Exhaust ventilation removes polluted air from rooms with active sources of pollution. Taking into account the characteristics of the object, the characteristics, equipment and technical features of the unit are adjusted. Exhaust ventilation systems are installed not only in residential buildings and apartments, but also in warehouse complexes and factories. Learn in detail about the principle by which these structures work, their varieties and the features of channel calculations for a specific object.

General supply ventilation system

General and local (local) ventilation

Experts divide all exhaust ventilation systems, taking into account the area of their design cleaning - local (local) and general.

A general ventilation hood is capable of quickly removing polluted air from all rooms in the building. A striking example is exhaust ventilation in an apartment. Its grilles are traditionally located in the bathroom and kitchen (in the upper part of the room), through which polluted air, small particles of soot and fat are removed.

General exchange systems are actively used in health institutions, warehouse complexes, storage facilities, residential buildings, shopping centers and shops. A characteristic feature of these objects is that the concentration of unwanted contaminants is minimal; they are evenly distributed throughout the volume of the room.

It is recommended to install general-exchange exhaust ventilation in a number of cases:

- the presence in the space of leaky mechanisms and machines that produce hazardous emulsions and substances;

- insufficient power of local solutions;

- absence of outlets for contaminated oxygen and unsafe substances.

Warehouse complex with mixed ventilation system

General exchange ventilation hoods eliminate the concentration of hazardous particles and impurities in the room to the optimal values stipulated by regulations.

Local exhaust ventilation is used to eliminate point releases of hazardous and harmful substances.

Due to their directional impact, they guarantee normal working conditions at the local site. The basis of the structures are exhaust pipes for ventilation, with the help of which smoke, air, dust, and unsafe fumes are removed, thereby preventing their spread.

The best clear example of such a device is mechanical kitchen hoods. The cost of equipment for a local system is an order of magnitude cheaper than a general exchange system. From an economic point of view, they are much more affordable. If the pollution is spread over the entire area of the room, the described solutions are ineffective.

Classification

In order for the design of exhaust ventilation to create a high-quality and reliable network suitable for a particular case, it is necessary to know and understand the types and types of exhaust ventilation in the room. They are divided by several factors. According to the method of setting air in motion, the exhaust ventilation of a room is:

- with natural urge;

- with mechanical impulse.

Also, networks are classified according to the volume of premises they serve. According to this principle, ventilation is:

- local (local systems);

- general exchange.

Natural urge

Naturally driven networks operate under the influence of natural factors. These include the most common exhaust ducts in the wall in our houses and apartments. The air in them moves under the influence of the pressure difference between the room and the outside atmosphere. The main positive factor of natural-type ventilation hoods is the simplicity of the device and low cost.

Natural exhaust system

But there are also negative properties. First of all, it is dependent on weather conditions. In some cases, natural ventilation in an apartment building or cottage may stop completely. This is possible when the pressure between the outside and inside air is equalized.

Just like the negative properties of natural networks include the difficulty of regulation. It is impossible to change natural factors in such a way as to stop or reduce the speed of air movement. Gate valves and dampers are used for these purposes. For example, an exhaust ventilation valve, which is placed at the entrance to the duct.

Mechanical urge

Mechanical networks appeared later than natural ones. Forced exhaust ventilation consists of a fan that is connected to the mains, as well as additional elements. These elements help regulate air movement and perform several other functions.

Their device is more complex and more expensive than the natural type. First of all, this is due to the need to purchase components, install them and connect them to the electrical network.

Mechanical exhaust ventilation system

Exhaust ventilation in a forced-type apartment or house in most cases includes the following elements:

- Exhaust ventilation unit. This can be a radial or axial type fan.

- Exhaust pipes for ventilation. They are designed to move air from the working area to the outside.

- Performance regulators. Basically, they adjust the speed of the fan to increase or decrease the volume of air passing through it. Such devices are produced in different types and are used for ventilation of industrial premises, living rooms, and public buildings equally.

- Filters. Their main area of application is industrial ventilation. They are designed to trap harmful pollutants and protect the atmosphere from them.

We recommend that you read: Ways to make a hood in the cellar and basements of a house and garage

Also, installation of a mechanical type exhaust ventilation installation involves the use of a large number of shaped elements, clamps, and fasteners that help to efficiently connect the ventilation network to the fan.

Exhaust ventilation of houses and apartments

Let's talk about exhaust ventilation in a private house or apartment. How does such a system work in housing? In most cases, owners make do with natural systems. In multi-apartment buildings, ventilation ducts are installed in the walls during the construction phase of any residential building. This is either a hole in the brickwork, or special factory-made concrete boxes for ventilation.

Plastic exhaust pipes

In private residential buildings, the natural network is also arranged in the form of channels in the walls. It serves various premises, including garages. In both private and apartment buildings, natural ventilation provides air exchange with proper design and calculation. Typically, the channel ends with a grill into which internal air is sucked. In modern conditions, separate channels are often installed for kitchen hoods. The hood is connected to ventilation using a flexible or rigid air duct. Special hoods with ventilation outlets are also produced to remove moisture and odors from baths and toilets.

