The efficiency and safety of a stove, fireplace or heating boiler directly depends on how competently the chimney was installed in a private home. If earlier this depended on the professionalism of the stove maker, today it is a matter of wise choice of the owner of the house. Sandwich chimneys, which can be installed independently to any type of heating equipment, are in great demand, and deservedly so. It is important to choose the right pipes and install them, observing all the necessary conditions.

Bathhouse projects

Number of projects 681

- 1 room

- 1 bathroom

Bathhouse project "Vyatka"

- To favorites

- 31.7² Total area

- 7 x 6m Building area

from 765,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bathhouse project No. 14033

- To favorites

- 33² Total area

- 5 x 8m Building area

from 3,737,325 rub.

Construction time individually

- 2 rooms

- 1 bathroom

Project Banya Dobrynya-2

- To favorites

- 72² Total area

- 8 x 6m Construction area

from 846,850 rub.

Construction time individually

- 1 room

- 1 bathroom

Bani Afonya project

- To favorites

- 43² Total area

- 9 x 7m Construction area

from 580,500 rub.

Construction period 35 days

Bathhouse project Standard No. 3

- To favorites

- 15.3² Total area

- 4 x 4m Building area

from 470,000 rub.

Construction time individually

- 1 room

- 2 bathrooms

Bani Toliman project

- To favorites

- 40.5² Total area

- 8 x 7m Construction area

from 546,750 rub.

Construction period 28 days

- 1 room

- 2 bathrooms

Bani Avisso project

- To favorites

- 142.57² Total area

- 9 x 19m Construction area

from RUR 1,924,695

Construction period 74 days

Available at the exhibition

- 1 room

- 1 bathroom

Bathhouse project 4x6m

- To favorites

- 24² Total area

- 6 x 4m Construction area

from 508,000 rub.

Construction period 15 days

- 1 room

- 2 bathrooms

Project Baths 11B-B

- To favorites

- 27.5² Total area

- 5 x 8m Building area

from RUR 436,590

Construction period 18 days

- 3 rooms

- 2 bathrooms

Bathhouse Kamelok project

- To favorites

- 83.65² Total area

- 6 x 10m Construction area

from RUR 1,129,275

Construction period 48 days

- 1 room

- 1 bathroom

Bathhouse Mylnya project

- To favorites

- 29² Total area

- 5 x 6m Construction area

from RUB 391,500

Construction period 30 days

- 2 rooms

- 2 bathrooms

Bathhouse project No. 12008

- To favorites

- 84² Total area

- 6 x 9m Construction area

from RUR 2,120,438

Construction time individually

- 1 room

- 1 bathroom

Project Bathhouse Golden Cone

- To favorites

- 121² Total area

- 10 x 15m Construction area

from 1,633,500 rub.

Construction period 64 days

Project Baths made of timber AR-037

- To favorites

- 17² Total area

- 5 x 4m Building area

from 229,500 rub.

Construction period 90 days

- 1 room

- 2 bathrooms

Bathhouse project "Riga"

- To favorites

- 81.5² Total area

- 12 x 10m Construction area

from 1,630,000 rub.

Construction time individually

- 1 room

- 1 bathroom

Bathhouse Dubok project

- To favorites

- 11² Total area

- 4 x 3m Building area

from 148,500 rub.

Construction period 15 days

- 1 room

- 1 bathroom

Bathhouse Zigzag project at Dacha

- To favorites

- 72² Total area

- 7 x 8m Construction area

from 972,000 rub.

Construction period 35 days

- 1 bathroom

Log bathhouse project AR-029

- To favorites

- 74² Total area

- 7 x 14m Construction area

from 999,000 rub.

Construction period 90 days

- 2 rooms

- 2 bathrooms

Bath Antoine project

- To favorites

- 115² Total area

- 11 x 7m Construction area

from 1,552,500 rub.

Construction time 62 days

Bathhouse project "Russian Izba"

- To favorites

- 26² Total area

- 5 x 6m Construction area

from RUR 362,489

Construction time individually

View all projects

Thanks to modern technologies, a sandwich pipe for a bathhouse has appeared on the construction market. It is increasingly being chosen when installing a chimney from a stove. Therefore, it is worth understanding the advantages, design features and use of the product. The information will allow you to communicate on equal terms with managers, engineers and craftsmen of a construction company during the order and installation work on the installation of a hollow channel that discharges flue gases into the atmosphere.

