Do you dream of building an economical, safe and warm house? Then you should turn to modern technologies, which intelligently combine centuries of experience, ingenuity and sometimes completely unexpected technical solutions. A good example of this is a two- and three-circuit chimney, inside of which there is insulation. Who would have thought a couple of decades ago that something like this was even possible? Moreover, such a chimney really has many valuable advantages; it is only important to do everything according to the stove rules, without deviating from them one iota.

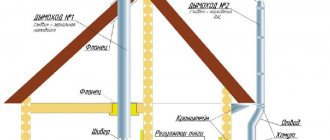

Proper installation of a sandwich chimney begins with the design of the house. Only by making a drawing can you correctly comply with absolutely all the requirements for fire safety standards, and then nothing will have to be redone or even rebuilt. If the house or bathhouse is already ready, then it will be necessary to make all the calculations as accurately as possible. We advise you, if you undertake to make such a chimney yourself, to approach this issue with all responsibility - you are doing it for yourself.

What is a sandwich, its advantages and disadvantages

A sandwich chimney is a double-circuit cylindrical structure consisting of several sections of pipes 1 meter long, which are inserted into one another during the installation process. The internal and external contours are made of rolled pipe, between which a thermal insulation material is placed - vermiculite, mineral wool or basalt fiber. It does not allow the chimney to cool quickly and prevents condensation from appearing inside it.

These insulation materials are characterized by a low thermal conductivity coefficient, resistance to chemicals, fire resistance and high moisture resistance. The internal circuit is made mainly of heat-resistant and corrosion-resistant stainless steel; for the external circuit, pipes made of stainless steel, galvanized iron, alloy steel with a decorative enamel coating are used.

Thanks to their design features, sandwich chimneys have the following advantages:

- Simplicity and ease of installation. Thanks to a wide range of connecting parts, you can give the structure a configuration of any complexity.

- Soundproofing properties. Due to the three-layer wall structure, the pipes significantly reduce the hum and noise that occurs during traction.

- Compatible with all types of heating devices, regardless of the fuel used.

- The lightness and versatility of the design means that sandwich chimneys can be installed both indoors and outdoors without the construction of additional support.

- Attractive appearance.

- High heat-shielding properties, thanks to which the structure is reliably protected from the formation of condensation.

- High fire safety. Effective thermal insulation also prevents the outer contour of the smoke exhaust duct from heating to very high temperatures that can ignite flammable materials in contact with the surface of the structural elements of the building.

- Smooth internal surfaces. During operation, they are less susceptible to soot deposits, which makes it possible to clean the chimney duct quite rarely.

- Long service life. The internal contour of the sandwich pipes is made of stainless steel, resistant to thermal and chemical aggression, so they retain their original characteristics for many years.

Despite the large number of advantages, sandwich chimneys also have a number of disadvantages:

- Fairly high cost.

- Loss of tightness resulting from the reaction of the material of the chimney components to temperature changes (narrowing or expansion).

Types of chimneys

Depending on the location of the stove or boiler, the availability of free space and the design features of the chimney, organizing the removal of smoke outside the building can be done in two ways - external or internal installation of the chimney.

Outer

An external chimney is a flue that connects the outlet pipe of the heating device to a pipe that goes outside through the wall. To ensure good draft, the height of the chimney pipe must be no lower than the level of the ridge or rise above it. The length of the horizontal section of such a structure should not exceed 1 m, the distance from the edge of the roof should be at least 0.5 m. A prerequisite for the normal functioning of the external chimney can also include the installation of external insulation.

The advantages of this option for placing a chimney are saving usable space in the house, reducing fire hazards, maintaining the integrity of the roofing, and independence from interior design decisions.

Interior

The internal smoke exhaust system consists of a vertical part located inside the house and led outside through the roof. The modules must be joined outside the attic and between floors so that there are no obstacles to checking their tightness. The chimney passages are protected from high temperatures using passage pipes and a roof penetration. Sealing of the joint with the roofing is ensured by the roof groove.