Recently, more and more often in new buildings in Moscow, and even in residential buildings, an exhaust ventilation unit is used. Although this increases the cost of construction, this solution helps control air exchange and create an optimal microclimate for family living.

Industrial ventilation

If ventilation in a house or apartment is at least regulated, but is still often not carried out fully, then exhaust systems are a very important engineering network for production. Without them, no production can be launched. If in everyday life general exchange ventilation is mainly used, then in production a large percentage of systems are occupied by local exhaust ventilation.

In many cases, the general exchange system for industrial exhaust is mechanical. It consists of an exhaust pipe connected to a fan, filters, a diffuser or other air intake devices. Aeration is mainly used as a natural system in production. This is the so-called ventilation.

We recommend that you read: Ventilation in the bathroom and toilet

Local exhaust systems are a separate group in industry and manufacturing. They are designed for localized removal of pollutants from their point of origin. Their use makes it possible to protect surrounding people from exposure, while at the same time not spending energy and money on creating a powerful general exhaust ventilation system.

Local exhaust ventilation

In addition to fans and other elements, they use specially designed products as receiving devices:

- local suctions;

- exhaust hoods;

- fume hoods.

Local suction removes contaminants in the immediate vicinity of their origin. Umbrellas are placed above the work area, and cabinets make it possible to completely protect the environment from the penetration of pollutants.

Natural and forced

Each exhaust ventilation system, regardless of type, design, complexity and cost, is aimed at removing waste air masses. To achieve this goal, various technologies, installations and methods are used. The exhaust ventilation system, taking into account the principle of operation, can be forced or natural.

If all processes with the “fifth ocean” are governed by nature and the corresponding laws, then the system works according to the natural principle. For cases where the exhaust ventilation unit operates using special equipment, the system is considered mechanical. These are automatic units that provide air exchange at a predetermined level, in accordance with passport and design standards.

Natural ventilation: pros and cons

The main advantage of natural exhaust ventilation in a house or apartment is its affordability. It does not require serious financial investments, and in terms of operation it is generally beyond competition, because free. Air mass exchange is carried out without additional equipment. The second important advantage is that solutions for this system take up minimal free space.

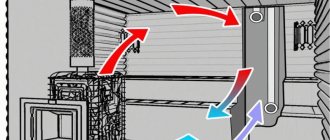

Natural ventilation works on a simple principle - hot air rises and cold air falls down.

Natural exhaust ventilation also has a serious drawback - its operation cannot be controlled, because it functions unilaterally. Air masses move in the system due to the fact that different pressures are formed at the inlet and outlet of the pipe. But conditions may develop in such a way that there will be no “traction” in principle.

If the temperature inside the house is lower than outside, the exhaust ventilation unit will work like a supply air unit. Air masses from outside are directed into the apartment. Taking this into account, they are equipped mainly within the residential space, but they are not suitable for production workshops and industrial facilities.

At large facilities their productivity is insufficient, which can be dangerous for workers.

Types of ventilation

Ventilation is the movement of air masses, during which exhaust air with various substances, for example, dust, wool, carbon dioxide, chemicals, is removed and replaced with fresh air. To properly and timely remove all this outside, you need to have good climate control equipment.

There are two types of exhaust ventilation system - forced or natural. For a comfortable stay of a person in a room, a proper exhaust ventilation system is required.

However, it is worth noting that the selection of this system is quite complex and has its own nuances, depending on the type of room. To determine, it is necessary to take into account such parameters as the area of the room, its configuration and purpose. There are different methods for carrying out calculations: according to multiplicity, sanitary and hygienic standards and area. All calculations for ventilation systems are carried out to determine air volumes. You can contact us at the Company for calculations, or try it yourself.

The area is calculated according to the following scheme: every hour, 3 cubic meters of fresh air per square meter of area should penetrate into the room. The number of people, in this case, is not taken into account. For calculations according to sanitary and hygienic standards, information about the number of people in the room is taken as a basis. So, every hour, 60 cubic meters per person should enter the room. If there are temporary visitors, another 20 cubic meters per person must be added every hour. The air exchange rate has a more complex calculation system, which refers to the amount of complete air replacement over 60 minutes. In this case, it is necessary to take into account the type of premises and the relevant standards, which are specified in SNiP 2.08.01-89* in the “Residential Buildings” appendix.

Each living space has its own regulatory requirements for air exchange. So, 3 cubic meters per square meter of area should be supplied to the living room every hour. In the toilet and bathroom the norm is 25 cubic meters per hour. The rate of air exchange in the kitchen depends on the installed stove. So, with an electric and two-burner gas stove in the kitchen, an air supply of at least 60 cubic meters per hour is required, and with a four-burner - 90. The calculation is made using the formula: L=N*V, where V is the volume of the room, measured in cubic meters (for to determine it, it is necessary to multiply the area of the room by the height), and N is the air exchange rate per hour. The total value of the sums of L readings will determine the required amount of fresh air in one hour. Thus, after making the above calculations, you can decide on the type of exhaust ventilation. Let's take a closer look at each of the existing types. So, the exhaust ventilation system: natural, forced.