Pipe for assembling a stove smoke exhaust sandwich duct Source o-trubah.ru

Design Features

Modern channels for removing smoke from sauna stoves are assembled from pipe sandwich parts. The products are popular among owners of country houses, despite the large selection of materials for creating chimneys.

The sandwich pipe is a double-circuit design. It consists of the following main parts:

- internal chimney;

- layer of thermal insulation material;

- protective decorative shell - an external contour in the form of a pipe product of a larger diameter compared to the internal chimney.

The double-circuit pipe has become widely used by homeowners when installing chimneys. It came to replace single-circuit similar products made of 0.5 mm thick steel. After all, a steel pipe product is not suitable for installing a smoke exhaust duct outside a building. The reason for this is its design, which does not retain heat in the off-season and winter period of the year. In cold weather, condensation forms in a steel channel with one circuit due to a sharp temperature difference. Therefore, the traction effect in the chimney decreases, and even traffic jams appear.

Design features of a thermopipe with two casings Source pechnoy.guru

The internal contour of the pipe sandwich product for removing combustion products is made of stainless steel. Its one-piece design is manufactured using TIG welding. It allows you to make neat, thin seams.

The outer casing is also made by welding from stainless or galvanized steel. The second type of metal allows manufacturers to produce more affordable products. In cooperation with a construction and installation organization, you can also order a chimney made of a sandwich pipe with an outer casing coated with enamel in the required color.

The thermal insulation layer in a product with two circuits is created from a material that is resistant to fire. Manufacturers use high-density mineral wool made from basalt raw materials. Typically the thickness of the thermal layer is 25-100 mm. Design engineers select this parameter taking into account the specifics of installation work and the conditions of use of the chimney.

Chimney with a thermal insulation layer made of basalt mineral wool Source festima.ru

The ends of the sandwich parts for the smoke exhaust duct are made in the form of sockets and narrowed ends. This interface system simplifies the installation process and allows elements to be tightly joined. To increase the strength of joints when installing a chimney, special clamps are additionally used. Depending on the design features of the smoke exhaust channel and the work conditions, parts connected to each other and other elements of the furnace system using flanges can be used.

Crimp type clamp for sandwich chimney Source ytimg.com

Main settings

The advantage of store-bought models of galvanized steel chimneys is that manufacturers produce a wide range of sizes. In addition, among the factory products you can find double-circuit, thermally insulated, corrugated, with increased flexibility and single-circuit. When making a homemade chimney, you have to limit yourself to only single-circuit pipes. In order for the smoke removal system to work effectively, the following parameters should be taken into account:

- Pipe section size. In order for smoke to come out of the firebox through the chimney, you need to choose the correct pipe diameter. A pipe that is too thin does not provide the required level, which can result in backdraft. A large diameter chimney, on the contrary, releases combustion products into the atmosphere too quickly, therefore increasing fuel consumption and energy losses. The more turns there are in the smoke exhaust duct configuration, the thicker the pipe should be. In most cases, a galvanized steel pipe with a diameter of 100 mm is suitable. Recommended chimney pipe cross-section for boilers of different capacities:

- Material. Chimney pipes are made of sheet metal. This material must be highly resistant to corrosion, moisture and high temperature. Therefore, simple galvanized steel is not enough, since the temperature in the chimney of solid fuel stoves and fireplaces exceeds 500-700 degrees. Therefore, for the manufacture of pipes, metal with increased heat resistance and corrosion resistance is used.

- Wall thickness. The service life of a chimney made of a steel pipe depends on the thickness of the metal used. Sheets of steel with a thickness of 0.25-1.0 mm are used. The higher the temperature of the gases leaving the furnace, the thicker the metal needs to be.

Important! A sheet of galvanized steel measuring 2500x125 mm in construction stores costs about 600 rubles, with proper cutting, one sheet produces 8.75 m of pipe with a diameter of 100 mm, the cost of 1 m is approximately 68 rubles, which gives 60% savings!

Advantages of chimneys made from sandwich channels

Metal pipelines have been used for decades to remove smoke from furnace devices. This is explained by their optimal cross-section for the passage of combustion products. They have a smooth surface inside that does not interfere with the removal of gases. There is less soot accumulation on their smooth walls. In addition, installation work is carried out using large parts. Therefore, installing a sandwich chimney is simpler and faster compared to laying a brick channel.