The internal arrangement of the chimney pipe with a 100% vertical position provides more stable draft, is easier and more convenient to maintain, does not require insulation, and does not spoil the architectural appearance of the building facade. However, this type of chimney will take up part of the usable space in the room; during its construction, the costs of arranging passages through the ceilings, ceiling and roof will increase, and the tightness of the roof covering will be compromised.

How to choose the right sandwich chimney installation kit

When purchasing such a kit, first of all you need to correctly calculate its geometric parameters - the diameter and height of the future structure. It is also necessary to take into account what material the component elements are made of, the thickness of each layer of products, so that during operation the sandwich chimney can withstand the temperature of exhaust gases, for example, from powerful solid fuel boilers.

Material of manufacture + GOST table for stainless steel

The pipes of both circuits of sandwich chimneys are mainly made of high-alloy and heat-resistant steel with a thickness of 0.5 - 0.7 mm. This material is resistant to chemical aggression and condensation. Stainless steel pipes can be combined with any type of heating device. The main requirement is the precise selection of steel grade depending on the maximum possible temperature of the exhaust gases.

| Steel grade, according to American AISI standard | GOST Russia | Characteristic | Heating device type | Maximum permissible exhaust gas temperature |

| AISI 304 | 08×18Н10 | Chrome-nickel steel | Gas and liquid fuel boilers | 450ºС |

| AISI 316 | 03×17N13M2 | Austenitic chromium-nickel-molybdenum steel | Gas and solid fuel appliances | 800ºС |

| AISI 321 | 08×18N10T | Non-magnetic austenitic chromium-nickel steel with titanium addition | Powerful gas and solid fuel appliances | 850ºС |

| AISI 310S | 10×23Н18 | Austenitic steel with increased nickel content (17 - 20%) and chromium (up to 25%) | Solid fuel pyrolysis boilers | 1000ºС |

In addition to double-circuit stainless steel structures, sandwich pipes for chimneys are produced, in which the outer and inner contours are made of galvanized steel. The cost of such products is much lower, but they are subject to deformation at temperatures above 450ºС. A more durable option is when stainless steel is used to make the internal circuit, and galvanization is used for the external circuit. In this case, the outer pipe is made of metal with a thickness of 1 mm; for the internal contour, stainless steel products with a wall thickness of 0.5 mm are used.

Wall thickness (for solid fuel, gas)

The wall thickness of the internal contour of sandwich pipes for gas units should be selected depending on their diameter:

- From 130 to 450 mm - 0.5 mm.

- 500 mm - 0.6 mm.

- Over 500 mm - 0.8 mm.

For solid fuel appliances, the determining factor in choosing the wall thickness of the inner pipe is the temperature of the combustion products:

- Up to 450ºС - 0.6 mm.

- Over 450ºС - 0.8 mm.

The design of the chimney of a solid fuel boiler must include a non-insulated section connected directly to the outlet pipe of this device. For these purposes, a monopipe made of heat-resistant stainless steel with a wall thickness of 0.8 mm to 1.0 mm is usually used.

The casing on the outside of the products, depending on its diameter, must have the following wall thickness:

- Up to 450 mm - 0.5 mm.

- Over 500 mm - 0.6 mm.

Selection of diameter + table of dimensions of minimum sections

The internal diameter of the sandwich pipe should be selected depending on the parameters of the heating unit. The cross-sectional area of the chimney is calculated based on the thermal power of the boiler, but its size over the entire height of the structure cannot be less than the cross-section of the outlet pipe of the device.

Table 2 presents options for the sizes of the minimum sections of the smoke exhaust duct depending on the power of the heating device.

table 2

| Heat generator power parameters, kW | Dimensions of the diameter of the internal and external sections of the pipe, mm |

| less than 3.5 | 120/180 |

| 3,5 — 5,2 | 140/200 |

| 5,2 — 7,0 | 150/220 |

| Over 7.0 | 200/260 |

Insulating layer thickness

The choice of heat insulator thickness also depends on the temperature of the exhaust gases. For gas boilers of low and medium power with a temperature of exhaust gases of 250ºС, an insulating layer 30 mm thick is sufficient, for more powerful gas and liquid fuel appliances with a temperature not higher than 450ºС - 50 mm. Gas ducts of solid fuel units, especially coal units, in which the smoke can heat up to 1000ºC, require a heat insulator 100 mm thick.

