- Brown coal is easily recognized by its brown color.

This “young” geological formation has a low combustion temperature due to the fact that it contains a large amount of water and volatile compounds. The moisture content can reach 30-40%, and combustible carbon levels - from 50 to 70%. Such fuel cannot be stored outdoors. Evaporation of water leads to a decrease in the density of the material - coal turns into ash. Most often it is used in subsidiary farms, and also as fuel for a heating boiler. Thus, the heating boiler "Kupper CARBO" is designed to operate on solid fuel. The device is equipped with a movable grate, which allows you to “shake” the coals during operation, and in the event of an accident, the coals are dumped into a large ash box. - Lignite is essentially a type of brown coal. This is a softer material in structure, the amount of water in which can reach 45%. Used in power plants, not suitable for home use.

- Coal is valued as a fuel and is widely available.

Formed in deeper layers of the earth under the influence of pressure and high temperatures. Has a dark gray or black color. The moisture level does not exceed 12%, and the amount of flammable substances - from 75%. Excellent for heating stoves. The specific heat of its combustion is approximately 5.5 thousand kcal/kg. - Anthracite is found even deeper in the ground and differs in appearance from coal with a metallic sheen. It is denser and contains up to 97% carbon, which is why it burns well, but ignites only at high temperatures. It releases even more heat during combustion - up to 9 thousand kcal/kg. It is characterized by smokeless combustion and does not sinter.

When purchasing a stove, be sure to pay attention to the manufacturer’s recommendations: what type of fuel is best to use. It is also worth finding out the cost and possibility of supplying coal suitable for the selected equipment model in your region.

For intensive combustion of such fuel, the flow of oxygen is very important; for this purpose, Teplodar furnaces and boilers have an air circulation and afterburning system.

Is it possible to fire a stove with charcoal?

Coal is used to fire stoves and boilers - stone, wood and brown. Hard coal has the highest energy value, brown coal has the lowest energy value. Wood is less often used as the main fuel material, although its specific calorific value is higher than that of firewood or fuel briquettes.

The benefits of charcoal are as follows:

- During the combustion process, no unpleasant odors or smoke are released.

- Does not contain hazardous components.

- Has a high calorific value.

- Burns longer than other fuels.

- Does not crumble during transportation.

Despite all the advantages, fuel has a significant drawback - high cost. So, for 1 kg of charcoal you will have to pay twice as much as for the same volume of hard coal. You can reduce the cost of purchasing raw materials by making them yourself. To produce 1000 kg of charcoal, you will need to burn 10 cubic meters. m of wood.

It is possible to use charcoal to kindle heating equipment, but it is not economically profitable.

Types of coal

Such fuel is a rock consisting of a carbon compound and non-combustible components that, when burned, form ash. In different regions there are deposits with different amounts of impurities.

Depending on the level of specific heat of combustion, humidity and age of impurities, the following types of fuel are distinguished:

Lignite

A young type of coal with a specific calorific value of no more than 2.8 thousand kcal/kg. The raw material has a loose structure and a high percentage of ash formation. Lignite ensures the operation of industrial facilities - plants, factories, power plants, but is poorly suited for domestic use as fuel.

Brown coal

Product of the transition phase between black lignite and coal. During the combustion process, it forms a large volume of ash and coking derivatives. The calorific value of the fuel is 5 thousand kcal/kg. With an average humidity of 50%, the raw material is used for industrial boiler houses and chemical production plants. Due to the rapid clogging of the chimney system and heat exchanger, it is not recommended to burn household stoves and boilers with brown coal.

Coal

High-quality fuel with a calorific value in the range from 5 to 5.7 thousand kcal/kg. It is an intermediate link between brown coal and anthracite. It contains about 70% carbon and only 3% ash. Due to low humidity (20%), the raw material is not used for gas generating units, but is suitable for most models of household boilers and stoves.

Hard coal is divided into two groups:

- Long flame. The fuel is suitable for most domestic heating installations, provides a high flame and long-lasting combustion, and does not require additional blowing. You can use a small amount of wood or wood chips to light it.

- Low caking. The raw materials are suitable for heating a private home, bathhouse or industrial facilities. It is characterized by high thermal conductivity and lack of caking. The combustion process takes place without flame or smoke.

Anthracite

The best type of fuel raw material with a dense structure and rich black color with a calorific value from 7.1 to 9 thousand kcal/kg. At a relatively low level of humidity (7%), anthracite forms a small amount of ash, which is removed from the heating equipment along with gases. It comes in different sizes: small as a seed, medium as a pea, and large as a fist.

As a result of the release of a large amount of heat, heating of rooms with anthracite occurs quickly and efficiently.

Useful tips

It is often difficult to light the stove after a long break, for example, at the beginning of the summer season. After a long period of inactivity, it is damp and cold. In this case, you need to know that such a stove needs to be melted slowly and gradually, otherwise cracks in the material are guaranteed. Moreover, they can not be detected immediately, but after a couple of years.

