Which lamp to choose

First you need to decide what type of lamp you like. On the Internet you can easily find photos of a homemade lamp of various types: rack-mounted, hinged, on a flexible bracket, etc.

How do they differ from each other? Let's figure it out.Rack lamp

The simplest design in a technical sense. Places on the table or any surface (chest of drawers, coffee table, etc.). Illuminates the nearby area.

In terms of design, there is complete freedom; the choice of lampshade and frame for such a hand-made lamp is limited only by your imagination.

Lamp on a complex breakable hinge

It looks impressive, but this option is not suitable for all interiors. In terms of mechanical parts, this design is more complex and expensive. Due to the presence of a large number of components, you will be able to save little on such a lamp.

How to make a lamp from cardboard with your own hands

Shot: @Sunny Lin / YouTube

What do you need

- Thick cardboard;

- ruler;

- pencil or marker;

- scissors;

- gold paint;

- brush;

- garland;

- glue gun.

How to do

Draw a large five-pointed star on the cardboard. Cut out the shape along the contour.

Shot: @Sunny Lin / YouTube

From each corner, draw a line with scissors using a ruler to the center. Do not cut all the way through the cardboard.

Shot: @Sunny Lin / YouTube

Bend the figure inward along the marked lines.

Shot: @Sunny Lin / YouTube

Turn the star over and bend the edges towards the center as shown in the picture.

Shot: @Sunny Lin / YouTube

Use dots to mark the corners of the folded figure on another sheet of cardboard.

Shot: @Sunny Lin / YouTube

Then connect these points with straight lines and cut out the second star.

Shot: @Sunny Lin / YouTube

Make many holes in the large star with scissors, equal to the number of almost all the bulbs on the garland. Paint the outside of the figure gold.

Shot: @Sunny Lin / YouTube

Insert one light bulb into each hole from the inside.

Shot: @Sunny Lin / YouTube

Glue the second star to the back of the bent star, smearing the edges of the figure with glue.

What other options are there?

Here's how to make a similar lamp in the shape of a unicorn:

Interesting lamp with stars:

Another unusual cardboard lamp:

You can even make a table lamp from cardboard that looks just like an ordinary one:

And a beautiful lantern:

Lamp on a flexible arm

Thanks to the flexible base, this design is very convenient to use: you can direct the light to the desired area.

But due to the complexity of the design and expensive elements, it is more profitable to purchase such a lamp in a store than to make it yourself.

LED lamp

You can make a table lamp from LEDs with your own hands. Such a lamp is much cheaper in cost than conventional ones (in terms of energy consumption), and it is assembled from inexpensive elements.

How to choose a phase meter - review, purpose, principle of operation, scope of application + instructions for use with photos- How to make a transformer with your own hands - step-by-step instructions, diagram, drawings, list of materials + photo of a finished homemade transformer

- Which hidden wiring detector is better? TOP 10 best manufacturers with photos and descriptions

Master class: Table lamp made of copper pipes

With a simple and elegant copper table lamp, you can decorate any corner of your home by making it yourself. It will fit perfectly into a modern interior from loft to rustic style. Prostate and laconicism are the main trump cards of this table lamp.

To do this you will need the following tools:

- Roulette, marker

- Pipe cutter and washcloth

- Wire stripping and stripping tool

- Pliers and a thin flathead screwdriver

- crosshead screwdriver

M materials:

- Copper pipes

- Acetone and super glue

- Copper corners 90°, 7 pcs.

- Electric wire

- Plug and Electric socket

- Switch and light bulb

Technique for assembling a table lamp

To get started, take a tape measure, a marker, a pipe cutter, a rag, copper pipes and acetone.

Mark and cut the tubes

- Use a measuring tape and marker to mark where you will cut the copper pipes.

- Do this carefully, measuring every millimeter precisely, because if the parts are different, then the end result will not be the same size as they should be.

- Guide the pipe cutter and use the nut to adjust the diameter of the pipe. Look at the copper tube, gradually adjust the diameter with the nut , so that the closure continues until the pipe is cut.

- Afterwards, using acetone and a rag, you can wipe the markings off the pipe.

TIP: Our parts have: 3 cuts of 15 cm, 1 cut of 20 cm, 1 cut of 45 cm, 1 cut of 25 cm. We used 12 tubes. When designing your light fixture, please note that the copper elbow size will be added.

