You cannot take a steam bath without first heating the stove. Of course, if you have an electric or gas model, then you don’t need to know any special tricks for heating a sauna. It is enough to read the instructions and strictly follow all the manufacturer’s recommendations. It’s a different matter if the stove in your bathhouse is real – wood-burning. Not all novice bathhouse attendants know how to properly heat a bathhouse with such a stove. Uninformed beginners spend hours lighting a wood-burning stove, surprised that the temperature in the steam room does not rise above 40 degrees. Or they forget about the dampers, and then dangerous carbon monoxide becomes a companion to bath procedures. There is no need to make such mistakes. Let's start learning how to heat a sauna correctly!

Features of Vesuvius stoves

Vesuvius models are distinguished by the complete absence of sharp corners. The design of the stove has a round shape, which allows thermal radiation to be evenly distributed throughout the room, warming the air to the specified temperatures. The outer casing of the unit is made of all-welded steel plates. The metal thickness is 8 mm. The plates are secured with bolts. Fastening provides increased strength of products.

Thanks to the outer mesh, the stones in the oven are heated evenly. They dampen the infrared radiation of hot metal. The disadvantage of the outer mesh is dry steam. You won't be able to get a light, damp cloud without additional devices. For lovers of Russian steam rooms, it is better to give preference to models with a closed heater. Full use of an open-type heater in a Russian bath requires the additional installation of a steam generator.

The body of the Vesuvius furnace is coated with a protective silicone compound. The coating protects it from exposure to high temperatures and humidity. Some models are decorated with forged parts. Typical for models with a fireplace function. If necessary, you can hide the equipment behind a brick screen; models without complex decor are purchased.

All Vesuvius models have a standard chimney diameter of 115 mm and a combustion tunnel depth of 290 mm. This is convenient when replacing components.

The warranty period for cast iron models is 35 years.

Bath stove Vesuvius Legend

The Vesuvius Legend stove model is constructed of 3 cast iron parts. The thickness of the material is 12 mm. The joints of the fragments are sealed with ceramic cord. The operating temperature that the cord can withstand is 1200 degrees. This is enough for a sauna stove. All parts are secured with bolts. The pipe from the chimney firebox is separated by a bumper. The design allows for rotation of the flame in the firebox. This increases the efficiency of heating equipment four times. Cast iron maintains a high temperature in the steam room for a long time.

The stone net is installed outside. When heated, the stones provide uniform heat and shield the radiation from the firebox. The large mass of stones provides light steam. The humidity of the vapor cloud depends on the heating temperature and the amount of water in the tank. You can add water to the stones from above. In this case, the steam will turn out heavy and watery. The steam room warms up within an hour.

In the “Legend” series, the manufacturer produces models of stoves with forged elements.

The manufacturer provides a 30-year guarantee for the Vesuvius Legend model. The model from the “Forging” series has an external firebox. The element makes it possible to heat the steam room from the adjacent room.

Furnace Vesuvius Skif

The Vesuvius Skif model series is a budget line of the manufacturer. They are made from engineered steel. The thickness of the sheets is 12 mm. This type of steel lasts a long time. The walls do not bend outward or become deformed. The stove is made using Finnish technology. The joints are laid with heat-resistant cord. The part can withstand temperatures up to 1200 degrees. The parts are connected to each other with bolts. The firebox is remote. The steam room is heated from the adjacent room.

The stone net is installed outside. The steam turns out to be dispersed. Due to the design of the stove, it is suitable for a Finnish steam room. For a classic Russian steam room, the unit does not have enough humidity. This is compensated by the additional installation of a steam generator or pipe system. The volume of the steam room for the standard model ranges from 8 to 18 square meters.

The advantage of the Skif stove is considered to be its price. It is cheaper than a cast iron product. Warranty period 2.5 – 3 years.

Vesuvius 16

“Vesuvius” 16 – closed heater. Consists of three elements: body, firebox, pipe. The parts are secured with a bolted connection. It increases the strength of the structure. A ceramic cord is laid at the joints. The operating temperature of the wire is 1200 degrees.

