Most often, when building a house, the attic space is immediately thought of as residential. At the same time, the question arises of how to insulate the attic so that it is a useful area not only in summer, but also in winter. But sometimes it happens that the idea of arranging a room in it arises already in the process of building an attic. If the roof slopes are located at an angle of 35 ÷ 45 degrees, and raised high enough, decorating the attic as a cozy room suggests itself.

How to insulate an attic

The rooms under the roof in winter are always much colder than those located under it, since there are no reliable solid walls that will protect from low temperatures, as well as from piercing winds. In summer, on the contrary, the roof slopes accumulate solar heat, and the attic can become unbearably hot. Therefore, it is worth making a lot of effort to purchase effective, high-quality materials in order to achieve ideal thermal insulation of the attic. In addition, an insulated attic will directly affect the preservation of a comfortable microclimate in the house itself.

Insulation of an attic space can be done in several ways and using various materials.

Waterproofing under the roof

In the case when the roof installation is carried out taking into account all technological rules, there should already be a layer of waterproofing under the roofing material. If this stage was previously skipped, then waterproofing must still be performed to protect the insulation from leaking atmospheric moisture or condensation. Such film waterproofing is done if mineral wool or polystyrene foam is used as insulation for the roof slopes. The membrane or dense polyethylene film is spread either in one sheet or with an overlap of at least 200 mm, and is attached to the wooden roof structures with staples using a construction stapler.

Films for attic waterproofing

However, if waterproofing material is not laid on the rafters, it is quite possible to use sprayed polyurethane foam for insulation.

Spraying polyurethane foam immediately solves the issues of hydro- and vapor barrier

Of course, in this case you will have to turn to specialists who are professionally involved in this technological process of insulation and have the necessary equipment for this. But on the other hand, you can free yourself from all further worries about insulating the slopes and get a thermal insulation layer that does not require waterproofing, since it itself will tightly cover the inner surface of the roof and rafters.

Materials for self-insulation of the attic

If a waterproofing film is laid on the rafters, then the following insulation materials can be used for further work:

- Mineral wool is the most popular insulation material, which in terms of parameters is excellent for thermal insulation of a wooden roof system and roof slopes. Mineral wool is heat and moisture resistant, has very low thermal conductivity, is durable, elastic, which is very convenient when performing installation work. In addition, all types of mineral wool are excellent sound absorbers and sound insulators. Sometimes, to enhance the insulating effect, sprayed polyurethane foam is used in combination with mineral wool. This option is especially in demand in northern regions with cold climates.

It is very good if mineral wool rolls also have a foil coating.

Mineral wool is produced in different forms - in mats and rolls. It can also have a foil coating. Material with a similar layer is placed with foil inside the room so that the accumulated heat is reflected back.

- Expanded polystyrene (foam) is a well-known insulation material that is affordable and easy to install. However, practice shows that often this material alone is not enough to make the attic room truly warm, since it does not adhere sufficiently to the roof surface.

Expanded polystyrene (foam) panels

It can also be used in combination with sprayed insulation. In addition, ordinary foamed polystyrene (not extruded) is not resistant to fire, and when burned it releases toxic substances - this fact must also be taken into account when choosing a particular insulation material.

- Polyurethane foam can be sprayed in several layers and, in principle, have any desired thickness that is required for high-quality insulation of the attic space. When hardened, it acquires a fairly high density and is easily leveled along the rafters by cutting off excess foam. The sprayed material will penetrate into all cracks and close them from the penetration of drafts and precipitation. Not only that, it also gives the roof and roof structures additional resistance to mechanical loads.

Cured polyurethane foam

The sprayed material quickly increases in volume and hardens. By using it, you can do not only without waterproofing, but also without vapor barrier, since this material, in a frozen state, easily copes with these problems - it does not delay the release of steam, but at the same time, it does not allow moisture to enter.

The process of spraying a thermal insulating layer of polyurethane foam

Sprayed polyurethane foam can be used not only for insulating the slopes and walls of the attic, but also for its floors. It is also sprayed between wooden structural parts, in this case between floor beams.

- Ecowool is a crushed material made from natural cellulose with appropriate additives. They are good for insulating the gaps between floor beams. Shredded ecowool is not very suitable for wall insulation, since it does not have such a pronounced adhesive property as polyurethane. However, there is a technology for wet adhesive spraying, but it necessarily requires sophisticated professional equipment.

