Heating

Author Anton

Date

Jan 25, 2016

0

1 071

Share

Owners of garages, production facilities, warehouses and other similar premises are faced with the problem of heating the air space, or rather, the complete absence of it. In such cases, it is necessary to stock up on an auxiliary source of heating the room. A heat gun copes with such tasks without any complaints. It is used for heating garages or storage rooms and as a dehumidifier for basement rooms or mine wells that are constantly collecting moisture in the autumn-spring period. The heat gun found a secondary application in the construction and agricultural sectors. Such a device will dry painted walls and putty in a short time, and at the same time it will easily achieve and continue to maintain the desired temperature level on the farm or in the granary.

- LiveJournal

- Blogger

You can easily make such a device yourself

- How to make an electric heat gun

- Principle of operation

- Stages of making an electric heat gun with your own hands

- How to make a heat gun using diesel fuel

- Stages of making a diesel heat gun with your own hands

- How to make a gas heat gun

- Stages of making a gas heat gun with your own hands

Thus, a heat gun is a unit with a built-in fan inside the housing, which supplies a hot air stream. Heating of the flow occurs when heating elements installed in front of the fan are heated. The name “cannon” comes from its similar appearance to the military weapon of the same name.

Depending on the power the heat gun is designed for, household appliances and industrial heaters are distinguished. In turn, according to the type of power supply, these devices are classified into the following types:

- Heat gun powered by electric current.

- Diesel fuel heat gun.

- Gas heater.

- Multi-fuel heat gun.

- Infrared or air gun.

- Heat gun with water device.

Each type of heat gun listed has a number of individual features. In specialized stores, such devices are sold ready-made, but the price range for them is not very attractive. Thus, a home-made heat gun will cost several times less. In order to make a gun of one type or another, it is necessary to have certain knowledge about the operating principles of specific heating elements built into the device.

How to make a diesel gun with your own hands and what mistakes can be made

It is quite possible to create diesel heat guns with your own hands, and with professionalism, raw materials and the proper tools, you will get effective equipment capable of heating large rooms of various types. Moreover, if the site does not have centralized heating, a homemade diesel gun will certainly help in providing a sufficient amount of heat. With the help of such a unit heating is allowed:

- large warehouses,

- pavilions for trading various goods,

- workshops,

- garages,

- construction projects,

- at facilities in the agro-industrial sector.

How to make a gas heat gun

As practice shows, a homemade gas burner is not the easiest option. However, using your own experience and special responsibility, you can make it yourself. A DIY gas gun has various uses. Gas guns are most often used for garages and construction sites, as they dry walls well. As in the previous case, there are two types:

- Indirect heating gas gun

- Gas heating stove with open heating.

Operating principle and types of heat guns

Heat guns, which got their name due to their specific shape, are considered one of the most effective ways to increase indoor air temperature.

The operating principle of such devices is quite elementary: with the help of rotating fan blades, cold air from the surrounding space is forced into the unit. Passing through the heating element, the air flow is heated to a high temperature, after which it is pushed into the room and gives off heat.

Heat guns operating on different types of fuel are used to heat industrial facilities, greenhouses, and warehouses. In case of emergency, they can also be used for emergency heating of entrances and apartments

All units can be divided into two large categories.

- Small in size and power household appliances used to heat relatively small spaces (basement, garage).

- Large and powerful industrial devices capable of raising the air temperature in a huge room in a short time.

In addition, heat guns differ in the type of fuel used.

Based on this criterion, the following types of units can be distinguished:

- Electric guns . Environmentally friendly devices operate without odor, noise and emissions of harmful substances. Their disadvantages: attachment to power grids, as well as consumption of large amounts of expensive electricity.

- Gas guns operating on various modifications of blue fuel are most often used in production, agriculture or during construction work.

- Steam guns produce heat, producing a rich stream of hot steam. Such environmentally friendly devices are successfully used in everyday life: they not only heat the room, but also improve its microclimate, saturating it with water vapor.

