If your heater explodes, you are most likely responsible. Although an oil heater cannot be called the safest option for the home, the likelihood of it exploding is low if you follow all the basic operating rules and adhere to safety precautions. Troubles that can happen with an oil heater are leaks, stoppages and explosions, which can lead to a fire, cause damage to your property, health, or threaten your life and the lives of your loved ones.

It is also worth considering the fact that not only a cheap Chinese device, but also a product from well-known manufacturers can explode. Therefore, the most important rule to avoid an oil explosion is: choose heaters carefully and responsibly.

Oil heater device

To use the heater correctly and carefully, you need to understand at least the general principles of its design.

Oil heaters are a sealed case with mineral oil, which is heated thanks to built-in electric heating elements.

Oil heaters have been known to everyone since childhood. At one time, this was the most popular option for obtaining additional heat in a room. However, over the past decades, the situation has changed, and on the modern market there are various models of similar equipment with more complex designs and improved operational safety indicators. It is the simplicity of the design that causes a large number of counterfeits or simply low-quality devices on the modern market. It is much easier to manufacture such a device than other types of heaters.

If desired, even a schoolchild who understands physics can make an oil heater. Therefore, it is better to go to a store with a good reputation for such a device, rather than buy dubious imported equipment second-hand. In addition to this basic rule for choosing equipment, adhere to two more.

First, pay attention to the labeling of the device. It should not raise the slightest doubt. Some counterfeit manufacturers simply print out the logo of a famous brand and glue it to the box. Such markings immediately catch the eye and look very dubious.

Secondly, when studying the operating instructions for the device, pay attention to its service life, which is indicated there. As a rule, this is 5 or 7 years. Longer periods are less common. Be prepared to use the heater for this period and not a day longer.

Otherwise, the likelihood that it will explode increases significantly. You should not save on this equipment. This is fraught with large material losses in the event of a fire. A heater that has served you for its entire stated service life must be thrown away. Before doing this, it is recommended to damage it so that no one else has the opportunity to use the potentially dangerous device.

Oil heater - warmth and comfort or the cause of a fire?

The heating season has ended and central heating has been turned off in apartment buildings. But while the house warms up, time will pass and therefore many residents use oil heaters, with their help creating warmth and comfort in their apartments.

So why do oil heaters catch fire, explode, and how to prevent this.

The weak point of the standard model oil heater, the kind many of us have in our homes, is the thermostat.

What happens to a heater when its thermostat fails? If the thermal protection of the oil cooler fails, the device becomes dangerous. The temperature of its surface begins to rise sharply, the oil inside the device begins to evaporate, and under the vapor pressure, the tightness of the seams may be compromised. As a result, oil will be released. With a further increase in temperature, it may ignite.

The oil radiator is simple: a sealed container filled with oil and an electric heating element. To prevent the oil from overheating, each heater has a thermostat, or thermostat. When the oil temperature rises, the thermostat automatically turns off the heater - that's how it should be.

Before using your oil heater for the first time this season, turn it on and wait 5-10 minutes. During this time, it should heat up to maximum and turn off. If the heater continues to operate, the thermostat is broken. This device must not be used under any circumstances.

What is the service life of an oil heater? Usually, unfortunately, until it breaks. However, the instructions for the oil heater always indicate the expiration date, usually it is about 5 years. Over time, parts of an oil heater can melt and fail; the oil loses its physical and chemical properties, but this is not always noticeable to the eye. Therefore, as soon as the expiration date has expired, the oil heater must be disposed of and not taken to the country house, garden or village.

In addition, do not forget about the load on the apartment’s electrical network. When the electrical network is overloaded, the insulation of the wires may melt: the contacts (connections) begin to heat up and the insulation on the wire begins to melt, exposing the current-carrying parts of the conductor. You yourself can visually determine whether the contact is good or already burnt. With the latter option, the insulation has a brownish-black color, and when the load is turned on, an unpleasant burnt smell of melted insulation is felt. If you feel noticeable warmth to the touch, then this is already a signal that contact has been broken, and you need to take action before it’s too late. Our advice to you is, do not delay this situation - call an electrician.

