Good devices used for heating baths and saunas are heater stoves called “Breneran”. This name was given to the unit by domestic manufacturers, who took similar Canadian devices “Bullerjan” as a basis. The design of such a furnace includes reservoirs for water, which, when heated, forms steam, and special compartments for stones. Hot cobblestones provide sufficient heating of the room in a short time. With the “Buleryan” (“Breneran”) stove you can create both a Russian bath and a Finnish sauna.

Device Features

Breneran stoves, which have a high efficiency (80%), are characterized by the presence of two combustion chambers. In one of them, flammable waste is generated, which is completely destroyed in the second compartment. Temperature regulators installed on the door and chimney of the stove provide control over the heating rate and maintaining a stable temperature. The firebox channel has a limited length, so such a heater needs to be installed and heated only in one room.

In addition, Buleryan stoves are equipped with a blind damper, which must be slightly opened during the next filling of the firebox with several logs. After 2-3 minutes, the damper opens completely and the entire volume of firewood intended for one-time loading is placed in the oven. The gradual implementation of this procedure is explained by the need to comply with fire safety rules, if violated, backdraft will lead to the release of carbon monoxide into the steam room.

The furnace structure is enclosed in an outer cylindrical casing, on top of which a reservoir for heating water and a container for stones are installed. A specially equipped pipe on the stove connecting the compartment with cobblestones and the chimney helps to effectively use the heat generated by the heater. Due to the wooden borders, an obstacle is created for direct contact with the hot unit, which makes it impossible to get burns.

The bottom of the firebox is lined with a cast-iron grate, through which combustion products enter the ash box installed under the chambers.

Models with water circuit

Traditional Buleryan stoves, not equipped with water circuits, can be adapted to heat several rooms. To do this, thermal chambers are created around them with grilles for taking in cold air and air duct pipes for distributing heat to other rooms. This scheme is characterized by exceptional simplicity and makes it possible to easily organize full heating of a multi-room building.

The disadvantage of the presented scheme is that the air in the air duct pipes cools quickly, so their length is limited. It is also necessary to consider the installation location of the stove in order to minimize heat loss in the air ducts.

A water circuit is a more effective solution for organizing heating of multi-room houses and other buildings. Water cools much more slowly than air, which is due to its high heat capacity. A large number of radiators can be connected to the water circuit, and using circulation pumps, it is easy to implement a circuit with long pipelines. Let's see how Buleryan works with a water circuit and how it works.

Aqua Buleryan is a slightly modified version of a traditional air oven. We have already said that its combustion chamber is surrounded by curved pipes, forming a productive convector. By briefly working with a welding machine, these pipes are transformed into a giant heat exchanger. To do this, all the lower tubes are welded together, forming a manifold to which the supply (return) pipe is welded. The same is done with the upper pipes, from which the outlet pipe departs - here you have a heat exchange system.

The resulting Buleryan wood-burning boiler with a water circuit, according to user reviews, has many advantages:

This scheme provides the best smoke removal. In addition, to improve the draft characteristics, a deflector is installed on the chimney head.

- Effective heating of several rooms - these are country houses and multi-room cottages;

- High heating rate - this is ensured by an efficient water circuit with a large heat exchanger;

- There is no need to frequently add firewood - the long-burning system eliminates many tedious approaches.

Thus, Buleryan stoves with water circuits have good technical characteristics.

Strengths and weaknesses of Buleryan stoves

A fairly simple design is characterized by low weight (95-120 kg), good transportability and ease of use. In addition, other advantages of such stoves are noted. Among them are the following:

- The durability of the unit is ensured by the material of its manufacture, namely heat-resistant steel, and the anti-corrosion coating of the housing.

- Soft steam, which allows you to take bath procedures, is formed due to the strong heating of the stones.

- The environmental side of using the device is due to the natural nature of this type of fuel, such as wood, which in no way can harm either human health or the environment.

- Ease of installation is ensured by simply installing the finished product and connecting it to a pre-equipped smoke exhaust system through a chimney.

- Excessive ultraviolet radiation entering the steam room from a heated metal firebox is shielded by a convection casing.

Among the disadvantages of Breneran stoves for baths, it is worth noting the following:

- Water tanks have a small capacity - only 30 liters.

- To collect condensate, a sealed container is required, which is not included with the oven. Liquid accumulation occurs in an unsealed plug glass, where moisture enters from the chimney.

Advantages

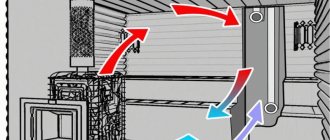

The classic version of the Breneran stove is an all-metal structure that includes a large number of pipes that create forced convection.

Therefore, the heated air quickly heats up and spreads throughout the room.

And due to its clever design, the stove manages to take air from under the floor, warm it up in a matter of seconds, and then direct it upward, creating circulation. On average, the outlet temperature is up to 150 ˚С

It is worth noting that the burning time of one bookmark in such a stove will depend on many factors. So, it could be:

- firewood quality;

- total height of the chimney;

- in what mode the stove is operated;

- various nuances of the Breneran installation.