Calculation of exhaust ventilation

Calculation of exhaust ventilation for large production workshops and enterprises begins with identifying areas of distribution of unsafe substances and emissions. At the next stage, specialists determine the volumes of air masses for removal and supply in order to ensure sanitary standards.

If there are no active sources of unwanted substances in the space, it is advisable to use a simple formula:

O = m*n

- O – the volume of pure oxygen provided for by sanitary standards and regulations;

- m – average value of oxygen consumption for 1 hour of active work;

- n is the constant number of workers working in the premises every day.

As for the value of m, it has specific definitions documented by SNiPs:

- m = 30 m3 – for ventilated rooms;

- m = 60 m3 – for objects without access to clean air.

The above values are adjusted to take into account hazardous volatile substances released during the production process. In this case, their total volume is taken into account, and the calculated data on the influx of fresh oxygen changes upward.

Description of certification of ventilation systems for industrial premises

The peculiarity of harmful substances is that they tend to spread throughout the entire volume of the workspace, pavilion or production workshop. In this case, the main task is to reduce the level of their concentration to values at which a person can stay and work in the room.

Specific threshold values are provided for each harmful substance. Taking this into account, the volume of fresh air inflow is calculated using the formula:

O = Mb/(Ko-Kп);

- Mb is the average weight of an unwanted or potentially hazardous substance entering the workspace per unit of time (1 hour);

- Ko is the value of the remote concentration of a potentially hazardous substance in the surrounding space;

- Kp – concentration of undesirable substances at the inlet of the air handling unit.

Taking into account the volume of clean air required, choosing an engine of optimal power for exhaust ventilation will not be difficult.

Natural supply ventilation

The natural exhaust ventilation system is the most common and is found in most residential buildings. It was this species that existed from time immemorial in the houses of our ancestors and during the Soviet Union. The fundamental feature of this system is that air enters the room independently through windows, doors and cracks and, passing through the room, exits through the ventilation system in the bathroom, toilet and kitchen. Then it is taken out through the ventilation shaft. This happens without any devices, according to the laws of physics based on temperature differences and pressure differences inside and outside the building.

Natural ventilation is mandatory during the construction of any room and has its positive aspects. It works silently, free of charge and virtually trouble-free. This type of ventilation is very convenient and practical, but in the modern world it often fails. Installing plastic windows and sealing cracks prevents normal air flow, which leads to a musty room, condensation on the windows and other negative consequences that we wrote about earlier. In addition, natural ventilation depends on the number of floors of a multi-story building and on weather conditions. For example, in summer this type of ventilation practically does not work due to the lack of temperature difference. In order to solve this problem, mechanical or forced ventilation is used.

Units for local exhaust system

Existing shelters that are equipped with exhaust ventilation systems are divided into several specialized categories:

- units installed at the source of pollution;

- solutions that cover the source of pollution;

- blowing products.

In practice, units are very popular, with the help of which the source of the spread of hazardous substances is localized in a certain area. However, such solutions are not always convenient and advisable to apply. They have been replaced by more modern hoods with ventilation outlets:

- metal and polycarbonate umbrellas with exhaust function;

- local suction units;

- powerful fume hoods;

- encapsulated solutions;

- removal of secretions from the body of machines and working units;

- display, shaped and on-board solutions.

Local ventilation systems are very common in places where it is necessary to provide the required air exchange standards in a specific, local area.

Exhaust hoods are the most popular and widespread suction designs. They equip small work areas (tables for soldering, cooking). Hazardous impurities are quickly collected and redirected upward, after which they are removed. Exhaust ventilation operates both through natural draft and forced draft.

Specialized suctions – extract unwanted and potentially dangerous substances with minimal oxygen consumption. Industrial exhaust ventilation is often represented by several local units. Their main feature is that they do not interfere with work.

Fume hoods are one of the most effective solutions for the forced removal of harmful fumes and substances, while creating a minimum level of air exchange. There are several types of such cabinets on sale:

- with a top exhaust device, through which hot and humid air is removed;

- with the removal of contaminated flows from the side structure - we are talking about some analogue of a “snail” for collecting residual products;

- with combined type outlet solutions located at the bottom of the unit.

Local hoods: a - fume hood; b - display case; c - cover-casing for the sharpening machine; g - exhaust hood; d — umbrella-visor over the open opening of the stove; e - exhaust funnel when welding large-sized products; g - lower suction; h - lateral suction; and - inclined exhaust panel; k - double-sided suction from the galvanic bath; l - single-sided suction with blowing; m - ring suction for a manual welding gun

A fan located in the air exchange system creates a turbulence in the flow so that the dust is localized in a small area and does not spread throughout the room. An example of such an installation is a welding station, where forced exhaust ventilation is represented by a small cabinet. The suction in them is located at the top of the structure.