In order to create the required thickness of the insulation layer, trusses made of galvanized metal profiles are installed across the floor beams. The space between them will be filled with ecowool. This process is carried out using special equipment - a compression unit, through a special pipe, pneumatically transfers material under pressure from a bunker or mixer to the place where it is laid.

Composition of the insulating “pie”

In houses with an attic, the process of insulating the ceiling consists of the following steps:

- The rafter system is carefully checked for all kinds of flaws, cracks and other signs of damage. If any are found, measures are taken to eliminate the identified defects.

- Waterproofing material is fixed along the perimeter of the attic ceiling. This is done using a construction stapler.

- Laying the insulation itself. Slab, roll or bulk materials can be used. When filling, niches for placing material must be divided into cells using wire. If the insulation is mineral wool, metal brackets can serve as fastening elements.

- When the thermal insulation layer is completely equipped, a film is laid on top of it, serving as a vapor barrier.

- The final stage is the installation of decorative cladding.

How to insulate an attic from the inside?

When choosing insulation, you should definitely calculate its weight. The weight of the thermal insulation material is an important parameter that will determine whether the rafter system and sheathing will withstand the load. To carry out internal thermal insulation work, you will need to fix the insulation to the sheathing.

Important! Insulating the attic in this way is carried out when the roof covering is already installed. In other situations, it is most advisable to carry out external thermal insulation of the structure.

Before you begin, it is recommended that you watch the video on this topic. If you use fibrous material as a heat insulator, then there is no need to install a windproof film. To ventilate fiber insulators, natural attic ventilation is sufficient.

Next, the insulation is installed directly (for example, mineral wool). The next stage is the installation of a vapor barrier film, which will protect the surface on the room side from condensation. Next, you will need to make a sheathing of timber so that the material is tightly fixed. At the end, the structure is sheathed with plasterboard sheets. If desired, drywall can be replaced with OSB.

Rating of the best insulation materials for attic insulation

The material must be selected in accordance with the requirements for the improvement of the attic space. The following main types of materials for thermal insulation are distinguished:

- At the top of the ranking are a group of materials called mineral wool.

- The second most popular insulator is a material made from natural cellulose - ecowool.

- In third place in demand is extruded polystyrene foam. The material is loved for its ease of installation and affordable cost.

The above types of materials for thermal insulation belong to the same segment of affordability. At the same time, each of them has both a list of advantages in terms of technical indicators and a list of disadvantages that must be taken into account if you plan to thermally insulate a room.

According to experts, it is quite possible to independently furnish an attic using inexpensive materials.

These include polystyrene foam, which is characterized by a high level of heat insulation both in the outer part of the gable and when used to insulate floor joists. Expert opinion

Konstantin Alexandrovich

Mineral wool can be considered the optimal material in terms of cost and quality characteristics. Its thermal conductivity index is quite low and amounts to 0.035 W/μ, the insulation has a long service life and is characterized by a low level of moisture absorption. If a layer of material is immersed in water for 24 hours, it will absorb no more than 1% of its weight in moisture.

Types of insulation

Mineral wool is the undisputed leader among other thermal insulation materials. Its additional advantage is high sound insulation. This material is recommended for beginners as it is light weight and easy to install. Mineral wool is produced in slabs and rolls. For insulating the attic, the first option is best.

Mineral wool has one significant disadvantage - it absorbs moisture well. Therefore, if you have chosen this material, you need to think about reliable waterproofing. It is recommended to pay attention to the photos of various thermal insulation materials. This will allow you to visually evaluate their advantages and disadvantages.

It is also worth talking about ecowool, which does not deform over time, such as mineral wool. Another advantage of ecowool is that it is not susceptible to mold and fungi. However, to install it, it is necessary to invite a qualified craftsman who can correctly drive the material under the vapor barrier.

Another fairly popular material is expanded polystyrene (EPS). It also has high thermal insulation properties, which explains its wide distribution. PPS is resistant to moisture, which allows it to maintain its characteristics under any conditions. The disadvantage of polystyrene foam is its cost.

A budget option for insulation, which is also in demand, is purchasing polystyrene foam. This material does not have high strength characteristics, but is able to retain heat in the room. The thermal insulation properties of polystyrene foam are lower than those of mineral wool and EPS.