Connection types

You can connect chimney modules with your own hands in the following ways:

- Bells. This type of connection is used for modules that have a slightly wider chamfer on one side. It provides a high degree of channel tightness.

- Corrugated edges. Assembling a chimney from modules with corrugated edges does not require high precision installation; the tightness of the joints here is ensured by a large amount of expensive high-temperature sealant.

- Flange. This method allows you to assemble a structure that has no obstacles to the escape of smoke, but with poorly closed joints where moisture can seep in and damage the thermal insulation layer.

- Bayonet. The parts are connected to each other by moving along the axis and rotating, and sometimes lateral displacement, one element relative to another.

Features of the sandwich chimney

There are many positive reviews about the use of chimney pipes due to the many undeniable advantages and structure of its structure. Chimney pipes using this technology are gaining popularity. What is a sandwich chimney? This is a pipe of a smaller diameter, in a pipe of a larger diameter, and between them there is fire-resistant insulation. Sandwich chimneys made of stainless steel are shown in the photo below.

The main advantages of sandwich chimneys

Sandwich ovens have the following advantages:

- In boiler equipment, the most important thing is fire safety. Good insulation, made of high-quality material, does not allow the outer pipe to heat up. This means there will be no fire in adjacent structures.

- The speed of sandwich pipe installation is amazing. If we compare it with the old methods, where it was necessary to install a pipe, then wrap it with something, then wrap this layer additionally. And here the pipe is completely ready and you just need to connect the parts together. Do-it-yourself sandwich pipe for a chimney can be assembled quickly, in one day.

- No special installation or capital foundation is needed for our sandwich structure. Everything is perfectly held by special brackets. No additional materials or devices are required.

- Any configuration option for the pipeline can be specified as long as there are fittings. With today's variety of architectural solutions, this is especially important and convenient. All kinds of columns, ledges, prefabricated houses, layouts with non-standard solutions.

- The efficiency and ease of operation of boiler equipment arises from a significant reduction in heat loss and condensation. Unpleasant indoor noise caused by pressure is a thing of the past. This is a bonus that comes from using sandwich pipes. Visitors to public baths and saunas equipped with such pipes will be safe.

- You can check the chimney yourself, easily and quickly. Cleaning it won't be difficult. Complete or partial disassembly of the entire structure is not required. The mirror walls inside the sandwich do not contribute to the accumulation of fat, soot and soot. Corrugated pipes are not comparable here and comparisons are not appropriate here.

- The appearance will not disappoint you. Wood, metal, glass - classics. The beauty of the sandwich design will not spoil the space.

Diagram with internal structure

Elements of the chimney system in the diagram:

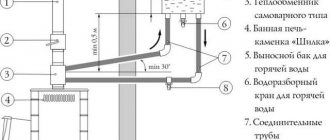

- A heating device with a vertical pipe for connecting a chimney in the upper part of the firebox.

- Connection unit for the chimney from the boiler, which includes a 90º inspection tee, a plug - an inspection hatch, a plug with a condensate drain and a 90º connection tee.

- Mono-pipe is a section of a smoke exhaust duct without thermal insulation. It is located in close proximity to the boiler. The need for such a section is explained by the maximum temperature effect on this zone of the structure, so there is a need for effective heat removal. In turn, the hot initial section of the chimney will become an additional source of thermal energy in the room. With a different approach to assembling the structure, high temperatures can lead to sintering of the insulation in the sandwich, which will increase the fire hazard in the house.

- Additional equipment: tank, mesh heater or convector. The thermal energy of the initial area without thermal insulation can be used to install a hot water tank or a heater grid on it. You can also make good use of the high temperature of combustion gases if you replace the monopipe with a convector equipped with channels and additional heat exchange fins. Using a convector will provide faster heating of the room.