- Infrared guns . The special design of these devices makes it possible to convert thermal energy into infrared radiation, which is used for heating. Such devices are often used in open spaces, for example, to heat restaurant terraces or a festive area.

- Multi-fuel guns , for which the cheapest types of fuel are used: used transport or household oils. Exhaust heat guns are universal and economical to maintain.

- Diesel guns . They operate on such types of fuel as diesel and diesel fuel.

Despite the general principle of operation, each of the above types has its own design features and recommended scope of application. A detailed classification of heat guns with a description of their operational features is given in this article.

How to make an electric heat gun with your own hands

Nowadays, in residential buildings and apartments, special heating devices - heat fans - are often used.

Such a device with a relatively small size can increase the air temperature in the room to a comfortable one in a matter of minutes. This is ensured by the fact that air is forced onto the heating coils. At the same time, the fan heater has, so to speak, an older brother - a heat gun. A heat gun is used in cases where it is necessary to heat a room that has a large area and high ceilings. These can be warehouses, hangars, trade or exhibition pavilions, greenhouses. Traditional heating systems with radiators are not beneficial for equipping such premises, since heating them would require the installation of dozens of radiators or convectors. With a heat gun of the required power, you can easily solve the problem of heating large spaces.

Types of heat guns

Before we get down to business, we must first decide what exactly we will collect and how it should work. First you need to choose a suitable design that can be done without any special costs or operational problems.

At the moment, 3 types of heat guns are produced and sold that can function on:

- liquefied and natural gas;

- diesel fuel;

- electricity.

A conventional heat gun consists of a standard set of parts: housing, heating element, fan and control unit. Units operating on different energy sources differ only in the type of heating element. Let's look at them in order and determine which one is best suited for making at home.

How the device works

A do-it-yourself heat gun is made with a certain amount of technical knowledge, simple tools and materials and components available to any person. The mobile fan heater can operate on various types of fuel: kerosene, waste oil, diesel fuel, hot water, electricity and liquefied gas. The principle of operation of such a heater is as follows: a special heat gun element selected in advance, for example a burner or heating element, is placed in a metal case and heated to the highest possible temperature. An air flow is driven through the heated device, which is created by a powerful built-in fan. The air heats up and is pushed out with a powerful hot jet. An undoubted advantage of mobile fan heaters is that even large areas can be heated in a few minutes.

Diesel fuel design

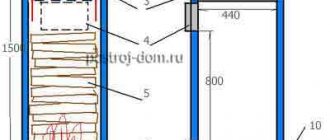

In areas where access to power is impossible or limited, it is optimal to make a diesel heat gun with your own hands. It is a little more difficult to make this equipment yourself, unlike its electrical counterpart, since you will need to make two housings and use welding. To heat a room measuring approximately 700 m², about 15 liters of fuel will be required.

Principle of operation

The bottom element in this design is the diesel fuel tank. A gun is installed directly on top, in which there is a fan and a combustion chamber. Fuel enters the chamber, and the fan transfers heated air. To ignite and transfer fuel, a fuel pump, connecting hose, nozzle and filter will be needed. An electric motor is connected to the fan.

The combustion chamber is installed centrally at the top of the housing. This is an iron cylinder with a diameter approximately 2 times smaller relative to the diameter of the body. Fuel combustion products are removed from the chamber using a vertically installed pipe.

Assembly Features

The lower part must be located at a distance of at least 20 cm from the upper body. To prevent the fuel container from heating up excessively, it must be made of a material with low thermal conductivity. You can also choose a regular metal tank, which must be covered with a thermal insulation layer.

The upper part must be made of thick metal. A piece of metal pipe will do. In the case you need to place:

- fan with electric motor;

- injector with fuel pump;

- combustion chamber with a pipe for removing combustion products.

Afterwards, the fuel pump is attached, and a metal pipe is connected to the tank, with the help of which the fuel is supplied first to the fuel filter, and then to the injector. Protective nets are installed along the edges of the upper body. You need to think about the power supply for the fan to operate in advance. If access to power is limited, you can use a battery.