Polyurethane foam is an excellent option if you need to insulate an attic space. This material is highly dense and does not deform over time. Among other things, it is worth highlighting its moisture resistance.

You can also insulate the attic using sawdust. However, this option has some disadvantages, which become quite acute during the operation of the thermal insulation system. Sawdust is not able to withstand moisture, and this increases the likelihood of fungus. Sawdust swollen with moisture loses its thermal insulation qualities.

Insulation of attic ceiling with mineral wool

Anyone can insulate an attic room from the inside in a private house with their own hands. Before you begin work, you need to carefully familiarize yourself with the main characteristics of the material and study all the intricacies of its installation.

Types of mineral wool

The market for construction materials is ready to offer a large number of types of thermal insulation. The process of insulation with mineral wool can be carried out using one of the following types of material:

- basalt or stone wool;

- glass wool;

- slag.

What materials are included in the insulation system?

Thermal insulation of the attic is made using various materials. The insulation system most often used by specialists includes three layers. Let's look at them in more detail:

- vapor barrier;

- thermal insulation;

- waterproofing.

The vapor barrier film performs a very important function, namely: it prevents the penetration of water vapor into the room. Without it, unwanted condensation will form on the inner walls. The waterproofing material is represented by a moisture-proof membrane.

The thermal insulation layer is the main one. There are many materials that can be used for high-quality insulation of an attic space. For self-installation, experts recommend choosing the most environmentally friendly of them. Ecowool and mineral wool are the leaders in this indicator. The second option is more preferable, since the cost of mineral wool is lower.

Note! It is best to insulate the structure from the outside. This will protect the attic space from freezing, as well as condensation on the walls.

External work should never be carried out in rainy weather. Before starting installation, you should inspect the roof. It is also strongly recommended that you familiarize yourself with the educational video material, which covers the topic of attic insulation in more detail.

Application of a membrane for insulation from moisture and steam

During the construction process, it is not uncommon for films with reinforcement or roofing felt to be used to waterproof the roof. After a few years, the owners may decide to equip the attic space for housing, and then it turns out that the structure must be completely dismantled. The problem is that such structures are completely devoid of ventilation, and any type of heat insulator in such proximity can lose its valuable qualities. If the roof of your home has not yet been installed, it is worth considering the use of a high-quality super-diffusion membrane to insulate it from moisture in the event that you wish to make the attic habitable.

Many people wonder how moisture can get into the insulation when steam insulation is already installed? This is explained by the extremely small sizes of vapor molecules, which none of the films existing on the market can completely retain. Therefore, despite the assurances of manufacturers, creating absolute protection against steam is impossible. Even the highest quality materials can retain no more than 80% of air vapor, and budget films cope with their task by approximately 50%. Therefore, one way or another, moisture will penetrate inside the “pie” of your roof.

To sum up the above facts, it should be noted that for effective insulation you will need to create a multi-layer roofing “pie”, which will contain two types of films - to insulate the insulation from steam and to protect it from moisture. The inner layer will not allow steam to penetrate into the thickness of the insulation, and the outer layer will allow the material to get rid of minor vapors that still manage to penetrate there.

Technological process

Insulating the ceiling in the attic begins with drawing up a work project. Measurements of the main geometric parameters are carried out:

- total length and width of the ceiling;

- the size of the gaps between the beams;

- niche depths.

All this serves as the initial data for calculating material requirements . The need for mineral wool and polyurethane foam is calculated by the specific volume of the substance, in roll and sheet materials - by the number of layers and area with a correction factor that takes into account trimming to the required shapes (it is usually equal to 1.1...1.4).

The next stage is preparing the necessary materials and tools, performing preliminary work, which includes marking and surface treatment, for example, applying antiseptic to wooden structural elements. After this, they proceed directly to installation.

The molded sheet materials are placed in the openings, leaving a gap of 2-5 cm to the waterproofing layer to ensure ventilation. It is extremely important to ensure tight fit and minimize the size of mounting cracks and gaps. To do this, during preliminary cutting, a small reserve of material is left, and the excess, if necessary, is trimmed directly during installation with a stationery knife.

In the case of using roll, cotton, or aerosol substances, you will need to install an inner film layer , which will serve as a mounting base. To do this, a thick film is attached with a construction stapler to the upper part of the side surface of the beams.

When the main insulation is installed in the openings, it is covered with a vapor barrier . This is usually a membrane, foil or perforated film. The layers are placed across the rafter system, gradually unwinding the roll.

