The movement of air along a chimney or other path is called draft. This movement occurs due to temperature differences or pressure changes in the atmosphere. Natural air draft occurs when cold and warm air collide without the use of a forced ventilation system. Backdraft in a chimney can occur when air flows do not move outward, but in the opposite direction.

Lack of a ventilation system is one of the reasons for backdraft

How to check the draft in the furnace and understand whether it is there or not

The sooner you notice the problem, the easier it will be to get rid of it. Therefore, inspect your heating system regularly. Among the obvious manifestations:

- puffs of smoke appearing immediately as soon as you open the firebox door;

- white, gray or even black smoke masses ooze from cracks or pipe joints.

When at least one of these phenomena is observed, it is time to sound the alarm. But even if they are not there, this does not mean that combustion products normally come out and do not stagnate in the outlet channel.

If there are no external signs, but there are suspicions, the lack of traction can be checked in the following simple ways:

- Using a candle, light it, carefully insert it into the firebox and look at the flame. If the light “goes” away from you, even further inward, then the situation is normal; if the tongue remains in place and does not even tremble, the air masses are not circulating properly.

- Using a ribbon or piece of paper, take it by the edge and bring it to the pipe. If the free end pulls into the sleeve, then everything is fine, if it does not move, the hood does not work.

- Using a mirror, you need to carefully bring it closer to the fuel-burning chamber and take a closer look. If moisture appears on its surface, there is a problem with the removal of combustion products.

- Look at the color of the flame: when it is yellowish-golden, everything is good, if it is bright orange or, even more so, red, there is poor air circulation.

After you have checked the lack of traction, you need to find out the reasons for its occurrence.

The principle of furnace draft

With the correct structure of the stove and clean channels, draft should form naturally, since the necessary conditions for its occurrence are inherent in the design of the heating structure itself.

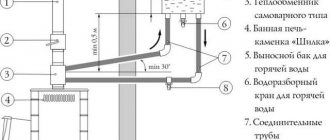

This diagram shows a combined design that includes not only a Russian stove with a stove bench, but also a separate kitchen stove with its own firebox. In addition, for the second floor, a fireplace is “embedded” into the common chimney.

The main thing in this process is the chimney, through which smoke is removed from the functioning stove. When the fuel mass burns, an area of rarefied air is formed due to the difference in the height of the combustion chamber, smoke exhaust channels and the mouth (outlet) of the chimney pipe. Thus, a traction force arises, facilitating the removal of gaseous combustion products.

Another significant factor is the temperature difference in the combustion chamber and in the atmosphere, since heated air tends upward to lower temperatures.

It would seem that the principle of draft formation is simple, however, there are enough points that can complicate the process of removing combustion products.

Often there is no traction due to external factors. But it may also depend on incorrectly calculated parameters of some parts of the furnace structure. In any case, if such a problem arises, first of all it is necessary to find its cause, and then look for ways to eliminate it.

Why there is no draft in the chimney: reasons for its absence

There are two fundamentally different situations:

- there was no normal traction initially;

- over time, the traction force weakened, and then completely disappeared (or is insufficient).

The reasons for their occurrence are associated with a number of factors, which we analyzed and combined into key groups - according to the nature, degree, and consequences of their impact. Next, we will look at the most important points and find out how to prevent each of them or eliminate their consequences.

Conclusion

The main thing in the design of a stove is the correct calculation of the parameters of the firebox and chimney. Seek help from specialists. Laying stoves is a very difficult task; it is no coincidence that the skill of a stove maker has been highly valued at all times. The second aspect of this problem is to use only high-quality materials that can withstand high temperatures and do not collapse.

Periodic maintenance of the chimney and firebox will not only eliminate draft problems, but also ensure fire safety. Monitor weather changes, use all stove settings correctly, and use high-quality fuel. If these simple conditions are met, your home will always be warm and cozy.

Reason #1 – chimney design

- There were errors in the configuration.