When operating a diesel heater, safety precautions must be observed. Even at a distance of one meter, the hot air flow can reach 450 degrees. It is not recommended to use this device in enclosed spaces, since the combustion products of diesel fuel pose a danger to humans.

In addition to heaters that run on diesel fuel, other flammable materials are also used for guns, for example, machine oil.

Advantages of a homemade device

Basically, a homemade diesel heat gun requires a small number of tools, some knowledge of engineering and quality parts to assemble. Used oil, kerosene, diesel fuel and liquefied gas can be used as fuel. But in our case, it is necessary to mount a device that runs exclusively on diesel fuel.

And if for some reason you do not have access to equipment from a specific manufacturer or you do not like the Interskol heat gun or reviews about it, you need to start installing your own unit.

Electric heat guns

These heating units are the simplest and most inexpensive, and they do not emit any harmful substances. They use a specially shaped air heating element as a heating element, repeating the roundness of the body.

In fact, the “barrel” of such a gun is empty from the inside; at one end there is an axial fan, and on the other side, where the air comes out, there is an electric heating element. In more powerful models, several heaters are installed. The device can be used in any enclosed space, as long as there is a source of electricity.

Electric appliances are much easier to operate than gas appliances. Therefore, the electric heat gun is equipped with a step-by-step power regulator and overheating protection, and can also be powered from 220 and 380 V networks. Thanks to such a simple design, the electric fan heater is most suitable for both self-production and household use.

Operating principle of the unit

To get truly functional equipment, you need not only to know its operating principle, but also to perform a competent calculation of the heat gun, since the parameters of the assembly units included in the design will depend on this. The main element in any heat gun is a burner or heating elements, which it is advisable to install in a metal casing.

After these elements reach a certain heating level, air must be supplied using a fan.

And if the structure is assembled correctly, the room will heat up in the shortest possible time, and a comfortable temperature can be maintained for a long time.

It is necessary to ensure the strength and reliability of the heating device, and if the diesel heat gun does not start, it means that errors were made during the assembly process. It is necessary to make a housing that can withstand mechanical shocks, exposure to moisture and temperature changes.

The diesel gun is a practical and innovative sustainable solution

The diesel heat gun is a kind of innovative national unit. It is mainly used for heating ventilation of large-sized residential premises. In connection with this, special vigilance is required during construction so that the use of such a device is completely safe. Very often I use a diesel gun to dry things. This moment is categorically unacceptable, since the likelihood of a fire in the entire room is very high! Since each clothing has a certain coloring and when heated, the paint ignites almost instantly, and the flame can spread to neighboring areas.

A homemade diesel heat gun is a common solution for heating an apartment or private house in the cold season, when the indicator on the thermometer has jumped minus. If you follow simple safety rules, then with the help of this homemade heating device you can provide economical heating of your own living space.

When using a homemade heating unit, it is necessary to ventilate the room once a week, at least for a short period of time, in order to eliminate the combustion products of the gas mixture and reduce the concentration of carbon dioxide.

HomeSite map

DIY heat gun: a brief analysis of the 3 most popular designs

This moment is categorically unacceptable, since the likelihood of a fire in the entire room is very high! Since each clothing has a certain coloring and when heated, the paint ignites almost instantly, and the flame can spread to neighboring areas.

A homemade diesel heat gun is a common solution for heating an apartment or private house in the cold season, when the indicator on the thermometer has jumped minus. If you follow simple safety rules, then with the help of this homemade heating device you can provide economical heating of your own living space.

When using a homemade heating unit, it is necessary to ventilate the room once a week, at least for a short period of time, in order to eliminate the combustion products of the gas mixture and reduce the concentration of carbon dioxide.

HomeSite map

Making your own diesel gun

A unit that runs on diesel and diesel fuel can not only be purchased at a specialty equipment store, but also made with your own hands.

It is important to know that assembling that device is a rather complex process. It is available only to experienced home craftsmen who know how to handle a welding machine and other complex equipment.

