The stove in the bathhouse is lined with bricks to preserve warmth and comfort in the room longer, as well as to increase the efficiency of the heating device. Often, it is necessary to line a metal furnace that has an external firebox. Such a unit cools down quickly, and during combustion it emits a lot of infrared radiation, which makes staying in the steam room uncomfortable.

It’s not difficult to brick a cast-iron stove yourself; the main thing is to carefully study all the rules and pay attention to the nuances.

Methods for lining a stove in a bathhouse

During the combustion process, the hearth heats up to a high temperature, which is accompanied by its thermal expansion.

All this must be taken into account when choosing a facing material and the method of its application. In this case, you need to plan the finishing of not only the walls, but also the pipes. You can cover the oven with the following materials:

- Ordinary red brick made of baked clay. It is better to choose solid blocks that conduct well and retain heat longer.

- Monolithic ceramic brick. An excellent material characterized by average thermal conductivity, strength and resistance to sudden temperature changes.

- Fireclay refractory stone. It is used for masonry fireboxes; it absorbs heat well, and therefore is not suitable for exterior decoration.

There are the following options for lining the hearth, regardless of its location:

- Continuous cladding. This is the easiest way to finish a boiler. It is similar to laying tiles on the floors and walls of rooms. Only here there are some nuances. The first is the correct choice of cladding. It is necessary to take tiles that are resistant to high temperatures and have the same coefficient of thermal expansion as metal. Another condition is the preparation of a solution with the desired composition. A mixture of clay, sand and cement is best. The seams must be grouted with a special waterproof grout.

- Heat shield. This design is a blank brick wall, laid at a distance of 2-3 cm from the outer surface of the boiler. The advantage of this design is that the heat is transferred to the stone, which ensures good heating of the room, while simultaneously preventing the risk of fire and burns. In addition, the absence of contact between metal and brick eliminates the appearance of cracks due to uneven thermal expansion of materials.

- Facing-convector with vents. Such structures are used for lining high-power fires, which are developed by pyrolysis plants or long-burning boilers. A vertical half-brick wall is laid out 4-5 cm from the stove. Vents are left in the lower and upper parts through which air circulates under the influence of changes in altitude and air temperature. This system works efficiently, evenly distributing heat throughout the steam room.

Oven screen options

It is recommended to line the sauna stove with half a brick; this is the best option. If the screen is made as thick as a brick, it will take a long time to heat up. In addition, a foundation will have to be built for such masonry. If you resort to a quarter-brick design, the bathhouse room will warm up quickly, but the radiation will be harsh. Regardless of the thickness of the masonry, the distance between the surface of the metal stove and the wall varies in the range of up to 10 cm.

The screens can be a solid structure with ventilation windows, while the chimney is often also made of brick. Another solution is possible: to cover only certain elements of the furnace.

As for decor, there are many different options. The neatly executed masonry itself looks quite beautiful. The color of the red brick contributes to the design of the stove structure. At the owner's request, the bath stove can be faced with porcelain stoneware, decorative brick, natural stone, and tiles. The choice is a matter of taste and the costs planned for these purposes.

Heater models

offers customers furnace equipment for heating rooms from 15 to 120 m³. There are four categories of Hephaestus bath heaters.

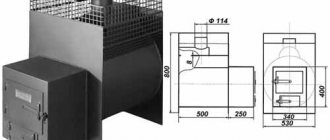

Design of the Hephaestus stove-heater

| Category | Description |

| PB 00 M and 000 M | These are cast iron sauna stoves. The line includes 4 models designed for heating rooms from 80 to 120 m³ |

| PB 01 | This series includes 4 models. This cast iron stove can heat a steam room with a volume of up to 35 m³ |

| PB 03 | The series includes 10 models, but only three of them are in demand. Such sauna stoves can heat a room with a volume of up to 25 m³ |

| PB 04 | This is the most popular line, consisting of 4 models. Such production devices are capable of heating a room with a volume of up to 15 m³ |

One of the most popular models is Hephaestus PB 03 M. With its help, the air is heated in a maximum of 20 minutes. In less than an hour, maximum heating is reached. Model PB 03 C is equipped with an open mesh heater. It differs from other models in having a sealed combustion chamber door.

Hephaestus PB 03 MS is equipped with a unique heater, thanks to which the air quickly warms up. "Technolit" produces models from the PB-03 series: PB-03 PS, PB-03 "Panorama", PB-03 C, and also produces other cast iron stoves from all other series.