- The pipe diameter is smaller than that required for the stove of the selected power and recommended by the heating unit manufacturer.

- When laying the channel, turns of 90° were made, while the maximum possible value (according to SNiP) is only 45°. Ideally, the chimney should be vertical throughout. But sometimes this can be difficult or impossible to achieve. In this case, tees and transitions (elbows) are used. If your channel has at least one transition at 90°, then you need to extend the pipe by 1 m, if there are two transitions (two angles), then by 2 m. If you used a transition at 45°, then two such angles - this is plus 1 m in height.

- Horizontal sections along the sleeve are either too common or too long - their total length should not exceed a distance of 1 m.

- A non-cylindrical or round pipe shape was chosen - weak draft in a chimney with a square cross-section occurs more often due to turbulence that forms in the corners and interferes with the exit of combustion products. As a rule, square sections have brick structures. You can select the appropriate option in the catalog.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

If your chimney is brick and not lined, be sure to line it with stainless steel pipes. These pipes are easy to install, have sealed joints and a smooth inner surface, on which the likelihood of soot accumulation is minimal.

- The vent is too short - there is no flow of fresh air.

- During lining, pipes of different diameters were taken, as a result, large quantities of soot accumulate at their joints, making it difficult to remove gas masses.

- The joints between the pipes are not airtight and there are gaps.

- There is no cap (umbrella, head) that protects against the ingress of foreign objects and precipitation.

Incorrect assembly

It is necessary that the pipe protrudes above the level of the flat roof by at least half a meter. The location of it is also important. If the distance to the ridge is less than 1.5 m, the channel needs to be increased by another 0.5 m. The total length of the hose, starting from the boiler, must be more than 5 m, but at the same time be within the building codes and comply with the recommendations drawn up by the heating equipment manufacturer.

The chimney is not properly insulated

If this is not done, the exhaust gases will cool before they escape and settle on the walls of the pipe in the form of condensate.

Therefore, in areas of low temperatures (attic, cold shop, street) it is necessary to install insulated sandwich chimneys made of stainless steel. Then the temperature of the exhaust gases will be higher than the dew point, and the likelihood of condensation will be less.

Stabilizing devices

The reason for the lack of draft in a chimney located in a bathhouse in a residential building may be overheating of the outlet pipe, leading to a temperature difference and sedimentation of combustion products on the inner walls of the pipe in the form of condensate.

The stabilizing device consists of a regulator equipped with a temperature sensor and a fuse damper. When the temperature rises, the sensor gives a command to open the damper, and cold air flows through the hole, equalizing temperatures and pressures.

Reason #2 – poor ventilation

Incorrect air exchange, in one of the rooms or in the entire building, is also a factor explaining why there is no draft in the stove of a house or bathhouse. Combustion products are not removed properly and/or in full if:

- In the boiler room/room, windows are constantly or often open, which are also installed at a level significantly higher than the firebox door.

- There are strong drafts that disrupt the usual movement of gas masses through the rooms.

- There is no flow of fresh air, and the sleeve seems to “suck” it from the street so that a vacuum is not created.

The difficulty and even danger here is that these shortcomings may not manifest themselves for a long time, and then lead to the release of exhaust gas, and this is fraught with carbon monoxide poisoning.

More complex situations

Coping with the complex causes of air backflow in a furnace is much more difficult. It is possible to correct an incorrectly designed chimney, but only by rebuilding it completely, so it is very important to entrust the design to specialists. It is best that the chimney or pipe be installed strictly vertically.

Along a vertical straight pipe, without encountering any obstacles along the way, the smoke will move upward quite dynamically and escape into the atmosphere. Bends, corners, inclined or horizontal sections in the chimney will make it difficult and slow down the outflow. In addition, soot will accumulate in the corners much faster, and this will also contribute to the fact that traction may one day disappear.