- A damper (gate) is a rotary or translationally moving device designed to regulate draft. This happens by changing the cross-sectional area of the channel for removing flue gases.

- Adapter from mono to sandwich - a special design with a round cross-section, used for connecting an uninsulated area with a sandwich-type pipe;

- Sealing all connections with clamps. Clamps are placed and tightened on each connecting node of the smoke duct.

- Ceiling-passage unit is an element of the system that ensures fire safety in places of passage through the ceilings.

- A sealed passage through the roof. A ready-made pass-through node is used - a master flush. It is installed at the junction of the pipe and the roofing to protect against leaks.

- The cap is the final element of the smoke channel. Protects the system from precipitation and decorates the structure.

Preparation for installation

When installing smoke ducts from sandwich pipes with your own hands, you do not need to build an additional cement foundation, as required by a chimney made of brick or ceramic masonry, because due to its low weight the structure acquires another advantage of a metal installation over ceramics and brick. But don’t underestimate the task ahead of you, because you need to do more than just secure the bracket, although this is really easy to do with your own hands.

What happens if done poorly?

Poor assembly and installation of a sandwich chimney can lead to poor or reverse draft, when gaseous combustion products do not evaporate into the atmosphere, but are concentrated in the room. The most common reasons for changes in thrust direction are:

- Incorrect calculation of pipe parameters depending on the boiler power.

- The configuration of the smoke exhaust duct is too complex with a large number of narrow sections and turns.

- Low position of the head in relation to the ridge or nearby tall buildings.

Options

Sandwich chimneys are good because they have a modular structure, which allows you to assemble any configuration, with any parameters. Before you go to the store, you need to know the required diameter of the chimney, the height of the pipe and those additional elements that will be needed.

Chimney diameter

When choosing the diameter of a sandwich pipe, a simple rule applies: it cannot be less than the diameter of the boiler outlet pipe. If your outlet pipe is 120 mm, then the internal diameter of the sandwich should be the same or larger. It may be wider, but definitely not smaller, and the narrowing cannot be done along the entire length of the chimney. If the chimney is slightly wider than the pipe, an adapter is purchased, which is placed directly at the boiler outlet, and then the working size comes next.

If you don’t have a boiler yet, but you know its power, you can choose a chimney based on these data:

- boiler power up to 3.5 kW - internal diameter of the sandwich - 80 mm;

- from 3.5 kW to 5.2 kW - at least 95 mm;

- more than 5.2 kW - 110 mm and more.

But it’s better to buy (or at least choose) a boiler, and then decide on the chimney, because many manufacturers insure themselves by making the outlet pipes wider to improve draft.

Installation of a sandwich chimney begins with determining the diameter

Pipe height

The height of the chimney above the roof surface depends on the location of its outlet, but its minimum height should be 5 m. That is, if the height of the house is small, in any case, install the pipe to a height of 5 meters. If the height of the house is above 5 m, then the pipe should rise above the roofing material to the following height:

- Should rise 50 cm above the ridge if it comes out at a distance of less than 150 cm from it.

- If the distance from the ridge to the pipe is more than 300 cm, then the pipe may be lower than the ridge level, but the angle should be no more than 10° (see figure).

- If the chimney exits at a distance of 150 to 300 cm from the ridge, its height can be at the same level as the ridge element or higher.

Under such conditions, normal traction is ensured. The smoke will go away normally regardless of weather conditions. To prevent leaves from getting into the chimney, they install special umbrellas, weather vanes, and in windy places - deflectors, which further improve draft.

Sandwich chimney pipe height

If it is not possible to bring the pipe to such a height, they install a smoke exhauster - a forced draft is obtained. A fan will not be needed all the time, but in some conditions, when natural draft is not enough, forced exhaust saves the situation.

The principle of correct installation of sandwich pipes (for smoke, for condensate)

Assembling a chimney from sandwich pipes can be done in two ways:

- Connection “through smoke”. The end of the lower module fits completely into the pipe of the upper module, which ensures unhindered passage of combustion gases.