Material and tools

Before starting finishing work, you need to prepare tools and consumables:

- reinforcing mesh;

- roofing felt;

- crushed stone, sand, cement, clay;

- heat-resistant mortar for bricklaying;

- boards, bars, slats for formwork;

- bayonet, shovel;

- trowel, trowel;

- building level, tape measure;

- knitting mesh, fittings.

Many people are interested in what kind of brick to line an iron stove in a bathhouse. You cannot use standard building bricks for this. For this it is better to use:

- refractory brick (fireclay);

- clinker brick.

Silicate blocks are not suitable for lining furnaces, since a large amount of lime is used in their production. Because of it, bricks are destroyed when exposed to high temperatures for a long time.

Bricks can have smooth or patterned surfaces. The latter are more suitable for decorative design of bath rooms.

Clinker brick

When deciding how to properly line an iron stove with bricks, you first need to decide on the materials suitable for this. They must have special characteristics.

Brick

The main material for cladding must be of high quality: without voids, with high heat resistance and fire resistance.

You can choose which brick to line an iron stove in a bathhouse from two options:

Clay brick. It is used for lining the body, masonry of the firebox and chimney of a wood-burning stove. It can be ordinary, front, or with a decorative front surface.

Fireclay brick With this type of masonry, the brick is placed on a spoon - a narrow long part

Solution

The ideal masonry mortar is made from clay and sand in certain proportions, which depend on the quality of the clay. Without experience, it is very difficult to do it. Therefore, it is best to buy a ready-made refractory mixture based on red clay.

Before covering the cast-iron firebox with brick, you just need to dilute it with water, as required by the instructions on the package.

Heat-resistant terracotta mixture

In addition to bricks and masonry mixture, masonry mesh and fire-resistant sheet materials may be needed to create a protective screen for wooden surfaces. And also roofing felt as a waterproofing material.

628998fca4610673d66cabc89e37795b.jpe

Tools

The following tools will be required to complete this job:

- Container for solution;

- Trowel for typing it;

- Hammer for adjusting bricks;

- Pickaxe for dividing them into parts;

- Jointing for seams;

- Ordering is a strip with divisions applied to it, the distance between which is equal to the height of one or several rows, taking into account the thickness of the seam;

- Construction level and plumb line for level control;

- Cord for controlling the evenness of horizontal rows.

Tools required for masonry

A sponge or rag and a bucket of clean water will also help to remove the solution from the front surface of the masonry.

Masonry materials

To build a partition around an iron stove you will need the following set of building materials:

- clay (ceramic) brick without voids;

- ready-made masonry mixture intended for stoves and fireplaces;

- metal corners with a shelf width of 35-45 mm;

- steel wire;

- stove fittings – doors, valves;

- water.

If you place a stone on its edge, you will save materials, but the heat capacity of the fence will decrease

In order for the screen near the potbelly stove to fulfill its function and conserve heat for a long time, the red brick must be solid. Hollow varieties are also acceptable for use, but their massiveness and heat capacity are significantly lower. Another option is natural stone (marble, granite), but it will cost more and is much more difficult to install.

A few words about which solution is best to use to line a stove in a steam room. If you are far from baking, then do not hesitate to buy a ready-made clay-sand mixture in the store. When this is not possible, prepare a solution from pure natural clay without impurities according to this recipe:

- Take a large container and soak the clay in it for 1 day. The consistency is thick, in the form of liquid.

- Pass the mixture through a coarse sieve to break up any lumps and remove any solids.

- Mix 1 bucket of slurry with 2.5 buckets of sand.

Immediately before laying, you can add a little cement to the solution for strength (no more than 200 grams per bucket) and mix thoroughly.

The best stones for a bath: reviews

By the way, everything is always complicated with reviews on the Internet; it’s better to go for an experiment and trust your own feelings than to strangers writing for unknown reasons.

Let's take the same jadeite . There are many reviews about “the best stone in the world,” but if you analyze them, the main advantages are: the steam has become lighter, the smell is pleasant. No one was healed by the healing stone, threw away their crutches and started dancing.

And there is reason to think about whether a person gets the most pleasure from the money spent? Checking it is as easy as shelling pears: buy a box (20 kg) of high-quality jadeite, put it in the top layer and try the steam. And the toad will not strangle, and the impressions will be personal, not from words.

The best reviews are those indicating the brand of the stove, operating mode, duration and results. One of the users says that he had two stoves at his disposal: Angara 2012 and Compact .