The use of double-circuit products for smoke removal also has the following advantages:

- the outer surface of the pipes heats up less due to the presence of a heat-insulating layer between the two circuits;

- the operating temperature of the exhaust gases can reach 850 degrees;

- the level of fire safety of the building increases;

- There is no noise when removing smoke.

The use of stainless steel in the manufacture of sandwich pipes increases the resistance of chimneys to corrosion. After all, its occurrence is well facilitated by the exhausted aggressive gases.

Chimney sandwich parts made of stainless steel have high corrosion resistance Source roof-tops.ru

Compared to conventional metal chimneys, channels made of sandwich pipes have improved technical characteristics and provide a higher level of fire safety. Thanks to the design, it was possible to achieve minimal condensation formation when removing smoke through dual-circuit products.

The sandwich chimney is characterized by stable draft due to a more even internal temperature along the entire length of the channel. In addition, the external circuit does not heat up much. Therefore, upon contact, a person will not receive a burn, with the exception of contact with the initial section of the chimney near the heating device. Indeed, at this point, even the outer thermally insulated wall of the structure becomes very hot. Therefore, it is dangerous for humans and can even cause a fire in the bathhouse.

The lower, very hot section of the sandwich chimney near the stove Source topijar.ru

Another advantage is the service life of the chimney sandwich pipe. Its durability is 15-20 years if installation technology is followed.

Waterproofing the passage

After completing the laying of the cap, you can install the umbrella and begin waterproofing the pipe passage through the roof.

Approximate diagram of chimney waterproofing

Waterproofing is a very important point in the design of a chimney, and the durability and efficiency of its operation depend on it.

The distance created between the pipe and the roof must be covered with an apron. Most often, roofing material is used for these purposes, which is fixed to a sealant.

On top of this layer of waterproofing is an “apron”, which is made from a wall profile or from a special waterproofing tape. It is also attached to the roofing material using sealant, and fixed to the pipe with a strip designed for this purpose.

"Apron" for the chimney pipe

Characteristics of sandwich pipe

Sandwich chimneys are made with the same appearance. The production of these products brings good income. Therefore, unscrupulous manufacturers have appeared that produce low-quality products. They don't care about reputation. Their goal is to obtain maximum profit. Therefore, to create a durable and efficient chimney, you need to seek help from a specialized construction and installation company with an unblemished reputation that cooperates with reliable sandwich pipe manufacturers.

Metal fabrication

Professionals pay special attention to the quality of the metal of sandwich pipes, especially from which the inner casing is made. Because products made from low-grade steel are deformed when exposed to high temperatures and even burn out. Such defects also occur during operation if the metal does not meet the operating characteristics of the furnace.

Burnt-out inner casing of a low-quality sandwich chimney Source ad-cd.net

Responsible manufacturers label their products and supply them with technical data sheets. They indicate the grade of steel.

The universal metal is AISI 316i stainless steel. This steel has ductility, high resistance to corrosion and can withstand temperatures up to 850 degrees. For bathhouse stoves, chimneys made of alloyed stainless steel AISI 316 and durable alloy AISI 439 with titanium additives are also suitable.

See also: Catalog of companies that specialize in engineering systems and related work

Inner diameter

An important technical parameter is also the diameter of the internal contour. It is selected by engineers taking into account the thermal power of the furnace device. The most commonly used sizes of sandwich chimney pipes are:

- 158 mm – up to 3500 W;

- 189 mm – 3500-5200 W;

- 220 mm – 5200-7000 W.

The indicated diameters are the minimum permissible values. However, the cross-section along the entire length of the smoke channel must be no less than the size of the stove outlet pipe.

Inner diameter of the smoke exhaust sandwich duct Source ytimg.com

Thermal insulation

Significant characteristics also include the type and thickness of the thermal insulation layer. High-quality chimneys with a sandwich structure are made using mineral wool. It does not burn and has a significant coefficient of thermal resistance.

The thickness of the heat insulator is affected by the type of heating equipment and smoke temperature. Wood-burning stoves typically discharge combustion products heated to a maximum of 600 degrees. For such operating conditions, a chimney is assembled from sandwich pipes with a thermal insulation layer 50-100 mm thick.

Advice from experienced professionals

In order for the chimney system to work efficiently, you need to follow some recommendations that professional stove makers always take into account.

