Peak Heat Load Calculation

In January, heating the greenhouse will require 57 kW/h at night. During the day, the influx from solar energy reduces the load to 31 kW/h.

In August, 21 kWh will be required to cool the greenhouse.

More details about thermal engineering calculations and an example of a calculation table can be found in our blog.

Thermal conductivity parameters of structural elements

Frame wall 142mm U=1.27 W/m2/S, mineral wool insulation U=0.3 W/m2/S. Thermal conductivity of a double film with an air gap is U=4 W/m2/S [1, 8]. Floor on the ground U=0.36 W/m2/S (6).

Infiltration

The influx from the street is estimated at 109 m3/hour, taking into account the height of the building, weather and wind factors and the air exchange rate at a pressure of 50 Pa, ACH50 = 3 air volumes per hour [9].

Heat load of plants

When plants evaporate water, they lower the air temperature in the greenhouse.

2040 bushes at ~4.4 watt/hour/bush with watering 0.2 l/day/bush [6].

Lighting

Turns on in the evening for 5 hours. Luminous flux density 5 watt/m2. It is not the main source of light for plant growth, in which lighting can be 300 - 500 watt/m2 [3, 6].

Solar energy

The heat flow from the sun is calculated based on the angle of incidence of the sun's rays and the position and inclination of the surface towards the sun [1].

Angle designations for calculating heat from the sun [1] qs = A * E * cosθ * SHGC [1]. where qs is the heat flux from the sun, kW/h A is the surface area, m2 E is direct solar radiation, kW/h/m2 (2) θ is the angle of incidence of solar rays (3) SHGC is the solar energy absorption coefficient of the surface

Heat consumption standards for greenhouses

If for a temporary seasonal greenhouse it is not necessary to install heating systems, then a year-round structure requires mandatory heating. Moreover, it is very important to calculate the heat consumption rates for the greenhouse in advance. This is done in order not to spend extra money on unnecessary additional equipment. Or, on the contrary, by setting up minimal heating, do not freeze the plants.

Thermal calculation of a greenhouse is an important step in planning the entire future structure.

Rules for designing a heating system in greenhouses

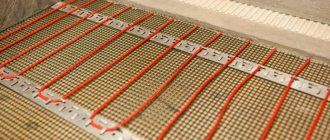

The main task of heating a greenhouse is to create the necessary microclimate for plants. The concept of “necessary microclimate” includes maintaining specified air and soil temperatures. Organizing this process correctly “at random” will not work.

Heat supply can be established through the use of the following resources:

- secondary energy resources;

- heat from geothermal waters;

- from thermal power plants, nuclear power plants, thermal power plants;

- own heat sources.

In capital year-round greenhouses, it is better to organize water heating or combined heating (water combined with air). It would also be a good idea to heat the soil. Combined heating is used in those regions where the thermometer drops below -20 degrees in winter.

If the greenhouse is single-span, then air heating should account for up to 35-50 percent of the heat generated. In multi-span greenhouses, the air heating load is reduced to 20-40 percent of the total heat consumption in winter.

Greenhouse heat loss

Calculation of heating a greenhouse cannot be done without taking into account heat loss, which is inevitable. A greenhouse, no matter how well sealed it is, cannot retain all the heat.

Heat is passed through cracks, vents and doors, ventilation, soil, if there is no artificial heating of the soil, and through the cladding and base of the structure.

To accurately determine the amount of heat loss, a special formula is used. Heat loss is found by multiplying the total surface area of the greenhouse by the thermal conductivity coefficient of the material (different for each covering material) and by the maximum temperature difference between the required temperature in the greenhouse and the coldest one outside.

Heat loss = Surface area * K * Temperature difference.

The thermal conductivity coefficient of covering materials has the following constant values:

- Single-chamber cellular polycarbonate 4 mm - 3.9;

- Single-chamber cellular polycarbonate 8 mm - 3.3;

- Double-chamber cellular polycarbonate 16 mm - 2.3;

- single glass 3 mm – 6;

- single-chamber double-glazed window – 2;

- single polyethylene film – 10;

- double polyethylene film - 5.8;

- double blown film - 3.5.

The thermal conductivity coefficient of a foundation or reinforced concrete plinth is 2.

Nuances of calculating the heat requirement for a greenhouse

There are many factors influencing exactly how much heat a greenhouse consumes, how much it loses, and to what level the coolants will have to be heated. Not everything is taken into account, only the main ones, or they are based on average data. So, it is generally accepted that:

- the temperature in the room is calculated as if it were night all the time, and it is not warmed up by sunlight;

- street temperature value is the lowest level recorded at night during the winter months;

- heat loss and heat transfer through the ground are not taken into account;

- most often, the average soil temperature is equated to the average air temperature, although the first value is calculated by area, and the second by volume;

- air humidity and carbon dioxide content are not taken into account;

- it is believed that the ventilation in the room is natural;

- all calculations are made as if there were no plants in the room, and they do not in any way affect heat transfer and heat loss;

- The starting point is taken to be that the most optimal heating system is initially installed, although the configuration can be anything, including an erroneous one.

How to calculate boiler power for a greenhouse

Whatever type of heating is chosen, in any case it is expensive to heat a greenhouse. Despite high-quality sealing, large heat losses cannot be avoided, and, therefore, it is necessary to heat intensively. Otherwise the plants will freeze.

A particular boiler is selected based on accurate calculations of all losses and the required load. You also need to pay attention to the efficiency of the boiler itself and what fuel it runs on. All this data allows you to calculate the peak load on the greenhouse heating system.