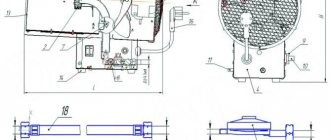

The diagram presented in the figure is not the only possible design option for a heat gun. The layout of the components can be varied based on ease of use (+)

Having decided to create a diesel heat gun with your own hands, first of all, start choosing the design of the model. Devices with indirect heating have the best technical characteristics, but they are much more difficult to assemble than devices with an open heat source.

Main design elements

To make a diesel device with your own hands, you need to take care of three components, each of which is an independent structure.

These include:

- The housing (casing) of the device, which will require a sheet of thick metal or a thick-walled pipe.

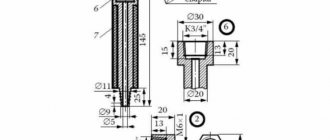

- The combustion chamber is a galvanized or other thick-walled refractory pipe, the diameter of which is half that of the casing.

- Fuel tank equipped with a pump and filter. This element, usually located in the lower part of the body, is made of a refractory material, which it is advisable to additionally cover with a heat insulator.

You will also need a fan with an impeller, with a desired power of 220 W. Such a part is necessary to create an air flow, which, after flowing around the heated combustion chamber, will come out.

To install a heat gun, you can use ready-made components or make do with available materials. In the first case, the cost of a homemade device will be higher, but its quality will be close to the factory one.

Assembly instructions

Before you begin assembling a diesel gun, you need to prepare all the instruments and materials, and then carefully inspect them for possible defects.

The casing of the device is made from a pipe or sheet of metal (in the latter case it should be rolled up and the edges joined). A fan is mounted inside the housing through a hole in the housing, with the help of which air from the room will be pumped into the interior of the device.

All operations for assembling a diesel heat gun are carried out in a strictly defined sequence. Particular attention should be paid to the quality of seams, fasteners and joints to prevent fuel leaks

The combustion chamber is installed and secured strictly in the central part of the casing, at the end of which the nozzle is secured. The element is sealed on both sides, and two technological holes must be made in it: one for the smoke exhaust, the other for the nozzle.

For comfortable use and fire safety, it is advisable to install a piezo ignition in the combustion chamber. For this, a factory version is suitable, which can be purchased at a specialized store.

A fuel tank of the required size and capacity is located below the hull. In the connected space, you need to fix the high-pressure fuel pump and the fuel fine filter.

Using a dimmer, you should connect the fan to a household electrical outlet. Such an element allows you to regulate the temperature of heated air without increasing fuel consumption.

It is also necessary to weld a smoke exhaust pipe to the combustion chamber, where combustion products will be removed.

When designing a diesel thermal device, it should be taken into account that the distance between the fuel tank and the burner with the reservoir must exceed 15-20 millimeters

Finally, you need to cover the ends of the device with a thick metal mesh (maybe in two layers). This is necessary to ensure safety, since the temperature of the air mass at the outlet can exceed 250 degrees.

All connections must be made extremely carefully, avoiding leaks, the consequences of which can be fatal. Before pouring diesel fuel into the tank intended for it, it is important to thoroughly check all components of the device. If you are not confident in your knowledge, it is better to take the help of a specialist.

A homemade diesel heat gun is an effective means of heating a garage during the cold season. It is important to ensure that the heating elements do not come into contact with frozen machine parts

The advantage of homemade diesel heat guns is their low cost, while at the same time their technical characteristics and ease of use are inferior to factory-assembled models.

Another disadvantage of such homemade products is the difficulty in determining the power of a home-made heat gun, which is why the device may not heat the room enough or too much.

Stages of making a diesel heat gun with your own hands

Let's consider a method for making a diesel heat gun with your own hands of the first type, that is, with direct heating of the air. So, for assembly you need to prepare the following materials:

- Tank or container for burning fuel.

- Tubular structure for making the outer casing. It is recommended to use fire-resistant metal.

- Pipes for the combustion chamber. We use any refractory material.

- Fuel burner.

- Compressor or pump.

- LiveJournal

- Blogger

A heat gun produces a huge amount of heat

. Manufacturing steps:

- A fan is inserted into the pre-prepared pipe casing of the device.