The compact was loaded with a mix, the revision was carried out 4 years after loading. It turned out that the following rocks suffered the most: abbro-diabase and crimson quartzite. Soapstone chlorite produced the most .

The jadeite did not break at all, so the user loaded the new stove exclusively with jadeite - both into the open and closed heater. Two years later, I carried out the first inspection: in the open one, nothing happened to the stone, but in the closed one , it broke into small fragments about 1/5 of the entire backfill.

Other users are in no hurry to share such detailed information. Someone boasts that his gabbro-diabase from Karelia stood for 10 years, and during the inspection only a few broken stones had to be replaced, and a little sand had to be raked out.

Another steamer reports the absolutely fantastic survival of soapstone from the Onot talc deposit : the stone worked for more than three decades in different furnaces!!!

Sometimes stones found independently in nature also demonstrate good survival: one user enjoyed steam from forest stones , another reported the survival of pebbles from a neighboring field for 10 years.

From the examples given, it is clear that no one has used all the options, but considers the best stones for a bath to be those with which he has dealt.

On the other hand, in the reviews there is nothing contrary to the nature of the stone: if you do not heat it to the limit, do not “wash” it with an open fire, in which everything oxidizes at a terrible speed, then it will live in your stove happily ever after. And if the stove is intermittent, with an open fire, then you need to be prepared to frequently replace the contents of the heater.

Video

Listen to a professional's advice on choosing the best stones:

And here is a review from a simple user.

And if you agree that there is nothing better than your own experience, then maybe share it with us? We decided to invite all readers who have experience using different stones and have formed their preferences to vote in our rating of bath stones:

Step-by-step instruction

Forming the base

In order for a brick-lined sauna stove to be strong and reliable, it is important to lay the foundation correctly. The strip foundation is considered the easiest to assemble and install.

To equip it, the wooden floor elements in the house are first dismantled, after which a trench is dug, the bottom of which is covered with a sand-crushed stone mixture. Everything is compacted well and watered. The next stage is concreting the foundation. For the strength and reliability of the structure, it is recommended to additionally lay a reinforcing mesh into the foundation before pouring it. The solution is then left to dry. Until the base is completely dry, further work is not recommended.

Preparation

Before constructing the protective apron, it is recommended to soak the lining brick for 12 hours. To do this, the required amount of material is separated, cleaned if necessary and placed in cold water. This event is necessary to ensure that the blocks do not absorb moisture from the solution during the formation of the order.

How to prepare brick mortar?

The installation of a metal furnace will be reliable if a cement-clay mixture is used as a masonry mortar. Both components are taken in equal proportions and diluted with water to obtain a creamy consistency. To mix the solution well and obtain a homogeneous mass, it is recommended to use a construction mixer. After mixing, you need to let the masonry mixture thicken, and then proceed directly to the masonry.

Bricklaying

In order for the apron to be reliable, it is important to correctly calculate the permissible distance between the brick wall and the iron body, because if the gap is small, the masonry will quickly crack and you will have to redo everything all over again. On average, it will take up to 15 orders to form a screen

It is recommended to divide the work into 2 stages: on the first day, form half of the rows, then leave the structure to dry until the morning. Then the rest of the masonry is done, the optimal row thickness is half a brick. The ordering scheme is presented in the table:

| Row | Description of work |

| 1 | The perimeter is completely laid with bricks, the row is started from the corner, with strict observance of evenness of laying |

| 2 | The wall is built up, reinforcement is carried out, air gaps are formed |

| 3 | Posted as 1st |

| 4—5 | A portal is formed for the firebox door and ash pan, |

| 6—8 | A metal corner is placed above the base of the portal |

| 9 | Can be stacked randomly |

Depending on personal preferences, you can arrange the arrangement with an arch at the level of the stove where the coals are located. This way the smoldering embers will be visible and you can admire them for a long time. You can also complete the arrangement by installing a round pipe in the bathhouse through which the smoke will come out. In none of the selected options, the step-by-step instructions for forming the order do not change.

11e848e1d3edc9508581e7ba9670a865.jpe

b93bf8b1cfe8d748c9f00f0289d65ea6.jpe

ca0a0831eef5a22c9c2b40b8d044df0d.jpe 4ee5b7901e5b4f12fd8d62f5442bdc66.jpe

First heating

When the brick finish dries, and this lasts on average up to 2 weeks, it is important to put the device into operation correctly. To do this, 2-3 test fires are performed, during which a minimum of firewood is used

This will prevent excessive heating and cracking of the structure. In this way, it will be possible to safely dry wet areas, thanks to which the stove will serve reliably and for a long time.