By the way, when choosing a boiler, you need to take into account the fact that its maximum power should exceed the calculated one by a maximum of 20 percent. If something happens, it’s easier to turn down the heating using a thermostat than to buy an additional boiler.

Experts also advise taking two boilers so that they operate at 60-70 percent of their capacity. Or use one of them as a spare in case the main one breaks down.

Heating system calculation

The greenhouse heating system is calculated using the following formula:

Q heating system = K (thermal conductivity coefficient of covering materials) * (T is the lowest possible temperature outside - T is the highest in the room) * k infiltration, that is, heat loss through cracks. The infiltration coefficient is generally 1.25. For factory greenhouses it is not taken into account.

For example, let’s calculate the heating of a polycarbonate greenhouse. Let the total area of the covering material be equal to 150 square meters. m. Covering material – single-chamber cellular polycarbonate 8 mm thick. For him, K will be equal to 3.3 W/m2C. The temperature in the greenhouse must be maintained at 16 degrees. In these latitudes the thermometer drops to -30 degrees. The temperature delta will be 46 degrees. Infiltration is present, we take the standard value of k - 1.25.

As a result, we get: 3.3*46*1.25=28.5 kW.

If a greenhouse of the same size is made of glass, then it will need almost twice as much heat - 51.75 kW. The film design will require a heating system with a capacity of up to 83 kW.

The formula can also be used for reverse calculation. If you already have a boiler, then you can use it to calculate what dimensions the future greenhouse should have, and what exactly it should be covered with.

Features of calculation and design of greenhouse heating

The terms of reference, where all the work on heating calculations will be carried out and the most optimal boiler options, types of heating and all the costs of its installation will be indicated, can be drawn up yourself or ordered from the appropriate authorities. Doing it yourself is cheaper, but much more troublesome. It’s easier to trust someone, but more expensive.

The technical specifications must be drawn up in detail. It can be of two types. In the first case, the entire heating system will be based on a specific amount that you are willing to spend on it. In the second, the starting point will be to create comfortable conditions for plants using a suitable heating system option and heat calculation standards for the greenhouse.

In this video you will learn how not to heat a greenhouse

The calculation of greenhouse heating must be done comprehensively and thoroughly. This will help you avoid a lot of problems in winter, as well as save money by not installing completely unnecessary heating devices. By following our advice, you will be able to heat the greenhouse in the most efficient way, and your harvest will be of high quality and bring good profits, which, in turn, will quickly recoup all costs incurred.

ogorodnik.net

Greenhouse microclimate

A vapor pressure deficit (VPD) between the plant stem and the air in the greenhouse promotes the movement of water from the roots to the leaves. The target VPD value is usually in the range of 0.5 to 1.5 kPa [7]. Control of the vapor pressure deficit in the greenhouse is carried out by maintaining a given dew point, which takes into account both temperature and humidity [5].

For example, with a target VDP value of 1 kPa and a desired greenhouse temperature of 23C, the relative humidity is 64%, the absolute humidity is 11.35 g/kg, and the dew point is 16C.

Read more about calculating the amount of water to humidify rooms in our blog.

CO2 concentration: 1400 – 2200 mg/m3 [1].

Features of polycarbonate

This material is currently widely used in the construction of various structures. It is also ideal for constructing greenhouses: both summer and winter versions.

Noteworthy features of polycarbonate include its strength, which is combined with lightness. In addition, polycarbonate is an elastic material, which makes it possible to construct structures of various shapes from it.

Arches of any degree of curvature, various geometric shapes: all this can be easily done using polycarbonate.

The material transmits light remarkably. According to research by the developers, polycarbonate transmits approximately 85% of sunlight. In addition, this unique material is an excellent heat insulator, and plants in such a greenhouse are quite comfortable. Thanks to the thermal insulation properties, greenhouse owners spend less expensive resources on heating: quite significant savings result.

In the video - winter polycarbonate greenhouses with heating:

Calculation of air heating / cooling

The air change rate (ACH) for air heating of greenhouses is 5 - 8 air volumes per hour [7].

The air flow for this greenhouse is estimated at 5000 m3/hour. Supply air parameters:

- January: Temperature 36C, absolute humidity 13.5 g/kg, relative humidity 35%.

- August: Temperature 16C, absolute humidity 9.2 g/kg, relative humidity 81%.

The speed of air movement in the greenhouse is 0.5 - 0.7 m/s (more than 1 m/s interferes with plant growth, more than 5 m/s can cause physical damage to plants). The speed of air movement on plant leaves is 0.03 - 0.1 m/s [1].

Bibliography […]

- ASHRAE Fundamentals volume. 1997

- Manual J Residential Load Calculation. ACCA. 1986

- Indoor Agriculture: HVAC System Design Considerations. Trane Engineers Newsletter volume 48-3. 2019

- Grow Room Load Determination. Application Note 25. Desert Aire's. 2019

- Grow Room Environmental Control. Application Note 26. Desert Aire's. 2019

- HVAC Systems and Grow Room Energy Usage. Application Note 27. Desert Aire's. 2019

- Vapor Pressure Deficit and HVAC System Design. Application Note 28. Desert Aire's. 2019

- Hyung-Kweon Kim etc. Estimation of Thermal Performance and Heat Loss in Plastic Greenhouses with and without Thermal Curtains. Energies article. March 2018

- ANSI/ASHRAE Standard 62.2-2013, Ventilation and Acceptable Indoor Air Quality in Low-Rise Residential Buildings