How to prevent an explosion?

To prevent the heater from exploding, you must strictly adhere to the basic rules of its operation. Your own safety and the safety of your property depends on this. These rules are quite simple and will not require much effort from you to follow. So, the rules for the safe operation of such equipment are as follows:

- The device must not be used in a horizontal position. In this position, the equipment will instantly overheat. For such cases, a special thermostat is installed in the devices, which ensures that they turn off when overheated, but you should not tempt fate if it is possible to avoid dangerous situations.

- Do not leave the device unattended. This is especially true if you have small children or pets living with you. They may unintentionally change the unit's settings or overturn it. In addition, there is a high chance that children may get burned. The oil heater should only be operated under your supervision.

- After the summer season, when the device has not been working for a long time, it is imperative to check the serviceability of its thermal relay before starting operation. During such a test, the device should turn off when operating temperature is reached. If this does not happen, then you cannot use the heater. It must be sent for repair or thrown away and purchased a new one. The serviceability of the thermostat is very important for the safe use of an oil heater, since most of the unpleasant consequences from their incorrect operation are associated with overheating of the device.

- A device that has developed a leak cannot be repaired. Theoretically, it is possible to seal it somehow, but in this case there will be less liquid inside the container with oil, since a significant part of the oil can leak out even through minor damage to the housing. It is unknown how equipment will operate with missing mineral oil. The heater may behave unpredictably during operation.

It should be remembered that no electrical device can be absolutely safe. However, there are safer options than oil heaters. The modern market for such equipment offers many alternatives, so if you are concerned about your safety, it is advisable to opt for a more modern and easy-to-use model.

In any case, if you are using an oil heater, you can avoid its explosion by following a few simple rules. Be careful and vigilant so that the heater in your home does not explode and cause damage to your property, health or even life.

The most popular blog articles of the week

teplomonster.ru

Rules for the safe use of electric heaters

Memories of five years of living in a university dormitory (80s) are associated with constant cold inside the room before the start of the heating season. A small room for five students was blown through by drafts through a door and 2 windows, which were not particularly insulated from the glued paper.

They saved themselves with a homemade electric “goat”: a piece of asbestos pipe wrapped with a nichrome spiral from an electric stove was placed on two bricks. 2 meters of aluminum “noodles” were screwed to the ends of the wire and inserted into the socket through a plug. They used it only late in the evening - the commandant (a stern retiree) was “atrocious” and severely punished everyone who found such structures.

We were lucky: we never fell into his hands, and most importantly, there were no electrical injuries or burns. With age, I began to understand the commandant’s concerns, however, I do not justify his actions. He relied only on the fear of punishment, and people need to explain the possible danger, show the risks of a fire, and formulate beliefs in safe behavior in their minds.

What are the dangers of electric heaters?

Excess load

Like all electrical appliances, there are wires through which current flows and insulation that limits its direction. It is made of flexible plastic materials that work reliably up to the upper temperature limit, and then melt, losing their dielectric properties.

Therefore, the wires should not only not be used near an open fire, but also should not be overheated by connecting powerful electrical appliances to them that create a large thermal load, such as electric heaters. When switching on, always analyze the capabilities of your electrical wiring.

How does the power of household appliances affect electrical wiring?

Connecting an unaccounted number of consumers through extension cords to one outlet often results in a fire. The wires cannot withstand the heat load.

Why is it dangerous to use tees and extension cords in an apartment?

Homemade products

The homemade electric “goat” described at the beginning of the article is considered one of the most dangerous devices. He not only has free access to exposed live parts, but also an increased possibility of a fire if paper, fabric and other flammable objects come into contact with a hot wire.

Let's add here unreliability, low structural strength, a tendency to tip over and the ability to touch heated metal. You can also list the disadvantages of unreliable homemade products. But why didn’t the commandant of the student dormitory do this?