Fire safety requirements

When installing any sauna stove, it is necessary to strictly comply with fire safety requirements, since the walls of the device heat up to fairly high temperatures during its operation. In order to ensure maximum safety and not have problems with regulatory organizations, it is recommended to install the stove in accordance with the provisions prescribed in SNiP 41-01-2003 (Chapter 6.6).

- The first thing that needs to be done is to equip a reliable foundation for the main structure of the stove, which will be adjacent to the wall dividing the room. The foundation should be covered with heat-resistant material and then with metal sheet. Asbestos sheets were previously used as heat-resistant insulation. Today on sale you can find panels of pressed mineral wool, which is less dangerous from an environmental point of view, sheets of foam glass or EZHKAKH (heat-resistant structural mica plastic).

- It is also necessary to provide a metal flooring in front of the combustion door, which will prevent the wooden floor from catching fire and simplify debris removal. The size of the pre-furnace sheet must be at least 400×800 mm.

- If the partition between the steam room and the dressing room is wooden, then the opening through which the fuel channel will pass must be separated from the wood by brick or stone masonry. The distance between the stove and wooden walls should be 400÷450 mm.

In the version shown, the owner chose to fill the opening with bricks

- Provided that an opening is installed along the end part of the wall through which the combustion channel will pass, a gasket made of heat-insulating material (mineral basalt wool or cement-fiber sheet) with a thickness of 40÷50 mm, the distance between the part of the wall built from combustible material and the outer wall oven can be reduced to 250 mm. If thicker thermal insulation material is installed, the safe distance can be 125 mm.

- The distance between the ceiling of the bathhouse and the surface of the stove should not be less than 1200 mm.

- The distance from the edge of the combustion door to the nearest door must be at least 1250 mm.

- If you purchased a non-factory-made stove, or the device is independently made from sheet metal, then it is best to cover it with brick. Thus, it is possible to protect the structure of the bathhouse from fire, and people taking water procedures from burns. Factory products, as a rule, are made with double walls, between which thermal insulation material is laid or convection channels pass through.

Characteristics

Gefest company is considered one of the best among domestic enterprises. For many years, the brand has been producing electric and gas stoves, air purifiers and many models of built-in appliances for home and garden. Russian bath stoves from this company occupy a leading position in their niche.

The units have a high level of thermal conductivity and are manufactured using a special casting technology, with the help of which the base of the original product has optimal quality without any damage.

Gefest sauna stoves are available in two modifications: with coil lining and with mesh for stone laying.

All units are made from fire-resistant raw materials and are resistant to corrosion, fungus or mechanical damage.

with mesh

with cladding

Base structure

Before laying brick over the unit, you need to thoroughly prepare and strengthen the base for it. Since metal structures are light in weight, they do not require a separate foundation for the furnace, but brick cladding will provide an additional load of tens of kilograms.

Not every floor covering can withstand such a mass. For this reason, before covering the boiler with bricks, it is imperative to dismantle the floor and arrange a separate foundation - columnar or monolithic.

Most often, a monolithic base is made. To do this, the floor under the stove is dismantled. The foundation parameters should be such that there is a gap of 10 to 15 centimeters between the future brick cladding and the metal body of the unit.

First, they dig a hole approximately 30 centimeters deep, pour crushed stone and sand onto the bottom, compact it, install reinforcement and fill it with concrete mortar. The foundation will harden in about 2 weeks.

To arrange a columnar foundation, pillars are installed at the corners of the facing box and in places of the highest load. The advantage of this base is that no drainage or waterproofing is required.

The sequence of actions during the construction of a columnar foundation is as follows:

- Markings are made at the corners of the furnace for mounting the pillars.

- Dig holes located strictly vertically, having a depth of about 50 centimeters.

- A 10-centimeter layer of sand is poured into the bottom of all holes and compacted.

- Prepare a solution of cement and sand in a 1:2 ratio; it should have the consistency of thick sour cream.

- The solution is poured over the layer of sand in a 10-centimeter layer. Crushed stone or brick chips are added to it.

- After hardening, brick pillars are laid out so that they rise 7–10 centimeters above the floor.

- Install the lower trim beam. The most reliable way would be to lay the channel around the perimeter and weld the edge.