- A fuel tank is installed next to the gun body. With a distance between them of two to three centimeters. For greater confidence, you can add a layer of thermal insulation to the tank.

- The combustion chamber, made of a pipe half the size, is installed inside the housing.

- Now we install the fuel injector into the combustion chamber and connect them with a metal tube.

Before starting a diesel heat gun, be sure to check the fuel cell connections for leaks.

- We connect the pump to the fuel tank and injector.

- We install a protective reflective screen directly in front of the combustion chamber.

Now, having checked the connections and each component of the diesel fuel burner, you can begin operating the heat gun.

Calculation of device power

In order for the gun to be as effective as possible in your room, you first need to calculate the minimum power of the device using the formula.

Qt=V×∆T×K/860, where

- Qt - minimum power of the heating device in kW/hour;

- V is the volume of the heated room in m3;

- ∆T is the difference between the minimum outdoor temperature and the required indoor temperature in °C;

- K - heat loss coefficient: 3.0 - 4.0, if the building is not thermally insulated;

- 2.0–2.9, if low-effective thermal insulation is present;

- 1.0–1.9 with medium-level thermal insulation (walls 2 bricks thick, few windows, simple roof without openings);

- 0.6–0.9, if the thermal insulation is good (the walls are insulated, there is a contour seal on doors and windows, double-glazed windows).

If your premises are not industrial (ceiling height no higher than 3 m), you can use the data from the table.

Table: dependence of the required gun power on the area of the room

| Heat gun power, kW | Volume of premises in a new house, m3 | Volume of premises in the old building, m3 | Area of a modern greenhouse with insulated glass, m2 | Area of a glass greenhouse without thermal insulation, m2 |

| 5 | 70–150 | 60–110 | 35 | 18 |

| 10 | 150–300 | 130–220 | 70 | 37 |

| 20 | 320–600 | 240–440 | 140 | 74 |

| 30 | 650–1000 | 460–650 | 210 | 110 |

| 40 | 1050–1300 | 650–890 | 300 | 150 |

| 50 | 1350–1600 | 900–1100 | 370 | 180 |

| 60 | 1650–2000 | 1150–1350 | 440 | 220 |

| 75 | 2100–2500 | 1400–1650 | 550 | 280 |

| 100 | 2600–3300 | 1700–2200 | 740 | 370 |

| 125 | 3400–4100 | 2300–2700 | 920 | 460 |

An overly powerful heat gun in a small room can cause a fire. Use appliances of suitable power (or with a regulator) and/or do not leave them unattended.

DIY waste oil heat gun (video)

Even already used liquid can become an excellent fuel for a heating device. The following video describes a device that uses the Babington burner principle:

A homemade gun is a heat exchanger that has two doors: one in the front part and the other in the side for cleaning the chamber. A whole blowing system is connected to it; a standard fan No. 2 is used for it. After heating inside the gun chamber, air is supplied to the room at a temperature of 60 to 90 degrees.

The modular system of the unit makes it possible to replace any of its components without dismantling the entire structure. The stove is lit manually - for it to work, you need to create an optimal pressure of 1 to 3 kg/cm2. The video demonstrates the process of ignition and combustion of the gun.

You can make all of the above options for heat guns yourself if you have the desire and the necessary materials at hand. They can effectively heat any home, the main thing is to choose an option using available fuel so that heating occurs economically.

Unit #2 - diesel fuel heat gun

Where access to electricity is limited or impossible, diesel fuel heaters are often used. It is somewhat more difficult to make such a heat gun yourself than an electric model. You will need to make two buildings and work with a welding machine.

How does this design work?

The bottom part of a diesel heat gun is the fuel tank. The device itself is placed on top, in which the combustion chamber and fan are connected. Fuel is supplied to the combustion chamber, and a fan blows hot air into the room. To transport and ignite fuel, you will need a connecting tube, a fuel pump, a filter and an injector. An electric motor is attached to the fan.

The combustion chamber is mounted in the center of the upper body of the heat gun. It is a metal cylinder, the diameter of which should be approximately two times smaller than the diameter of the body. Diesel fuel combustion products are removed from the chamber through a vertical pipe. To warm up a room of about 600 square meters. m may require up to 10 liters of fuel.