- “Condensate” connection. This is a more complex assembly scheme. In this case, part of the inner pipe of the upper section is inserted into the lower composite segment, and the outer part - the end of the lower one is inserted into the upper module. This method of installing a gas duct ensures unhindered drainage of condensate and natural precipitation down its surfaces. With this connection option, moisture will not penetrate into the insulation and the pipe will not corrode, however, if the joints are loose, smoke may enter the room.

It would be more correct to combine both assembly schemes so that the inner contour of the pipe is mounted along the condensate, and the outer contour is mounted along the smoke.

Safety Tips

If there is a possibility of a noticeable increase in pressure in the channel, the connection points are also closed with special couplings, just in case. Often, when installing steel pipes, heat-resistant sealants are used to cover the joints. The more insulated the chimney, the more correct the draft.

Despite the excellent insulating properties of “sandwiches”, when pipes cross floors, there is some likelihood of overheating and ignition of materials adjacent to the pipe. To guarantee a certain level of fire safety, it is recommended to increase the thickness of the thermal insulation layer at the joints.

Preparation

The preparatory stage includes carrying out calculations on the proposed configuration of the chimney, developing a diagram - drawing, marking the mounting points. This will allow you to calculate the required number of modules, connecting parts, and develop a plan for further work.

Consumables and tools

In addition to the standard elements included in the sandwich chimney kit, for independent installation you will need the following consumables and tools:

- Clamps.

- Wall brackets.

- Fasteners.

- Fireproof sealant.

- Scissors and jigsaw for metal.

- Hammer.

- Side cutters.

- Construction hairdryer.

- Putty knife.

- Master OK.

- Measuring tools: tape measure, square.

- Construction level and plumb line.

- Marker.

What to fasten with?

The structural parts must be secured with special clamps, which are tightened with nuts. The finished chimney, if it is located along the wall, must be secured to it with brackets in increments of 1.5 - 2.0 meters. A stretcher should be installed on the upper element.

Chimney height (total + on the roof)

When calculating the height of the structure, the following rules should be observed:

- The height of the channel from the nozzle of the heating unit to the final element - the head - must be at least 5 m.

- The part of the pipe located on the roof must rise above the ridge by no less than 0.5 m and the roof of neighboring buildings by no more than 1.5 m. If there is a need to lengthen this section of the smoke exhaust duct, then a guy should be installed for additional fixation .

Connecting the tee to the heating device + sealing + mounting to the wall

A heating device with a horizontal outlet pipe on the rear side is connected to a monopipe using a tee (mono), equipped with a plug at the bottom with a condensate collector. Before installing it, the inner surface of the central outlet should be covered with a layer of heat-resistant sealant.

Next, the tee should be tightly placed on the stove pipe, pushed in all the way and secured in the area of connection with the pipe with a clamp and bracket. In this case, it is important to check the verticality of the tee axis using a building level; only after this procedure can it be secured to the wall with a bracket using anchors or dowel plugs.

Installation of a monopipe

To install a straight section of a monopipe, you must first mark on the wall the place where the bracket is attached, so that the markings coincide with the junction of the module and the tee, and drill holes for the fasteners. Then you need to put a clamp on the upper branch of the tee, but do not tighten it completely, but fix it with a bracket to the wall.

Further installation work will be carried out using the “condensate” method - inserting the lower end of the monopipe into the tee. A heat-resistant sealant is used to seal the joint. It is applied with a narrow spatula and distributed in an even layer in the joint zone.

Then the pipe moves in the tee pipe until it stops. The installation of this section of the monopipe ends with tightening the clamp. The next block with a damper is installed according to the same scheme: a clamp is put on the already installed pipe, its free end is coated with sealant, where the upper part is inserted, and the clamp is tightened. It is advisable to mount another section of monopipe, 50 cm long, behind the damper to ensure maximum heat transfer from the flue.