So, for example, some bathhouse attendants manage to provide heating for up to 12 hours in a row in one load. Although at the same time, it will not be possible to provide high-quality heating. It is most correct that with one load the furnace operation lasts an average of 7 hours. This will allow you to achieve maximum effect.

The main advantages of such furnaces are:

- high productivity (about 80%);

- greater efficiency;

- possibility of heating in a short period of time;

- versatility, allowing use both in the house and in the bathhouse;

- independence from stationary fuel sources (gas, electricity).

Considering the simplicity of the entire design of such a stove, in most cases it surpasses its main competitors in the form of gas boilers for private homes in many respects.

The most important thing is that it does not release any harmful substances into the air. In addition, an important point is that the design of such furnaces has been tested by time.

We recommend: Calculation of heating radiators, number of sections and battery power

Review of the model range of Buleryan stoves for baths

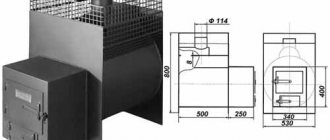

Models AOT-8 and AOT-12 represent the “Breneran” family of heating devices for steam rooms. There are modifications equipped with a glass or solid metal door. An extended remote firebox allows you to light the stove from the room adjacent to the steam room. The Breneran unit may include a mounted water tank with a capacity of 25 liters and a heat exchanger to which such a tank will be connected.

Installation of the furnace

To ensure the stability of the Buleryan bathhouse device and prevent its displacement under the influence of any mechanical factors, it is proposed to build a foundation. This structure provides protection for the lower part of the structure from damp and cold soil.

To construct the base, three piles are concreted into the floor of the bathhouse, each of which has a length of 1700 mm and a diameter of 200 mm. Then a slab is taken, the dimensions of which are approximately 1000x1400x200 mm, and combined with the grillage lintel. To strengthen the foundation, a mesh of reinforcing bars with a diameter of 10 mm and a dimensional pitch of 150x150 mm is used. If all actions are performed correctly, the slab will be laid 25 cm below the finished floor level. To hold it and reinforce it, it is necessary to make several dozen holes into which reinforcement rods are glued. Suspended formwork is removed immediately after the concrete mixture has hardened.

Installation of the Buleryan stove for a bath requires compliance with the following safety rules:

- The device should not be installed near the wall of the room, but at a distance of at least one meter. It is allowed to reduce this gap by 20 cm if the wall is finished with a two-centimeter layer of plaster.

- This requirement also applies to all flammable objects and structures that may be within the range of the heating device. Therefore, it is important to ensure that there is a free zone in front of the stove itself. The distance to the nearest object must be at least 1.2 m.

- Even in the case when the Buleryan sauna stove is installed on a specially constructed foundation, it is necessary to place a fire-resistant gasket under it. Along the edges of the span it is necessary to build screen protection or brickwork.

- Before installing the Breneran stove in the steam room, you should test the device outdoors. With the help of the first kindling, all technical oils used to process the body in production evaporate, releasing a small amount of acrid smoke and an unpleasant odor. Thus, the protective layer of paint undergoes final polymerization. The next time you use the unit, the negative phenomena will no longer be so noticeable, and will soon disappear altogether.

To ensure full draft, when installing the chimney, it should be aligned perpendicular to the stove foundation. To construct a chimney, a metal or ceramic pipe, stone or brickwork, or specially strong concrete blocks are usually used.

It is important that the outer end of the chimney protrudes at least half a meter above the ridge of the bathhouse roof.

The figures below show installation diagrams for the Breneran stove depending on the type of chimney.

How to choose a Breneran boiler

The manufacturer of air-heating furnaces of the Breneran brand, JSC Laotherm, produces a whole range of heat generators that differ in power and design features. For ease of selection, all gas generating equipment is divided into the AOT series.

The line includes models for domestic and industrial operating conditions, operating on almost any type of solid fuel: firewood, pellets, wood and paper industry waste, with the exception of coking coal.

Model range of heating boilers Breneran

The model range of JSC Laotherm includes six basic modifications of the Breneran stove. When choosing a suitable heat generator, you should focus on the equipment characteristics specified by the manufacturer in the technical documentation:

- AOT 19 – the design contains 8 pairs of convection pipes. Furnace power 35 kW. The model copes with heating rooms with a volume of 1000 m³. The total weight of the structure without firewood is 240 kg. The firebox can be loaded with fuel up to 200 kg. The Breneran wood-fired gas-fired heating stove, long-burning AOT 19, is optimally suited for heating a residential building with several floors and rooms.

- AOT 16 is another productive stove, suitable for heating rooms up to 600 m³. The weight of the structure with an empty combustion chamber reaches 190 kg, which during installation will require the manufacture of a foundation. The model is optimally suited for industrial purposes. Based on the Breneran AOT 16 stove, air heating is installed for several rooms isolated from each other.

- AOT 14 – the series includes two types of equipment, differing in the presence of a glass door made of heat-resistant glass. The model with glass is designed for installation under brickwork, imitation under a fireplace or Russian stove. The maximum performance is 18 kW, which is more than enough to fully heat rooms with 180 m² or a volume of up to 400 m³.

