The article was prepared with the participation of DOZATECH specialists

Despite the fact that our country is one of the largest exporters of blue fuel, there is no need to talk about widespread gasification. For many consumers both in Moscow and Siberia, the cheapest heating method is unattainable now, and it is not a fact that it will be available in the future. Therefore, we have to look for alternative heating sources; fortunately, the choice in this area is impressive. And in recent years, the range of heating equipment has been replenished with an interesting unit - a pellet boiler. Let us dwell in more detail on this type of equipment, for which we will consider the following aspects:

- What is a pellet heating boiler and what fuel does it use?

- Unit design.

- Advantages and disadvantages of a pellet boiler.

- What to look for when choosing a unit.

What is a pellet boiler

In essence, this is a type of solid fuel boiler, but designed for a specific type of fuel (pellets) and with the possibility of full or partial automation of the work process.

It is the ability to function autonomously with minimal intervention from the owners that makes pellet boilers radically different from conventional solid fuel boilers.

They have a higher efficiency (efficiency factor) - both due to the characteristics of the pellets and due to the design features. Pellet boilers can be either highly specialized - intended only for pellets, or combined (universal) - capable of running on wood or coal, some models operate on almost any biomass; husks, wood waste and the like can be used as fuel.

Alexander DimitrevRepresentative of DOZATECH, a manufacturer of pellet boilers

With a certain boiler design, it can burn any biomass of very low calorie content - wood chips, bark, wood waste, agricultural waste, sunflower husks and more.

Pellets, or wood pellets, are environmentally neutral fuel, obtained mainly from waste from the wood processing industry (chips, shavings, bark), but they can also be from agricultural waste. Pellets appeared in the thirties of the last century, when the first installation for pressing waste from local sawmills into pellets was invented and tested in the state of Idaho. Under strong pressure, the raw material mass is heated, which provokes the formation of lignin, which binds the smallest particles into dense, smooth granules. This allows you to abandon the use of chemicals - pellets are a completely natural, environmentally safe fuel. The diameter of the granules varies between 6-8 mm, length – up to 50 mm. In European countries, pellets are classified as standardized fuels and are produced according to the DIN plus standard.

In our country, their production is not so developed and supervised; the quality of the granules, on which both the efficiency of the boiler and its performance will depend, is determined visually - white ones are better than gray ones. Unlike wood, pellets have low humidity and high density, which is why when burning, more heat is released and a minimal amount of carbon dioxide is released. If we translate this property into numbers, for comparison, we get the following ratio: when burning a ton of pellets, the same amount of heat will be released as when burning 1.6 tons of firewood. The ash content will be only 0.5% of the burned volume, and the emitted flue gases will be colorless.

The approximate calorific value of pellets is 5 kW/hour per kilogram, but how close the actual efficiency will be to the theoretical data depends on the quality of the pellets themselves and on the performance of the boiler in which they will be burned.

Types of pellet boilers

Equipment of imported and domestic production comes in different types. Each of them has its own advantages and disadvantages.

Boilers are classified according to several criteria.

For example, by type of fuel they distinguish:

- Devices operating only on pellets.

- Combined models. Other options for solid fuel are used - firewood or briquettes.

In the latter case, at least 2 combustion chambers are provided, each of which is intended for a separate type of raw material. Such devices differ in size.

There are also conditionally combined boilers. The devices operate on wood or briquettes, but not all the time, since they are also designed for pellets.

Based on the type of fuel supply, a distinction is made between semi- and automatic models (in the former, the loading of raw materials is carried out without human intervention, but the power is adjusted manually). There are also mechanical devices (the owner will have to add fuel himself).

There are also several types of boilers based on their intended purpose:

- Hot water models that provide hot water supply as standard. They are installed in separate rooms. The devices are distinguished by their dimensions and high performance.

- Convection boilers. These are mini units. They can be installed in residential areas, since the devices are compact, safe and have a stylish design. But the units serve only for direct heating of air.

