Thrust is a separate aerodynamic process in which combustion products move from a zone with an increased pressure level to a zone with a lower pressure level. In this regard, chimney draft is the most important parameter when calculating the entire heating system of a private house. If the calculation is incorrect, reverse draft occurs, in which combustion products are not removed, but enter the living space. What factors determine the level of traction? How to correctly calculate the parameter? In what ways can you increase cravings if there is insufficiency? Read on.

The process of removing combustion products

What is traction

The process of formation of natural draft in a chimney can be described from the point of view of a science such as physics as follows:

- gases heated by the combustion of wood or their analogues in a stove (boiler) have a temperature of about 1000ºС;

- according to the laws of physics, heated air always rises;

- rising through a special pipe (at a speed of approximately 2 m/s), the gases create an area of low pressure;

- the pressure is stabilized due to the influx of fresh air, which enters the furnace (boiler) through special blowers, grates and other similar equipment.

Movement of gases with proper draft

Based on the physical processes of the formation of natural draft in a pipe, it is possible to determine a list of factors influencing its value. These include:

- chimney length. In accordance with current standards, the length of the chimney duct should not be less than 5 m. The optimal length can be determined based on the location of the chimney on the roof;

Calculation of the length of the chimney in accordance with its location

- the material from which the chimney is made. To make the passage of gases as easy as possible, it is recommended to make the chimney from materials with a smooth inner surface. And if this rule is not followed, then resort to periodic cleaning of the channel to remove soot and other deposits;

- presence/absence of insulation. If the smoke channel is not insulated from the outside, then when the gases cool, a large amount of condensate will form, which negatively affects the draft level;

Protection against condensation

Chimney insulation can only be done with non-combustible materials.

- pipe section. The level of draft depends on the correctly selected diameter of the chimney.

The draft in the smoke exhaust duct is also determined by natural factors:

- temperature and humidity inside the living space;

- weather conditions (wind, precipitation, low temperature, etc.);

- number of residents;

- frequency of ventilation and so on.

How to check the presence/absence of traction? You can check the draft level in the pipe using a lit match, candle or paper.

Self-check of draft in the pipe

Natural and forced traction

The purpose of gas boilers is to burn fuel.

…

During the combustion process, flue gases are generated. To remove combustion products, draft is required.

Natural draft boilers

Natural draft necessitates a chimney for a gas boiler. The requirements for the size of the chimney depend on the power of the unit. Such boilers have an open combustion chamber in their design, due to which the necessary amount of air is supplied to maintain the combustion process. The air is taken from the room in which the boiler is located. Atmospheric burners are used to burn fuel in such boilers.

…

Advantages of natural draft boilers:

- Simple design.

- Less dependent on electricity than forced draft boilers.

- They have a lower price than analogues with forced draft.

- Silent operation of the unit.

- Completely non-volatile models can only be designed with natural draft.

Disadvantages of natural draft boilers:

- A chimney is required, which is often impossible.

- Due to the open combustion chamber, oxygen is burned in the boiler room, and combustion products are partially released into the room.

- Weak resistance to a decrease in pressure in the gas pipeline.

Attention! The room in which the natural draft boiler is installed must be periodically ventilated to remove accumulated carbon monoxide and supply fresh air.

Forced draft boilers

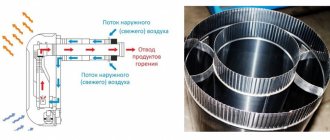

Forced draft in gas boilers is provided by an additional fan - a smoke exhauster. Combustion products are removed through a pipe of smaller diameter, so there is no need for a traditional chimney.

On a note. Smoke exhausters for domestic boilers are hidden in the body of the unit itself, their operation is fully automated. To protect the boiler, draft sensors are installed. If for any reason the draft is lost, the boiler will be stopped immediately.

The combustion chamber of units with forced draft has a sealed design, so air is also forced into it. Gas burners for heating boilers of this type are equipped with a blowing device to supply the required amount of air. They are called blower or fan burners. For safe operation, a gas boiler draft sensor is installed.

…

Coaxial pipe

A coaxial pipe can be used to remove combustion products. Its design includes 2 pipes of different diameters. One goes inside the other. This design ensures smoke removal and air supply, which reduces the number of required holes in the wall.

