Guide profile

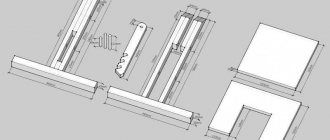

The main element of the slatted ceiling is the guide profile. It is called a stringer or traverse. They have different shapes, but U-shaped options are most often used.

The downward facing shelves have teeth. With their help, the ceiling slats are subsequently fixed. Holes are made at the top of the profile to secure the hangers.

Material calculation

Before calculating the required number of elements of the suspended structure, it is necessary to determine the standard size of the aluminum slats and mark the frame. • The perimeter of the room will be equal to the total length of the U-shaped profile, which will be needed to install the frame. It will ensure a strong and neat connection of the panels to the walls of the room.

• The markings will also indicate the required number of stringers - these are guide bars with special locks in which the slats are actually fixed. The tires are held by means of hangers, which are aimed at the main ceiling at one end, and hold the profile with the other, providing it with some free movement.

• Based on the area of the ceiling, you can calculate the optimal number of aluminum profiles. If the room is more than 4 meters, the panel will have to be spliced. To do this, the kit should include special intermediate inserts that give the connection a neat appearance.

Suspensions

The next element of slatted ceilings are suspensions. They are sold complete with a guide profile or selected separately. Their design can provide different distances between the ceiling and the slats.

Sometimes installation occurs without hangers. At the same time, there is practically no free space between the ceiling and the decorative slats.

Preliminary preparation - materials and tools

At the initial stage of construction, you will need tools to help you correctly mark distances . A guarantee of a good result is clearly measured and marked lines and angles. It is recommended to acquire the following items:

- square;

- graphite pencil;

- construction thread (may be needed, but always);

- water or laser level;

- ruler and tape measure.

Using these tools, you can perform preliminary marking and preparation of the ceiling surface . First of all, a guide profile is installed around the perimeter of the entire room. Therefore, it is extremely important to determine the height at which the future structure will be fixed. As a guide, you can take the top facing tile. If the wall decoration is made of another material (plastic panels or putty), then the height is measured from the floor.

The slatted ceiling perfectly hides all irregularities and communications

In addition to items for marking, the master will need a knife or scissors (if the ceiling is planned to be plastic), a hammer drill or impact drill, a screwdriver and a screwdriver . For aluminum slats, you will need to have scissors on hand that are designed for cutting metal.

Important! Before purchasing materials, you must first calculate their expected quantity. It is necessary to optimally select the length of the profile in order to obtain a minimum of waste at the output. Take a little extra so that the repair process is not abruptly interrupted due to a lack of parts.

Ceiling slats

To make the ceiling decorative, ceiling slats are used. Photos of slatted ceilings in the bathroom show how varied slatted models are.

To fix the rail, you need to snap it into the protrusions of the stringers.

Holes for lamps

If the bathroom has spotlights, holes for them are cut out with a special drill attachment - a “crown”, or metal scissors are used. To avoid damaging the slats, it is not recommended to perform cutting by weight. The panels are removed and drilled on a flat surface. Or cut out a circle, having previously measured the diameter of the lamp base with a caliper. A circle is drawn in the right place on the staff with a compass. A hole is drilled in the center of it, from which the shape is carefully pulled out along the line using metal scissors. But it’s better to use a ballerina for this!

Drilling a hole for the lamp

Sometimes the lamp is placed between two adjacent slats. If an individual panel is damaged, it can be easily removed and replaced with a new one. Also, the structure of a suspended slatted ceiling can be dismantled and then reassembled and this will not affect the quality of the ceiling in any way.

Types of slatted ceilings

Slatted ceilings are made open, continuous, gapless and closed.

If the slats are placed leaving a distance between them, the ceiling turns out to be open. Filling these gaps with decorative slats will create a continuous surface. In this case, the cracks are almost invisible.

In the closed version of the ceiling, the new rail partially overlaps the previous one.

Steel slats

Steel slats are not very expensive. They are coated with polymer materials that prevent metal corrosion. This is very important when used in high humidity.

During installation it is necessary to cut the slats. Because of this, there is no protective coating left on the edges.

Pros and cons of river ceilings

Before purchasing materials, you should evaluate the pros and cons of slatted ceilings.

The advantages of using slatted ceilings include:

- No need to perfectly level the ceiling surface.

- Lightweight design and ease of installation.

- Possibility of hiding pipes and wires under the slats to illuminate the slatted ceiling in the bathroom.

- A slatted ceiling made of high-quality materials will last a very long time. Dust does not accumulate on the slats, and any dirt that appears is very easy to remove with a damp cloth.

The disadvantages of using slatted ceilings are:

- The presence of a distance between the ceiling and the slats, since moisture can accumulate in it and mold can appear.

- When using slats, the height of the room is reduced.

When to install

The construction of a hanging system is one of the points in arranging a bathroom; therefore, it is necessary to determine its role among other planned activities. Installation of fasteners, guide rails and slats is a fairly clean and quick process when compared, for example, with decorating walls with ceramics. There is practically no dust and debris during such work, and the most difficult step in implementation is the precise fastening of the perimeter and suspensions. Therefore, such a structure is built at the last stage, after laying the floor and cladding the walls . This is the most competent and logically correct sequence of actions.

Finishing the ceiling at the finish makes it possible to hide all errors made during the installation of ceiling communications, and also allows you to adjust its height.

Interesting! You can implement a slatted ceiling without any specific skills, simply by attaching a guide rail and “typing” the required number of panel elements.

The ceiling can be installed last.

In simple terms, this is an inexpensive ceiling covering option that can be assembled or disassembled with your own hands at any stage of construction.

Subtleties of choosing a ceiling made of slats

Before purchasing materials, you should carefully measure the size of the room and think about the direction of placement of the slats.

When arranging a gapless option, it is recommended to place the slats from the entrance in the direction of view. In this case, the gaps will be almost invisible.

If the ceiling has a linear structure, it must be taken into account that the transverse arrangement of the slats can visually make a small room wider, and the longitudinal arrangement can lengthen it. When contrasting inserts are used, this effect is enhanced.

The diagonal arrangement of the slats looks especially original, but it is not always appropriate.

The slatted ceiling looks quite beautiful, and installing it is simple and quick. If the technology is followed, even a novice master can cope with its installation.

Photo of slatted ceilings in the bathroom

Tell your friends