If we are talking about the removal of non-hazardous substances, then the speed of movement is allowed within the following limits:

- 0.5 – 0.7 m/s;

- 1.1 – 1.6 m/s – for those cases when toxic impurities and metal fumes are removed from the room.

Fume hoods are installed in chemical laboratories

As for suction panels, they are used in cases where the air in a confined space is saturated with toxic gases, dust and heat. The panel is positioned so that toxic compounds are located at the maximum distance from the worker. Exhaust pipes for ventilation are equipped with a built-in motor and quickly remove dangerous suspensions. The installations in question are used at welding stations when processing large products. They are located at a distance of up to 3.5 m from welding and are equipped with fans with one or two motors.

The speed of movement of air masses must meet the following criteria:

- from 3.5 to 5 m/s, if we are talking about the release of hot dust;

- from 2 to 3.5 m/s, if toxic or non-dusty suspensions are released during operation.

Experts focus on one important point - installation of exhaust ventilation is carried out under the condition that 1 m2 of panel removes 3.3 thousand m3 of air every hour.

Onboard suction is relevant for cases where the source of pollution is kept in a vertical position using special lifts. Such installations are widespread in workshops where galvanic processing of metals is carried out, in which hazardous substances are poured into a special container and then sucked in through a small hole.

From a constructive point of view, the exhaust ventilation of industrial premises consists of several air ducts, the inlets of which have a narrow shape (up to 10 cm), they are located at the edges of the bathtub.

Supply and exhaust ventilation with recovery

This type of ventilation appeared in Russia relatively recently, but has already won its place of honor. The design of exhaust ventilation systems with recovery is based on the process of recycling exhaust air from which part of the heat is returned. So, completely exhausted air comes out, fresh and already heated air enters the room. This is achieved by heating the cold air entering the room using special devices that are heated by the heated exhaust air.

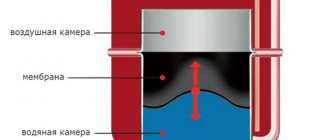

There are several types of recovery

- Lamellar. The air to be removed and entered into the room passes through the plates, which, through the exchange of heat, are cooled or heated accordingly. This method has a drawback on cheaper models of supply and exhaust ventilation, because condensation may appear, which, when freezing, blocks the operation of the system for some time.

- Rotary recovery is an open system in which, according to manufacturers, there is no air mixing and heating occurs due to heat transfer from the rotor.

- Chamber recuperation consists of heating air from the walls of the chamber, where there is a damper that prevents air mixing.

- Recovery with an intermediate coolant, where the carrier is water or a water-glycol solution, which circulates from the exhaust to the supply.

- Heat pipes. This type of supply and exhaust system with recovery consists of numerous tubes that are filled with special freon. It evaporates when heated by the drawn air and increases the temperature of the air entering the room. Supply and exhaust ventilation with recovery can be used in apartments, cottages, country houses and cottages. In addition to cleaning and heating the air, this type of ventilation with recuperation humidifies it and maintains the air exchange necessary for a person, which has a positive effect on the microclimate of the room all year round.

Thus, the principle of operation of such ventilation can be explained with an example. For example, the air temperature outside is -20C°. Entering with the help of fans and cleared of dirt, the air is heated from the cassettes and enters the room at a temperature of about +14C°. In addition, there are additional installations, for example, air heaters, which, when turned on, can heat the air to the required parameters. This type of ventilation significantly saves money not only on electricity, but also on heating. The advantage of the system is also the ability to cool hot air from the street to a comfortable temperature.

Installation of this type of ventilation units is carried out using special equipment. Depending on the selected ventilation device, one or two holes are made in the wall, floor or ceiling. After installation, our specialists will conduct trial testing to clarify the correct operation of the device.

Calculation of local hood parameters

To absorb emissions and vapors hazardous to human health, suction units made in the form of umbrellas are installed. If they are difficult to purchase, you can always make them by preparing the appropriate drawing.

At the first stage, the following data and parameters are determined:

- area of release of harmful substances – a * b, as well as the diameter of the umbrella – d;

- air movement speed at the work site - VB;

- calculation of local exhaust ventilation is carried out taking into account the suction speed into the umbrella - Vз

- the height of the installation of the structure above the source of hazardous pollutants is designated Z.

One of the key parameters that determines the efficiency of absorption of harmful substances is the installation height of the exhaust hood. Engineers recommend hanging it as low as possible to the work area so that all fumes and emissions are effectively absorbed and removed.

The installation of exhaust ventilation is carried out based on the following dimensions of the umbrella:

D = 0.8×Z+d, taking into account other parameters – A = 0.8×Z+a, while B = 0.8×Z+b.

The optimal level of umbrella opening is 60 degrees. With this value, the danger of the formation of stagnant zones is eliminated. If we are talking about a very low room, it is better to increase the opening angle to 90 degrees. As for the height of the lower edge, it ranges from 180 cm. The hood is connected to the ventilation in such a way that there is access to the folding curtains from 3 sides.