- When laying brick rows, be sure to carefully select the excess mortar that will protrude into the chimney channel. These surfaces must be very smooth so that as little soot deposits settle on them as possible.

- The binding of bricks in the brickwork of a chimney requires special attention, since in such a design a large number of not whole bricks can be used, but their halves, plates, third or fourth parts. In order to evenly cut or chip off bricks, you can use a grinder (grinder). If you file the desired part with it, it will be easier to separate a fragment of the required size. The plates that are needed in some rows of masonry will have to be sawed off completely, since such thin parts can simply break.

- The seams in the chimney masonry should not be too thick - their thickness can be four to five millimeters. This must be observed because the mortar, even in a frozen state, is more susceptible to destruction when exposed to external factors than hardened brick.

- And, of course, a very important measure when servicing a chimney during its operation is its timely cleaning or periodic preventive maintenance to prevent clogging.

Chimney outlet options

The design features of the bathhouse affect the installation of sandwich pipes. It can be performed inside or outside the building. When laying internally, holes are created in the ceiling and roof. During external installation, the chimney is fixed to the wall with a preliminary hole created in the supporting structure for laying the pipe.

Basic options for installing a sandwich duct for smoke Source feflues.ru

Internal installation

It is the installation of a chimney from sandwich pipes through the roof with the preliminary creation of a passage in the attic floor that makes it possible to reduce the negative external influences on the smoke exhaust system. With this installation method, the appearance of condensation in the channel is practically eliminated.

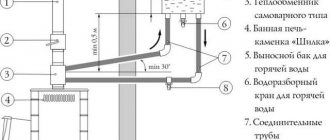

This option is often used in a bathhouse because it does not complicate the installation of a water tank. After all, its installation is carried out above the stove. It is mounted at the initial section of the smoke exhaust system. Often, a mesh section is installed in the same section, allowing stones to be placed for better heating and creating steam in the room.

Mesh sauna heater Source oteplicax.ru

A module without thermal insulation is always installed between the furnace and the sandwich pipe. The section is usually equipped with a gate. It is a damper to change the amount of heat removed along with the smoke.

Installation inside an object is a labor-intensive process, since you have to create at least two holes. This option is not suitable if you need to save the free internal space of the bathhouse.

External installation

When a chimney is laid through a wall, labor costs are reduced. After all, you need to create one penetration in the supporting structure. The parts are attached to the outer surface of the wall using special brackets.

Less labor-intensive installation of a chimney from sandwich pipes through the wall helps to save free internal space. This option reduces the likelihood of fire and minimizes the risk of poisoning from combustion products.

The disadvantage of such a gasket is the negative impact of the external environment on the channel. It creates more condensation. Some people are still not satisfied with the placement of a metal pipe on the wall.

Calculation methods and rules

The calculation rules have their own tolerances; you need to know them before calculating the diameter of the pipe. There are several calculation methods, they depend on who and for what conditions they will be fulfilled:

- High-precision, used in the production of boilers and carried out by the design departments of equipment manufacturers.

- Approximate calculations performed by non-specialists based on graphs, diagrams and tables.

- Automatic, obtained on the basis of online calculation.

Accurate calculations are understood as those in which many factors are taken into account: the temperature of the flue gases at the outlet of the boiler and from the pipe, the speed of movement of gases in the furnace and in sections of the smoke exhaust system, the loss of gas pressure along the movement in the gas-air tract. Most of these parameters were obtained experimentally by manufacturers of boiler equipment and depend on the brand of the boiler, so this type of calculation is practically not available to users.

With regard to the indicative method, before calculating the diameter of the chimney, the volume characteristics of the combustion chamber are taken into account. To determine the geometric parameters of pipes, there are various tables and graphs. For example, with a firebox with dimensions of 500x400 mm, a round pipe from 180 to 190 mm will be required.

The third method is based on the use of special online calculators. They take into account almost all important parameters, so they produce very accurate results. In order to use them, the operator will need to know a lot of starting data.

Exact method

Accurate calculations are based on a rather labor-intensive mathematical base. To do this, you will need to know the fundamental geometric characteristics of the pipe, heat generator and fuel used. For this calculation, you can use the following method for determining the diameter of a round pipe for a wood-burning stove.

Calculation input parameters:

- Gas T readings at the boiler outlet t – 151 C.