Advantages of forced draft boilers:

- The closed combustion chamber design is safer than the open type.

- The burners are resistant to gas pressure changes.

- Increased efficiency (efficiency factor) in comparison with boilers with natural draft.

- Oxygen is not burned in the house.

- Possibility of installation even in an apartment.

Disadvantages of forced draft boilers:

- Complexity of design.

- Increased noise level during operation.

- Energy dependence.

- High price.

Regardless of the type of draft, gas boilers can be wall-mounted or stationary, double-circuit or single-circuit, propane or methane.

Natural draft boilers are best used in separate rooms, as this is a safer type of placement. Often this is not possible even in a private house; in this case, it is more advisable to use a gas boiler with forced draft.

Thrust calculation

So, draft calculation is the calculation of the cross-section of a chimney for a gas boiler, fireplace, stove or other heating equipment. How to calculate the cross section? To do this you need to define:

- the volume of gas that will pass through the chimney in 1 hour;

- cross-sectional area of the chimney;

- section diameter.

Calculation of gas volume

To calculate the volume of gas passing through the smoke channel, the following formula is used:

V = B x V1 x (1 + T/273) /3600 , where

B – mass of fuel burned per 1 hour of operation of heating equipment;

V1 – correction factor, which depends on the type of fuel used for heating;

T – gas temperature determined at the exit from the chimney.

Indicators V1 and T can be obtained from the table available in GOST 2127 - 47.

Table from GOST for determining calculation parameters

Calculation of cross-sectional area

After determining the volume of gases passing through the smoke channel, you can calculate the cross-sectional size of the pipe:

S = V/W , where

V – volume calculated earlier;

W is the speed of passage of gases through the smoke channel (this value is constant and equal to 2 m/s).

Diameter determination

The next step is to directly determine the diameter of the chimney. The following formula is used for this:

D = √4 * S/ π , where

S – cross-sectional area of the smoke exhaust channel;

π is a constant equal to 3.14.

Example

For example, let’s carry out the calculation using the specified formulas with the following parameters:

- 10 kg of wood is burned every hour in the stove installed in the bathhouse;

- the temperature of the gases at the outlet of the pipe is 130ºС.

Let's calculate the volume of gases:

V = 10x10x(1+130/273)/3600 = 0.041 (m³/hour)

Let's determine the cross-section of the smoke exhaust pipe:

S = 0.041/02 = 0.0205 (m²)

Let's find the most suitable pipe diameter according to the given parameters:

D = √ 4 * 0.0205 / 3.14 = 0.162 (m)

This means that for the stove used in the example, it is enough to install a chimney with a diameter of 165 - 170 mm.

How to make calculations and install a chimney yourself, watch the video.

How the smoke goes away

Draft is the movement of flue gases up the chimney, from an area of high pressure to an area of low pressure. In a chimney (or simply in a pipe) of a certain diameter, with a height of at least 5 m, a vacuum is formed, that is, a necessary minimum pressure difference is formed between the lower part of this chimney and the upper one, due to which the air from the lower part, entering the pipe, begins go up. This is called traction. The draft can be measured with particularly sensitive instruments, or by taking a piece of fluff and bringing it to the pipe. Traction manifests itself in the same way as in any terrain - the higher we rise, the lower the pressure.

Therefore, if we take a pipe of sufficient diameter for air to move there, and extend it high up, we can make it so that the air from the ground will constantly flow upward. This will happen because there is very low pressure at the top, a large vacuum, and naturally the air will tend there. And air will come in its place from other sides. In the “firebox (or stove) + chimney” system, draft (the concept of draft) also operates if the stove is not working. When burning wood, a fairly high pressure is formed in the internal combustion chamber and, accordingly, the flue gases generated during combustion must escape somewhere. All the fireboxes and stoves we are talking about are made in such a way that the flue gases exit into the chimney, which has a certain height in order to create draft, in order to create an initial vacuum. In the combustion chamber, during combustion, physical and chemical processes occur with the release of heat, gases and excess pressure occurs. Firewood changes from a solid state to a gaseous state, releasing heat. Gases begin to move in the chimney under the influence of draft, tending to move from an area of high pressure to an area of low pressure. Everything works exactly the same as in nature.