For rooms where the speed of movement of air masses is from 0.4 m/s, it is better to supplement the umbrella with special folding curtains. The presented calculation data will help you more accurately determine the cost of the finished product, as well as determine the appropriate equipment. However, before connecting the hood to the ventilation, it is better to consult with a specialist who can carry out the appropriate calculations and recommend specific models of devices.

Factors influencing the calculation of the ventilation system

- Layout and dimensions of the dining room.

- Planned number of visitors.

- Thermal stress in the kitchen area.

- Exact equipment location.

- Supply air heating power.

- Location of supply and exhaust units.

- Thickness of external walls.

An example of the implementation of a ventilation system for a small dining room

If the room has less than 50 seats, then it is allowed to combine supply and exhaust systems in the following cases:

- If there are several halls for visitors in the eating area, then supply ventilation systems can be combined.

- Exhaust hoods from production systems can be combined into a single exhaust system.

- Local ventilation from hot shops can be combined with general ventilation from other kitchen shops.

- Exhaust from bathrooms can be grouped into a single exhaust system.

For the food hall, the ventilation scheme is most often implemented using the displacement method. What it looks like: supply air enters the room at a low speed, no more than 0.3 m/s, and it is exhausted in the upper zone of the dining room. In this case, there is no mixing of air masses, but its gradual displacement through the exhaust ventilation system.

Ventilation of dining rooms is a complex task that is difficult to approach with a standard solution. In each specific case, it is necessary to solve the complex problem of providing effective ventilation and air conditioning for all its premises.

DIY exhaust ventilation

The easiest way to install exhaust ventilation is in a private house, and you can equip it yourself, without turning to specialists for help. A separate air duct is installed for each room, and it is placed in a strictly vertical position. It is important to remember that each bend, “knee” or turn reduces the traction force in the channel by 10-15%. The speed is reduced by differences in diameter, protrusions or unevenness of the air duct.

Ducted exhaust ventilation ends above the base of the house's roof. The minimum cross-section of air ducts is 100 cm2, the larger the better. Preference is given to round exhaust ducts because they have minimal air resistance.

The design of exhaust ventilation begins at the construction stage of a country house, making it easy to hide ventilation ducts and shafts in the walls. If this is not provided for at the stage of construction of the facility, you will have to make holes of appropriate sizes in the ceilings, lay pipes and equip a brick box for the shaft.

The shaft exit area is formed independently, while the upper part is covered with a special umbrella to protect the channel from debris and precipitation. It is best to place the deflector there. In terms of price, it will cost more than traditional canopies, but it also helps to increase traction inside the shaft.

Ventilation schemes for private low-rise buildings

Before starting construction or reconstruction of a facility, a preliminary assessment and calculation of the required volumes of air movement in various rooms should be carried out. For houses with a small area, built according to standardized designs, such a calculation can be carried out independently, but for complex objects with different air exchange requirements in the premises, specialized companies should be involved. Engineers will carry out calculations and draw up a cost-effective project.

For an approximate calculation of what you can do on your own, you can use the following developments.

- If the living space has an area of less than 20 m2, an air exchange of 3 m3/hour is sufficient. This volume allows you to maintain indicators at the recommended level.

- For larger rooms, this approach is irrational, since it requires the installation of large air ducts or the installation of power units. Therefore, the calculation is carried out based on the maximum number of people simultaneously present in the room - 30 m3/hour per person.

- Special approaches are applied to rooms with increased requirements for air exchange. In utility rooms, sanitary areas, laundries, drying rooms, a constant air flow must be maintained at 110 m3/hour. If your kitchen has a gas stove that actively uses oxygen, the figure increases to 140 m3/hour.

Such parameters ensure the comfort of living in a private multi-storey building and maintain a healthy atmosphere indoors. To achieve these indicators, various technical solutions have been developed, which we will discuss further.

Natural ventilation

Ventilation device in the house, the organization of which does not require the installation of complex power and auxiliary installations. This is not suitable for all buildings. It is acceptable for a small house area located in an ecologically clean area with a smooth, temperate climate (in summer the temperature is up to 25 0C, and in winter not lower than -5 0C). Natural ventilation through window openings reduces the temperature, making air preparation and control over the parameters of air masses impossible.

In its pure form, the natural scheme is rarely used; it is supplemented by power and mechanical units that make it possible to organize the direction of air movement. The simplest schemes can be implemented with minimal costs.

- Exhaust systems are placed in “dirty” areas (kitchen, toilet, pantry, bathroom and shower rooms). A standard kitchen hood can be supplemented with a ceiling or wall fan to expand the coverage of the room.

- For inflow into the windows or walls of “clean” rooms, non-return valves with recovery are installed, which allow the incoming air to be heated. If this is not possible, then a conventional non-return valve is installed at the top of the wall or directly next to additional heat sources, increasing the thermal efficiency of the house.

- If the garage is located in close proximity to living rooms, care should be taken to remove exhaust gases. To do this, install a local exhaust hood with a receiving device in the form of a fire-resistant hose, which removes the resulting gas outside the room. This is a simple, inexpensive device that consists of a mobile corrugated thin-walled metal pipe equipped with a duct fan.