- The average speed of flue gases is 2.0 m/s.

- The estimated length of the pipe, which is standard for stoves, is 5 m.

- Mass of burned wood B= 10.0 kg/hour.

Based on these data, the volume of exhaust gases is first calculated:

V=[B*V*(1+t/272)]/3600 m3/sec

Where V is the volume of air masses that are necessary for complete combustion of fuel - 10 m3/kg.

V=10*10*1.55/3600=0.043 m3/sec

d=√4*V/3.14*2=0.166 mm

Swedish method

Chimney calculations are often performed using this method, although it is more accurate when calculating smoke exhaust systems for fireplaces with open fireboxes.

Swedish method

According to this method, the size of the combustion chamber and its gas volume are used for calculation. For example, for a fireplace with a portal, the height is 8 masonry heights and 3 masonry widths, which corresponds to the size F = 75.0 x 58.0 cm = 4350 cm2. The ratio F/f = 7.6% is calculated and it is determined from the graph that a rectangular chimney of this size cannot work; it is possible to use a structure with a circular cross-section, but its length must be at least 17 meters, which is not really high. In this case, it is better to make the choice from the opposite direction, according to the minimum required diameter section. It is easy to find by the height of the building, for example, for a 2-story house, the height from the fireplace to the chimney cap is 11 m.

F/f ratio = 8.4%. f = Fх 0.085 = 370.0 cm2

D= √4 x 370 / 3.14 = 21.7 cm.

Chimney equipment

The installation company completes the chimney in accordance with the approved installation diagram. It is not difficult for a specialist to select the necessary parts. After all, manufacturers produce a full set of required sandwich elements. They allow for quick and high-quality installation of a sandwich chimney.

When installing a smoke exhaust system from a stove in a bathhouse, the following is usually used:

- a transition piece that allows you to connect the chimney with the outlet of the furnace equipment;

- a right-angle bend designed to change the direction of the channel;

- tee with a central pipe at an angle of 87 degrees - used to transition from a horizontal section to a vertical pipe;

- a part with a hermetically sealed hole for cleaning the channel;

- a support platform equipped with a tap designed to drain accumulated moisture - used together with an inspection element;

- a wall bracket that allows you to attach the chimney to the wall;

Fastening structure for fixing smoke ducts to the wall together with an inspection element and a support platform Source katlavan.ru

- a tee with a central pipe located at 45 degrees - used when installing a single chimney for two stoves;

- a metal plug for closing unprotected heat-insulating material when connecting a single-circuit pipe with a thermoelement - prevents the penetration of a humid environment into the heat insulator;

- 45 degree bend - used to bypass protruding structural elements of a building, for example, a roof canopy;

- clamp for strengthening the connections of sandwich parts;

- straight pipe elements 1000 mm or 500 mm long;

- a conical roof with different angles depending on the slope of the roof slope - used when laying a chimney through roofing material and used in conjunction with a metal apron;

Cone roof Source ytimg.com

Okapnik Source prom.st

- a cone-shaped part with which the thermal chimney ends - usually installed with a spark arrester and a fungus in the usual design or a similar thermoelement, deflector, weather vane.

Frequent errors and problems during installation

Low height of the chimney device. As a result, traction is lost.

The chimney outlet must be higher than the ventilation ducts if they are constructed in the same block. Otherwise, backdraft occurs.

Choosing a chimney based only on low price. Single-wall pipes made of ferrous metal, thin galvanized are suitable only as temporary devices. Even stainless steel, not all brands are heat resistant enough. Preference should be given to alloys that can withstand temperatures of 700 oC and above: AISI 304, 309, 316, 321.

Basic rules for installing a sandwich chimney

The number of all components depends on the length of the chimney. Regardless of the configuration, it is not created with a length of less than 5 m. If the chimney is installed through the wall directly in the steam room or its installation is carried out elsewhere in the bathhouse, conditionally parallel to the floor, then the length of the straight “horizontal” section should not be more than 1000 mm. In this case, such a segment is fixed with an inclination of 3 degrees towards the condensate collector. This allows moisture to flow in the opposite direction from the heating equipment.

When installation is carried out next to a wall, the channel is fastened at a distance from the supporting structure of the building, which is determined by the manufacturer of double-circuit pipes. However, the minimum distance is 250mm. To simplify the installation process, adjustable brackets are often used. They are fixed at a distance of no more than 2000 mm from each other.