While the cable is inside, we connect the parts

Insert the parts together and glue with super glue. In order to avoid problems in the future, it is better to glue each part and place it next to each other.

Even though the glue works instantly, you may want to wait a few minutes before proceeding to ensure that the pieces are glued together perfectly.

Tip: It will be more convenient to apply glue if you use a brush. If you want the cover to be at the very top, install it first. This way the first part will be ready, and the cable will go in a different direction.

Tools:

- Wire Stripper and Wire Stripper

- Incisors

- thin flat screwdriver

- crosshead screwdriver

- fork

- electro chuck

- switch

- Copper pipes

- electrical wire

Install the electrical system

- Open the front panel of the cover and start by stripping the insulation. Connect the ground (blue color) and phase (brown, gray or black) using the two screws that you will find inside.

- Repeat the same process on the plug and switch.

- In the switch you will find two pairs of small screws, a cable that you must cut to the height you want the switch to be and connect to the corresponding sockets going inside the small screws.

- All you have to do is screw in the light bulb to create your copper table lamp.

Finally, place the lamp in a corner or place you like and see how it will become a wonderful addition to your interior, lighting up the space!

Electromechanics

The electrical circuit of a table lamp is simple. You will need: light bulb, socket, switch, plug and cable.

Like store-bought copies, the DIY lamp is designed for 220V.

The main thing to remember is electrical safety (especially when designing hinged lamps). The cable must be double insulated and under no circumstances strained, the wiring must be reliably protected.

So, detailed instructions on how to make a rack lamp with your own hands:

- Tie the cable with the plug in a knot (or put on a washer to fix it

- Select your rack (it could be a glass or plastic bottle, jar, clay base, etc.) and run the cable through it

- Fix the light bulb socket on the stand and attach the cable to it

- Secure the frame (it can be made of wire or a bottle)

- Put on a lampshade

Design Features

The table lamp consists of the following elements:

- Electromechanical part. Thanks to electromechanics, electricity is supplied from the mains to the lamp socket.

- Support part. This element supports the illuminator or reflector.

- Illuminator. It is a lamp under a lampshade or in a reflector.

In lamps with stands, the main aesthetic is usually the design of the lampshade, with the stand acting as an accessory. In articulated models the opposite is true.

Electromechanical part

The electrical circuit of a table lamp includes a power plug, cable, switch and socket. In some cases there is a voltage controller.

The E27 chuck is installed only on a threaded shank (M10, M12). The cartridge for a narrow base (E14) is also installed on a thread (another option is a lamella in the form of a metal strip). The best option for a table lamp is chandelier sockets equipped with threaded flanges. A metal faceplate with a lampshade structure or a hinge clamp clamp is clamped between the flanges. The figure below shows lamp socket options.

During production, special attention is paid to electrical safety. To do this, adhere to the following rules:

- The cable must be round, covered in a double insulating layer.

- The current-carrying conductors are selected to be flexible and contain many wires. A suitable core cross-section is from 0.35 sq. mm or more.

- Areas where the cable is laid through conductive parts, as well as damp places, are protected with dielectric bushings. Knees or cuffs are also used.

- The cable tension inside the lighting fixture should not be excessive.

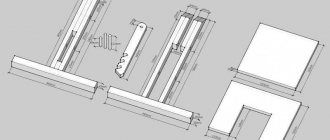

The figure below shows a diagram of the mechanical components of a rack table lamp support.

Before insertion, the cable is tied from the inside with a knot or threaded through the opening of a dielectric locking washer. This is done so that after tensioning the cable from the outside, it does not lose the integrity of the internal part.

Hinge Features

The design of a table lamp stand is simple, unlike a hinged bracket. The wire to the lamp socket is supplied through fireproof dielectric elbows. If the hinge link is solid, the cable is routed along its top (right and center). At the same time, they are carefully fixed to the link. In the case of tubular links, the cable is placed inside them. Cable loops are created above the kinks of the links (diameter of at least 60 mm, or from 12 conductor diameters). In the area of cable transition from the bracket to the illuminator, the loop is larger - from 90 mm, or 20 cable diameters.

The position of a table lamp with a hinge varies widely, so it is not easy to ensure its stability with a load. Because of this, a table lamp with hinges will require screw clamps. For a homemade lamp, you can use, for example, a small carpenter's clamp. What is needed is carpentry, not metalworking, since the latter lack a soft coating.