Correct ignition looks like this:

- It is necessary to ensure a normal flow of oxygen, as well as smoke output. It is necessary to warm up the smoke channels of the stove and the chimney just so that cold air does not accumulate in the chimney, since it prevents the escape of smoke, which moves in the opposite direction and fills the house.

- To eliminate this undesirable option, start kindling with small portions of dry firewood. A medium-intensity flame should burn quietly, and smoke should be produced to a minimum. Afterwards you can increase the intensity.

- A common problem is that at the beginning of the kindling the flame goes out. Before lighting the stove, you need to check the stove's smoke duct and chimney to ensure everything is clean and free of obstructions. Do not under any circumstances speed up the process by adding flammable substances. You just need to close the vent and wait for the chimney to clear, starting the kindling with thin, dry wood.

If the chimney becomes clogged, do not immediately try to disassemble the stove. It is not so easy. Sometimes it is easier to build a new one than to correct the flaws in the old one. In any case, the help of a specialist is required. A simple way to solve the problem is to flood the stove slowly, checking the air outlet system. If everything is normal here, then the cause may be fuel. It is better to prepare firewood in advance.

Finally, a few secrets for stacking firewood. Thin splinters or paper should be located below the firewood itself. The firewood must be dry , stacked so that there is a small distance between them. This is done to ensure an even flow of air to the firewood and smoke exit through the chimney. Fill no more than half of the total volume of the firebox. And one more tip: practice more often. Along with experience will come knowledge of how to properly light a stove in the house.

What kind of coal burns for the longest time?

Often, long-flame coals are used to heat private homes, which are suitable for any type of solid fuel boilers, stoves and fireplaces. This is due to their long combustion process, rapid combustion and high calorific value. Charcoal for the firebox is easy to use and burns for a long time due to the formation of a flame with long tongues.

The combustion process of one load of fuel lasts several hours and contributes to the release of a large amount of thermal energy.

In addition, it is cheaper than anthracite, so it is used as the main fuel for heating government buildings. Marked with the letter "D".

How does a coal boiler work?

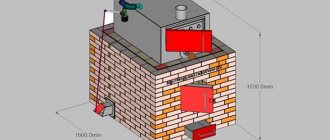

What is a coal boiler? This is a simple installation that consists of two compartments. Coal is placed in the upper firebox. After it burns out, ash and slag remain, which fall into the lower compartment and are removed from there as necessary. Between the chambers there is a regular grate made of durable cast iron.

Such furnaces can be additionally equipped with sophisticated automation, which allows the unit to switch to offline mode and control the draft. If there is no automation, coal stoves operate using natural circulation. The first type of device has several operational advantages, but

Long-burning furnaces are much larger than simple devices.

Automation works extremely simply. Thanks to it and the operation of the fan, it is easy to control the flow of oxygen into the firebox. The more it is, the hotter the coal burns, and the faster the fuel burns, giving off the maximum amount of heat. Restricting oxygen access leads to the opposite effect. The fuel burns more slowly, the amount of heat released decreases, but the burning time of the coal increases.

The heating temperature is regulated by a special temperature sensor. The boiler operating modes can be programmed. If the set temperature is reached, the sensor is triggered and turns off the fan. At the same time, the oxygen supply decreases and the furnace burns out more slowly. When the temperature drops, the fan turns on and begins to intensively pump oxygen into the firebox. The coal is actively burning again. If you take into account such features of the operation of a solid fuel boiler, it becomes clear when and how to put coal in the stove.

Improved combustion process

The intensity of fuel combustion in the stove is regulated by the volume of air entering the fuel compartment. You can properly regulate the air exchange in the firebox using a blower and a viewer.

The intensity of combustion can be determined by the color of the flame. Too much air results in a white flame and a humming furnace, while too little air results in a red flame and black smoke.

Normal combustion mode is an orange or golden flame with transparent smoke.

To improve the fuel combustion process, it is necessary to adjust the chimney view. Insufficient opening of the view leads to the penetration of carbon monoxide into the room, excessive opening leads to heat loss and poor heating of the heating equipment.

The selection of the optimal combustion mode is carried out taking into account the operational characteristics of the stove or boiler, as well as the type of fuel.

Why might there be smoke?

Even if the stove is heated correctly, plumes of smoke may form and enter the home. More often, this is caused by low quality coal. However, the causes of problems are:

- Clogged chimney or ducts.

- The appearance of cracks and holes in the masonry. The draft and smoke temperature are significantly reduced.

- Destruction of internal masonry or well.

If ignition is carried out in a cold firebox, smoke may appear. Soot will begin to form if several heating devices are connected to the chimney. To prevent carbon monoxide, smoke dampers must be installed.

Is it possible to leave dead coals in the stove?

Many homeowners are interested in a completely logical question - what to do with the extinct coals that remain after fuel combustion?