It would be nice to explain to him the danger of using homemade boilers made of razors, horseshoes or metal plates, which in a short time heat the water so much that when the light bulbs “squat” it begins to “jump” out of the glass jar (God forbid metal utensils or added salt /sugar when heated).

Use only certified, tested equipment.

Why are the “goat” and the homemade boiler dangerous?

Unattended electrical appliances

On October 24, 2014, the Minsk Ministry of Emergency Situations prevented a fire in a private house from a faulty heater that was operating from the network when the owner was absent. A vigilant neighbor called a rescue team in time.

The Dovzhenkov family from the Kursk region celebrated New Year 2012 at home. It was cold, the mother turned on the oil radiator, and she went out into the yard for a couple of minutes. Nastya (5 years old) and Vanya (3 years old) were near the Christmas tree. A working heater exploded, mineral oil scattered throughout the apartment, instantly igniting.

The hostess could not run through the door: everything burned down in moments.

Manufacturers indicate in advertising that oil radiators are considered the safest heaters, and the Ministry of Emergency Situations publishes photographs of them after a fire on their websites.

What are the dangers of oil radiators?

Heat transfer from the heating element to the surface of the device body is ensured by mineral oil and is controlled automatically by a temperature sensor. Any technical device can break down. As the volume of oil decreases, it will begin to boil. To prevent this, the temperature is monitored by a sensor and transmitted to the automation. If there is a malfunction in the system, then a fire is guaranteed.

Recommendations of the Ministry of Emergency Situations:

- do not use devices with an expired warranty, even if they are working correctly;

- Always check the operation of the thermal protection at least when turned on. After 7 minutes of operation, the heater should reduce the temperature. If it continues to grow, then the device is faulty and will explode;

- constantly monitor the operation of the device and have automatic fire extinguishing means;

- repairs must be carried out only in centers that provide a guarantee;

- Never leave children alone near operating appliances.

Additional tips:

When purchasing a heater, carefully consider the method of making stickers with the production date, GOST or TU. Printed labels may be a sign of counterfeit products.

The presence of corrosion on the metal of the heating element is another reason for the contact of oil with electricity, a prerequisite for an explosion.

Therefore, manufacturers who install stainless steel heating elements always indicate this in the passport and on the labels. Such heaters are allowed to be used in garages, workshops and rooms with high humidity. It is forbidden to turn on other heating elements even at the dacha.

Heat guns

The powerful release of thermal energy associated with a cannon shot can quickly heat up large rooms. Therefore, they are used everywhere in construction and industry.

Electrical converters

The operating process of electric converters is based on the supply of cold air from the floor level to the heating element, taking heat from it and releasing it through the upper openings into the room. Air currents are created by temperature differences and access to heaters. The structure can be installed on the floor or attached to the wall. There are options for embedding inside the floor.

When operating a convector, it is important to maintain a balance between incoming energy and its removal: incoming or outgoing windows must not be blocked. Otherwise, overheating and critical conditions are possible.

To the credit of modern manufacturers, it should be noted the transition to low-temperature large-area heaters, which have significantly reduced the risk of fires.

Old models, working on elements made of nichrome wire, very closely replicated homemade designs, but in a factory-made, safer design. If you still use such devices, then seriously think about your safety.

Fan heaters

In them, electrical voltage is supplied to a spiral blown by air from a fan. In ceramic designs, the heating element is hidden inside the body, while in spiral designs it is brought out.

The safety of the fan heater is ensured by the balance of heat release from the current in the coil and removal by the fan. The automatic thermostat removes the voltage from the heater when the upper temperature limit is reached without blocking the air flow.

The airflow is constant. Dust falling from the air flow onto the hot metal burns out: the proportion of oxygen in the air decreases and carbon monoxide is formed, which blocks the flow of oxygen into the cells of the human body.

Based on laboratory studies, Emergencies Ministry specialists advise:

- Ceramic heaters, as less dangerous, should be turned on for no more than three hours;

- Spiral structures are used less frequently. Their continuous operation for 6 hours is very dangerous. They are designed for short-term heating of the room.

Final Recommendations

Before turning on the electric heater, be sure to read the manufacturer’s documentation for it and comply with all safety requirements.