The model is equipped with a sealed door made of cast iron. The design includes heat-resistant glass. The body is made of steel. The ventilated oven casing is made of textured metal sheets. They are coated with heat-resistant bronze-colored paint. The stove is heated from the room adjacent to the steam room. For this purpose it is equipped with a combustion tunnel.

Vesuvius 16 will warm up a steam room up to 18 cubic meters in size in 50 minutes. The heat-resistant glass built into the door allows you to observe the burning of firewood in the stove.

Operation of the stove-fireplace

Everyone was happy with the stove - easy to use, provides stable heat, requires little wood. True, until that moment there had been no frost, so the heating of the stove took place in the evening and that was all. An electric convector operates in standby mode and maintains the optimal temperature by morning. But, it was noticed that cast iron surfaces and fireclay in the oven give a very effective and excellent result. Even when the wood burns out, heat continues to flow from the surface of the stove. There was no tracking by time, of course, but the indicator for the author was morning. When, after opening your eyes in the morning, you touch the stove and it is still warm - this is an excellent result. I have been convinced of this more than once by the author with the Vesuvius PK-01 stove. An electric convector also brings its own convenience. It turns on when the temperature in the house drops below the set level. You don’t have to watch the stove at night and be afraid that something will happen. The oven begins to release heat almost immediately.

Another point that was noticed during operation is that the glass smokes. In this case, the author had to clean it every day to restore its beauty, although this cleaning session takes a little time, it is still unpleasant that the stove gets dirty so quickly. If you don’t pursue beauty, you can clean the glass less often, but aesthetics are still necessary. Glass smokes so quickly because the stove does not provide air supply to the glass, as in other fireplace stoves - most of them European.

Among the shortcomings, I can also highlight cast iron circles for cooking - the manufacturer could have made it much better, cast these parts with more attention to the process. The second minus, already mentioned, is that the glass smokes (not exactly a minus, but there is a valuable remark).

The firebox of the Vesuvius PK-01 device is designed for firewood of 30-35 cm. Ordering firewood of this size is not a problem at all.

As a result, the author was pleased with the choice. You have to turn a blind eye to the shortcomings because the price is not at all high, and the stove fulfills its main tasks in full. The appearance of the stove is also satisfactory. We must wait for frost, and then it will become clear how the oven will manifest itself.

Installation of the Vesuvius furnace

Installing a stove is the most important undertaking. The equipment interacts with flammable materials indoors. Fire safety standards must be strictly observed during installation. But before describing the installation process, a few words should be said about choosing a model.

The market offers the installation of metal heaters in bathhouses and stone ones. Metal models benefit from their practicality and safety. The choice of model depends on factors:

- volume of the steam room;

- type of thermal insulation;

- area of the entire bath;

- desired temperature and humidity levels in the steam room;

- heating time.

Attention!

If you decide to install the device yourself, you need to carefully read the manufacturer’s instructions. It indicates the installation features of a specific model. The first step is to prepare the floor. The furnace installation area is covered with a metal sheet, or brickwork is installed. Indentations are made by 15-20 centimeters on all sides. The top is covered with a steel sheet or a cement screed is poured.

The oven is installed on the surface, observing the indentations. They are specified in the installation instructions for a specific model.

Important! The distance from the stove to the ceiling is 120 centimeters, from the heating device to the partitions is at least 32 cm.

It is possible to reduce the distance by several centimeters if there is additional protection in the form of a metal sheet.

When installing the stove, you should take into account the direction of the heating chamber. Models may involve loading fuel from adjacent rooms. This condition complicates installation, but provides more advantages when operating the furnace.

The next step is the installation of a mounted tank. It is installed in an adjacent room, or, in accordance with the instructions, for a specific stove model.

The heat exchange system consists of the following parts:

- heat exchanger;

- fittings;

- remote tank;

- connection elements.

When installing a heat exchange system, you should not use flexible plastic or rubber liners. In order to avoid freezing of water in the system in winter, a drain valve is built into the lower part of the fitting.

The last step is to install the pipe. It must be at least 5 meters. It is worth paying attention to the chimney pipe. It is made from fire-resistant materials. The height of the pipe must exceed the roof level of the nearest houses.