After finishing the fire, you need to make sure that all the coals are really extinguished and do not give off flames. Extinguished coals can be left in the fuel compartment until the next filling. They will help you quickly and easily light up an already cooled stove and reduce overall fuel consumption. At the same time, it is recommended to complete the process of heating a potbelly stove or boiler 1.5 hours before going to bed or leaving the house.

If there is no free time for the fuel to burn out, the remains are laid out in a free container and filled with water.

Ignition stages

Proper lighting of the stove allows you to heat the room evenly and at the same time avoid dangerous situations. We recommend the following sequence of steps:

- Place sheets of paper on the bottom of the combustion chamber and small wood chips on them.

- Then place dried firewood on top of the wood chips crosswise, leaving gaps between the logs. Usually birch firewood is used.

- You need to set fire to the paper, then close the firebox door and open the ash pan. This will allow the chimney to warm up due to the natural air flow.

- After the logs burn, add fine coal to the ashes. The first stack should be approximately 15 cm high. Small particles will catch fire from the ash.

- When the draft increases, the ash compartment must be closed and the air circulation system must be turned on, if it is provided for in the design.

Carry out the next filling only after the first one has completely burned. When the fuel burns 50%, you should stir it with a poker - this is necessary for uniform combustion.

What is more profitable: wood or coal?

Why is it more profitable to use coal than firewood for heating rooms in winter and organizing hot water supply?

Firewood is much cheaper than coal; it seems that it is economically profitable to use it. But is this really so?

The main parameter of choice is the calorific value of the fuel material, i.e. the amount of thermal energy that is released during its combustion.

Firewood has a low level of heat transfer in the range from 1400 to 2500 kcal. High calorific value is provided by raw materials from oak, alder and birch, low - from pine, spruce, white alder and linden.

When determining the calorific value of firewood, one should take into account its moisture level, which should not exceed 15%.

Coal of various grades is capable of releasing from 5000 to 9000 kcal of thermal energy, which is several times higher than that of firewood.

Firewood will be cheaper than coal, so 1 kW of energy obtained by burning it will also be cheap. In this case, the volume of thermal energy when burning 1 ton of raw materials will be: for coal - 6.46 Gcal, for firewood - 3.44 Gcal.

Heating a boiler with coal is beneficial for the following reasons:

- low fuel consumption;

- high heat transfer;

- burning duration.

The main disadvantage is the formation of slag and unpleasant odor during the combustion process.

The main reasons why it is profitable to heat a wood-burning stove or solid fuel boiler with wood:

- environmental safety of raw materials;

- affordable price;

- possibility of storage in bulk or boxes;

- a small amount of ash and no unpleasant smoke.

Despite its cheapness, firewood has a lower calorific value, which means burning with coal is more efficient and profitable.

General recommendations

Loading and lighting the stove correctly is not just a sign of the homeowner's skill with the fireplace. In case of efficient kindling, the efficiency of the stove will be maximum.

Before lighting wood or charcoal, factors to consider include:

- furnace structure;

- its location;

- what and how much fuel is used for kindling;

- experience in handling the firebox.

How to light a stove with wood:

The first thing you need to do is clean the cast-iron grate (grate), designed for free access of air under the fuel, and also remove all the ash from the ash pan.

This is required to ensure that air flows equally evenly to all fuel. If you plan to heat the stove with wood, then they must be dry, of the same size, 8-10 cm in diameter. Good to know: the combustion temperature of different types of wood in a stove is in Celsius.

The best firewood is birch and oak. With their help you can quickly heat a room. It is necessary to fill the internal cavity of the stove with firewood, taking into account that there should be a distance of at least 20 cm between the top of the firewood and the ceiling of the firebox. It is necessary to lay all the firewood at one time, so as not to constantly open the firebox, adding fuel and thereby cooling the fireplace.

In order for the firewood to ignite, you need to set fire to a splinter, paper or birch bark, placing it all under the fuel. The use of gasoline or similar flammable substances is strictly prohibited, so as not to deform the firebox.

Alternative fuels

Today, the most popular type of fuel used for heating residential and industrial facilities is coal. If desired, it can be replaced with alternative raw materials:

Peat

One of the most efficient types of fuel raw materials. Peat is suitable for stoves with special fuel chambers that increase draft during its combustion.

The material is produced in pieces and pressed briquettes. Peat moisture levels range from 22 to 40%, which leads to the formation of large amounts of ash. In terms of its calorific characteristics, it is significantly inferior to firewood, which is the main disadvantage.

Pellets

Fuel pellets are produced from dry biomass (sawdust, wood chips, bark and wood dust) by hot pressing. These are small capsules whose humidity level does not exceed 10%, so they are an excellent fuel for a brick or metal stove.

Unlike firewood, pellets can burn for quite a long time, releasing carbon dioxide and water. They are distinguished by environmental friendliness, safety and high calorific value.