What is “backdraft”?

Reverse draft is the movement of flue gases from an area of high pressure to an area of low pressure, but not upward (as we noted above), but downward. When reverse thrust occurs, a so-called pressure inversion is formed, when for some reason the pressure at the top is higher than at the bottom. This can occur quite simply if the room is sealed, there are double-glazed windows, if in addition to the chimney there is an exhaust hood (exhaust ventilation or something like that), which sucks air from the room and creates a reduced pressure relative to the surrounding area. Therefore, especially at the initial stage, when the chimney is still cold, the air in the upper part of the chimney has greater pressure than in the room, and accordingly, the smoke will go where it is easier for it. Many people say that a so-called “cold column” sometimes appears in the chimney. The chimney cools down very much, a column of cold air forms in it, which presses down and because of this, reverse draft occurs. If the room has normal pressure, not reduced, then warm air in any case (it is lighter than cold air) will tend to rise and will tend to go out into the chimney.

Thus, if we do not have a reduced pressure in the room (tightness, a kitchen hood easily creates a reduced pressure), there will be no collapse of cold air into the firebox. By the way, this can be observed very well. If in winter we start to light a fireplace (stove), before starting to light it, we set fire to a newspaper and put it into the chimney (bypassing the combustion part), and the fire does not go into the room, no matter what the column of cold air, but the fire burns very well and only comes out into the pipe. This is an indicator that warm air normally tends upward and, if the pressure in the room is not low, then there will be no flow of cold air. When we light a stove or fireplace, a situation may arise that smoke comes into the room. The resulting flue gases during the initial kindling are not yet very hot, and, rising upward and coming into contact with the cold walls, they cool very quickly. When their temperature reaches a critical point, they will naturally rush down as they cool. This is where the so-called reverse thrust comes from. In order to normalize the draft in the furnace, it is important to melt it correctly, understanding what processes take place there and what needs to be done about it.

How to properly assemble a chimney?

Prefabricated chimneys, sandwiches, collect smoke and condensate. There is an opinion that it is correct to collect by smoke. They explain that the flue gases, escaping into the pipe and rushing upward, will clog into the cracks, which may remain at the joints of the pipes and, accordingly, go out. There is an opinion that if you collect the smoke, the smoke will not come out. Usually in such disputes, if you had the opportunity to work with an existing stove, you can suggest drilling a hole anywhere in the chimney in order to see what will happen. It is especially interesting to do this in some lower part. You can drill any hole, even a centimeter in diameter. What will be observed? Naturally, no smoke will come out of this hole (unless, of course, we completely closed the chimney from above).

What is more important to consider when assembling a chimney?

The most important thing is to take into account that condensation may occur in any chimney, especially initially, when it is still cold and warm flue gases, not yet very hot, rise and become very cool. Condensation may form on the walls and flow down the pipe. If the chimney is assembled according to the smoke, then condensate, unlike smoke, can much more easily penetrate even very small cracks and moisten the existing insulation, thereby eliminating the heat-insulating properties completely, and from here to a fire is one step away. Therefore, the assembly of modular chimneys should only be based on condensate. Chimneys must be assembled at a good joint, with sealant along the inner pipe - firstly. Secondly, the chimneys themselves must be of high quality so that there are no large gaps left. But if there are any gaps left, then the smoke will not escape through them, but the opposite will happen. Air will be sucked in, and a situation will arise that has been observed more than once with low-quality chimneys - the pipe is large, high, but there is not enough draft. You flood the stove, but the stove does not heat, there is practically no draft.

At the same time, the chimney is large, high and you, not understanding what’s going on, call specialists. Specialists come and take a look. What can they see? When it is clear that there is not enough draft, and that this is due to the design of the chimney itself, a very simple move is made. The chimney is covered with something on top, and they look at where and from which cracks the smoke will come out. All kinds of inconsistencies in the chimney lead to the formation of suction through them, because there is draft in the chimney, that is, movement from an area of high pressure to an area of low pressure. Air will be sucked into the chimney from any gap. Why? Because the air will tend upward, because... With altitude, a pressure difference is formed. Therefore, the more cracks, the worse the draft will be at the bottom, because there are a lot of suction at the top. Therefore, the logic of those who advocate smoke assembly completely ignores the very essence of draft. This logic only implies that the fire is burning and smoke is rushing in all directions. No. Smoke comes from an area of high pressure to an area of low pressure, not in all directions, but only where it is easier for it. At the very least, those who want to collect smoke should be encouraged to conduct experiments of this kind. This includes experiments with soaking the insulation and seeing how the outside of the chimney heats up.