Start the oven only after thoroughly checking all connections and fasteners. During the first heating, an unpleasant smell of burning and chemical industry products may be felt. These are burning oils that got into the unit during the manufacturing process. It should be heated for an hour. During this time, the tank, heat exchange system and other parts of the furnace are checked.

Important component No. 3 is the correct combustion algorithm.

- We construct a “seed” from 4 small, approximately identical logs, wood chips, shavings and paper.

We place two logs parallel to each other on the grate at a distance of 10-15 cm. Between them is a crumpled sheet of paper, which we cover with wood chips or shavings. The “seed” is completed by two more logs laid diagonally on top.

- We set fire to the “seed”.

Using a match or kitchen lighter, light the wad of paper in the “seed”. You cannot use flammable liquids to speed up ignition: gasoline, diesel fuel, kerosene, xylene, acetone, etc. If the firewood is damp and cannot be ignited, you can use a dry alcohol tablet. We wait for the characteristic flame noise to appear in the stove, close the firebox door and cover the vent (not completely).

- We throw firewood into the stove.

The “seed”, of course, will not be enough to light the stove. Therefore, to continue combustion, you will have to add firewood from time to time. The first time this is done 10-15 minutes after igniting the “seed”. We open the firebox door, level with a poker everything that remains of the “seed” and place the firewood in approximately 2/3 of the volume of the stove firebox. In the future, a new portion of firewood is laid when the old one burns out - approximately once every 1-1.5 hours.

- We complete the heating of the bathhouse.

In winter, the sauna is heated for at least 5-6 hours, in summer it is faster - on average 3-4 hours. When the bath has heated to the required temperature, the firebox can be finished. We wait for the last portion of firewood to burn out, open the firebox door and check for bluish flames above the coals - signs of the presence of carbon monoxide. If everything is in order, close the vent, smoke valve and firebox completely.

After everything has been done, we open the doors of the steam room and the window so that the bathhouse can be ventilated. 15 minutes is enough for the bathhouse to be filled with fresh air. After that, close everything except the window. The bath should last for about two hours. Don’t be afraid, during this time it will not have time to cool, but the heat will become soft, uniform, and the steam will become light. Afterwards we close the window and begin the bath procedures.

Heat exchanger for Vesuvius furnace

The heat exchanger for the Vesuvius stove looks like a geometric stainless steel container. Material thickness 1 mm. It is designed to heat water in rooms adjacent to the steam room. The heat exchanger is attached to heating and water supply systems using a fitting. To prevent depressurization of welding seams, water is poured into the heat exchanger before starting the system.

Plastic pipes must not be placed close to the heat exchanger. The material is not able to withstand high temperatures. A metal corrugated pipe is used for the tank.

“Russian Steam” and “Premium” series

Vesuvius "Russian Steam"

With this miracle stove, the air will be like in a real Russian bathhouse: with light dry steam and a relatively low temperature (60-70 degrees). The body has a mesh heater around it; in the upper part of the combustion chamber there is a closed heater, where the temperature rises to 400 degrees or higher, making the steam “light.” The steel heater is perfectly suited to imitate the atmosphere of a Russian steam room. Better than the wood-burning stove Vesuvius “Russian Steam” is only a brick stove, professionally made by a stove maker and heated by an equally skilled craftsman.

Recommendations for use

The manufacturer of equipment for Vesuvius steam rooms prescribes recommendations for operating the device in the instructions for the models. You should familiarize yourself with them in advance and strictly follow them. This affects the service life of the device and the company’s warranty obligations. When working with company equipment, it is prohibited:

- Use peat, coke, gaseous and liquid materials as fuel. This does not comply with fire safety regulations. The combustion temperature may exceed that for which the device is designed.

- Firewood must not exceed the permissible dimensions of the firebox.

- Do not use the device if the tank is not filled with water.

- Install in residential areas for heating.

- The chimney can only be closed when the fire has completely gone out.

- Do not burn soot from the smoke duct.

- Make changes to the original design of the furnace.

Important! To prevent the destruction of cast iron, you should familiarize yourself with the rules for laying stones. You can water the stones for steam generation at a minimum interval of 5 minutes.

If these simple requirements are met, the company undertakes to eliminate all defects during the entire warranty period or replace the device free of charge.