Unit design

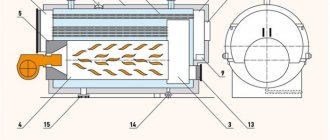

The pellet boiler itself consists of three main components:

- Furnace - equipped with a special burner (retort or torch) and two doors (control, cleaning).

- Convective zone - a heat exchanger is located in it: it can be vertical, horizontal or combined, tubular or plate type. In the convective zone, the coolant in the heat exchanger is heated by gases released during the combustion of pellets. Most units are designed only for heating and have one circuit, but some models have two circuits: heating and water heating.

- Ash pan - it receives combustion waste (insignificant during normal afterburning), which is periodically removed through the cleaning door.

However, the listed components are, although the main part, but only a part, the operation of which requires the APT attachment (automatic fuel supply). This attachment includes the following components:

- A hopper is a container for pellets of a certain volume, from which the pellets enter the combustion chamber; it can be built-in or external.

- Auger - portions feed granules to the burner as needed, driven by a gearbox.

- A fan is necessary to maintain the combustion process, since the boiler design does not provide for natural draft.

Since the pellet boiler is an automated system, its device also includes a control unit with a display, which displays information about the current state, and through which the main operating parameters are set. The controller regulates the ignition of the burner, the supply of pellets and air, and stops when the desired temperature is reached, maintaining the heating mode selected by the owner.

Depending on the capacity of the bunker and the selected mode, one filling can be enough for several days, a week or even more.

To make the heating process fully automatic, the boiler can be connected directly to the storage - a pneumatic pipe will supply granules to the bunker as it is emptied.

The best models of pellet-wood boilers

Combined heaters are produced by many Russian and foreign companies. A number of models with the best price-quality ratio are especially popular.

Heiztechnik HT Daspell Duo

The Polish unit operates on all types of fuel, incl. on coal. The line includes models with power from 12 to 65 kW.

Description:

- 1 circuit;

- Heiztechnik Pellhard Plus torch burner with self-cleaning and ignition function;

- water-cooled grate;

- electronic weather-compensating automation;

- possibility of installing a display, ash removal system and Internet connection.

Heiztechnik HT Daspell Duo is a Polish boiler.

The device is made of steel 5 mm thick.

Zota Pellet 15S

Russian 2-burner unit with a power of 15 kW.

Main characteristics:

- automatic switch to pellets after firewood burns out;

- maximum pressure of the working medium – 3 atm.;

- only forced circulation;

- 2-screw feed (protection against flame penetration into the hopper);

- flow meter – calculates daily and total fuel costs;

- control panel with the ability to connect up to 3 pumps and indicate their priority.

Zota Pellet 15S is a two-furnace unit.

Additionally you can install:

- 12 kW heating elements - turn on automatically if the user forgot to add solid fuel in time;

- GPS module for controlling SMS commands from a smartphone;

- Matrix uninterruptible power supply.

The fire is maintained at the top of the burner, which prevents the auger from burning out.

Automation – weather-sensitive, with programming function.

The device is resistant to high temperatures and voltage surges.

Stropuva Mini S8 P

Lithuanian top combustion boiler with a power of 8 kW. There is no automatic fuel supply. But due to the fact that the load is ignited from above and the air is supplied strictly to the combustion zone, the duration of operation is (in hours):

- wood-burning – 18;

- on briquettes – 30;

- on pellets – 42.

The firebox volume is 163 liters. It holds 106 kg of pellets.

Stropuva Mini S8 P is a top combustion boiler.

The advantage of the heater is energy independence. The coolant temperature and performance are controlled by a bimetallic mechanical sensor connected to the air damper.

Installation efficiency is 85%.

Svetlobor VD 16

Russian equipment with a power of 16 kW. Together with the boiler, a pneumatic fuel supply system from a remote storage facility is offered. It frees the user from even having to load pellets into the hopper. The boiler is approached once a month for maintenance.