To create a holder from a clamp, use a metal tube socket (inner diameter - at least 10 mm, length - 120-150 mm). A longitudinal groove is sawed in the tube with the same thickness as the clamp holder. The socket is fixed to the clamp using through bolted connections. A metal pin with an eye is installed in the socket, acting as a stationary element of the lower hinge of the bracket.

Note! The clip is made of high-carbon steel so that the clamp does not deform under the pressure of the parts. However, such steel is brittle, so the drill must be made of a durable alloy. Do not hit the clip with hard objects or try to bend it.

Reflectors

For articulated table lamps, only reflectors are suitable. The lampshade is too heavy for this type of lamp. A parabolic type reflector is required because it produces a very even, directional light. You can purchase a reflector or make it yourself. Usually only single reflectors are made independently. However, the lighting from them is not the most uniform. But high-quality reflectors (fourth order of curvature) cannot be made on your own; you will have to buy this part.

The reflector on the hinged bracket needs an upper opening to remove heated air. Although LED and fluorescent lamps heat up moderately, the life of the product is still reduced, so the removal of hot air is highly desirable.

Shade

It depends only on you and your imagination what material your lampshade will be made of. This can be paper, glass, plastic and any available means, even the most unexpected ones.

Technological maps in construction - what is it?- How to fix a laptop that won't charge

- Insulated dielectric screwdrivers up to 1000V - tips on how to choose the best manufacturer

Rice paper lampshade

It looks impressive in almost any interior, and a wide range of colors will allow you to choose the color that suits you. To create such a lampshade, you simply need to wrap the lamp frame in paper.

Wallpaper lampshade

An interesting idea at no extra cost. Cut a rectangle of wallpaper measuring 150x30 cm, carefully fold the piece like an accordion.

Then make even holes (for example, with a hole punch) on the long side of the segment, stepping back at least 2 cm from the edge. Thread a cord (rope, ribbon) through the holes and tie. Glue the outer edge to create the appearance of a lampshade. Ready!

How to make a lamp from cotton wool in the shape of a cloud

Shot: @TiffyQuake / YouTube

What do you need

- Several paper lanterns of different sizes;

- glue gun;

- cotton wool;

- fishing line;

- wooden stick;

- hooks;

- garland.

How to do

Cover one lantern with a large amount of cotton wool.

Shot: @TiffyQuake / YouTube

Hang a wooden stick from hooks in the ceiling. This can be done using fishing line or thin rope. Tie another piece of fishing line to the base of the flashlight.

Shot: @TiffyQuake / YouTube

Hang the flashlight by a fishing line from a stick.

Shot: @TiffyQuake / YouTube

Cover the rest of the lanterns with cotton. Hang them from a stick to form a cloud. Fasten the parts together with glue.

Shot: @TiffyQuake / YouTube

Insert a garland into the lanterns. You can make it hang down from the cloud.

What other options are there?

You can also use cotton wool to cover plastic bottles with garlands:

Or balloons:

Beaded lampshade

The result is a delightful sparkling lampshade that will fit perfectly into any interior. Take the fishing line and attach one end to the frame.

String beads or seed beads onto the fishing line. Then secure the fishing line to the other end of the frame. Place the fishing lines with beads at a distance of 2-3 cm from each other.

Making a table lamp

After I made my last floor lamp (previous master class), I thought for a long time about my next work. And then I came up with the idea that I could make a table lamp in the same style as the floor lamp, so that I could get two works that would complement each other. That is why, as many will think, these works are twins. It may be true, of course, but this is what I wanted to achieve. So, let's begin.

I started by deciding to think about the foundation. In this case, as in many of my earlier works, I decided to use a brake disc from a car as a base. Only if before I took an already used brake disc, this time I decided to take a new one. I went to a spare parts store and bought a brake disc from a VAE-2109 car. The seller tried to prove to me that a disk for 800 rubles is much better than one for 570 rubles, and said that I should take two disks, not one, but I did not explain to him that I was not interested in this at all - I was not going to slow them down , and I need exactly one disk, not two. He looked at me for a long time, but still didn’t understand why I needed one disk.

I would then usually weld the 3/4" socket to the base, but this time I decided to cheat on myself and attach it some other way. To do this, I drilled the coupling in four places.

Then, using the corners and holes that were originally on the disk, I attached the coupling to our base.

The next stage of our work was assembling the lamp itself and laying the wires along the connection of the structure.

