Cabinet assembly rules

Experience and practical skills in assembling structures such as a cabinet certainly play an important role. However, even with minimal skills, it is possible to get the job done.

To do this, you need to follow a number of specific aspects on how to properly assemble a cabinet:

- Before starting work, you should carefully read the instructions for assembling the cabinet.

- Prepare the necessary tools and clean the area for installing the cabinet.

- Carefully lay out all the parts on the floor or table and count them. The lack of just one element can disrupt the entire assembly process.

- Carry out the work gradually; haste in this case is not the best help.

- If you encounter any difficulties, you can watch several video tutorials on assembling the cabinet.

All mirrors and glass panels are assembled last, so as not to scratch or break them during the work.

Self-assembly of furniture provides a number of beneficial advantages: you do not need to set aside time to meet with a master, and carry out the work at a time convenient for you.

Progress

The speed of assembly and the quality of the future product depend on the correct sequence of actions. All manipulations must be performed without haste, according to the recommendations below.

Marking and necessary drawings

Before constructing a cabinet, you need to measure its future location in the room and build a project. Such preliminary measures will help to assemble the furniture in the shortest possible time.

When creating layout diagrams, it is necessary to take into account the dimensions of the product. The first step is to measure the future location using a tape measure. When taking measurements, it is worth determining all the distances - to sockets, electrical appliances, window sills, radiators, baseboards and pipes. If you neglect this step, the wardrobe simply may not fit into the space allocated for it, and problems will arise with opening the doors.

When thinking about how and what to make a built-in wardrobe with your own hands, take a look at the different options for drawings that are in the public domain. If you haven’t found anything, you can create a project using a CAD software module or with a simple pencil on paper. The last option is simpler, so it is used more often. The basic drawing consists of two diagrams:

- • View from the front - a similar drawing displays the dimensions of the wardrobe in width and height, the size of the base and sections, the distance between the shelves. When creating a plan, it is important to take into account the thickness of the external walls and take into account the internal space. The points for mounting door leaves and shelves are also schematically indicated.

- • View of the furniture from the side and from above - in this figure, the depth of the product itself and its internal parts are marked. When specifying the parameters, do not forget about the thickness of the side walls and doors. To ensure that the internal parts do not interfere with the fastening of the facades, they should be placed at a distance of 8-10 cm from the edge of the edge of the front part of the furniture. If you plan to make rounded shelves, then you need to indicate their radius.

Niche and its dimensions

If the cabinet is of a built-in type, then you need to correctly measure the niche in which it will be installed. When determining the size, do not forget that the product should fit freely with outerwear. As a rule, the depth is taken to be at least 0.6 m, the height to the ceiling, and the width based on the number of future things and the available area.

Facade plane

One of the main stages of assembling such furniture is the correct vertical marking of the façade. When making marks, take into account that the racks should not form gaps relative to the plane of the walls. To make it convenient to install them, the projection of the future product should be transferred to the wall and the appropriate marks should be made.

Installation of vertical racks

One of the most important stages of creating a cabinet. Support structures must be installed from the lowest point of the floor level. Next, markings are applied to the surface along which the verticals will be placed. When marking, consider the width of the doors for each department. Door leaves are mounted using hinges that completely cover the edges of the side posts. If installation is planned on an intermediate internal support, then it is worth using special fasteners. Errors that arise during the work process are eliminated using an electric planer.

When the vertical supports are installed in their intended place, the accuracy of their placement is checked once again with a level. Then they are fixed. This is done using a metal corner. Consistently, they are screwed to the floor and to the wall.

Manufacturing and installation of the roof

If the wardrobe is not structurally up to the ceiling, then the covering is cut to the appropriate size. When the roof is ready, its edge is glued using a special PVC film. Next, the surface needs to be attached to its proper place. For fastening to vertical posts, the same metal corners are used, two on each side. The distance is chosen so that it is not less than 1.6 cm from the edge of the corner to the front edge.