Description:

- volumetric type burner;

- automatic cleaning of grates and heat exchanger, removal of ash;

- Efficiency – 94%;

- pellet consumption in nominal performance mode – 3.5 kg/hour;

- weight – 450 kg;

- option – GSM module.

Svetlobor VD 16 - Russian equipment.

The boiler tank is located vertically, which reduces the rate of formation of deposits on its walls.

The entry of flame into the feed auger and hopper is prevented due to the special shape of the burner. It is designed for pellets of any quality.

Metal Fach SD Duo 14

Single-circuit boiler with a capacity of 14 kW, made in Poland. Description:

- water-cooled grate;

- volumetric type burner;

- cast iron screw;

- Efficiency – 90%;

- control – electronic, information is displayed;

- weight – 485 kg;

- ability to connect 4 pumps, weather and room thermostat to the controller.

Metal Fach SD Duo 14 is a 14 kW boiler.

The unit operates on all types of fuel, incl. on coal. Fire protection for the feeder must be purchased separately.

Faci Base 15

Italian 1-circuit unit with a power of 15 kW. Equipped with an automatic feeder for the following types of fuel:

- pellet;

- coal up to 15 mm in size.

The volume of the standard bunker (263 l) is enough for 3 days of work.

The device is made of heat-resistant steel and equipped with a volumetric pellet burner.

Fire precautions:

- 2-screw feed;

- screw temperature sensor;

- extinguishing system (emergencyly dumps all ignited pellets into the boiler).

Faci Base 15 is an Italian unit.

Options:

- auto ignition;

- GSM module;

- more spacious bunker.

Efficiency – 92%.

Conversion to gas is possible.

Advantages and disadvantages of a pellet boiler

One of the main advantages of pellet boilers is their efficiency; in this indicator they are second only to gas main heating. This is due to the high efficiency of the equipment, the high calorific value of pellets, and their affordable cost. The second aspect that attracts consumers is process automation. Unlike other solid fuel boilers, pellet boilers do not require constant monitoring and regular manual fuel supply. It also wins over units running on diesel fuel in terms of environmental friendliness - no odors or black smoke.

The main disadvantage of these units is their substantial price - these are the most expensive solid fuel units, the cost of an automated station made in Europe is measured in hundreds of thousands, domestic ones are slightly cheaper. Not every private owner can afford such investments into the heating system of their home. However, with equipment longevity now approaching two decades, it is a wise investment in the long term.

In addition to the high cost, the disadvantages include energy dependence - the automation requires electricity, and if a shutdown of several hours (on average up to 10) is acceptable and will not disrupt the settings, then a longer shutdown will stop the operation of the boiler. The station must be equipped with an independent energy source, which will further increase the cost of the system.

What to look for when choosing a unit

Despite the relative “youth” of this type of solid fuel, there is a large selection of boilers of foreign and domestic production on the market. To choose the optimal unit for your conditions, you should pay attention to several important parameters.

Power - each manufacturer has a fairly wide range of models, including both household and industrial units. As with any heating equipment, power is measured in kilowatts (kW), the power of household models starts from 15 kW. Since heating a room with average heat loss requires about 1 kW per 10 m², such a boiler is capable of heating a house of 150 m². However, it is worth considering that the boiler is needed with a small margin.

Efficiency - the higher this indicator, the more economical the heating process. For pellet burners, the efficiency varies between 85-95% and depends both on the quality of the pellets and on the design features.

Alexander Dimitrev

The five-pass heat exchanger ensures high efficiency of the boiler - it allows you to obtain maximum heat removal when gases pass through the convective zone to the chimney.

The specialist advises paying attention to the material from which the boiler is made and the type of heat exchanger.

Alexander Dimitrev

Boilers made of thick metal (6 mm and 8 mm, depending on power) are more durable. The thickness of the metal affects the service life of the boiler; this is also important - how many years the unit will operate. A plate heat exchanger has advantages over a tubular one - it is more convenient to clean.

Review of pellet boiler models

Companies involved in the supply and installation of boilers offer a fairly large selection of boilers, both imported and Russian-made.

