Heat pump (HP) is a heat machine for heating/cooling a room or heating water. The principle of operation is the transfer of thermal energy from air, water or soil to the heating system / water heater (DHW).

The coolant is a liquid that circulates through the HP pipes and transfers heat to radiators, convectors, fan coils, hot water tanks and other heating devices.

Advantages of TN:

- saving money on heating and hot water supply;

- environmental friendliness;

- independence from heat and gas communications;

- compact dimensions;

- significant motor life (20 years before major overhaul);

- safety of use;

- multifunctionality (heating and cooling).

Disadvantages of TN:

- high price of equipment, the payback of which is affected by the intensity of operation;

- complexity and high cost of installation.

Important: if there are frequent voltage drops or power outages in the electrical network, then it is not recommended to install a heat pump. Also, you should not purchase equipment in a building with an area of up to 100-120 m2. In this case, the costs are not economically feasible (the larger the building area, the cheaper the heat energy is and the shorter the payback period for the pump).

Due to the operating principles of the HP, it does not heat the coolant above 70°C. Therefore, such a device is effective only in a well-insulated room. In this case, it is better to connect the unit to low-temperature heating systems, for example, heated floors or warm walls (the coolant temperature does not exceed 35°C).

It is more difficult to use radiators with this temperature schedule (45/35) due to their increased dimensions. The lower the coolant temperature, the longer the length of the battery to produce the required thermal power. It is not always possible to install such radiators.

Heat pump

System type

Air-water (air, aerothermal) - receives energy from the air. Advantages: ease of installation, no land required, possibility of installation at height. Disadvantages: relatively low efficiency and service life, strong dependence on temperature conditions.

The air pump is used as an additional heat source (heat pump + heated floor, heat pump + boiler). The choice in favor of this equipment is also made if it is impossible to install a soil pump, or the cost of drilling is close to the cost of a HP.

Ground-water (ground, geothermal) – draws energy from the ground. Advantages: high efficiency, independence from air temperature, durability. Disadvantages: high price, complexity and high cost of installation (the pump is buried in the ground), impossibility of installation on the upper floors of buildings. The geothermal pump is used as the main heat source.

The soil pump comes in two varieties:

- vertical - laid in a relatively small area, but requires high costs due to the high drilling depth (40-200 m);

- horizontal - cheaper to install due to the shallow drilling depth (1.5 m), but takes up much more space.

An area with a horizontal heat pump is not suitable for agricultural and landscape work. A vertical heat engine will not spoil the landscape design and is therefore optimal for a landscaped area. A similar option is also used on heavy soil.

Important: the vertical HP differs favorably from the horizontal model by being completely immune to weather conditions. As a result, the coolant temperature at the outlet of geothermal wells remains constant regardless of the ambient temperature.

Water-water (water, hydrothermal) - takes energy from groundwater or a reservoir. Its characteristics are similar to a ground-water pump, but it is less reliable due to additional equipment, for example, a submersible pump or filters.

Air/ground-water is a universal pump that draws energy from air or water. Advantages: simple installation, comfortable operation. The disadvantage is the high price.

How does a heat pump work?

A heat pump transfers heat from one environment to another using three interconnected thermal circuits. The first medium is atmospheric air, water or soil. The second is either a coolant that heats the radiators, or a water-heated floor, or indoor air.

Types of Heat Pumps

- air - air (this type is used in household air conditioners);

- water - air;

- earth - air;

- air - water;

- water - water;

- earth - water.

The most widely used models are those in which the first medium is air or earth, since suitable bodies of water are not available everywhere. The second medium is water, due to the popularity of water heating.

A circuit of pipes is laid through the medium, which acts as a heat source, and coolant circulates through it. As the coolant passes through it, it acquires the same temperature as the medium. It then goes to the evaporator heat exchanger, where it heats the liquid freon in the secondary system to a boil. Gaseous freon passes into the compressor, where, during compression, it is strongly heated to 55–75 ° C. Next, the freon enters the condenser, where the heated gas gives off heat to medium number two, air or coolant fluid from the heating system.

Visualization: Igor Smiryagin/ Burda MediaSchematic diagram of a heat pump: 1—heat source; 2 - low-temperature primary circuit; 3 - evaporator; 4 - compressor; 5 - capacitor; 6 - third circuit (heating).

Visualization: Igor Smiryagin/ Burda Media

Options for installing the primary circuit in the ground: vertical (borehole) location, horizontal location.