Advice. It is more convenient to do the work together - otherwise it will be difficult to manage the bulky roll and distribute the material evenly.

The vapor barrier is attached to the ceilings with an overlap, with a margin of 10-15 cm , using a construction stapler. The material should not be too tight; even slight sagging is allowed. All joints should be additionally taped with special tape.

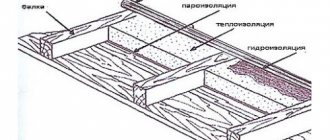

Then the vapor barrier layer is hidden under any type of decorative coating . This can be plasterboard, plywood, chipboard, fiberboard, lining and other materials. It is possible to install them directly to the beams through the vapor barrier, however, in order to avoid ruptures of the latter and to improve ventilation, it is recommended to install an internal sheathing of slats 1.5-2 cm thick. As a result, the design of the “pie” of the ceiling and roof should resemble the one shown below.

We hope we helped you understand how to insulate an attic ceiling and decide on the choice of technology and material. Let your attic always be warm and cozy!

Insulation of the second floor ceiling

In a wooden house there must be an attic above the second floor. To prevent heat from penetrating upward from the first level, the ceiling must be well insulated. The thermal insulation layer must consist of several types of insulation materials, which should be laid in a given sequence.

Typically, the thermal insulation “pie” of the floor in a private wooden house consists of the following elements:

- first floor ceiling;

- vapor barrier;

- load-bearing beams made of high-quality timber;

- mineral wool laid in cells formed by beams;

- waterproofing;

- any floor covering.

This sequence must be strictly observed, otherwise the effectiveness of thermal and waterproofing of the second floor may suffer significantly. If the second floor will be occupied by a teenager who likes to listen to loud music, or the house is located near a roadway, you should take care of the issue of high-quality sound insulation of the floor and walls of the room.

In addition to the thermal insulation material, two layers of plywood are added to the “pie”, which create a sound barrier. When using expanded clay during insulation, a concrete screed should be made on top.

How is insulation installed?

The most important point is the correct use of insulation material. The insulation must be installed in such a way that there is enough space for ventilation between the insulating layers and the surface. Warm, moist air will escape through this same space.

Scheme of single-layer attic insulation.

Insulation of the attic must be carried out efficiently not only to protect the house from atmospheric influences (precipitation), but also to prevent the temperature of the attic floor from decreasing.

A reliable fact is the movement of warm layers of air to the upper part of the room, because the temperature under the ceiling is about 2 degrees higher than in the room itself. Unlike the entire house, the attic room has the highest heat loss rates.

Thermal protection features

Warm air indoors contains more moisture than cold air outside. It is because of this that water vapor is directed out of the room, penetrating through the walls. The outer top roofing layer serves as waterproofing for the room. But water vapor does not pass through it, which causes condensation to form inside the roof.

All this will lead to the fact that the surface of the roof from the inside may become stained or mold may appear. The insulation will lose its thermal insulation qualities, and condensation will lead to dripping water directly from the ceiling.

Attic roof insulation elements: 1 – mineral wool; 2 – vapor and wind barrier (membrane); 3 – waterproofing; 4 – air flows; 5 – rafter; 6 – roof; 7 – attic cladding.

Due to the negative effect of water on building materials and their quality, it will be necessary to protect the insulation from wet vapors. Therefore, it is advisable to use a vapor barrier material, distributing it at the bottom of the insulation.

There are frequent cases when attics are made from the attic floor. And to reduce the load on the ceiling, they use the lightest insulation material, but it doesn’t make it any warmer, because the wind simply starts to blow it out. It is in order to protect the floor structure and preserve the heat-protective layer that vapor barrier and windproof material are needed.

We must not forget that any unsealed space will contribute to air loss. Therefore, everything needs to be insulated: ceiling, floor, walls, and so on. Remember that the selected material must meet all standards and requirements.

Methods for insulating the attic

In order to figure out how to insulate an attic roof for winter living, you need to know that there are several insulation options: internal and external.

Insulating the roof from the outside is an ideal option, since such a structure will not let in heat from the inside due to the warm circuit and will be reliably protected from freezing. This prevents the formation of condensation, therefore, the risk of mold and mildew is minimized. However, if the attic roof is already covered with roofing material, then insulating it will be extremely difficult, and the roofing material will have to be removed.