- AOT 11 - starting with this series, the manufacturer Laotherm offers stoves that are more adapted for domestic rather than industrial conditions. The small dimensions of the boiler made it possible to reduce its weight to 100 kg, while maintaining high productivity of 11 kW. The stove can handle heating one large room or hall with a volume of 200 m³. By installing an air duct system for individual rooms, the AOT 11 boiler is capable of heating an entire house with an area of about 100 m².

- AOT 08 is a small, dimensional, but at the same time productive stove, optimally suitable for heating unheated premises: dachas, garages, greenhouses. The weight of the structure, with the combustion chamber empty, is only 70 kg. For improved circulation of heated air, there are 7 convection channels on the body. The series offers models with and without glass doors. Maximum productivity 8 kW, heated room volume 140 m³.

- AOT 06 – long-burning domestic solid fuel air-heating boilers using Breneran AOT 16 wood, designed for efficient and fast heating of rooms with a total volume of up to 100 m³. The model is successfully used for heating individual rooms. The stove's power is not enough to connect the air duct system. The series includes models with glass and all-metal doors.

For the convenience of consumers, the Laotherm company lists the standard sizes of furnaces in the full names of the models, from 01 to 04. This parameter affects the number of convection pipes and the dimensions of the structure.

Cost of Breneran stoves

Prices for Breneran solid fuel pyrolysis heating boilers make the purchase of such equipment affordable for almost any category of the population. What affects the cost of a boiler?

- Performance - the most powerful model AOT 19, will cost about 38 thousand rubles, a small household heat generator only 10,400 rubles.

- The presence of a fire door with a glass insert - this function is provided in models AOT 06, 08, 11 and 14. The presence of an insert increases the cost of the design by approximately 1000 - 1500 rubles.

The stove manufacturer specifically maintains the same price for stoves in all company stores to reduce the likelihood of purchasing a surrogate. According to representatives of Laotherm, the stove at a lower cost is a fake.

Adjusting modes

Using the switch, which functions for the “Russian bath” and “Finnish sauna” modes, you can adjust the heating temperature and humidity level in the steam room. This device is located near the door through which firewood is supplied to the firebox.

Switching modes occurs according to the following principle:

- If it is necessary to create a dry sauna atmosphere in the steam room, the valve of the device opens, allowing cold air to pass through. The air flow moves through the pipes and, already heated, enters the heater. The temperature of the stones increases, which warms the surrounding space and dries out the air in the room.

- If you want to have a good steam in a bathhouse with a broom, you need to close the valve tightly. Thus, air access is blocked and the heater is heated from the hot stove body. To create wet steam, the stones are poured with liquid.

Almost always, the Buleryan heating device for a bath includes a water tank installed on top of the structure. The liquid heated in it is usually used for washing. Wooden strips connected to each other serve as protection against contact between a person and the hot stove body.

Installation

The recommended distance of the stove from the walls is at least a meter

When installing, it is important to take into account the principles of its operation and create conditions for maximum performance and heat transfer. To save on installing a stove in a country house, in a bathhouse or in a wooden house, you can do all the work yourself.

- Fireproof cutting for the chimney is carried out. To do this, a hole is drilled in the wall of a frame house between the posts and it is sheathed with galvanization.

- After this, the asbestos sheet is laid.

- It is also necessary to make a support bracket for the chimney using bolts or welding.

- To install the bracket, be sure to strengthen the wall frame and install a tee on it with a container where the condensate will collect.

- A protective screen is created on the surface of the wall.

- The installation of the furnace base must be carried out very responsibly. Thick porcelain tiles are laid out on the wooden floor as the first layer. It is fixed at the edges with ordinary screws. A thin layer of basalt wool and asbestos is laid on top.

- Next, place a galvanized sheet and secure it with galvanized screws around the perimeter. A low edge around the perimeter prevents ash and wood chips from flying around the room.

- The oven is connected to the tee through an adapter, which must be placed on a heat-resistant silicone sealant.

- At the last stage, the chimney is assembled and fixed to the wall using clamps.

Operational moments

When starting the Breneran unit, you need to slightly open the vent and carefully burn a small amount of paper or wood chips in the firebox. After the flame burns, you can add firewood. Until the required temperature is established in the steam room, the oven will operate continuously. In just 45 minutes the room will warm up to 100 °C. Then you can cover all the holes through which oxygen enters the firebox. This reduces the intensity of the flame in the fuel combustion device, but the stove is already so hot that the heat emanating from it heats the water and stones. When the cobblestones are heated sufficiently, the steam room receives a high temperature that can last up to two hours.

Kindling technology

To use the stove, no specialized knowledge or skills are required. The boiler is easy to heat and maintain.

You can melt Buleryan as follows:

- Fuel is loaded into the firebox. First, firewood of small thickness is used. The fuel should be dry, this will minimize the amount of condensation that forms and allow the fire to start quickly.

- The wood is set on fire. The dampers that regulate the draft and the amount of air supplied are fully open.

- After hot coals have formed in the firebox, thicker firewood is loaded through the door. The dampers are installed in the desired position to ensure long-lasting combustion.