- The price of heating equipment depends on several factors:

- thermal power;

- configurations;

- level of automation and availability of built-in protections;

- type of loading and bunker;

- possibility of using the boiler for combustion with other types of fuel;

- body material;

- manufacturing company.

In order not to overpay for the brand, you need to compare the technical characteristics of the offered models and choose the most suitable pellet boiler with automatic feed.

Czech boilers OPOP BIOPEL

Power of various models - from 10 to 200 kW

OPOP BIOPEL boilers are equipped with a vertical three-pass heat exchanger, which improves heat removal and increases efficiency - for these boilers it reaches 92%. A special smoke turbulization system stabilizes draft and combustion mode.

All models are equipped with weather-compensating control and electric ignition, as well as an Internet control function. Additionally, they can be equipped with self-cleaning systems for the heat exchanger and burner, and ash removal. When ordering them, manual cleaning of the boiler is required only once per heating season, and without self-cleaning systems - once a month.

The price of the least powerful model OPOP BIOPEL 10 kW is from 285 thousand rubles.

Boilers Kostrzewa Pellets Fuzzy Logic, Poland

power from 15 to 100 kW

The dimensions of the built-in bunker allow loading once every 1-4 weeks, depending on the power of the model. The dimensions of the fuel chamber allow boilers to operate on wood and coal without removing the pellet burner. The design of the ash pit and its dimensions allow it to be cleaned no more often than the hopper is loaded. During cleaning and loading, the exhaust fan is turned on to avoid dust formation.

All models have a high level of automation and have a built-in controller and sensors, as well as a lambda probe for the best regulation of the combustion process. The automatic return water supply uses the bypass principle and regulates its temperature.

The price of the Kostrzewa Pellets Fuzzy Logic 15 kW model is 270 thousand rubles.

Wirbel EKO-CK PELLET-SET boilers, Austria

universal solid fuel boilers with built-in pellet burner

The basic models are equipped with automatic ignition and pellet supply, but can also operate manually using wood or briquettes. Control is carried out from the remote control, and it can also regulate the operation of the heating circuit pumping equipment. Cleaning and servicing the boiler does not take much time and is carried out no more than once a week.

The price for a set of equipment for 20 kW is 300 thousand rubles.

Boilers Grandeg Bio, Latvia

Simple and reliable with increased fire safety and a sluice gate in the top, service life - more than 20 years

The price for a 25 kW model is 347 thousand rubles.

Boilers Svetlobor, Russia

power from 20 to 170 kW automatic supply, ignition, cleaning and ash removal are distinguished by unpretentiousness to fuel quality

Price - from 250 thousand rubles.

Pellet boilers Obshchemmash, Russia

Valdai boilers with a capacity of 15-200 kW are designed for heating residential and industrial buildings. They are equipped with all the automation necessary for a pellet burner: auto-ignition and automatic fuel supply, burner self-cleaning, and a controller that regulates the mode. The unit can be controlled remotely via GSM.

Price - from 138 thousand rubles.

“Peresvet” control models – via Wi-Fi and the Internet

Price - from 146 thousand rubles.

Boilers "Teplodar-Kupper", Russia

The cheapest model equipped with the necessary functions

The price is the lowest of all the presented models; a fully equipped Kupper-OK with a power of 15 kW costs 92 thousand rubles.

The choice of a pellet boiler with automatic supply of granulated fuel depends on preferences and financial capabilities. All models presented in the review are certified and safe.

Conclusion

Pellet boilers are modern, environmentally friendly and cost-effective heating equipment. At the moment, they are less in demand than conventional solid fuel units, but in the future they may well conquer the market due to the high quality of heating and decent performance.

On our portal, in the forum section about boiler equipment, an entire thread is devoted to pellet boilers. No less useful and interesting is the article on how to prepare for the heating season. Another option for autonomous heating is heat pumps. In the video, a portal participant shares his experience of installing a pellet burner with his own hands.

Subscribe to our Telegram channel Exclusive posts every week