- In residential premises, the supply and exhaust ventilation system is located in the basement, attic or in specially designated rooms.

A significant part of small houses and cottages are equipped according to this scheme. Ventilation successfully copes with the assigned tasks. To optimize system operation, you should select equipment with optimal power and performance. Knowing the size of the premises, this is quite simple to do.

Increasing air exchange efficiency

To improve the operation of natural ventilation, the building should be equipped with vertical channels; the higher they are, the better the draft. Based on this, installing wall hoods is ineffective. When designing, all channels are located in close proximity and form a single technical shaft, the outlet of which is located in the area of the ridge at the maximum accessible height.

- In brick houses, air ducts are formed during laying - this is the most economical and effective solution. In frame and wooden buildings, using brickwork only to form vertical air ducts is neither aesthetically pleasing nor practical, so the ducts are made of plastic or metal pipes (the latter require surface protection). They are installed in the space between the walls or in the thickness of the wall.

- Increasing the height of the outlet pipe should not be overused. The channel will have to be additionally insulated to minimize the release of condensate and protected from precipitation. An excessively high pipe requires additional reinforcement.

- Exhaust ducts should not be placed in the same shaft as sewer pipes. In multi-story construction, such a solution is permissible due to the high natural draft in the shaft, but when constructing one- or two-story buildings, it may not be enough. When weather conditions change, a reverse movement of air masses occurs, and odors will begin to spread throughout the house.

- To prevent this phenomenon, the outlet pipes are equipped with non-return valves, but it should be remembered that the formation of ice will completely stop the operation of the system.

- If natural draft is not enough, it is necessary to strengthen it by installing an additional fan in the exhaust air duct. Modern devices are not susceptible to excess moisture and are capable of operating outdoors with minimal protection provided by the cap and channel walls.

We figured out how the ventilation system of a small cottage is organized. Its arrangement is economical, and the advantages are undeniable.

Forced ventilation

For large houses with a complex architectural design, the natural scheme is not enough, so forced air exchange is used. It can be implemented in two ways: by installing a centralized or local system.

Some contractors offer a scheme in which only forced exhaust is formed, with channels assembled into one air duct. In this case, the inflow is carried out through open transoms, the air enters unprepared, which reduces the energy efficiency of the system. This is a cheaper approach, but the operating costs of such a scheme are much higher.

Centralized ventilation

The circuit consists of a compact installation, the housing of which contains all the elements necessary for operation (heaters, recuperators, fans, filters, humidifiers/dehumidifiers, automation). The unit can be installed in any convenient place (attic, basement, utility room, technical room). The supply and removal of air masses is carried out through special channels built into the walls.

This scheme is implemented during the construction period, since laying ventilation ducts in an already erected building requires large costs for subsequent repairs.

The operating principle of the device is simple:

- air is sucked in from the street by a supply fan and enters the housing through the primary filter through the ventilation duct;

- goes through a filter system, air treatment (stabilization of temperature, humidity) and enters the premises;

- Exhaust air from the premises is sucked in by exhaust fans and, after passing through the recuperator, is discharged outside.

The air masses in this device move at a given speed and in a controlled volume, so optimal conditions for living are created in the premises. The operation of the power plant and auxiliary components is controlled by automation. You can turn the equipment on/off or change its parameters from the remote control or remotely using a smartphone.

The recuperator is an important element of the system. It reduces home heating costs. Exhaust air with an elevated temperature passes through a heat exchange unit, where it transfers heat to the supply air coming from the street. This exchange increases the energy efficiency of the building by 70% - 90%, minimizing the cost of expensive energy resources. Sometimes (moderate climate, warm winters) it is possible to refuse centralized heating, supplementing the heat consumption with the operation of a heater located in the installation.

Supply and exhaust ventilation device

If the architectural design of the house does not allow for the installation of a network of air ducts or the installation of systems and equipment is carried out after the renovation is completed, a local ventilation scheme can be used.

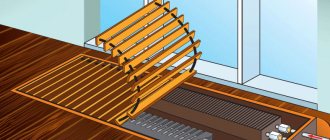

When implementing it, a local supply unit with the possibility of air preparation is installed in each room of the “clean” zone, and exhaust is carried out using standard systems from the “dirty” zones. The appearance of the devices is quite aesthetic. They resemble small air conditioners and are placed at the bottom of rooms. The only difference is the need to create a through hole, but installation teams equipped with diamond tools successfully cope with this task.

Installation of such a system is carried out quickly; after the calculation, a special team will cope within a few working days. Upon completion of work, damage to the decor will be minimal. Installing a local system completely solves the issue of control over the parameters of air masses in the house.

Now we know how to organize ventilation in a private house at minimal cost. The most effective engineering solution should be selected. If you doubt your abilities, seek advice from a specialized company. Equipped with everything necessary, specialist installers will quickly carry out a complex of works.

Frequently Asked Questions

How to order exhaust ventilation repair in Almaty?