- Heating

4 common mistakes in arranging heating in a country house

Purpose

Heating is the main function of heat pumps. However, not every model is capable of providing the necessary thermal power for full heating.

Cooling – provided in most air models. But many ground devices are not capable of cooling without additional equipment, which is purchased separately. Vertical heat pumps provide better cooling than horizontal heat engines.

Hot water supply (DHW) - implemented through a built-in water heater or the possibility of connecting to an external boiler. Such pumps are of the air type and are rare.

Heating and hot water supply are a combination of two modes. A universal option.

Heat pump equipment

The choice of heating equipment usually begins with determining its required power. A thermal calculation of the room is carried out, heat loss is calculated, and the required amount of hot water for hot water is taken into account. It is better to entrust this calculation to a specialist to avoid mistakes. The approximate order of numbers is given by calculator programs on the websites of manufacturing companies.

Next, you can select the type of device taking into account the area. If you have a sufficiently large reservoir at your disposal (several hundred cubic meters), then it may be suitable for placing the system. The latter resembles a coil made of flexible polymer pipes; it is carefully laid on the bottom and secured there with a load.

Air heat exchangers are quite suitable for the windy southern regions of our country or for bivalent systems. They can be placed at a distance of up to 30 m from the indoor unit. In fact, they tend to be located as close to the house as possible, since long connecting lines increase losses and reduce useful power. Ideally, this is a blank wall of the house, away from the bedroom windows.

An important parameter is the minimum outside temperature in heating mode. For models specially adapted to frost, it can be –25 °C.

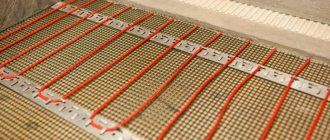

A ground collector can be constructed in several ways. For example, in the form of horizontal laying of a long (several hundred meters) pipeline on a plane with a depth above the freezing level (usually 1.5–2.0 m). The pipeline can be laid along the perimeter of the site or in a snake, like a heated floor pipeline, but with a much larger step. The total occupied area of the land plot is several hundred square meters, and the possibilities for additional use of this land are significantly limited. It will not be possible to grow a vegetable garden or plant trees. Therefore, many homeowners consider horizontal installation of the collector to be irrational and prefer vertical, in the form of several wells spaced 5–10 m apart from each other. Or in the form of one “cluster” of wells (wells are drilled from one point on the surface, but not vertically, but under angle is usually at least 30° in azimuth). This “vertical” approach allows you to save on space, but increases construction costs by 30-50%.

Due to technical features, it is better to use a heat pump for a country house in which you live for a long time. They achieve maximum efficiency in combination with “warm floor” systems, which are inertial. The economic effect will be directly proportional to the intensity of use. In domestic conditions (European part of Russia), the most common options are “brine (earth) - water” with vertical probes. They provide the ability to fully cover heating and hot water loads almost regardless of climatic conditions.

Ariston

Heat pump with built-in tank and battery.

Viessmann

Outdoor unit of air heat exchanger.

- Heating

Selecting a circulation pump for a heating system: overview of important parameters and useful tips

Thermal power

This indicator characterizes the efficiency of the heat pump. The more powerful the HP, the more heat it can extract from the environment and transfer to the heating or water heating system. At the same time, the price and energy consumption of the heat engine increases. To evaluate power, two parameters are used - maximum and at a temperature of 0°C.

Maximum thermal power is a nominal value, which is indicated based on ideal conditions, primarily high air temperature. Practice shows that the actual power of a heat engine is always lower than this indicator

At 0°C - the main indicator of power, allowing you to more accurately assess the actual power of the heat pump.

When choosing a heat pump based on power, the area of the heated room, hot water consumption (depending on the number of people living), the rate of heat loss and other parameters are taken into account. The calculation of the required power is carried out by specialists using formulas.

The maximum cooling power is also indicated (for HP with this function). This characteristic is influenced by the area of the room, thermal insulation and other factors. Cooling power is calculated using special formulas.

Important: the same heat engine is not able to heat and cool a room equally well, since the thermal power of the device is higher than the cooling power. It is recommended to choose a model that heats the entire area of the room and cools only part of it (it is not necessary to cool the air in corridors or technical rooms).