In rooms with children and elderly people, use only safe, closed structures that exclude the possibility of direct contact.

The heater should heat the air, but not create a fire, and if it does occur, then first turn off the voltage with an input circuit breaker or by unplugging the plug from the socket. Only after this, throw a thick cloth over the fire to isolate the burning area from air access.

Common oil heater malfunctions, their symptoms and repair methods

Troubleshooting an oil-filled electric heater, like repairing an infrared heater of any other type, requires certain skills and compliance with a number of rules.

Important! If any of the structural elements of the oil heater fail, operation of the heater must be stopped until the malfunction is eliminated.

Actual image of one of the models of oil heaters with a list of external equipment

First of all, you should be aware that restoring the functionality of most of the components of this heating device at home is impossible or requires professional knowledge and skills. Experimenting with failed electrical components is fraught with unpredictable consequences (electrical injury, thermal injury, fire, explosion), so repairing an oil heater with your own hands, without professional training, in most cases should only be done by replacing the part that has become unusable.

In addition, when repairing an electric heater, the following rules must be followed:

- the device must be unplugged from the outlet;

- the heater must be cooled to room temperature;

- equipping the device with homemade components is prohibited;

- Avoid contact of transformer oil with the body, as well as with the wiring insulation;

- Replacing a standard power supply cable with a grounding conductor with a wire without grounding is prohibited.

Oil leak

A leak in the oil cooler usually occurs due to mechanical damage or as a result of corrosion caused by a defect in the protective paint coating.

When a long-used, familiar oil radiator leaks, a natural question arises: what to do, why not try to restore its tightness with your own hands?

However, repairing an infrared heater on your own in the event of a leak is only possible if the device is an old-style domestically produced unit with a flat steel radiator and a removable heating element.

Flat oil electric heaters of domestic production with steel radiators

To carry out repairs, the control unit, under which the heating element is located, is disconnected from the device body. Then, after disconnecting the contacts, the heater is unscrewed and the oil is drained through the mounting socket into a clean container. The remaining oil is allowed to drain, after which the radiator is filled with water to prevent the oil inside from igniting.

The wall thickness of such radiators is 1-1.2 mm, which allows the use of electric welding. The leakage area on the body is cleaned with a grinder with a grinding disc or manually with coarse sandpaper. Depending on the location and size of the damage, a patch of steel of appropriate thickness is cut out, applied to the hole and scalded using a Kemppi semi-automatic machine.

Kemppi machines of various models for semi-automatic electric welding in domestic conditions

The welding seam is cleaned and ground, after which, if necessary, it is welded again. After degreasing, the repair area is painted with heat-resistant paint, for example, Rustins High Heat Black Pain.

Important! If the heater is painted using powder technology, then when carrying out repair work you need to strive for minimal damage to the coating - it is impossible to restore it under domestic conditions.

Heat-resistant paint Rustins High Heat Black Pain in small volume packaging

After the paint has dried, the radiator is filled 80% with oil, and the heater is assembled in the reverse order.

If the oil heater clicked when heating before the repair, you should not expect that the clicks will disappear after the seal is restored - the mating parts of the housing are deformed when the temperature rises and at the same time crack.

Repairing radiators of finned oil heaters is not advisable, since they are made of thin sheet steel using laser welding. Restoring the tightness of such tanks is technically difficult, does not guarantee success in domestic conditions, or is comparable in cost to the cost of a new heater. In addition, if the heating element is non-removable, then the oil can be drained through damage, but it will no longer be possible to fill it back.

No heating

A technically sound oil-filled household heater makes a quiet noise when plugged in. This factor is not dangerous, as it is caused only by the expansion of the assembled body of the unit, which clicks when heated.

If, after turning on the unit and setting the required power and temperature values, the heater is silent, it means that the radiator is not heating, and the fault should be looked for in the electrical part.

First of all, visually inspect the integrity of the electrical cable. If there is no visible damage, you must first remove the racks with wheels from the bottom of the unit body.