Specialists provide service and repair of industrial and domestic ventilation systems in Almaty. Exhaust system service and repair services can be ordered on the company’s website climtech.kz, at the specified telephone number or email address.

Current prices for ventilation systems?

For detailed information please contact. Our specialists will calculate the cost of ventilation systems individually.

How does exhaust ventilation work?

The exhaust ventilation system operates forcibly through duct/axial/fans, recuperators, etc. removes exhaust air. Fresh air is supplied through grilles, windows and leaks/cracks in the building structure.

Calculation

Design of exhaust ventilation is the main stage in the design of both domestic and industrial systems. Household ventilation is calculated mainly based on standardized air exchange. Design consists of finding the required parameter in the codes and regulations and calculating the amount of supply and exhaust air for each residential premises.

For apartments and houses, SNiPs exist and are actively used, which indicate standardized air exchange for each room. For apartments this is SNiP 01/31/2003 “Residential multi-apartment buildings”. When calculating, it is necessary to calculate the volume of each room and its purpose, and then determine the amount of air that must be removed or supplied to each room according to the following rules:

- residential premises with an area per resident of up to 20 m2 - 3 m3 of air per 1 m3 of area;

- residential premises, taking into account the fact that a person has more than 20 m2 - 30 m3/h per person;

- kitchen equipped with an electric stove – 60 m3/h;

- kitchen with gas stove 100 m3/h;

- storerooms - exchange 0.2 times per hour;

- rooms with boilers and other gas equipment – 100 m3/h;

- bathrooms, toilets and toilets 25 m3/h.

Data is taken similarly for residential private houses. For such buildings, SNiP 31-02-2001 “Single-apartment residential houses” is relevant. There are also standards for industrial and public buildings.

Exhaust check valve

We should also talk about how local exhaust ventilation is calculated. Basically, in production, local exhaust systems are calculated based on the type and amount of pollutants. The calculation is made in such a way that the influx replacing the exhaust air completely dilutes the contaminants to the maximum permissible concentration. The calculation uses the amount of incoming substance over a certain period of time.

Specifics of calculations for natural exhaust ventilation systems

The calculation of natural exhaust ventilation will be carried out according to other principles and using other formulas, so it is worth talking about its specifics in more detail.

When installing a system of this type, polluted air will be discharged outside through specially equipped ventilation shafts. The influx occurs through technological openings or simply through cracks and gaps in window and door structures. First, it will be necessary to calculate the pressure difference at the beginning and end of the exhaust ventilation shaft. To do this, you will need to apply a special formula, which is given in SNiPs. Next, the inflow volume is calculated. All these actions are necessary to determine the cross-section of the system’s air ducts, at which there will be no stagnation of air in the system, or the effect of rarefied pressure or reverse draft. Calculations for natural ventilation networks are simpler, but mistakes should also be avoided.

If you are not sure that you can independently calculate all the key parameters for productive natural or forced exhaust equipment, entrust this task to specialists. The help of professionals is especially relevant when developing a ventilation network project for industrial, commercial and administrative premises.

§ 4. TYPES OF VENTILATION. AREA OF APPLICATION OF VENTILATION SYSTEMS

| The main purpose of ventilation - maintaining acceptable air parameters in the room - can be achieved in various ways. For example, for an ordinary room with excess heat, maintaining the necessary conditions can be achieved by natural ventilation (aeration), and by organizing air exchange in the room using fans, and by supplying specially treated (cooled) air into the room. The methods for supplying and removing air are very diverse. When choosing a ventilation system, sanitary, hygienic and technological requirements, as well as economic factors, must first be taken into account. When designing ventilation, preference is traditionally given to the simplest methods that provide the given conditions. At the same time, one should strive to reduce the productivity of systems by taking appropriate design and planning decisions for the building, introducing technological processes with a minimum of harmful emissions, and arranging shelters for places where harmful emissions are generated. The most appropriate ventilation system is selected with the participation of specialists in various fields - plumbers, builders and technologists. Ventilation system is a set of devices for processing, transporting, supplying and removing air. According to their purpose, ventilation systems are divided into supply and exhaust, providing either general or local ventilation. Supply systems are systems that supply air to a room. Systems that remove polluted air from a room are called exhaust systems. If the entire room or its working area is ventilated in the presence of dispersed sources of harmful emissions, then ventilation is called general ventilation. Removing air directly from equipment - the source of harmful emissions - or supplying air to any specific part of the room is called local ventilation. Local exhaust ventilation can be more effective than general ventilation, as it removes harmful emissions from the places of their formation and with greater concentration. Based on the method of stimulating air movement, ventilation systems are divided into systems with mechanical drive (using fans, ejectors, etc.) and systems with natural drive (using natural forces - the influence of wind and gravity). In this case, ventilation of the room can be carried out through an extensive network of channels (air ducts) - duct ventilation systems or through openings in external fences - ductless ventilation. |

General information Supply duct ventilation

system

with art, inducing air movement, is used in industries, companies, and buildings.

Sometimes the ventilation

systems

of public buildings combine heating functions during working and non-working hours.