How is thrust measured?

Thrust is measured in Pascals. The draft norm for a conventional stove or fireplace is approximately 10 Pascal (Pa). The draft is measured directly behind the smoke pipe, because in the design, in the stove-chimney system, it is this place that is decisive and shows how quickly the evacuation of flue gases occurs and how well this corresponds to the parameters, that is, the ratio of the size of the stove firebox and the diameter of the chimney.

What else affects the amount of thrust?

First of all, of course, the height of the chimney. The minimum required height is 5 meters in order for natural vacuum to occur and upward movement to begin. Therefore, the relationship is, in principle, quite direct. The higher the chimney, the greater the draft. But this dependence is not as direct as it might seem at first glance. In a brick chimney with a cross section of approximately 140 by 140 mm, at a height of more than 10-12 meters, the draft no longer increases. This happens because the roughness of the walls with a small cross-section of the chimney begins to prevail with increasing height. Therefore, even if the chimney is 15-20 meters high, this no longer affects the draft. This question arises quite regularly due to the fact that in some houses there are ducts that people want to adapt for chimneys. They can be very tall, but have a small cross-section, so you must keep in mind that it is not always possible to connect a large fireplace to such a chimney.

Factors influencing traction:

- Flue gas temperature. The higher the temperature, the faster the flue gases rush upward, and accordingly, greater draft occurs.

- Chimney heating. The faster the chimney warms up, the faster the draft normalizes.

- The degree of roughness of the chimney and internal walls. Everything that we said about the small diameter can be said about chimneys in general: the rougher the walls, the more it affects the draft, accordingly, the draft decreases; the smoother the walls, the better the draft.

- The cross-sectional shape of the chimney. A round cross-section is ideal; oval, rectangular and so on. The more complex, intricate the shape, the more it affects the thrust, reducing it.

It is also very important to note that the ratio of the size of the firebox, the diameter of the outlet pipe and the diameter of the chimney pipe itself has a great influence. If the height of the proposed chimney is excessive, you should consider reducing the cross-section of the chimney by about 10%. Place an adapter directly on the firebox, on the smoke pipe, for example from a 200-diameter to a 180-diameter, and then run the 180-diameter pipe. This is allowed by many manufacturers. For example, if we talk about specific ones, he describes in the instructions for his fireboxes what diameter the chimney should be depending on the height. For example:

- height up to 3 m – diameter 250,

- height from 3 m to 5 m – 200,

- height from 5 m and above – 180 or 160.

There are very specific recommendations. Other manufacturers simply accept that changes are possible. Some don't allow it at all. Therefore, in this case, it is better, of course, to follow the manufacturer’s instructions, but also, understanding the processes occurring in the chimney, to develop your own recommendations for each client individually.

How is thrust measured?

It is necessary to light the stove or fireplace and heat it for at least half an hour so that all processes normalize. Then, having previously made a small hole in the pipe slightly above the smoke pipe, insert a special deprimometer sensor there and measure the draft. Thus, it will be revealed how much it is redundant or lacking. In fact, there are a lot of factors influencing cravings, so you can focus on at least a few more.