Installing shelves

The installation of boxes follows the same principle as the installation of vertical racks. The only difference is that they need to be aligned in a horizontal plane. Please note that the shelf should have a width 2 cm less than the side, that is, 58 cm. At the next stage, a mark is made along which the tier is supposed to be placed. Using a regular level and a pencil, the line is transferred around the perimeter, onto the wall and the second stand. To secure one shelf you will need 4 to 5 corners. Sections are installed at a distance of 35-50 cm from each other.

Preparation and installation of doors

When the main structure is ready, you can proceed to installing the door leaves. They are adjusted, taking into account the thickness of the rack and their own edges. They are attached to hinges, taking into account the deflection in the desired direction. The curtains along the edges of the cabinet should be hung on 4-hinged hinges, and those that will be placed inside should be hung on elements intended for the middle planes. Afterwards, the door handles are installed and the doors themselves are hung on the main frame. To ensure their correct location, it is recommended to perform the following steps:

- • Open the loops.

- • Place any object under the door leaf that will serve as support.

- • Align the canvas to the desired height.

- • Place the edge of the door against the vertical post and mark the installation location with a pencil.

- • At the last stage, the door is screwed on (with 3.5*16 self-tapping screws).

After sequentially completing the above steps, you should have a neatly assembled cabinet, according to your project.

Tools required for work

Before starting work, you need to prepare the tools to assemble the cabinet. To install a classic wooden model you will need the following kit:

- Straight and Phillips screwdrivers.

- Stationery knife.

- Construction pencil for marking.

- Screws and screwdriver.

- Roulette.

- Drill.

- Glue.

- Hammer.

For additional decorative finishing, sandpaper may be needed to smooth the edge surfaces.

Installation of a classic cabinet model

Assembling the cabinet is a relatively simple task. The master will need a minimum of skills and strict adherence to instructions.

The entire installation process can be divided into several successive stages of cabinet assembly:

- Preliminary stage (preparatory work).

- Marking surfaces and parts.

- Installation of supporting structures.

- Installation of cabinet walls.

- Installation of the top and rear walls.

- Installation of facades and doors.

If each stage is followed correctly, assembly will take minimal time, and the process itself will not cause difficulties for the master.

Note!

Sofa with drawers - TOP-130 photos of sofa options with drawers. Design advantages. Types of transformable sofas. DIY making- Modern sofas: types of designs and frames. Stylistics of modern sofas. Shapes and sizes of sofas. Photo and video reviews

Wardrobe in the corridor: TOP-160 photos and videos of wardrobes in the corridor. Features of types of cabinets. Nuances of closed and open cabinets for the corridor

Assembly sequence

You need to start assembling the cabinet by combining the side panels and shelves, then with its top and bottom parts. We connect all the cabinet parts using confirmations. To do this we use a screwdriver. All the holes on the parts are already present; you just need to connect and tighten the screws according to the instructions.

Then you can mount the back wall, which will give the structure rigidity and stability.

In order to avoid possible distortions and further problems with adjusting the facades using a tape measure, you need to measure both diagonals of the future cabinet: they must be equal to each other.

Compliance with the conditions of equality of diagonals and a design angle of 90 degrees is mandatory in this case.

We attach the fiberboard to small furniture nails, which are usually supplied with the furniture. Be that as it may, if there is a shortage, additional nails can be purchased at any building materials store.

When the cabinet box has already been assembled, you can begin hanging the facades and adjusting them. On the fronts and side walls of the cabinet there are mounting points with holes for hinges. All that remains is to attach the loop and secure it with the screws included in the kit.

Correct installation of facades requires minimal gaps in their closed position and the absence of distortions. Easy and unhindered opening and closing of the facades indicates that they were hung correctly.

Adjustment is made by screwing in and out the screws located on the hinges. turning the adjusting screw brings the façade forward towards the wall or, conversely, moves it further away. By moving the hinge away from you, you adjust the gap of the facade from the end of the cabinet wall. After adjustment, tighten the fixing screw.

At the last stage of cabinet assembly, shelves are installed in the places of the box provided by the manufacturer.