Important component No. 1 is good firewood.

The choice of firewood determines how quickly your sauna will be heated and how hot the sauna will be. Preference should be given to hardwood: hornbeam, oak, ash, maple. These rocks have the highest heat transfer, that is, they release the greatest amount of heat during combustion. The calorific value of wood from fruit trees (apple, pear, cherry) is somewhat lower, but it also provides good heat in the oven. The calorific value of deciduous trees is even lower: birch, alder, etc. Despite this, deciduous trees are used most often due to their availability and low cost. Coniferous firewood is the least popular choice for heating a sauna stove. This wood produces little heat; in addition, when burned, it produces a lot of soot, which settles in the chimney and on stones. Another important characteristic of firewood that is also worth paying attention to is humidity. The smaller it is, the better the sauna will be heated. Ideally, the moisture content of the firewood does not exceed 20%. Freshly cut wood has a moisture content of 33 to 50%, so it burns poorly. To dry such firewood, it is enough to let it sit for some time in a dry, well-ventilated room.

Now let’s figure out what kind of wood it is better not to heat the bathhouse with. Not suitable for this: old boards and logs - due to the unpleasant smell when burning. Rotten firewood burns poorly and produces a lot of ash. Wood impregnated with chemical compounds releases substances hazardous to health during combustion.

Reviews

The quality of Vesuvius stoves depends on the model and compliance with operating rules. Skif class models are a budget option. They require careful handling and periodic maintenance. Cast iron stoves “Legend” are highly resistant to temperature changes. Let's consider the reviews.

Banshchikov Zakhar, 53 years old, Moscow.

I have a stove installed - a Vesuvius Legend fireplace made of cast iron. It's been standing for three years now. There were no changes in it during use. Once a year I paint the grille to prevent rust. Heat for a long time. There are no other complaints.

Kravtsov Ilya, 30 years old, Kamyshin.

I bought a Skif stove. It burned out after a year and a half of operation in two places.

Bondarenko Roman, 30 years old Nizhny Novgorod.

Vesuvius "Skif" 28. They provide a two-year guarantee. In the third year, three walls burned through. You can't lay it with bricks. The walls are warped by the waves. The far support burned out. The unit is only suitable for waste.

Problems with holes forming in the stove body may be due to improper placement of stones. A dense, mosaic distribution of stones without ventilation leads to the formation of holes in the walls of the body. The second cause of the problem is frequent watering of stones with water in order to create a steam cloud. The interval between watering should be five minutes. Otherwise, frequent changes in temperature and humidity lead to the destruction of the cast iron material.

Reviews about Vesuvius sauna stoves are different. The quality of the model depends on the material from which it is made and the nuances of operation. The cheapest models of the “Skif” line are considered the “weakest” in the line. These are simple units. They are suitable for those who rarely heat the bathhouse and do not bring it to high temperatures.

How long the stove will last depends on the installation. Incorrect installation can reduce the service life of the system several times.

Important component No. 2 is oven preparation.

Now that the firewood has been selected, you can think about lighting the sauna stove. First you need to prepare it - we will melt it later. We follow the instructions:

- We clean the grate and ash chamber (ash pan) from ash and coals;

- Wash stones in clean water;

- We determine whether there is draft (chimney permeability) necessary for carbon monoxide to escape from the stove. To do this, open the smoke valve in the chimney, the firebox and ash doors. Then we bring a lit match into the firebox and watch where the flame rushes. If it goes up, that is, it is drawn into the chimney, then everything is in order - there is draft. You can start kindling. Otherwise, you will have to first clean the chimney, since it is prohibited to heat the bathhouse without draft - the stove will “smoke”.

Do you want a gift?

80% of buyers select the wrong equipment. Leave a request for a FREE selection of a fireplace, stove, chimney taking into account all your parameters/needs. You will receive advice from a specialist who has been working in the furnace business for 15 years. AND 500 RUBLES AS A FREE!

Series “Rusich”, “Lava”

These 2 series include 24 and 27 modifications, respectively, installed in steam rooms from 6 to 30 m3. The internal working part again remained unchanged, as did the thickness of the metal walls. But the rectangular or cylindrical heater here is open only at the top; on the sides it is fenced with a convection casing with grooves made for the passage of air.