Rose of Wind

A very important factor is when the prevailing winds blow directly into the chimney and, accordingly, contribute to the occurrence of reduced draft or even its overturning. The chimney should be installed on the windward side, of course, if the priorities of the prevailing winds are determined. In no case on the leeward side, especially if the chimney is located quite far from the ridge and its height is not higher than the level of the ridge. It is important to look at what is at a relatively close distance, 10-20 meters, how tall the nearby houses are, trees, everything that can affect traction. Why have anti-wind deflectors become increasingly used recently? At least they somehow compensate for wind gusts and the location of the chimney. According to the standards, the chimney, which is located in close proximity to the ridge, is installed approximately half a meter above the ridge. If the distance from the ridge is from 1.5 m to 3 m, then it is displayed approximately at the same level as the ridge. If the distance is more than three meters, then the following formula applies: from the horizontal line drawn directly from the ridge, 10 degrees down. In practice, it is always better to strive to ensure that the chimney is either higher than the ridge, or approximately at the same level as the ridge. It is very important to use chimneys in such a way that one chimney works with one stove. Because there are cases when two chimneys are connected. If possible, and not absolutely necessary, it is always important to follow the rule - one device, one chimney.

Rollover traction

Another frequently asked question is traction tipping. In what cases does this happen? Basically, it occurs in situations where the chimney is quite long and cold (in particular, for example, brick), and the pressure is quite low. Therefore, even if the ratio of the dimensions of the firebox and the cross-section of the chimney correspond, even if there is relatively normal pressure in the room, a situation may still arise when, during the initial kindling, the flame does not have enough strength and the exhaust flue gases manage to cool very much in the chimney and collapse down. I have seen similar cases, but mostly this happened when the weather was cloudy, there was wind outside and a cold chimney that had cooled down. What happened was that for the first five minutes the fire flared up normally, but then the smoke began to pour heavily into the room. This was due to the fact that during combustion, air was taken from the room, and the pressure dropped slightly; there was no air flow - this is the first thing. And the second is that the flue gases rose upward, cooled, became denser and, having passed the critical point, fell down. What should you keep in mind in such situations? Of course, it is very important to light fireplace stoves correctly. Proper kindling initially creates such combustion that it prevents reverse draft or overturning of the draft. Of course, you need to check the pressure in the room. Open the window slightly, which is very important when starting kindling, especially if the room has double-glazed windows and is generally quite airtight. It is important to prepare the firewood, its proper stacking, drying, proper ignition, and compliance with some other rules so that extreme situations do not arise.

go to sections

Related Products

Chimney ISOKERN

Single-layer chimney system of modules made of volcanic pumice. System…

27.00 €

Chimney RONDO PLUS

Three-layer construction, reliable and safe Chimney system Schiedel Rond…

0.00 €

Aura – soot remover 1 kg

Chimney cleaner concentrated soot remover Aura. The volume of the jar is 1 kg. ...

13.42 €

ecoKOM AIR – Controller for convection fireplaces

The ecoKOM AIR controller is a modern electronic device with a graphic LCD display that provides…

290.00 €

Calculation of the dimensions of a household chimney

An important parameter of a household device for removing harmful combustion products is the diameter of the mouth of the chimney, that is, the size of its upper part. To determine the values of this indicator, you do not need to perform complex calculations; it is enough to take into account some data and perform calculations according to a simple scheme.

With a known amount of fuel burned, a special formula can be used to determine the volume of gases entering the pipe.

Knowing the speed at which gases move through the pipe, you can calculate its cross-sectional area. And using the formula for determining the area of a circle, it is not difficult to find the outer diameter of the pipe.

The main thing is the power of the boiler, in other words, how much fuel can be burned per hour in a certain device. The manufacturer must indicate such data in the equipment passport.

Other data for household structures necessary to perform calculations have approximately the same meaning:

- The temperature of the gases entering the pipe is 150-200C.

- The speed of gas movement through the chimney is 2 m/s or more.

- The height of the chimney in a domestic boiler room must be at least 5 meters from the grate. This value is controlled by Sanitary Norms and Rules.

- The natural pressure of the exhaust gas is at least 4 Pa per 1 meter.

In some cases, it becomes necessary to calculate the chimney draft. This value is determined by the product of the height of the structure and the difference between the air density and a similar parameter of the flue gas.

Knowing the amount of fuel burned, the power of the boiler or other equipment is calculated.

Taking into account a certain value of the thermal coefficient, the heat loss of the pipe per 1 meter is calculated.

Based on the constant values and the results obtained, the value of the natural pressure of the exiting gas is calculated.

Based on the above, we can conclude that the method for calculating a chimney for both domestic and industrial purposes makes it possible to determine the important parameters of the structure being built.