Sandwich + polyurethane foam installation

Sandwich modules are installed in the same order: applying sealant, joining parts and tightening with a clamp. In the ceiling, in the place where the channel will cross it, you need to drill an opening and continue assembling the structure, checking the verticality using a plumb line. The factory-made ceiling pass-through assembly consists of a box-shaped body made of galvanized steel, covered at the bottom with a stainless steel plate.

In the middle of the body there is a through hole corresponding to the outer diameter of the sandwich pipe. The PPU is placed on top of the already installed module and lowered into the ceiling opening. The bottom of the polyurethane foam should be flush with the surface of the ceiling, the top of the box should be filled with fire-resistant insulation - basalt wool, expanded clay or vermiculite and immediately closed with a lid.

Mono-pipe again (if the room is 2nd floor residential)

If the building is two-story and the rooms on the second level are residential, then in order not to lose useful thermal energy, the part of the structure passing through them should be assembled from monopipe sections. To do this, first install an adapter from a sandwich module to a single-circuit pipe. Then, in the usual manner, the chimney is assembled from monopipe sections up to the attic floor, fastened with clamps to each other and brackets to the wall.

Again sandwich + polyurethane foam

An adapter is installed in front of the attic floor, now from a mono section to a sandwich pipe, and then the assembly of the channel to the head will be carried out from sandwich products in the order already discussed. At the point of passage through the attic floor, an opening is also cut out and polyurethane foam is installed and filled with heat-insulating material.

Making a hole in the roof

The hole in the roof must be calculated so that it does not affect the elements of the wooden rafter structure and is located at a distance of at least 13 cm from them. The shape of the hole can be rectangular - for a roof covering laid on a continuous or frequently spaced sheathing, or oval - on a pitched roof. You can make an opening using an electric jigsaw, having first marked its boundaries.

Installing master flash

After the chimney is brought out through the roofing, the passage must be sealed by installing a special master flush passage unit. It consists of an elastic base (flange) with flexible aluminum strips around the perimeter, ensuring the best possible fit to the roofing material. Connected to it is the upper part - a corrugated cuff in the shape of a truncated cone, made of silicone or EPDM rubber. In the working position, the cuff fits tightly to the pipe, preventing the penetration of atmospheric moisture and dust.

Before installation, the top of the cone-shaped cuff must be cut so that the cross-section of the resulting hole is approximately 20% smaller than the outer diameter of the sandwich section. Next, the seal is put on the pipe and moves down to the roofing, to which it is fixed with silicone glue.

On pitched roofs, additional fastening with self-tapping screws and fixation with rivets is required. The installation of the masterflash is completed by treating the upper cut of the cone and the lower edge of the base with sealant, and fixing the upper edge with a metal clamp.

Installation of the head

The cap is the final element of the structure; it fits tightly onto a pipe brought to the required level and is attached to it with three or four metal screws.

Video:

1. Passage through a soft tile roof

2. Installation through ordinary tiles

Organization of a node through the walls of a house or bathhouse

Today, sandwich chimney installation is practiced in two main ways: inside the house or outside. And indeed, more and more often you can notice that chimneys are installed directly through the wall to the street, and from the first floor - and from there they are directed vertically upward. And this makes sense: this way the chimney cools much faster and does not pass through fire-unsafe ceilings and roofs. On the other hand, a chimney that rises through the attic usually serves as an additional heating element. But the risk of fire here, of course, will be higher.

You will be surprised, but in fact the outer casing of a stainless steel sandwich is not far from the temperature of a single-circuit chimney. Indeed, in fact, initially such a chimney was designed to improve draft, and therefore the gases that leave the stove usually have a temperature of 800 degrees Celsius, and the outer casing can heat up to 300 degrees! And this is far from a fireproof surface.

A modern sandwich chimney is exhausted both through the roof and directly through the walls of a residential building:

You can see the node in more detail in this illustration:

So, the following step-by-step instructions will help you organize the correct angle of passage of the sandwich chimney through the walls:

- Step 1. Before starting work, be sure to calculate the length of the horizontal sandwich pipe that will need to be passed through the wall. And also take into account the tee that you will install. Calculate the roof slope so that the chimney does not end up too close to the eaves.