For hot water supply

All thermal pumps can not only heat the room, but also supply hot water all year round. But you need to take into account that this equipment is low-temperature; accordingly, the temperature of the water in the water heater will be no more than 40−50C. That is, the volume of the boiler must be greater than during operation of a conventional heating system. Therefore, it may be necessary to strictly conserve hot water in winter.

This fact must be taken into account when designing the location and corresponding area for the boiler room. Also, when choosing a boiler, you must not forget that this will require special equipment that is designed to work with heat pump units. The main difference between this boiler and a traditional one is the large heat exchanger area required for efficient transfer of thermal energy from the thermal pump.

Heat conversion coefficient

Heat conversion coefficient (COP, KPT) is a figure expressing the relationship between the thermal and power consumption of a heat pump. This parameter is used to evaluate the performance of a heat engine.

KPT shows how much thermal energy the device moves, expending 1 kW of electricity. The higher the COP, the more efficient the heat pump is. Modern models generate 4-5 kW or more of heat per 1 kW of electricity (COP – 4-5).

Important: COP is affected by the ambient temperature and the temperature of the coolant at the outlet of the heat pump (supply temperature). As the difference between them increases, the conversion factor decreases. Therefore, for a more accurate characterization of the heat engine, manufacturers indicate the CPT for specific temperatures.

Do not confuse CPT and efficiency (coefficient of performance). Unlike COP, efficiency is always less than 1.

Nutrition

220 V – connects to a single-phase (household) network. This power supply is most often used in models with power consumption up to 3.5 kW.

380 V - connects to a three-phase network, which is usually used in industry. For domestic needs, a similar line is laid separately. In practice, three-phase power supply is more economical than single-phase power supply (with the same power of a constantly operating VT).

220 V + 380 V - a combined option that allows you to power the heat engine from a single-phase or three-phase network.

Compressor type

The compressor is the main component of the HP, responsible for the movement of the coolant along the circuits of the unit and the transportation of thermal energy from the environment to the room.

Types of compressors used in heat pumps.

- Inverter - low noise, durable, consumes relatively little electricity. Most air pumps are equipped with such compressors.

- Spiral - has a low noise level and a long service life, but will cost much more than the previous option. Scroll compressors are used in ground HP and air-to-water models of medium power.

- Screw - characterized by increased efficiency and reliability, but is very noisy. These compressors are found only in powerful units with high energy consumption.

Operating principle

The operating principle of heat pumps is simple. The work is based on the ability of the refrigerant to absorb or transfer heat, taking into account changes in its state of aggregation. In fact, thermal pumps are practically no different from refrigeration units.

Schematically, a heat pump can be represented as a system that has three circuits:

- The first circuit contains a thermal fluid that transfers energy from a low-grade heat source.

- The refrigerant circulates in the next one. It can evaporate, taking thermal energy from the primary circuit, or condense again, transferring heat to the third circuit.

- In the last circuit, a heat sink (usually water) circulates, which transfers heat through the radiators to heat the house.

That is, liquid freon enters the evaporator, in which it is converted into a gaseous state. The required energy to complete this process is taken from the coolant that circulates through the primary circuit. Then gaseous freon, heated by 2-3 degrees, enters the compressor , the main purpose of which is to compress the gas.

The gas pressure increases, and it heats up greatly (at the inlet the temperature can be 7-12C, and at the outlet more than 50C). Next, the hot gas passes into the condenser and transfers heat to the heating system, while turning into a liquid state. Afterwards, the excess pressure is released by the release valve, and the cycle repeats.

Options and equipment

Water heater - allows you to heat and supply water to the hot water supply. There are two ways to use a water heater paired with a heat pump:

- built-in water heater - makes it possible to use indirect heating and heating elements;

- possibility of connecting to an external water heater - uses only the principle of indirect heating, which reduces its efficiency. True, a HP with an external water heater is more compact than its counterpart with a built-in water heater. The user can also choose the installation location of the water heater.

Heating element - increases the thermal power of the heating element, which is useful at very low temperatures. The downside is high energy consumption.

Wi-Fi module – designed for remote control of the HP using a mobile device, such as a tablet or smartphone.

Connection to the “smart home” system - allows you to monitor the status of the heating system, regulate the temperature of the coolant and air in the room.

The TN also provides an LCD display (simplifying operation of the device).

Operating modes

Automatic - the heater independently controls and maintains the room temperature at a given level. The device automatically regulates the coolant temperature based on the ambient temperature (weather-dependent mode). Also, the heat engine can independently control radiators and heated floors.

