on wooden structures will lead to distortion of the original parameters and properties (for example, doors and window sashes will close poorly and loosely);

- The pores of mold fungi in a poorly ventilated room are in the air, there is a constant smell of dampness and musty air. This prevents you from feeling comfortable when visiting the bathhouse;

- ventilation after taking bath procedures is also necessary for the building itself. It will last longer and function better if it is thoroughly and regularly ventilated and equipped with a proper ventilation system.

Methods of natural ventilation

Dense and heavy cold air always sinks down, and heated air is displaced by it and rises. This is how moving air currents arise in rooms with any heating device. But without an influx of fresh air, it is not renewed, but simply moves.

If you make a hole in the lower part of the wall, air from the street will flow through it if its temperature there is lower than in the room. And through the hole at the top it will be pulled out. This is natural ventilation.

Scheme of the movement of air masses in a heated room Source e-derslik.edu.az

This elementary law of physics is used when thinking about how to make ventilation in a bathhouse with your own hands without using any mechanisms. As a rule, natural ventilation without forced air intake is quite enough for a small bathhouse. Unlike residential premises, where in summer it can be as hot as outside, the temperature in the bathhouse is always higher.

But it is necessary to maintain a comfortable temperature for receiving procedures, and in such a way that drafts do not form and there is no sharp change from heat on the shelf to cold on the floor. To do this, air flows must move along a certain trajectory, which is set by placing supply and exhaust openings in specific locations.

Ventilation through the chimney

The easiest way to solve the problem is how to make ventilation in a steam room if it contains a furnace firebox with a blower. It will serve to remove exhaust air through the chimney, in which draft occurs during fuel combustion. But this scheme will only work if there is an influx of air from outside.

Ajar door to the steam room Source prodverivdome.ru

Inflow can be ensured in the following ways:

- from time to time slightly open the door to the steam room;

- make a small gap of 1 cm in the door or leave the same gap between the door and the floor;

- if the log house of the bathhouse is not sheathed, such a gap can be left between the first crowns located below the floor level, provided that the boards are not laid tightly;

- make a special opening in the wall opposite the stove at a height of 20-30 cm from the floor.

In any of these cases, the cold flow penetrating into the room moves towards the heat source and displaces the air already heated by it upward. As it moves, it warms up the entire room, gradually cooling down and descending. Here it is drawn into the ash pit and discharged through the chimney to the street.

Air movement pattern Source i.ibb.co

Note! This scheme only works if there is draft in the chimney, which occurs when wood burns. In the absence of combustion, air exchange practically stops.

This method of making ventilation in a steam room is not the most reliable and effective, since most of the fresh air is immediately drawn into the stove. Therefore, even during the construction of the bathhouse, it is advisable to think through other options for installing vents in the walls.

See also: Catalog of projects of houses with a bathhouse made of timber

Ventilation through vents

To ensure that air exchange does not depend on the operation of the stove, special openings are installed in the walls for air inflow and outlet. It is guaranteed to work subject to the following conditions:

- the exhaust hole is placed under the ceiling of the bathhouse - where heated air accumulates;

- the supply opening should be located low above the floor on the opposite wall, the closer to the stove, the better, so that the cold currents drawn in do not hit the legs;

- the optimal vertical distance between the vents should be 150-200 cm;

- The cross-section of the exhaust opening must be larger.

Cold air immediately enters the heating zone Source ventilation-conditioning.ru

The ideal location of the supply air is behind the stove. Entering the room, it immediately begins to warm up, displacing the already hot air mass upward and towards the hood. Therefore, cold streams and levels with noticeably different temperatures do not form in the steam room.

If you want to know how to properly make ventilation in a bathhouse and steam room, provide this diagram at the design stage and before installing the stove. It is also important to make sure to make a difference in height between the ventilation holes. If they are located at approximately the same level, this will lead to a draft and rapid passage of fresh air in a straight line, without circulation in the room.

Advice! It is best to make an exhaust vent directly above the shelf to allow hot air to flow into it and quickly remove waste materials.

Natural ventilation hood Source stroyfora.ru

In order to be able to regulate ventilation or limit the access of too frosty air into the steam room, you need to provide covers or valves for the vents.