We cut the wires to approximately the size with a margin, at the top there will be a power button, at the bottom there will be a light bulb and under the base there will be a connection of all the wires using terminal blocks.

We are preparing our lamp for painting. Cover all holes with masking tape.

We also temporarily cover the wires below with masking tape, just so as not to crush the terminal blocks during transportation and installation.

We are priming our lamp; for this I took the lamp to work.

A day later we paint our work in two layers. Allow at least an hour between coats. Copper colored paint.

Next, we let the work dry for two days to be sure. While our lamp is drying, we are working on the lampshade. The lampshade is exactly the same as in the previous floor lamp, namely from chains. As a base for the lampshade, again, we take a device known to us, namely a plastic base from a glass for forks and spoons from Ikea.

We mark according to the size of the pre-purchased chain and drill holes around the circumference.

This is what we get.

In the center of the lampshade we make a hole with a diameter of 25 mm.

Next we cut the chain. We got 48 holes in the base and cut a chain of different lengths, namely three sizes, and during installation we will alternate them.

After our blanks for the lampshade are ready, we proceed to install the power button, a rheostat for adjusting the brightness and a socket. The button fits perfectly into the washer, which we pre-painted together with the lamp, and we glue the washer itself using Paxipol to the top of the lamp in the place where we previously ran the wires under it.

We also glue the base of the cartridge to the coupling.

We connect the power cable with a built-in rheostat to the terminal blocks, having previously threaded it through the hole in the brake disc. To prevent the wire from rubbing against the base over time, we make a spacer from a regular dowel.

To be sure, we wrap the terminal blocks with electrical tape so that they do not accidentally open inside the lamp.

We glue the base so that the lamp does not scratch the table, and close all the terminal blocks with wires inside the lamp.

We install the base of the lampshade and fasten the chains.

After this, we install a light bulb (60 watts), and our work is ready. Look what happened. I hope you will enjoy.

Thank you all for taking the time to view my work.

Lampshade made of lace

A light, romantic and delicate lace lampshade will definitely please your better half. Cut the lace into strips. Inflate the balloon and place it in a container so that it is convenient for you to work.

- Dielectric insulated tool for work - which one is better to choose? Review of manufacturers, photos + video

- Properties, scope of application of Paroc basalt insulation

- Mitsubishi Electric: company history

Apply glue to the lace and glue the strips to the ball so that you end up with a semicircle (no need to glue lace to the bottom of the ball).

The lace should overlap each other and the more, the stronger the structure will be. Leave a small circle at the highest point to fit the lampshade onto the stand. We are waiting for the glue to dry. All! The lampshade is ready.

Anyone can make a beautiful and inexpensive lamp. Turn on your imagination and show your creativity, and your interior will be decorated with a unique piece of furniture that will warm your soul and illuminate your home with light.

How to make a table lamp from improvised materials

Hi all! Today we will first assemble a useful homemade product. Namely, in today’s article we will analyze in detail how to make a table LED lamp. Surely many of us have had a table lamp break at least once in our lives, for various reasons, and we had a need for a table lamp, sometimes even an urgent need. But, as usual, there is no money for a good lamp, and it’s a pity to spend money on a cheap one, since it will literally be thrown away. So, a homemade product is perfect especially for such situations, since it will be assembled literally for “free”, because it will consist of the most accessible and available materials. Well, well, I think there’s no need to delay with a long preface, let’s go.

You can find links to some design components at the end of the article.

For a table lamp you will need:

- Lamplight (can be found at a flea market) - A small piece of 40 mm PVC pipe - About a meter piece of 20 mm PVC pipe - A sheet of plywood (as much plywood as you can find) - A small piece of sheet plastic - A wire with a plug - A cartridge (optional) - Light.

You will also need some tools.

— Drill with drills — Hacksaw — Marker — Ruler — Superglue — Sandpaper — Soldering iron with soldering accessories — Hair dryer (a simple hair dryer will be enough) — Jigsaw — Scissors — Hot-melt glue.

Making a table lamp.

First, you need to find a suitable lampshade that suits your taste and color; many people probably have a similar one lying around in the garage from their grandmother’s old chandeliers. Well, if not, then various sites with advertisements will help you. But if you’re just really lazy and don’t want to spend money on everything, then you can use some kind of plastic canister or bottle of a suitable size, but in this case it’s worth considering the fact that with such a plastic lampshade an incandescent light bulb is contraindicated.