Energy saving - reducing heating temperature and electricity consumption when there are no people in the room. To implement this mode, the heat pump is equipped with special sensors.

Bivalent - operation of a HP in tandem with another source of thermal energy, for example, a boiler. The heat engine operates up to a certain temperature value (bivalence point), after which another heat generator is switched on. If the air temperature rises, this heat source will turn off. Compared to the monovalent mode (using one TN), this mode is more effective, but more expensive.

Important: bivalent mode allows you to purchase a device with lower thermal power. Experts recommend choosing equipment that covers 80% of the thermal energy needs for heating and hot water supply. The remaining 20% will be provided by an additional source of energy.

Thermal disinfection – destruction of microorganisms by raising the water temperature to 70°C.

Frost protection – defrosts the external VT unit. Makes it possible to use a heat engine in low ambient temperature conditions. Most often, this option is found in air-to-water models.

Which is cheaper for heating: electricity, gas or heat pump

We present the costs of connecting each type of heating. To present the general picture, let’s take the Moscow region. Prices may differ in regions, but the price ratio will remain the same. In the calculations we assume that the site is “bare” - without gas or electricity.

Connection costs

Heat pump. Laying a horizontal contour at MO prices - 10,000 rubles per shift of an excavator with a bucket bucket (removes up to 1,000 m³ of soil in 8 hours). A system for a house of 100 m² will be buried in 2 days (true for loam, on which you can remove up to 30 W of thermal energy from 1 square meter of circuit). About 5,000 rubles will be required to prepare the circuit for operation. As a result, the horizontal option for placing the primary circuit will cost 25,000.

The well will be more expensive (1,000 rubles per linear meter, taking into account the installation of probes, piping them into one line, filling with coolant and pressure testing), but it will be much more profitable for future operation. With a smaller occupied area of the site, the output increases (for a 50 m well - at least 50 W per meter). The pump's needs are covered and additional potential appears. Therefore, the entire system will not work for wear, but with some reserve power. Place 350 meters of contour in vertical wells – 350,000 rubles.

A gas boiler. In the Moscow region, for connection to the gas network, work on the site and installation of the boiler, Mosoblgaz requests from 260,000 rubles.

Electric boiler. Connecting a three-phase network will cost 10,000 rubles: 550 for local electrical networks, the rest for the distribution board, meter and other contents.

Consumption

To operate a HP with a thermal power of 9 kW, 2.7 kW/h of electricity is required - 9 rubles. 53 kopecks at one o'clock,

The specific heat during combustion of 1 m³ of gas is the same 9 kW. Household gas for Moscow region is priced at 5 rubles. 14 kopecks per cubic meter

An electric boiler consumes 9 kW/h = 31 rubles. 77 kop. at one o'clock. The difference with TN is almost 3.5 times.

Exploitation

- If gas is supplied, then the most cost-effective option for heating is a gas boiler. The equipment (9 kW) costs at least 26,000 rubles, the monthly payment for gas (12 hours per day) will be 1,850 rubles.

- Powerful electrical equipment is more profitable from the point of view of organizing a three-phase network and purchasing the equipment itself (boilers - from 10,000 rubles). A warm house will cost 11,437 rubles per month.

- Taking into account the initial investment in alternative heating (equipment 275,000 and installation of a horizontal circuit 25,000), a heat pump that consumes electricity at 3,430 rubles/month will pay for itself no earlier than in 3 years.

Comparing all heating options, provided that the system is created from scratch, it becomes obvious: gas will not be much more profitable than a geothermal heat pump, and heating with electricity in the next 3 years is hopelessly inferior to both of these options.

Detailed calculations in favor of operating a heat pump can be found by watching a video from the manufacturer:

Some additions and experience of effective operation are highlighted in this video:

Refrigerant

TN very rarely uses R22 freon, which is distinguished by its low price and operating pressure, as well as its homogeneous composition (makes it easier to refill the system in case of leaks). Disadvantage: danger to the ozone layer.

The less toxic R134A refrigerant, with similar homogeneity, is more demanding in terms of operating conditions, in particular, it requires the use of polyester oils.

Refrigerants of the R407C and R410A brands are the safest for the environment. But due to the high operating pressure, such freons are used in expensive equipment, and they themselves are not cheap. R410A compares favorably with R407C in its homogeneity of composition. But if R407C leaks, it is completely replaced.