Build process

The lower housing must be at least 15 cm from the upper part. To prevent the fuel tank from overheating, it should be made of a material with low thermal conductivity. You can also use a regular metal tank, which will have to be covered with a layer of heat-insulating material.

The diagram clearly shows the design of a heat gun running on diesel fuel. The device should be mounted on a strong, stable frame

The upper body must be made of thick metal, this can be a suitable piece of wide steel pipe. The following must be secured in the housing:

- combustion chamber with vertical outlet;

- fuel pump with nozzle;

- fan with electric motor.

Then a fuel pump is installed, and a metal pipe is removed from the tank, through which fuel is supplied first to the fuel filter and then to the injector in the combustion chamber. The ends of the upper body are covered with protective nets. The power supply for the fan will have to be taken care of separately. If there is no access to the electrical network, a battery should be used.

When using a diesel heat gun, it is important to adhere to safety regulations. Even at a distance of a meter from the body, the directed flow of hot air can reach 300 degrees

It is not recommended to use this device in enclosed spaces as diesel fuel combustion products may pose a health hazard.

In addition to the unit running on diesel fuel, other types of liquid combustible materials are also used for heat guns, for example, waste engine oil. An interesting version of such a device during “testing” is presented in the following video:

Briefly about classification

The difference between guns depends on the type of fuel on which these heating devices operate or on the method of heating the air flow. Hence the names:

- electric gun;

- diesel;

- gas;

- infrared type of heating elements;

- water;

- monofuel.

First of all, we are interested in how to make a mains-powered heat gun, because this is the most common and safest option. Simple maintenance, no need to check for fuel in the tank, environmentally friendly.

Features of operation and care

If you want the device to last as long as possible, you must:

- use only high-quality fuel (gas, diesel, gasoline);

- do not allow strong voltage drops in the electrical network (if they happen frequently in your region, the gun should be connected through an RCD - residual current device);

- do not allow water to get on the electric heat gun, and also do not use it in rooms with high humidity (over 93%);

- protect the device from shocks, falls and mechanical loads;

- place the device further than 0.5 m from flammable items, including fabrics and furniture;

- maintain an adjustment period (from 2 hours) after transporting the device in the cold (below 0°C);

- Clean the protective grilles and housing regularly.

Clear indications for repair:

- visually noticeable damage to the housing, tubes, wires;

- sparking at wire connection points;

- repeated activation of the protective relay.

Please note: Causes and remedies are valid for electric heat guns

If you purchased a heat gun, you can obtain more detailed information about its operation from the warranty card or the booklet supplied by the manufacturer. Those who assembled the device themselves can familiarize themselves with the rules by finding instructions for a similar model online.

As you can see, with due attention and diligence, you can build a heat gun that will provide you with comfort in any unheated room.

What types of diesel thermal heaters are there?

All units that consume diesel fuel as fuel can be divided into two types:

- Direct fired heaters

- Heaters using the principle of indirect heating of the air mass

The first category has the simplest principle of operation: the fuel burns, and the air forced by the fan, passing through the flame, heats up and releases heat into the room.

Such heaters have one significant drawback - along with the heated air, all the combustion products of diesel fuel enter the room.

That is, all the fumes, soot and smoke fly out of the gun along with the warm air and remain in the heated room. Very good ventilation is necessary to avoid exhaust poisoning.

But even when ventilation is organized, the smell and soot will be constantly present in the heating zone.

Of the positive aspects of this solution, we can only note the low cost - such units are the cheapest, since apart from the fan, housing and burner, there is practically nothing in the design.

The second type of heaters is more interesting. Such diesel heat guns use a different operating principle - they heat the heat exchanger, which, in turn, releases heat to the air.

In this design, all heated gases, along with the rest of the heat, passing through the heat exchanger, are discharged into the smoke channel. If you attach a pipe to it, you can remove exhaust gases and soot from the room to the outside, providing clean air in the heated area.