Preliminary stage

At this stage, the master faces several important tasks:

- Assessing the quality of parts and counting their quantity.

- Study the assembly instructions.

- Protection of surrounding furniture from dust and splinters that may appear during the assembly process (from drilling surfaces).

- Separately for drilling, you should prepare an old stool or a sheet of chipboard. All work will be carried out on this surface.

- Evaluation of components, fittings and rotating mechanisms (if they are provided in this cabinet model).

The preliminary stage allows you to prepare the basis for assembling the structure, and the master can study the sequence of work.

Advantages of sliding wardrobes

The characteristics of such furniture, which are undoubtedly its advantages, can be depicted in a table:

Advantage

Description

Compact and spacious

In such a closet you will place twice as much clothes without the expense of the enormity of the furniture itself.

Possibility of convenient placement of the cabinet in a room of different sizes and shapes

Some models of wardrobes can be transformed to suit the features of the room: the presence of a corridor, recesses in the wall where the wardrobe can be placed.

Room zoning

With the help of a wardrobe, you will visually separate different zones in the room, for example, a working area from a relaxation area.

Sliding door mechanism

To open the closet, you don't need to remove chairs or move other furniture

Convenient assembly and disassembly of the cabinet with your own hands

Assembling a wardrobe with your own hands is quite easy and anyone can do it simply by following the instructions.

Beautiful design

Compared to conventional furniture, built-in compartments are distinguished by a variety of shapes and a palette of colors. A huge selection of shades and color combinations, various designs and thematic images will give the room in which the compartment is located a special character and mood.

Marking parts and surfaces

The markings include both marks in the places of future installation of shelves and cabinet compartments, as well as marking boundaries on the walls.

Modern apartments allow you to install furniture not only along an adjacent wall, but also in a building niche.

Before starting assembly, you should take measurements of the area where the cabinet is supposed to be located. Correlate the obtained parameters with the dimensions of the furniture so that in the future you do not have to move the massive cabinet in its assembled state.

Note!

IKEA cabinets: TOP-170 photos and video reviews of IKEA cabinets. Advantages and disadvantages of the manufacturer. Varieties of shapes and designs of cabinetsSliding wardrobes: pros and cons of sliding wardrobes. Varieties of designs, shapes and sizes. Materials for manufacturing the body and doors (photos and videos)

Black furniture: TOP-160 photos and videos of design ideas with black furniture. Rules for combining colors and shades. Choosing an interior style for black furniture

If the set is placed in a niche, the back wall is not attached to the base, and this stage can be safely excluded from the general progress of work.

Marks are made with a pencil on the inside surface of the cabinet - they mark the installation locations of shelves and axial strips for hangers.

Installation of support structures

Depending on the type of structure, the legs can be installed in two ways:

- In the first case, the support legs are screwed to the bottom surface of the base. These models provide the ability to adjust the height.

- In another case, the plugs are removed from the support legs, and the parts themselves are inserted into the prepared holes on the lower surface of the base. These models do not provide for height adjustment of the structure.

After fastening, the supports must be adjusted so that the cabinet subsequently stands level. You can use a building level or a guide bar.

Manufacturing of parts

All work begins with a section of chipboard sheets. You need to cut the sheets into the required elements. When dimensions are set during design, the width of the saw itself must be taken into account (usually 3 mm). If you ignore this additive, the parts will be smaller.

Related article: Windows with built-in blinds: advantages and disadvantages

The sheet can be cut, as mentioned above, in a special workshop. The chipboard will be cut very accurately, the edges will be without burrs. It is quite difficult to obtain this quality at home using hand tools. But this is up to your choice and experience.

Edging parts

Edging parts can be done using a regular iron

After cutting the sheet, edging is done. This term refers to ordinary PVC tape (2 mm). A very thin tape, whose thickness is less than 1 mm, is used mainly for finishing invisible ribs; everything visible is covered first.

It is very convenient to glue edges at home with a heavy iron, heating it to the desired temperature. It is selected depending on the material used. This is where the preparatory work ends, all that remains is to assemble the cabinet with your own hands.