The material from which the chimney is made is very important. It is best to use ceramics and bricks. The height of the pipe also matters, which cannot be less than 5 meters. Its inner surface should be smooth. Today there are various devices that can eliminate backdraft. These include :

- chimney deflectors;

- fans;

- smoke exhausters for chimneys;

- rotary turbines;

- chimney weather vanes.

The purpose of using these devices is to increase traction by creating additional air flows. The disadvantage is that in the absence of wind, all these devices are ineffective.

Reason #3 – external factors

First of all, these are atmospheric phenomena. Precipitation in the form of prolonged rains and snowfalls, fogs with increased humidity levels, squally or simply sharp winds - all this creates a pressure difference. As a result, when leaving outside, combustion products encounter strong air resistance, return back and enter the room. Their accumulation results in the deposition of soot and condensate on the walls of the hose, which means a decrease in its cross-section (throughput), up to complete clogging.

If you have poor draft in the chimney, the reasons may be the following, for example:

- a tall tree grows next to a house or bathhouse, the branches of which cover the chimney;

- in the immediate vicinity of your building some new structure has appeared; it is higher than yours and becomes a “wind support”, that is, it reflects the combustion products coming from you;

- When there is high humidity or frost, the air becomes heavier, falls down and presses inside the pipe.

It is clear that not every such factor can be eliminated with equal ease. If you can trim the same branches without difficulty, then how can you negotiate with the person living nearby? You will have to use special elements like deflectors or rotary turbines, which we will discuss in detail below.

What is backdraft

Direct draft is the process of lifting hot combustion products through the chimney and removing them through the mouth of the pipe. The operating principle of direct thrust is based on the phenomenon of gas expansion with increasing temperature, decreasing gas density and the tendency of rarefied gases to rise upward. Reverse draft, or reversal of draft, is characterized by the absence of vacuum in the channel for exhaust gases (the gas pressure in the channel is higher than in the room), combustion products are not removed from the heating unit, or even emissions of combustion products into the room are observed.

The release of hot exhaust gases back into the room is very dangerous:

- may cause a fire;

- can cause carbon monoxide (CO) and carbon dioxide (CO2) poisoning.

How to solve the problem of lack of traction

First of all, it is important to determine what exactly the reason is and what its nature is. If there is no normal air exchange at all and the problem is an incorrectly laid out smoke duct, you need to make structural changes:

- Increase the section of the hose - expand it to the level of the firebox pipe, this will increase the activity of circulation of gas masses.

- Extend the pipe - make it rise above the roof (ridge) by at least 0.5 m, and if there are trees or other buildings in the immediate vicinity of the building, then it is better by 1.5 m.

- Simplify the chimney - replace its horizontal sections with inclined ones, remove straight turns (remember, a change in direction is allowed by no more than 45 degrees).

But if this is not the case, and there is no draft in the heating boiler, what should you do then? Most likely, the lack of traction is due to errors made when installing the heating unit. In such a situation, it is necessary to identify and eliminate the defect, and then recheck the quality of air exchange.

If combustion products were initially discharged normally, but over time they began to accumulate in the channel, most likely something is simply clogging the sleeve, and this obstacle will have to be removed.

Try cleaning the chimney

This can be done both “the old fashioned way,” that is, mechanically, and with the help of chemical means.

- Buy a long brush from a specialized store or design one yourself (for this you only need a rag and a strong metal cord). Take this tool and run it along the walls of the pipe. This way, you will remove soot, condensation, frozen moisture and even debris that has accumulated inside.

- Or add a composition to the firebox that will mix with the combustion products and, when the gas escapes, take soot and liquid with it. Naturally, it is important that it is a non-toxic product. Consider the option of natural remedies, for example, when lighting with wood, it may well be the rock salt that everyone is familiar with. Or you can purchase ready-made chimney cleaning products, which are available in a wide range on the market.