How to make a heat gun using diesel fuel

A diesel heat gun is a more complex version of the heater than an electric one. Based on their mode of action, the following types are distinguished:

- Gun heater using diesel fuel with direct air heating. Used for heating small areas.

- Diesel fuel gun with indirect air heating. Used as diesel heating for warehouse or industrial premises.

The first type includes heat guns with a simple and effective operating principle, but they are also extremely dangerous. The housing consists of two parts: one burns diesel fuel, the other contains a fan that forces hot air through the flame. Due to the fact that the entire process takes place openly, fuel combustion products enter the heated room along with the hot air flow. Therefore, a diesel heat gun for a garage is most often used.

The second type is more complex in design and less effective, but it is absolutely fireproof and does not harm health. A self-made diesel gun is used as a heat exchanger heater, which heats the area of the room by releasing heat into the air. A smoke channel is connected to it, through which exhaust gases exit. Gasoline is also used as fuel. A gasoline burner is slightly more expensive due to the fact that the cost of fuel is higher than diesel fuel. A do-it-yourself gasoline burner is made using the same method as a diesel one.

Additional recommendations

When the fan is turned on, it will circulate air around the combustion chamber, and when heated, it will come out already hot on the opposite side of the device. It should be taken into account that when operating the device within a meter of warm jet output, its temperature can reach about 300°. The manufactured heat gun will be able to heat a room of up to 600 square meters. m with a maximum fuel consumption of 10 liters per hour.

It is not recommended to use a diesel heat gun in completely enclosed spaces, especially if there are always people in them, in order to prevent poisoning from combustion products. To ensure standard operating conditions, you can independently remove a special outlet for exhaust gases outside the premises.

Additionally, it is recommended to equip the device with small wheels to make it mobile and easy to use.

Production method

Diagram of operation of a heat gun with an electric motor. Before making a heat gun with your own hands, you should decide on the choice of model, electric or diesel fuel. To choose the dimensions of the fan heater correctly, it is necessary to calculate the power of the device, taking into account possible heat loss, the volume of the room and the average temperature of the surrounding space. A do-it-yourself diesel heat gun is a design consisting of two buildings. The upper housing is the outer casing of the device, and the lower one is used as a tank for diesel fuel. The lower casing is made from materials with low thermal conductivity, since it is located close to the device with a high temperature. When it is not possible to purchase specialized materials, you can take care of protecting the heat-insulating layer. Directly above the fuel tank is the body of the gun, made in the form of a wide steel pipe (or from any other durable metal, the main thing is with thick walls). The ends of the housing are covered with gratings or meshes. The following are rigidly fixed in the finished housing: a fuel pump with a nozzle, an electric motor with a fan and a combustion chamber. The housing must not be installed directly on the tank. It must be raised above it by at least 15-20 cm. A fuel filter is placed between the tank and the housing. Next, remove the metal tube from the fuel tank. It is connected to the filter. The diesel fuel pumped through the pump, passing through the tube and through the filter, enters the nozzle and ignites. The combustion process itself is carried out in the combustion chamber, in a thick metal pipe, less than half the diameter of the housing, rigidly fixed in the center of the housing and having a vertical outlet to remove combustion products.

Diagram of a diesel heat gun. The switched on fan circulates air near the combustion chamber and, when heated, comes out already hot on the back side of the device. It must be taken into account that when using the device, the temperature of the warm jet in the outlet meter can reach about 300 degrees Celsius. The heat gun can heat a room up to 600 square meters. m with a maximum fuel consumption of 10 l/h. A diesel heat gun is not recommended for use in completely enclosed spaces, especially if there are always people in them, in order to prevent poisoning from combustion products. To ensure normal operating conditions, it is necessary to independently remove a special exhaust gas outlet outside the premises.

When choosing a heating element, you must not forget that the temperature of the outlet air will depend on the number and power of these heating elements. In this case, the speed of the fan will not affect the temperature, however, the faster this device rotates, the more evenly the heat is distributed throughout the room. That is, the heating element is responsible for the heating temperature, and the fan is responsible for the quality of distribution.