The use of concrete pillars is allowed. You can make sure that they are vertical using a building level.

The method of constructing the base depends on whether it already exists and what kind it is. It also depends on whether you are covering an already connected and operating stove or installing it and covering it at the same time.

If you have already poured a solid concrete foundation with a thickness of 20 cm or more, it will most likely withstand the expected load. In this case, you can line the iron stove with bricks immediately, without preparatory work.

If there is no foundation for the furnace, it is recommended to pour a solid reinforced concrete base. Its area should be larger than the cladding area. When calculating it, keep in mind that the distance from the metal body to the brick walls is assumed to be 8-10 cm.

The foundation is being prepared in stages:

First, you need to dig a hole 30 cm deep in the ground, fill it with sand, crushed stone, broken bricks and compact this pillow;

Installation of crushed stone cushion under the base

- Then, along the perimeter of the pit, formwork is built up to the level of the floor in the combustion room;

- A concrete mixture is poured into it, which is reinforced with metal mesh or rods;

Poured base for stove and cladding

- The concrete base must be allowed to dry for 2-3 weeks;

- After which it is covered with roofing felt and a brick platform one or two rows high is laid on top of it.

The brick base is laid on a layer of waterproofing. A common picture is that it is necessary to cover an already working stove with bricks

This is possible if the wooden flooring is able to withstand the additional load from the brickwork. To verify this, the floor must be disassembled and the joists inspected. To do this, the stove will still have to be temporarily dismantled by disconnecting it from the chimney.

ffcaa0f9f1b6b9a8cdc29457b0afc02c.jpe

389a356c3b5100ee2ba34c643a374d09.jpeAfter opening the floors, inspect the joists.

They must be dry, without signs of damage or rot, and the distance between them should not exceed 60-80 cm. If it is larger, another support with a cross-section of at least 10-15 cm must be laid in the place where the stove is installed.

The distance between the logs and their cross-section must be such as to withstand the load from the furnace

The floor boards themselves should be dry and strong, and their thickness should be no less than 30-40 mm.

After the inspection and reconstruction of the wooden base, first a metal sheet and then a fire-resistant material such as asbestos cardboard are laid on the floor according to the markings and secured with self-tapping screws. And a brick foundation is already laid on it.

Part of the stove and brick walls will rest on a wooden floor - we cover it with fireproof material

Dimensions

As already mentioned, they are delivered disassembled.

This decision by the manufacturer is due to the large mass of the unit (from 100 to 900 kg), which makes it more convenient to install the stoves directly on site. They are distinguished by a powerful body with reinforced walls with a thickness of 10 to 60 mm. The walls are equipped with vertical stiffeners. They can withstand significant loads, for example, when laying a large number of stones. Model parameters are indicated in millimeters.

Each product has its own dimensions:

- PB 01M – 711x495x887 mm;

- PB 01S – 887x600x860 mm;

- PB 01MS – 887x600x860 mm;

- PB 02M – 855x458x645 mm;

- PB 02S – 855x600x750 mm;

- PB 02MS – 855x458x645 mm;

- PB 03M – 755x418x590 mm;

- PB 03S – 755x500x700 mm;

- PB 04M – 645x394x490 mm;

- PB 04S – 645x450x570 mm;

- PB 04MS – 645x450x570 mm.

The combustion stove "Hephaestus" is designed in such a way that the steam room receives dynamic and fast heating. The heating of the stones occurs thanks to the equipment with a flame cutter, which evenly distributes the flue gases. The heater of the stoves has a unique three-section design. The equipment provides unique steam, which is considered ideal for a Russian bath. Wet steam is considered light and good for health.

Depending on the standard sizes, one or two specialists can do the assembly. The manufacturer prepares the kits in such a way that the work associated with their installation will not cause difficulties. To facilitate the installation process, the manufacturer pre-divides devices into two main categories. The devices are united by common requirements.

To connect the models, framed with soapstone, a chimney and a strong foundation are installed. Variations in the appearance of the finish can be adjusted by the owner himself. Usually stoves are lined with bricks, and they take on the appearance of a Russian stove.

Considering that the dimensions of the stoves are adjusted in accordance with the dimensions of the room, it is worth paying special attention to the use of certain types of fuel. Hephaestus stoves should be heated with wood or fuel mixtures

Do not use coal or wood waste for this. The best option is to fire the stove with hardwood logs. Firing a stove with wood has an advantage over other options. For example, the aroma of wood has an effect called aromatherapy.