The benefits of natural ventilation are that it works without the need for devices that require mains power and can break down. Its installation and operation do not require large expenses.

Requirements for dressing room ventilation

Proper ventilation in the sauna dressing room is organized with your own hands, following the criteria:

- supply and exhaust flows must be of the same volume;

- The direction of the air flow should be strictly organized from the dressing room to the bathroom or vestibule. When the air moves back, foreign odors may get inside;

- the outlet of the ventilation opening is located at a height of at least 2 m above ground level;

- if the hot air flow is removed from the steam room through air ducts, it would be advisable to use it to organize heating of other rooms of the bath;

- for a dressing room, a combined ventilation system will be effective, when a mechanical hood is installed and supply air is supplied naturally;

- the air exchange rate should be 3;

- Mounted fans must be moisture resistant.

Methods for installing forced ventilation

It is not always possible to provide natural air exchange of acceptable intensity. Such ventilation does not work well both in bathhouses with a large number of rooms, and in those that have a common wall with the house or are built into it.

In such cases, they resort to a device for forced injection and/or release of air, artificially creating flows or forcing them to move faster. To do this, fans are built into the system - exhaust or supply.

Supply fan installed in the corresponding hole Source engvent.ru

See also: Catalog of companies that specialize in the construction of baths, ventilation and air conditioning equipment

Depending on the type of object, one of the following types of forced ventilation is used:

- supply and exhaust when both types of fans are used. A rather rare option in private baths, since they do not require high ventilation intensity;

- supply , with mechanical suction of air through the supply opening and increasing the pressure in the room, due to which the exhaust air is squeezed out into the hood. Its main drawback is the too active supply of cold air masses;

- exhaust , the operating principle of which is the opposite: a fan in the exhaust hole forcibly removes polluted air outside, creating a vacuum inside, forcing clean air from the street to fill the vacated volume, entering the supply hole.

If you choose how to properly make a hood in a bathhouse, then preference should be given to the last option as the most optimal.

Fan on the exhaust vent Source stroi-remontirui.ru

Fan selection

Any mechanisms operating in a bathhouse must withstand difficult operating conditions: high humidity, heat, frequent temperature changes. Therefore, the fan is selected primarily based on these requirements.

Video description

It is easy to find units on sale that are specifically designed for baths and saunas - these are the ones shown in this video:

It is also necessary to decide on the power of the device, since excess power is completely unnecessary here and is even contraindicated. This is easy to do if you know the volume of the ventilated room and the air exchange rate recommended for baths, which is 5.

For example, for a 2x3 m steam room with a height of 2.2 m, the fan power is calculated as follows:

2 x 3 x 2.2 x 5 = 66 m3/h

Advice! Buy a device with variable adjustable power and a timer that will periodically turn the device on and off. You can fully automate the system by including humidity and temperature sensors configured to certain values, upon reaching which they will start the fan.

If desired, you can assemble an automated system with remote control Source nevoton.ru

Such devices, depending on the design, can be installed directly in the exhaust vent (duct fans) or on the wall behind it.

Video description

The following video shows an example of such a combination of ventilation and heating:

- If the floor in the steam room and washing room is made in the form of a flooring with slots on a concrete base, an exhaust duct can be made under it by combining the underground of the two rooms and equipping it with a fan. In this case, it is simply necessary, since the trajectory of the movement of air masses is complex, and natural ventilation is unlikely to cope with its task. A channel through a hole in the foundation removes moist exhaust air to the street. The supply opening should be located as close to the stove as possible so that the cold air begins to heat up immediately after entering the room. If openings are made in the walls between adjacent rooms, it will circulate throughout the entire volume, simultaneously warming both the washing room and the rest room.

Scheme of ventilation of a bathhouse through the underground Source youtube.com

Arrangement of supply and exhaust openings

When designing a bathhouse, you must immediately provide for the location of vents in the walls or foundation. It will be easier to make them during the construction process, rather than punch them after completion. In the case of forced ventilation, their dimensions are not particularly important, since a fan of calculated power will provide the necessary air exchange.