“Rusich” or “Lava” is well suited for those people who cannot tolerate the direct heat emanating from the stove in the form of infrared radiation. The barrier in its path is the convection casing, and the heater is ventilated through it.

In fact, all furnaces have the same body (“Rusich” is rectangular, “Lava” is round). A variety of modifications is achieved through various configuration options, which include:

- an external channel for the firebox from the adjacent room;

- fireproof and panoramic glass.

According to company representatives, purchasing and installing a stove from one of these series will provide the fastest heating of the steam room, while the temperature of the heater can reach 350 °C. So the presence of an outer casing in the design is very useful here.

Results

Despite the apparent simplicity and uncomplicated design of sauna stoves, they have significant differences in design, design and performance. But any of them can be distinguished for their own features inherent only to this model. Based on consumer preferences:

- The best sauna stove for the price – Vesuvius Optimum HF

- The best stove with a modern design - Harvia

- The best stove in terms of price/quality ratio - Vesuvius Skif

- Best innovative stove - Kastor

- The best wood stove in terms of service life - Hephaestus

- The best powerful stove – Vesuvius Legend

- The most time-tested stove Termofor Tunguska

All that they have in common is that with their help you can get healthy conveniently and without much hassle and enjoy such a useful and pleasant process as visiting a bathhouse.

What do they say about Lava-12?

These Vesuvius stoves generally receive good reviews. This is primarily due to the quality of the frame. According to buyers, it can withstand heavy loads. The device reaches its maximum temperature quickly. If necessary, the converter can be removed and cleaned. The model's remote tunnel is wide.

Another advantage is a high-quality ash pan, which rarely breaks. However, the bottom cover can sometimes become deformed. The model has a cutter with four holes. The afterburning chamber of the furnace is wide, but the model weighs a little. The valve used in the device is durable. If you believe the opinion of buyers, the gate can be removed independently. The manufacturer recommends using this stove in a steam room with an area of no more than 12 square meters. meters.

Cast iron stoves

Structurally, these units are almost identical to their steel “brothers”. A similar combustion chamber with an ash drawer, a two-pass smoke circulation and the presence of an open-type heater fenced with a mesh. The difference is that the firebox is a 12 mm thick cast iron with external ribs. They perform 2 functions: they give rigidity to the body and provide intense heat transfer.

The Vesuvius cast iron stove is produced in two names - “Legend” and “Hurricane”. Accordingly, modifications 11 and 3 are intended to serve steam rooms with a volume of 8–30 m3. The design is as varied as that of steel heaters - different types of glass, a remote tunnel and a tank for heating water for washing.

Choosing a stove for a bath - manufacturers

The range of stoves is truly impressive - in addition to many Russian manufacturers, several foreign brands sell their products. Finnish wood-burning stoves for baths are in particular demand among consumers, and there is a clear explanation for this - long-term traditions of use and production technologies refined over the years make them unusually convenient and durable.

Among the most noticeable brands on the Russian market it is worth noting:

- Vesuvius

- in the ranking of the most successful wood-burning stoves for baths would take one of the first places. They are distinguished by the quality of manufacturing of parts, the density of mating components, and not the highest price. Vesuvius steel or cast iron wood-burning stoves will decorate any bathhouse; - Wood-burning stoves Harvia

- they began to be imported and sold for baths even when current manufacturers from Russia did not exist; - Termofor

is another well-known domestic manufacturer. Wood-burning stoves for Termofor baths are supplied in a wide range and price ranges; - Feringer

- produce stoves made of steel, lined with natural stone.

Model "Lava-16 SV"

These Vesuvius stoves have good reviews, but it should be borne in mind that they are suitable for rooms whose area does not exceed 15 square meters. meters. The lower frame of the model is made of stainless steel as standard. Many buyers praise this oven for its high-quality convector. It is installed on the model immediately above the frame. If necessary, you can clean the ash pan yourself.