Technologies

There are several proven technologies for bricklaying around metal furnace equipment:

- Heat shield. A brick fence that does not exceed the dimensions of the furnace in height. Promotes better heat transfer.

- Continuous cladding. It quickly releases heat to the surrounding space, which increases the cost of heating the premises. This technology is used when it is necessary to make a beautiful decorative design, sacrificing the performance of the furnace equipment.

- Convector masonry, which has vents. Suitable for metal heating units. In this case, the size of the steam room is not important.

Cast iron stove lining

The advantages of this solution

A metal stove heats up very quickly, but cools down just as quickly. In order for the temperature in the bath to be comfortable, it must be constantly heated during washing. And this is an extra consumption of firewood or other fuel.

In addition, the heat from the hot metal is too dry, and it is easy to get burned on its surface and cause serious injury.

Hot metal walls are a common cause of burns

But if you line an iron stove with brick, these disadvantages disappear, but significant advantages appear.

Namely:

- Long and uniform heat transfer, since the heated brick cools down slowly;

- Reduced fuel costs, the price of which is of particular importance if the stove heats the house and is heated daily;

- The heat from such a stove is not sharp and scalding, but soft and pleasant;

- It's much safer to be around her;

- A lined potbelly stove looks much more aesthetically pleasing;

Homemade potbelly stoves made of ferrous metal especially need finishing

Covering a metal stove with brick is much easier than laying a fireplace with a chimney, and it will cost less.

Today, a metal stove in a bathhouse is already a standard equipment, without which it is difficult to imagine the wellness procedure beloved by many. Compared to other types of ovens, it has a number of advantages:

- Easy to install. It is easy to make with your own hands.

- Easy and simple operation.

- It melts quickly.

- Has good traction.

- High performance.

- Economical in fuel consumption and affordable in price.

But in order to really appreciate all these advantages to the maximum, you need to learn how to use it correctly!

Oven in the steam room

No one, of course, would argue that a stone stove is ideal for a bathhouse. But it needs to be heated for at least 5 hours so that it really begins to give off its heat, imagine how much firewood will be consumed during this time. And this, in turn, does not suit everyone. And the price of a brick building will be many times higher than that of a metal stove lined with stone.

Air mass movement pattern

In addition, in order to build a brick stove for a bathhouse, you need to have the basic skills and knowledge of a stove maker, since in this design you need to take into account many nuances that are invisible, but play a decisive role!

Brick oven

A metal stove can be bought ready-made, and the lining will not entail large financial expenses.

Metal stove without brick lining

What necessary parameters should a metal sauna stove have?

- It should have small dimensions so as not to clutter up the space.

- You should not choose too high a power, since the sauna room is usually small. It will be difficult to control the optimal temperature.

- The characteristics of the stove must strictly comply with fire safety regulations.

In addition, it is necessary to take into account the location where the stove is located. According to SNiP standards, the metal unit must be located at a distance of at least 15 cm from wooden floors.

95bb0a6a0ae6834cc7092d91d0c2ddad.jpeSauna stove

What else is the highlight of Hephaestus?

Economical - The stoves are designed with two combustion chambers, the first is the main firebox, the second is the gas afterburning chamber, making the efficiency higher than that of stoves with only one firebox. Fresh heated air enters this afterburning chamber along the technological path and the gases that have not burned out in the furnace are burned out. The afterburner also allowed Hephaestus to meet European standards and be in demand in Europe.

Factory warranty - Thanks to high-quality materials and successful design, the factory is confident in its furnaces and provides a 5-year warranty on the product, and an estimated service life of more than 30 years, with proper operation.

Door with glass - If you purchase a stove with a door with glass, keep in mind that special ceramic glass from the German company Robax is installed at the factory. The door itself, like the entire oven, is made of cast iron. An air control valve is located under the glass; it regulates the air supply to the firebox.

Remote combustion tunnel - All models come with a distance of 200 mm from the door to the firebox. If necessary, you can purchase an extension of the combustion tunnel (it is called a combustion tunnel adapter) with a width of 100 mm, if you have a wide ceiling and 100 mm is not enough, then by purchasing another such element, you can lengthen the portal by 200, these elements are joined to each other and so This way you gain the desired length.

Equipment - All stoves are equipped with a starting cast iron chimney element, 234 mm long (working size 111 mm). The first chimney pipe is always the most thermally loaded, and made of cast iron, it lasts as long.