Installation of cabinet walls

Before installing the side walls, pins are attached to the upper surface of the base. The side walls are mounted on prepared pins.

The next step is to attach the internal walls and shelves in a perpendicular direction. At the same stage, it is necessary to drill holes and then tighten the confirmations.

Note!

Computer desk: TOP-130 photos and videos of types of computer desks. Choice of shape, size and material of manufactureSolid wood table: advantages of the material. Tips on choosing the type of wood and the shape of the countertop. Photo and video instructions for production

- Corner sink in the bathroom: TOP-180 photos and videos of options for corner sinks. Pros and cons of small sinks. Types and shapes and materials

It is very important to monitor the force applied, because twisting too tightly can damage the material.

Installation of the top and rear walls

To carry out this work, it is better to hire an assistant who will support and guide the installation of prefabricated panels.

The panels are placed on the prepared frame, fastening is carried out by tightening the screws. For additional fastening, you can use metal corners.

Installation of facades and doors

In modern design, sliding doors with mirrored or figured facades are often used. Installation of such panels is carried out last, so as not to damage the decorative coating.

Instructions for assembling the facade:

- The protective coating is removed from the doors.

- The wheels and sliding slots are examined for compliance and absence of defects.

- If necessary, you can adjust the wheels or slots to match their size and shape.

- The master or his assistant lifts the door and arranges it alternately in the upper and lower groove.

- Lastly, the bumpers are installed and the stoppers are adjusted. This moment is necessary for the doors to fit tightly to the frame.

If the selected model includes decorative coverings on the facades, it’s time to attach them to the front doors of the cabinet.

Beginning craftsmen will be helped by photo reports of cabinet assembly, presented in magazines and practical design web resources.

Some features

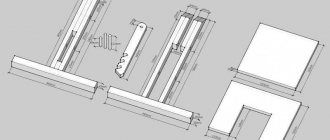

Diagram of a typical corner cabinet.

When designing furniture, you need to split the cabinet into several parts. This will make it easier to see what parts it will be assembled from. For an experienced designer, such work will not be difficult, but if it still causes great difficulties, then such a drawing can be made using a special computer program.

Related article: What to hang in the kitchen: maybe strip curtains?

Based on the finished drawings, you can start sawing the parts. You can, of course, do this work yourself, but it is much better to turn to professionals. This is due to the fact that such sawing is a complex matter; it is quite difficult to obtain accurate dimensions and good quality. A sawing machine is expensive, but purchasing one to make a cabinet is simply pointless. Of course, you can use a jigsaw at home, but it will cause chips. You can cut the chipboard and get the corresponding parts where the chipboard is sold.

Cabinet parts will require hardware. Before buying it, you need to determine how the doors will open. A lot of opening mechanisms are known today. For example, opening in different directions, moving according to the coupe principle, opening up, and so on.

Scheme of an ordinary cabinet.

Be that as it may, if the floors in the room are uneven, then gaps will certainly appear between the cabinet doors. They can be removed when adjusting the installation canopies intended for ordinary doors, or by selecting the height of the wheels that are used for wardrobes.

Depending on the number of parts, you can accurately determine the required number of confirmations. They help assemble the walls and various partitions of the cabinet. The number of confirmations determines the number of rivets, required guides, and how many shelf holders are needed. In addition, the dimensions of the edge of the chipboard are determined.

Holes are made for confirmations with a specific drill diameter. The location of the holes must be kept strictly symmetrical. The appearance of the assembled cabinet depends on this.

Wardrobe diagram.

Using a screwdriver, the cabinet frame is attached directly to the confirmations. The standard door system is reinforced with canopies, and guides are screwed in for the sliding wardrobe mechanism. The holes are marked in the locations of the shelves, and places for the guides are marked for attaching the shelf holders. This operation must be performed very accurately, otherwise the shelves will be installed crookedly.

The guides must be strictly parallel. Having made the markings, you need to drill holes and secure the guides.