The back wall of the stove is low. Three hole cutter. In this case, the design does not provide for a dispenser. The stove's vent is small. Installing a chimney is quite simple. According to the owners of the model, the valve rarely overheats. During installation, the chimney apron should be very tight. Today a stove costs about 33 thousand rubles.

Advantages

The safe operation of furnaces is achieved by reliable bolted or welded connections of elements and assemblies. The technological joints of the fireboxes are sealed with a ceramic seam (the products can withstand temperatures of 1200 °C without breaking the seal). Universal stove options are recommended for use in Russian or Finnish baths.

The main advantages of Vesuvius stoves are described:

- ergonomic design;

- stylish design;

- increased efficiency - efficiency factor;

- specialized self-cleaning system;

- durable heat-resistant glass on the doors;

- increased fire safety.

Against the background of the above features, an additional advantage is the self-cleaning system of the glass door, thanks to which it is constantly kept clean.

The manufacturer launched 8 bath models on the market:

- "Rusich";

- "Scythian";

- "Vertical";

- "Lava";

- "Optimum";

- "Premium";

- "Russian steam";

- "Legend".

“Lava” - fireplace type sauna stove

The company's staff guarantees the buyer accelerated heating of a 40-kilogram mass of stones to 350 °C. After the end of the heating session, the stove maintains the temperature in the steam room for a long time. An accelerated heating firebox was specially developed for this model. Structural steel with typical values of 6–8 mm is used. In some places the thickness reaches 12 mm.

The combustion intensity of the selected fuel (dry firewood) is regulated using a movable ash pan. When the structure is carefully pulled out, the intensity of the flame increases. With proper selection of the location when closing the ash element, the user achieves smoldering firewood without extinction.

Series "Skif"

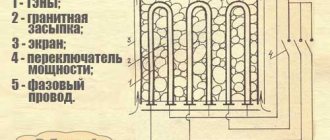

The difference from “Optimum” here is expressed in the configuration of the partition, which forces the flue gases to transfer heat more efficiently, bending around it. In addition, the upper and rear walls of the combustion chamber are reinforced; the metal thickness there reaches 8 mm. At the same time, as planned by the designers, the side walls “lost weight” to 4 mm. By the way, stainless steel is not used in the manufacture of Vesuvius stoves, hence the reasonable price of the products. The structure of the Skif furnace is shown in the diagram:

From the diagram it is noticeable that the structure of the ash pan and heater remained the same: respectively, a drawer and a cylindrical mesh for holding stones. The series includes 5 lines of stoves, each of which is designed for a specific steam room size, ranging from 6 m3 to a volume of 40 m3.

Bath heaters Vesuvius "Skif" cover the widest range of thermal powers, the series includes the largest number of stoves - 36.

Wood-burning stoves "Skif" are equipped with an expanded package of options. This includes a hanging tank for heating water with a capacity of 30 liters, heat-resistant and panoramic glass instead of a blank loading door. Thanks to the combustion chamber pushed forward, it is possible to heat it both directly from the steam room and while in an adjacent room.

Advantages of cast iron stoves

- cast iron is an alloy of iron and carbon, it is safe and environmentally friendly;

- does not deform when temperature changes, which is very important when working in external cladding;

- has high strength, corrosion resistance and, therefore, a long service life (30 years or more);

- has a relatively light weight compared to brick (about 60 kg) and does not require a foundation or other reinforcements;

- quickly heats the room with continuous combustion and then slowly releases heat into the steam room;

- quickly and easily installed, and after which it is immediately ready for use;

- compact and powerful with excellent thermal conductivity properties;

- sealed and fireproof;

- easy to disassemble, dismantle and move;

- retains heat for up to 10 hours with a single load of firewood;

- Various models with a decorative stove facade, as well as simple DIY decoration using brick or ceramic tiles, allow it to fit into any bathhouse interior.

Warning: cast iron is not tolerant of thermal shocks and may burst if there is a temperature difference of more than 80 °C between adjacent sections of the furnace, so extremely careful use or additional lining of the body is recommended.

The modern market for cast iron foundry products offers a variety of models of cast iron stoves, differing in technical characteristics and external design. In this diversity, it is sometimes difficult to determine which cast-iron stove is best to use in a particular bath room and what parameters should be used to select the product first of all?