Convection operating scheme - Hephaestus stoves heat the steam room not only by thermal radiation, but also by convection. Regardless of whether you line the stove with brick or buy it in stone, the design of the stove provides convection spaces; they help remove heat from the walls, cooling them and, as a result, the air heats up faster.

Furnace lining – factory lining of furnaces is made only from natural stone from Karelia and the Urals, soapstone and coil stone are used. Both stones are volcanic rock, confidently withstand temperature changes when cold water hits heated surfaces, the stone does not crack or fly into fragments.

According to their characteristics, the stones differ primarily in color, one is green, the other is gray. Serpentinite, also known as coil, is more durable in its structure and, as a result, lasts longer and this point is reflected in the form of a higher price. In terms of heat capacity, soapstone chlorite is ahead of the coil, but since the volume of stone in cast iron stoves is significantly less than the bricks used in a Russian stove, this volume of stone will not retain heat in the steam room for a long time, so this plus is not significant.

There is also a difference in the technical properties of the stone, but these points primarily affect the processing of the product and for the common man they are also not significant. In general, choose the color and service life of the stone.

Functionality - according to operating experience and testing results, the Hephaestus stove heats the steam room to 80 degrees in 40-60 minutes. In this case, the stove operates in forced mode, i.e. You open both dampers - one on the door, the second on the chimney and burn with medium-sized dry firewood, in this case you effectively use the available firewood.

Wet firewood does not produce as much heat as dry firewood. Large wood burns longer, but produces less heat; it is better to use it to maintain the temperature in a heated steam room. After you have warmed up the steam room, you need to switch the oven to economy mode, i.e. close the air supply on the door and slightly cover the damper on the pipe, in this mode the stove uses wood economically and maintains the temperature in the steam room.

Hephaestus sauna stove with closed heater

This line of stoves is marked with the mark ZK; it differs from all other stoves by the presence of a cast iron lid that covers the heater. This gives the effect of finer and heated steam. This modification of the stove is recommended for bathing gourmets.

Assembly of Hephaestus furnaces

The assembly process is described in detail in the accompanying passport for the stove. Everything was assembled without bolted connections according to the assembly diagram; there are only 19 oven elements (in the PB 04 oven). During assembly, all joints and grooves are coated with heat-resistant sealant. The resulting design is confident and rigid.

We invite you to familiarize yourself with a chimney for a bathhouse with your own hands

Insulation methods

There are several techniques that allow you to reliably insulate wooden structures from the heat of the stove. Some of them involve a fairly large amount of work, while others are much simpler.

- Creating a protective box from brick or stone.

- Installation of a special industrially manufactured screen.

- Creating a protective structure with your own hands from non-combustible materials.

The construction of a box made of brick or stone will require the most time - it will be necessary to lay out several walls that will protect the wood from heat. In addition, this protection option requires a gap between the wood and the brickwork from 5 to 15 centimeters. There should be about 10 centimeters between the casing being built and the walls of the stove. All this eats up useful space and requires some mason skills to work on.

Factory screens are installed quite simply and are not that expensive. They could be an ideal solution if they did not require even larger technological gaps between different surfaces. Therefore, such finishing of the wall near the stove is possible only in a fairly spacious bathhouse. If you need to save space, it is better to look for another solution that allows you to reduce all the gaps from wooden partitions.

The third option allows you to reduce distances to 15 centimeters, which is already more acceptable

At the same time, this method allows you to create the most beautiful design, which is important. However, there will be a lot of work and the costs in this option may be much higher than in the previous ones. In addition, this insulation method requires a more detailed consideration due to the features of the assembled structure

In addition, this insulation method requires a more detailed consideration due to the characteristics of the assembled structure.

Clients about our work

Andrey, 06/20/2014

First of all, I would like to note that the store works with all payment methods. This is extremely convenient. The choice of products is extensive; you can consult with specialists on all questions. Delivery was free for me, everything was done efficiently, on time.

Sergey Ivanov, 08/09/2014

I finally decided to take on the arrangement of a long-built bathhouse on a summer cottage. After some deliberation, I ordered this stove and was satisfied. We haven’t used it much, but so far I’m happy with everything. The steam room was designed to be quite spacious, and the stove copes with its task well, no problems with heating.

The sellers are competent - there were no arguments like “Take another model,” the communication was calm and knowledgeable, especially considering the fact that I had previously studied the market. The order and delivery were processed quickly, I was also pleased with the delivery itself - everything was on time, as agreed. Thank you!