- Step 2. Fill the box that you insert into the wall with non-flammable basalt material.

- Step 3. Close the pass-through assembly with a lid so that the basalt cardboard gasket remains visible.

- Step 4. Cover the edges of such an assembly cover with a platband from the components of the exterior decoration of the house, for example, siding.

- Step 5. Treat the edges of the box with clear roofing sealant.

- Step 6. At the outlet of the chimney from the wall, install an inspection.

- Step 7. Secure the chimney using special wall brackets, one for every 1.5-2 meters.

- Step 8. So, after you have installed the pipe, check its verticality using a level.

- Step 9. Be sure to make sure that the seam faces the house.

After all, the most important rule is this: the chimney passage through the wall of a house or bathhouse must be protected as much as possible from fire. Here is a good example of such a node:

In order for the horizontal element of the sandwich chimney to be installed securely, it must be properly supported with a metal corner:

Special structures will also help to secure such a chimney to the wall in a strictly vertical position:

Believe me, the work is not over at this stage, especially if your chimney has a complex design (which we strongly do not recommend):

Installation according to external circuit

In the case when a sandwich chimney is installed outside a building, it has one horizontal section of a single pipe, the length of which should be no more than 1 m. It is connected to the stove with a slope towards the vertical channel and is connected to the sandwich, which passes through the wall.

If the wall is built from non-combustible building material, then a metal or asbestos sleeve is installed at the passage point. The gap between it and the surface of the smoke channel is filled with basalt wool or asbestos cord. The tee for connecting the vertical part of the structure should be placed outside the house and a condensate drain should be connected to its lower branch pipe.

The vertical channel is assembled from the bottom up and attached to the wall with brackets every 1.8 - 2 m, each part is fixed with a clamp, and the joint is filled with sealant. A deflector or umbrella must be mounted at the top of the flue.

Pipe layout

To prevent moisture from entering the attic, roof trims are used. They are made taking into account different roof slopes, when the angle can vary from 14 to 56 degrees.

The “cut” element is put on through the pipe, while the edges are fixed and fastened under the roof ridge. The pipe extends half a meter above the outer roof, when positioned within 1.5 meters of the roof. If the gap is from 1.5 to 3 m, then the extreme point of the pipe can be located on the same plane as the roof ridge. If the distance is more than three meters, then the extreme point of the pipe is located according to the following diagram:

- A line is drawn on the diagram from the top point of the pipe to the ridge point.

- A line is drawn from the ridge parallel to the horizon.

- The angle between the two lines is about 10 degrees.

Installation step by step:

- The corrugated sheet is installed away from the pipe.

- The split block is installed at least 16 cm

- The top sheet is removed, the upper part of the roofing trim is laid, then the sidewalls are covered by 18 cm.

- The previously removed sheet is mounted and fixed.

- Joints and seams are sealed with sealant.

- Mineral wool is wrapped around the pipe and fixed.

- An “umbrella” is installed for the chimney.

Common mistakes

Errors in choosing the material and assembling the chimney can lead to a number of problems during its operation.

Traction problems

Traction problems can occur due to:

- Insufficient height of the canal or its incorrect location.

- The passage is too narrow or wide for gas outlet.

- Pipe deviations from the vertical.

- The location of the head is below the outlet section of the ventilation hood.

Building fire

A fire can occur if there is insufficient thermal insulation where the flue pipe passes through the structural elements of the house.

Roofing leaks

Insufficient sealing of the joints between the surfaces of the smoke exhaust duct and the roofing will inevitably lead to the entry of atmospheric moisture into the attic and the wetting of the ceiling.

Expert advice

The construction of a proper chimney system is the basis for the efficient and safe operation of heating equipment. If you plan to assemble it yourself, then advice from masters - professionals in this field - will not be superfluous.