Then you need to disconnect the control unit from the radiator, for which purpose, using a screwdriver, pry up and remove the standard plate on top of it with the inscription Do not cover, under which there are fastening screws.

Placement of fastening screws of the control unit to the housing

Having unscrewed the fasteners from above, the screws in the lower part of the control unit are also released or the fixing springs are unfastened (depending on the model), the shell is removed from the edge of the junction of the block with the radiator, and the dismantled unit is laid with the inside out.

Sequence of removing the control unit from the oil heater housing

Perform a visual inspection of the integrity of the wiring and insulation, as well as the quality of contacts at the junctions of the wires, paying attention to areas with kinks and oxidation. A wire with obvious internal damage is replaced with a new one, the oxidized contacts are disassembled, cleaned with sandpaper and reassembled.

Upon completion of the visual inspection, they begin to “test” the components using a tester - a multimeter, which begins with testing the cores of the wire section from the plug to the nearest connection. The operation is simplified by the different colors of the cores in the cable of the electrical appliance, which makes it easy to track the direction of the wiring.

The sound signal from the tester indicates the integrity of the area being called, while the absence of a signal indicates damage.

The initial stage of testing an oil heater using a multimeter is the section from the plug to the heating element

Replacing the Tubular Heater

The heating element, in addition to heating elements, is equipped externally with current and temperature fuses, the presence of which must be taken into account when dialing. It is possible that, with a working heating element, one of these fuses burned out, or even both failed.

Heating element fuses: on the left - by temperature, on the right - by current

If testing nevertheless reveals a failure of the tubular heater, then further actions depend on the method of installing the heating element in the radiator. The threaded fastening of the heater in the absence of rolling allows its replacement. In this case, the heating element is unscrewed from the radiator, and in its place, with the replacement of the sealing gasket, a heater with identical parameters in terms of power and shutdown temperature is installed.

Tubular electric heater with a threaded installation method in a heating unit

With a non-removable installation option, the heater is rolled into the radiator socket. In domestic conditions, it is very difficult to flare an old heating element and install a new heating element by sealing it, so you should think about buying a new oil heater.

Temperature controller malfunction

Testing this node is done as follows:

- ring the section of the chain from the plug to the thermostat;

- the regulator is set to the minimum temperature value and tested - the circuit must be open;

- when turning on each of the heaters individually, as well as two heating elements simultaneously, when setting the temperature regulator to a value other than zero, the circuit must be closed.

View from the inside of the thermostat of a Sinbo household oil heater with a power of 2 kW.

If a test of the thermostat shows its malfunction, that is, the oil heater does not respond to switching power modes or changing the temperature by turning the flywheel, the device must be replaced, since diagnostics of its technical characteristics with subsequent repairs based on the test results in industrial conditions are not advisable, and it is extremely difficult to do this in domestic conditions.

If there are no malfunctions, the regulator is cleaned of dust and the contacts are tightened.

Failure of the bimetallic strip

The question of whether an oil heater can explode is relevant, since the oil pressure in the radiator reaches high values, and the air “cushion” in the form of 20% of its volume still has limited potential. To prevent this from happening, the heater design contains a thermal relay, which should turn off the heater if it overheats.

Under normal conditions, this relay, which is a bimetallic strip, should complete an electrical circuit. If the multimeter detects an open circuit in this thermal fuse, then it should also be replaced with a new one with identical characteristics.

Continuity of the thermorelay of an oil-filled heater and appearance of the thermorelay

Oil heaters explode extremely rarely precisely because they have several degrees of protection that duplicate each other, and the likelihood of simultaneous failure of all safety devices is low.

No heater shutdown when tipping over

Opening the electrical circuit when the oil heater is tilted or tipped over is ensured by a device whose operating principle is based on the presence in its design of a suspended weight, which retains its position when the unit deviates from the vertical.

An option for equipping the oil heater with a circuit-breaking device when the device overturns is a plumb line with a metal weight

Testing of this device is carried out by manually deflecting the heater from the vertical. If the device does not turn off, the element must be cleaned of dust and removed, or better yet, replaced with a new one, the installation of which is not difficult.