Galina Komkova, 08/26/2014

I ordered a Hephaestus PB-04Optima bath stove from this store. I want to say thank you very much, I liked everything very much! A very polite operator answered my call to the company and gave detailed advice on the cost of the stove and the conditions and delivery time. The order was processed promptly, the delivery was also pleasing - everything was done quickly and on time! Moreover, the stove was delivered from Moscow to Chita. I also liked the stove itself - reliable, beautiful and looks great in my new bathhouse.

Polina, 08/16/2014

The store was recommended by friends. I was pleased with the choice. The old stove had fallen into disrepair and was long overdue for replacement. The new one fits perfectly into our usual environment. In the store, I especially want to note the friendliness of the staff. The manager answered all my questions in such a way that there was no longer any doubt about which stove to order.

The advantages of this solution

Below is a list of the advantages that this design has:

- Even heat distribution. This is due to the fact that the brick first accumulates energy and then releases it into space.

- The presence of pleasant warmth instead of scorching heat. There is always humid air in the room due to the fast and efficient heating of the stones.

- Long-term preservation of high temperature. Brick is a natural accumulator of thermal energy. That is why you can heat the sauna well and steam there for several hours, without thinking about additionally increasing the temperature or adding fuel again.

- Ensuring safety while in the steam room. Hot metal poses a certain danger: the possibility of accidental burns upon contact with the walls of the tank. The lining of the sauna stove with bars acts as a barrier that protects against extreme heat and sudden injury.

What kind of brick is best to line a stove?

As always, the start of work is preceded by the selection of suitable material. It must be said that when constructing such small structures, homeowners tend to use materials available on the farm or their remains from previous construction. This desire is quite understandable, so we will approach the selection of bricks from the same point of view. So, there may be remains of bricks in the household:

- silicate;

- fireproof (fireclay);

- red hollow;

- red ceramic solid.

Let's go in order. Sand-lime brick based on a slaked lime binder is very durable and tolerates various environmental conditions well, which is why it is an excellent cladding material for houses. But lining a metal stove with lime-based bricks is a useless option.

Lime material is not suitable for the temperature range at which the sauna stove operates, and yet there is still high humidity in the room. In such conditions, sand-lime brick will begin to collapse quite quickly. In addition, it is heavier than red brick and requires mandatory cladding, since its original appearance will not fit into any interior.

Fireclay stone is suitable in all respects for the construction of a heat shield. It is not afraid of temperature changes, the weight and heat capacity of the brick is almost the same as that of a red stove brick. The situation is worse with the appearance; not every homeowner will like it inside the house or bathhouse. But the solution here is simple: the stove is lined with porcelain stoneware or other material.

If you take any red brick, then this is what you need for a heat shield. Of course, the best option is a solid stone, but a hollow one will also work quite well. True, it will not retain heat for a long time, since it does not have such massiveness and heat capacity as a solid stone.

It must be said that lining a metal stove with brick allows the use of both standard stone sizes 250 x 120 x 65 mm and thicker ones 250 x 120 x 88 mm. The quantity depends on the height of the heater and the type of masonry; as a rule, it is done in the usual way, half a brick. You can put the partition in a quarter of a stone, but then you will need to take additional measures to strengthen it and bandage it, which complicates the process.

Cast iron stoves Hephaestus for rooms from 45 to 120 m

The stoves included in this group are characterized by higher power ratings; they weigh quite a lot, but are also able to effectively heat large rooms:

- PB 80 M (weight - 700 kg, dimensions - 1171x726x1100 mm). Productivity - 35 kW, heated room - up to 80 m³.

- PB 80 MS (weight - 710 kg, dimensions - 1171x950x1200 mm). The technical characteristics are completely identical to those described above. The cost of such a bath unit is approximately 260,000 rubles, the same as the 80 M model.

- PB 120 M (950 kg, 1200x926x1382 mm).

- PB 120 MS (950 kg, 1100x726x1382 mm). This model, just like the 120 M, is capable of effectively heating baths with an area of up to 120 m³. This is due to the fact that the equipment has high power - 45 kW. The difference between m and ms is in the dimensions and external design of the case. Cost - 300,000-360,000 rubles.

We suggest you familiarize yourself with how to treat shelves in a sauna: how to cover wood in a sauna, what to impregnate doors and walls with, what to paint, is it better to wax the inside, impregnation in photos and videos