A housing element should be added to the lampshade itself, to insulate the contacts and inside which the wires from the light bulb will pass, and also the leg will be attached to it. A PVC pipe with a diameter of 40 mm is perfect for this. From this pipe you will need to cut off a part approximately 6-7 cm long. To do this, use a piece of paper and a marker (see photo) to draw an even outline. And we saw off this part strictly along the contour, doing all this extremely carefully. And after that, we remove all the nicks from the cut with sandpaper.

The next step is to make a leg on which the lampshade will be installed. For this task we will use a PVC pipe with a diameter of 20 mm. You choose the length of this pipe yourself based on your needs. The author of the homemade product took a piece approximately a little more than half a meter long.

In order to reliably connect these two elements (the leg and the modified lampshade) and so that the connection itself looks more pleasant. One of the cuts of the 20 mm pipe should be processed, or rather, a “groove” should be made in it so that the pipe fits tightly to the other pipe. To do this, take a large pipe, apply sandpaper to it, and rub a smaller diameter pipe (leg) against it.

Then we connect the two blanks. To do this, treat a pipe with a large diameter at the gluing site (in the center) with fine-grain sandpaper (grinding). Let's connect the two blanks together and pour superglue around the joint in a circle.

At this stage of assembling the homemade product, you need to bend the leg. You should bend the lamp leg as you need it, that is, as it will be more convenient for you to work with this lamp. To do this, take an ordinary hair dryer, warm up the bend area thoroughly, and before the plastic cools down, bend the workpiece.

Now we will make a rack on which the structure will actually be installed. To do this, take a sheet of plywood and draw a rectangle on it. The rectangle should be of such a size that the entire structure does not overhang or fall during its operation. To give your homemade product a more aesthetically pleasing appearance, you should cut out a rectangle with rounded edges (see photo). The workpiece should be cut using a jigsaw and then it is important to sand the workpiece with sandpaper.

The next step is to make a fastening element for the leg with the lampshade. You can simply make this element square and not bother anymore. But the author decided to do it beautifully. Therefore, two identical parts should be cut out of cardboard, exactly like those shown below. We cut it out using a jigsaw and sand it with sandpaper.

After which the newly cut pieces should be placed and secured to the base. These parts should be fastened exactly in the center relative to the sides, and moved to the “back” part. Also, these parts should be installed exactly parallel to each other, at a distance of approximately 4-5 cm. They should be glued using superglue, and the gluing should be reinforced with plywood sawdust or soda.

As you have already seen, the attachment of the leg to the leg is not entirely simple, and has a beautiful bend. And as you understand, it will be very problematic to bend the plywood so that it envelops the workpieces, and we have a completed fastening. Therefore, for these purposes we will use sheet plastic. To do this, cut out a plastic rectangle of the required width, and so long that it is enough to make a bend and cover two sides with one piece of plastic (one side and the top).

And glue the plastic blank to the plywood blank exactly as shown in the photo below. We will also glue it using superglue. But as you understand, due to the bend, this will be quite problematic. Therefore, you should glue it in parts, first the side, and then the top, pressing the straightening plastic with something.

We drill a hole for the wires in the plastic part of the homemade product that we glued earlier. And glue the leg to this part using superglue, having previously sanded the joint with sandpaper.

In order for the homemade product to have a more pleasant appearance, we paint it the way you want. Then we glue the LED light bulb to the lampshade using hot glue. The light bulb should be LED and not very powerful, since due to excess heat generation it can greatly heat up the hot melt adhesive.

Then we glue the lampshade to its mount. As you already understood, we have one side left that is not covered with plastic at the place where the leg is attached. We glue the “blocks” to the corners in this part with superglue and screw the closing plastic panel to them. The socket itself should also be cut from the same sheet of plastic that was used previously.

A hole for the wire should be made in the last fixed element. Having made a hole in the indicated place, we insert the wire itself. We solder the ends of this wire with a soldering iron directly to the light bulb (if you decide to use a socket, then you need to solder to the socket).

All is ready! That's all, in the end we got a homemade product that will certainly find application in the household and can help you out more than once. It should be noted that this homemade product can be used as a secret safe for a stash (see photo below).

You can purchase components that may be useful for assembling this homemade product here:

- LED light bulb - Plug with wire

Here is a video from the author of the homemade product:

Well, thank you all for your attention and good luck in future projects DIYers!

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Photos of DIY table lamps

Did you like the article? Share

0