So that a few years after installing the heat generator you don’t have to wonder why there is no draft in the stove at home, do not let it clog. Use a brush or chemical at least once or twice every six months - remember, regular prevention is important and often saves you from air exchange problems.

If cleaning doesn't help

If the issue is not soot or debris, or errors in installing the heat generator and smoke duct, then what is it? This means that the problem is in an external factor - in wind pressure from a tree or a nearby building, in heavy gusts of air currents.

Is there a solution to this situation? Yes, this is the installation of one of the auxiliary elements. Below we will look at each one that deserves attention.

Stabilizing devices

The reason why there is no draft in the stove in a bathhouse or in a house may be that the exhaust gases heat up the hose too much, does not create the necessary difference in atmospheres, and as a result does not have time to escape completely, but accumulates near the walls of the channel.

If this is the case, a regulator should be hung at the end of the pipe - a device equipped with a temperature sensor. It works clearly and quite reliably:

- triggers when the temperature rises (which is observed when gas accumulates) and opens the fuse valve;

- Fresh air enters the chimney from the street.

As a result, the pressure difference stabilizes - hence the name of the device, which, by the way, operates in automatic mode.

Deflectors

If there is no draft in the furnace, and the reason is wind pressure, the solution to the problem is to install one of these devices. Already from the name it is clear what it does - it deflects air masses reflected by high interference (the wall of a neighboring house, a trunk or branch of a tree). This is a kind of outlet, thanks to which exhaust gases are completely removed to the outside. Most often, such an element reduces pressure and improves the aerodynamic effect of the emission of combustion products. It is useful even during heavy gusts, which is why it is appreciated.

The high popularity explains the variety of models, among which deflectors-vanes stand out - a kind of hybrid that takes the best from both devices. Thanks to the presence of the upper glass, it perfectly captures the direction of wind flows, and due to the cap it is well protected from precipitation and mechanical debris.

Ferrum's product range includes an umbrella with wind protection, which is easily and tightly inserted into the chimney without the use of self-tapping screws. The price list can be found on the website.

Rotary turbines

If all the reasons for the lack of draft are eliminated or corrected, there is no draft in the furnace anyway, what to do in such a situation? Place this final element - a rotary turbine - at the outlet of the channel: it will forcefully push out the waste combustion products when necessary.

A screw on an electric drive is responsible for removing the gas, the timely activation of which is carried out by the activation of temperature and air speed sensors. The design of the device is modern and at the same time simple and reliable, which is why rotary turbines are popular.

Revision of the ventilation system

It is necessary to reconsider its organization, think about how to correct the shortcomings, in particular, remove drafts. This is relevant when you have gone through all the options, found out that the problem is not in external factors and not in the chimney, but you still don’t understand why there is no draft in the boiler. All you need is:

- frequently ventilate the rooms, and especially the one where the heating unit is located;

- install supply valves on the windows so that they provide fresh air in portions;

- use devices that will forcefully ventilate rooms;

- and all this should be combined with competent prevention - not only with cleaning the pipes, but also with heating the entire system. It is also necessary to carefully monitor the performance of all devices such as rotary turbines or deflectors.

Correcting the operation of the ventilation system

Natural ventilation helps prevent the smell of smoke in the room. You can do this in several simple ways:

- Regular ventilation of premises (bedrooms, as well as the room in which the heating unit is installed);

- Installation of special wall and window supply valves, which will ensure uninterrupted flow of fresh air into the room;

- Installation of specialized forced ventilation systems. This decision should be made if previous methods have proven ineffective.

Thus, it is quite possible to eliminate the backdraft effect. This issue needs to be resolved in several stages:

- Analysis of the operation of the heating unit for the presence of a reverse draft effect;

- Identifying the causes of this problem;

- Selection of an effective elimination method taking into account the cause.

If there are minor problems, you can solve the problem yourself. If the problem is in the design of the chimney itself or in the ventilation system, then it is better to entrust the solution to the problem to a specialist.