Therefore, to ensure air exchange in industrial premises with multiplicities of more than 0.5, artificial ventilation

using

ventilation systems

.

Ventilation

system

.

Ventilation

.

ENGINEERING SYSTEMS

Heating,

ventilation

and smoke protection…

The preparation and treatment of air is carried out by air conditioners, purifying the air emitted into the atm. air in exhaust ventilation

systems

- cyclones, scrubbers, etc...

Ventilation

systems

.

ventilation

system regulates air exchange to create a favorable air environment in the premises.

The ventilation

system

can be supplemented with a unit for using secondary heat or replaced with a circulation unit with a heat pump.

Main equipment of the supply system

- an air filter, air heaters and a fan with an electric motor - mounted in one place and called a supply and

ventilation

...

VENTILATION

PUBLIC BUILDINGS,

ventilation systems

... HEATING,

VENTILATION

AND AIR CONDITIONING Calculated ...

Ventilation

installation, as well as the air conditioning installation, include a complex Unlike

ventilation

system (SV),

system

(ACS)…

Latest additions:

Turning reinforcing steel SEWAGE SLUDGE Recycled resources Thermal insulation Tidal power plants

Agronomist's Handbook GLASS GRINDING AND POLISHING Production of compound feed Sable Fur hats Reinforcement and concrete

Cladding works - tiles and mosaics Refractories Wood waste Production of fibreboards

Complete set of local exhaust ventilation systems

One of the main elements of the system will be the so-called shelter.

This element allows you to cover the source of the release of harmful compounds and, accordingly, qualitatively block the process of their spread throughout the rest of the room. The shelter can be located outside the object emitting toxic compounds, completely block it, and blow all substances out of the room immediately at the moment they enter the local atmosphere. However, it is not always possible to use this particular effective component. Then you can choose to equip the system with one of the following equipment options:

- Pull out drobe. The process of removing harmful substances using this equipment is carried out with a high degree of efficiency, since the cabinets have suction units located in different parts of the structure and absorbing different types of substances - from hot steam and smoke to dust and gaseous substances.

- Blowjobs. This element will allow you to eliminate contaminated air masses with the lowest possible air loss. Suction units are often used in industrial premises and are installed directly in the area where equipment is located that emits toxic substances during operation. However, the device must be placed so that its location does not interfere with the normal process of work.

- Exhaust umbrellas. Their function is to collect toxic impurities that do not settle down, but, on the contrary, rise up.

The exhaust ventilation system necessarily uses a motor and an electric fan, which will create the effect of swirling air flows, due to which dust, small shavings and other types of contaminants do not spread throughout the workspace.

The speed of movement of air masses has standard values for substances of different types. Different values are provided for non-poisonous and toxic compounds. All values are specified in the reference documentation, which should be carefully studied. Suction panel elements are used in conditions of active release of large amounts of dust, toxic substances, and significant amounts of radiant energy into the local atmosphere. The element is mounted in such a way that the flow of harmful substances passes at the maximum distance from the person working behind the equipment, and then the panel is connected by air ducts to the system motor. This element has its own values for the absorption rate of contaminated air masses, which may vary depending on the type of harmful substance.

On-board suction devices are activated when the source of pollution is in a vertical position and when it is impossible to place exhaust equipment on top of it.

The process of selecting equipment for exhaust hood in an industrial building is a rather complex and specific task. It is required not only to correctly select specific elements, but also to correctly calculate their power. The cost-effectiveness factor of the finished system must also be taken into account. For this reason, the design and installation of industrial exhaust systems are activities that are carried out by professionals. Only in this case will it be possible to obtain effective, safe exhaust ventilation for production, which will strictly comply with all the requirements of sanitary and building standards.

Another point worth paying attention to is that exhaust systems require regular and high-quality maintenance, for which certain deadlines are also established. Maintenance activities are important: they allow the system to operate without failures and extend the useful life of expensive and complex equipment.

Main parameters of the ventilation system

The main working element is a fan, but not the usual propeller, but an impeller, which is a wheel with blades - this design allows you to reduce the size of the equipment.

The efficiency of the installed structure directly depends on the accuracy and correctness of the preliminary calculations. For example, it is equally bad if insufficient or excessive engine power is selected. In the first case, the engine will wear out and soon enough it will have to be replaced. If the power is excessive, this means regularly inflated maintenance and electricity costs.

Calculations of performance and dynamic parameters of air flows are made using algebraic formulas. It is recommended to entrust the calculations to a specialist who will not only do it correctly, but also obtain the necessary approvals from the fire inspectorate.

Firefighters check the operation of the supply and exhaust ventilationSource aireng.ru

The calculations take into account the following data:

- Premises parameters: purpose - residential or non-residential, internal area, number of floors, humidity level.

- The number and type of activity of people simultaneously present inside the building.

- Required level of air exchange according to SNiP 2.04.05-91. For example, in living rooms it is 3 cubic meters per hour per 1 meter of living space.

- Pipeline cross-section and installation diagrams.