Most often, the attic is heated for further living in it from the inside. For this purpose, a wooden frame is being erected in the attic, which will serve as a niche for laying insulation. There are various technologies for thermal insulation.

External insulation of the attic occurs during the construction of the building. The gable roof is insulated. Internal thermal insulation is carried out with the roofing material already covered (if there is a need to make this room comfortable for living at any time of the year).

External thermal insulation

A ventilation hole with a diameter of at least 2 centimeters should be drawn through the layers of insulation. It is necessary to remove steam and condensate from the vapor barrier membrane. These holes are made in both the upper and lower parts of the roof slope. Thus, the air flows from bottom to top along the hole, collecting excess moisture from the vapor barrier film along the way and removing it out through the top hole.

However, all work on external insulation of the attic is carried out exclusively in the warm season in dry, sunny weather. All surfaces are carefully examined for any defects before thermal insulation. All areas must be dry. The wood must be impregnated with antiseptics. To prevent corrosion, metal surfaces

External insulation of the attic occurs as follows:

- Lathing from boards is stuffed from the bottom of the rafters

- Vapor barrier film covers the sheathing and rafters

- Insulation is laid between the rafters

- The thermal insulation material is covered with steam and waterproofing on top

- The sheathing of boards is stuffed over the insulation

- The roofing material is attached using self-tapping screws to the sheathing.

Insulating the attic floor with foam plastic

The installation technology process is similar to insulating an attic floor with polystyrene foam.

The advantages of these materials:

- low cost;

- ease of operation;

- waterproof.

Among the disadvantages: flammability.

Technology for insulating attic floors with polystyrene foam or polystyrene foam

The process of installing rigid foam-based insulation is more than simple and can be done with your own hands. The work can be divided into two stages:

surface leveling. To ensure high-quality insulation, there should be no significant unevenness on the base floor. Such differences can be eliminated by screeding with sand-cement mortar.

The slabs are laid end-to-end or between beams. The presence of timber increases the strength of the floor.

Tip: carefully seal any seams, incl. joints with beams. When going around an obstacle, try to cut the holes as accurately as possible. A homogeneous thermal insulation layer retains heat better.

Insulation of the attic floor with polystyrene foam Rough coating

Polystyrene foam must be protected from destruction with film in an uninhabited attic. In a frequently used or residential attic, you need to move somehow, so it is better to install an OSB subfloor on top of polystyrene foam or expanded polystyrene or use a sand-cement screed.

Scheme for proper insulation: creating a roofing pie

Proper insulation of the attic involves the use of materials with a low level of thermal conductivity and additional insulating layers against water and steam. It is these parameters that will subsequently become reliable protection of the room from external atmospheric influences.

Of course, the creation of a system contributes to the intake of free meters of the room, but with correct calculation, taking into account SNiPs and other regulations, it allows not to significantly exceed the thickness of the rafters. In this way, you can create an insulating “pie” recessed into the frame of the house.

The first layer when insulating an attic ceiling is thermal insulation. You can do it yourself, thereby reducing costs. Increased attention is paid to this layer due to the fact that the house loses a high level of heat through the roof. Accordingly, this entails an increase in payments for heat energy.

Further, for waterproofing, PVC films are used, which allow steam to pass through, but do not allow water to penetrate into the room. Waterproofing protects insulating materials from precipitation penetrating into the house and condensation forming inside.

In some cases, waterproofing and vapor barrier are carried out separately. This is only relevant for climates with high humidity. For example, in the south of Russia, steam and water insulation is performed in one layer.

The final stage of the insulation scheme is decorative cladding. In this case, the home owner chooses materials to suit his taste and budget. Popular materials are plasterboard, chipboard and OSB.

Cold roof: features, insulation methods

The term “cold roofing” arose due to the lack of a “pie” structure. That is, in this case, the simplest design option is used. This is due to low budget expenditure and reduced construction time.

This type of roof is optimal for further arrangement of utility rooms. As for living rooms, you will have to create a “pie” inside the room.

If it is necessary to insulate the ceiling of an attic with a cold roof, then you will need to carry out high-quality waterproofing work. In addition, the floor of the room must have a reliable base and containers for collecting condensate.

There are two structural methods for insulation. The first is to install materials from the attic side and then residential square meters will not be used. The second is from inside the room, which wastes free space.