Subtleties of switching from a brick pipe to a sandwich

At the point of transition from a brick pipe to a sandwich, it is better to install not a homemade, but a ready-made metal adapter. Its lower part corresponds in size to a brick channel, and the upper part has a round shape with a diameter equal to the diameter of the sandwich. A reliable heat insulator is already installed inside. The use of this device ensures the necessary tightness and fire safety of the connection.

Subtleties of passing through a wooden roof

When using ready-made polyurethane foam, it is necessary to take into account that wood can expand at high humidity, so there should be a small gap between the walls of this device and the opening, approximately 3 - 5 mm. In addition, it is important to impregnate the wood in the joint area with anti-friction agents, which increase its fire resistance.

Where is the best place on the roof to install the pipe?

It is better to move the place where the pipe exits through the roof slightly from the ridge to one side. If it passes through the ridge, then when installing the passage unit, it will be necessary to violate the integrity of the rafters and the ridge beam.

Where is the best place on the wall to make a conclusion?

It is advisable to cut a hole in the wall at the level of the boiler connecting pipe, the main thing is that there are no communications in this place. If you choose a higher place for the outlet of the gas duct, then additional transition elements and installation of horizontal sections will be required, which will negatively affect the draft.

Protecting wood from hot pipes

In the place where the gas duct passes through a wooden wall, a rectangular opening should be cut and a special unit, PPU, should be installed. This is a universal design and is used not only for fire protection of floors, but also walls. The pipe will pass through it, and the free space in the housing can be filled with basalt wool.

How much could such work cost?

Of course, the cheapest option is for the homeowner to assemble the chimney himself. But nevertheless, it is better to invite professionals to perform this work. It is only at first glance that the installation of the structure does not seem at all difficult, but during the process various problems may arise that only experienced specialists can solve. The cost of assembly and installation work depends on the total length of the channel, the method of its placement, the number of overlaps and varies among different craftsmen from 1,700 to 2,000 rubles per meter.

Cutting a chimney on the roof

The cutting of the chimney on the roof is carried out taking into account several dimensions:

- the minimum distance from the roof surface to the rafters is 250-300 mm;

- if roofing felt or roofing felt is used as a surface covering, the size up to the chimney pipe is from 300 mm;

- if metal or concrete parts are used as rafters, this distance is reduced to 200 mm.

Difficulties arise when pipes pass through layers of roof protection (steam, waterproofing, wooden sheathing of the structure and layers of insulation). We carry out the work very carefully, trying not to disturb all layers of insulation and structure.

To install the glass, we perform additional lathing, connecting 2 adjacent rafters with 2 jumpers according to the size of the sleeve.

We carefully pull up all the old layers and tuck them inward, fixing the edges with a stapler or nails with heads. We fill all gaps with a layer of thermal insulation and sealant.

Waterproofing surfaces is carried out in several stages:

- on the roof we lay a groove over the entire surface of the pipe for drainage and removal of possible leaks;

- we fix and fill all the gaps and install the outer waterproofing apron. It can be made of steel or rubber. We place its edges under the roof covering and fix it on top of the internal apron of the main structure and seal all the joints;

- Now, when water passes through small cracks, it will enter the drainage groove or be removed along the covering of the roof apron.

After laying the roof covering layer, we install the outer apron and seal it tightly to the surface of the chimney and roof.

Scheme:

Scheme of cutting a chimney on the roof

Installation of a brick chimney

Maintenance of the assembled system

During operation, soot growths may appear on the walls of the sandwich chimney, reducing its cross-sectional area, which can lead to smoke in the room and a fire. Therefore, it is necessary to clean the duct at least twice during the heating season. It is convenient to carry out cleaning through the inspection hatch in the plug; if there is none, you can open the plug completely for these purposes by unfastening the clamp.

The condensate collector also requires regular inspection to ensure timely discharge of accumulated liquid. If the condensate drain is connected to the sewer system, then the condition of the connecting tube must also be examined: clean it if it is clogged and replace it if it fails. To clear a clogged drip line, you can use a thin, strong wire.