It is easier to lay a piece of pipe when pouring it into the foundation than to drill a vent in hardened concrete Source readmehouse.ru

Another thing is how to properly make ventilation in the steam room of a bathhouse if the use of mechanisms is not provided. For good natural air exchange, the cross-section of the supply opening must be sufficient. It is calculated according to a standard that regulates the dependence of this section on the volume of the room. For each cubic meter of ventilated space it is necessary to install a vent with a cross-sectional area of 24 cm2.

If we take our example with a steam room 2x3x2.2 m, then its volume will be equal to 13.2 m3. Multiplying it by 24 we get 317 cm2. To determine the diameter of a round hole with such an area, use the converted formula for the area of a circle: divide it by Pi and take the square root from the resulting value. The radius of our hole is equal to 10 cm, so its diameter should be 20 cm.

The radius is found using the inverse formula for the area of a circle Source ds04.infourok.ru

It is even easier to find the length of the side of a square hole - it will be approximately 18 cm. The sides of the rectangle are also selected in accordance with the cross-sectional area - for example, 10x32 cm.

To arrange round vents, steel or plastic pipes of the appropriate diameter or slightly larger are used, and the channels in the rectangular wall are made in the form of wooden boxes made of boards.

The exhaust hole, as already mentioned, should be made larger than the supply hole. The gaps between the wall and the walls of the channel are filled with tow, other insulation, or foamed.

Another important point in such a matter as making an outlet in a bathhouse is protection from the outside from the penetration of insects, rodents, and debris into the channel. To do this, cover the hole from the outside with a mesh or lattice.

Ventilation grille with insect mesh Source www.video-sovety.ru

And inside, to regulate the intensity of the air flow, valves are installed, partially or completely blocking the holes when necessary. For example, in winter, the draft, due to the huge difference between the low temperature of the street air and the high temperature in the bathhouse, increases so much that the cold currents do not have time to heat up from the stove and quickly cool the room. It is reduced using a valve, leaving only a small gap or completely blocking the vent for the duration of the procedures.

Schemes for arranging a hood for a bath

The main task of ventilation in the relaxation room of the bathhouse, as well as in the dressing room and steam room, is to ensure constant renewal of air, maintain constant temperature and humidity, and remove carbon monoxide to the outside. Since all bath rooms are constantly in contact with high temperatures and humidity, they need regular drying.

However, simply ventilating the steam room and drying the wooden elements is not enough. To prevent the wood from accumulating moisture, the bathhouse must have a constant, stable exhaust hood. Then it will last much longer and remain hygienic and clean.

Ventilated floor system

To improve air circulation in the steam room, you can install a ventilated floor.

To organize such a design, a number of conditions will need to be met:

- air holes must be provided in the foundation of the bathhouse;

- in the boardwalk you need to leave gaps of 1 cm, sufficient for the passage of air;

- supply channels are located in parallel walls, having previously protected them with gratings;

- the finishing coating is laid out above the level of the furnace vent so that it serves as an additional hood;

- At the end of the bath procedures, all doors in the bathhouse are left open until the floor is completely dry.

Air exchange in the waiting room

Both the dressing room and the relaxation room are not exposed to the aggressive effects of high temperature and humidity. Therefore, ventilation and air exchange in these rooms is easiest to do. Here, the method of natural ventilation is used, or the installation of additional fans in exhaust openings connected to air ducts in the bathroom, vestibule or steam room.

If desired, you can install electronic ventilators. However, they require an electrical connection and direct access to the street.

Hood in the shower room

Typically, a shower room requires a power-assisted ventilation system to remove accumulated steam and moisture. In this case, the dimensions of the inlet and outlet holes are made the same. The inlet channel begins at a level of 2 m above the ground, and the outlet channel ends above the roof.

Ventilation system in the steam room

One of the main requirements for the ventilation system in the steam room is the absence of drafts. In this case, the room should heat up quickly, and the humidity level should be maintained at the level necessary for bath procedures. In this regard, the principle of location of supply and exhaust openings installed during construction is considered optimal.

The intensity of air flow can be adjusted using valves. At the same time, the large size of the room requires the installation of additional fans for blowing or blowing.

Thus, by adhering to the recommendations and rules for organizing a hood in a bathhouse, as well as following the tips in the photos and videos, you will be able to properly and efficiently equip this structure and use it for your pleasure.