It should be noted that if the protective switch fails, the oil heater does not explode - if heating elements that are not covered with oil overheat, the thermal protection of the tubular heater is triggered, or the thermal relay opens the electrical circuit.

Which heater is the most energy-efficient for the home: oil or convector

These are the options that are used most often today, so it is worth comparing them. Each solution has its own advantages and disadvantages, as well as operational nuances. For convenience, the features of each variety are first described, and then a comparative analysis is carried out.

Oil heaters

They are most common because they are extremely easy to use. You need to place the equipment in a suitable place, plug it into an outlet and set the optimal settings. The size of the heater depends on its power, the higher it is, the larger the design; it can be a flat plate or fins, like traditional heating radiators. As for the design, it is as follows:

- The base is a sealed container containing oil. The choice of oil is due to its good heat transfer and fire safety.

- There is a heating element inside the structure, which transfers heat to the liquid filler.

- The body usually has a paint or polymer coating.

- A rheostat is responsible for regulating the temperature. You can set one of several modes depending on the room temperature.

- Modern equipment must have an overheating protection unit installed, which automatically turns off the heater when a certain temperature is exceeded. Also, many models have rollover protection - if there is a strong deviation from the horizontal position, it turns off.

Many people choose this option because they are well familiar with its features and are confident in its reliability. In addition, oil heaters have a number of advantages:

- Reasonable price.

- Silent operation (except for variants with a fan, but it can be turned off at any time).

- In modern models, a thermostat is installed that allows you to maintain the temperature at the same level.

- The structures usually move on wheels, so despite the heavy weight, the heater is easy to transport from room to room.

Important!

It is best to buy a model with a timer to turn on the heater at the right time and not waste electricity.

Convectors

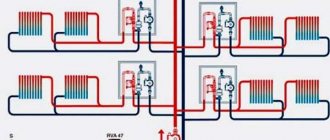

They work using the principle of air convection. In comparison with the first type, they are much more compact and represent a panel of small thickness. The room is heated not by heat radiation, but by air movement, and this is the main difference. The design and operating principle are as follows:

- The housing is a convection chamber with a heating element located inside. Most often, the structures are mounted on the wall, but there are also options on wheels for moving to the right place.

- Cold air enters the chamber and heats up, causing it to rise to the top of the housing and accumulate there. Then, due to excess pressure, it is squeezed out, but does not move upward, but to the side thanks to the special shape of the slots.

- Due to this principle, the equipment operates silently and at the same time effectively heats the room, replacing central heating.

- The heat is distributed evenly across the entire width of the plate; insulating spacers prevent contact of the heating part with the body.

Such solutions are being used more and more often, as they have proven themselves in operation and have a number of advantages:

- Many operating options and a built-in thermostat allow you to choose an economical mode.

- Fire safety meets all European and international standards.

- Equipment can be combined into one network and managed centrally.

For your information!

Convectors are equipped with high-precision modern control systems.

This option is much more practical, as it effectively heats the room over its entire area, and not just in one place. Due to convection, there is a constant movement of air and it warms up evenly.

Comparative analysis

By comparing the main parameters, you can figure out what the advantages and disadvantages of each solution are. Of course, a lot depends on the model and manufacturer, but the following aspects can be highlighted:

- In terms of price, these options are almost equal, although previously oil radiators were much cheaper.

- The energy consumption of a convector with comparable power is 25-30% lower.

- Oil radiators take an order of magnitude longer to heat up, but they also cool down slowly.

- The weight of convector models is much less, as is their size.

- The oil-filled option is more dangerous, since at maximum heating you can get burned on the surface. Convectors in this regard are much safer, since they cannot cause harm.

- Both solutions last quite a long time; the average lifespan of a high-quality model is 10 years or more.

Important!

Since open fire is not used anywhere, the oxygen in the room is not burned.

When heating, warm air always moves upward, so small dust particles inevitably rise when using both options. You should not believe sellers who claim that oil-based equipment is free from this drawback.