During installation, the distance from the chimney to the wall must be at least 250 mm Source krovlyakryshi.ru

If the sandwich pipe is located at a distance of 1500 mm from the ridge, it must rise above it by no less than 500 mm. When the distance is 1500-3000 mm, the head of the chimney should be flush with the ridge. If the thermal pipe is mounted at a greater distance, then the height of its upper cut is determined by drawing a conditional line from the ridge at an angle of 10 degrees relative to the horizon.

The height of the chimney above the roof Source stroyfora.ru

If there is a flat roof, the thermal pipe must rise above it by at least 500 mm. When the roof is covered with a fire hazardous material, the height of the sandwich chimney above it must be at least 1200 mm. Typically, a structure of this or greater length is secured with braces.

Important! The smoke exhaust channel is installed with a minimum number of bends. Its effective operation will be ensured if the pipe changes direction no more than 3 times.

Conditions for normal operation of the chimney

- The length of the smoke exhaust channel must be at least 5 meters.

- The thickness of the steel for the inside of the sandwich is from 0.5 to 1 mm. Optimally – 8 mm.

- It is prohibited to install more than 3 turns.

- The diameter of the chimney should not be narrower than the stove flue pipe.

- The horizontal section of the pipe should not be longer than 100 cm.

Remember that the rules are created on the basis of qualitative tests and negative operating experience. Failure to comply with the nuances of installing a chimney in a private house is fraught with fire or poisoning.

Stages of installing a chimney from thermal pipes

After concluding the contract, developing the project and its approval by the customer, the construction company will install a chimney in the wall or roof in stages:

- An adapter is put on the stove pipe. It is lubricated with a sealant that can withstand temperatures of at least 1000 degrees. For reliability, the transition element is secured with a metal clamp.

- A length of single-wall pipe is installed to prevent the sandwich from overheating, which turns to stone when exposed to high temperatures. This leads to failure of the chimney.

- A heater or metal container for heating water is mounted on a single-wall pipe piece.

Metal tank for heating water in a bathhouse above the stove Source pechimax.ru

- If a chimney is installed through a wall in a wooden house, bathhouse or other building, a chimney section no more than 1000 mm long is created with a 3-degree slope towards the street.

- A hole is prepared in the wall for the chimney outlet. Its diameter is always larger than the cross-section of the sandwich pipe. If the wall is made of combustible material, then the gap between the smoke exhaust duct and the supporting structure is at least 200 mm. Often a square hole measuring 400*400 mm is created.

- The walls of the opening are covered with basalt cardboard.

- A factory-made chimney passage through the wall is installed.

Pass-through block in the form of a box Source masterweld.ru

Operation, repair and cleaning of steel chimneys

Steel chimneys are easy to use. It is recommended to check the condition of the traction in them using the inspection hole left during installation. This must be done once every three months. The chimney must be cleaned at the same frequency.

Mechanical cleaning methods can scratch steel pipes, so they are best left to professionals.

At home, chemical methods are often used using special substances that are placed in the firebox. Burning chemical compounds in the form of gases rise up the chimney and dissolve the soot that has accumulated in it.

Condensation often forms in steel chimneys, which can be drained through a left inspection window.

Repairing a steel chimney most often involves replacing the entire structure or a section of it with new pipes. This is the most reliable method of fixing the problem.

Video description

Video material will help you understand the principles of creating connections “through smoke” and “through condensate”:

The installation process is completed by installing a cone of the required height and the selected head. If the last section is long, a clamp with eyes is attached to it. This product allows you to fix the final section of the chimney using guy wires that are attached to fixed, durable parts of the roof.

Special clamp for guy wires Source yandex.net

Correct arrangement of chimneys and differences in types

How to make the right chimney? First of all, you need to start from what material is used. We remind you that chimneys are:

- Metal.

- Ceramic.

- Brick.

- Concrete and others.

The installed channels also differ in the nature of construction. For example, for heavy structures, such as brick, concrete, ceramic, you need to pour a “cushion”. Their weight is quite large. In addition, special rules apply for sealing seams and joints. In this regard, it is more optimal to use, naturally, taking into account the type of boiler or furnace. In addition, metal chimneys differ in their segment; there are more than three varieties. That is, you can choose the most profitable device for each heating equipment. In order for the correct chimney to work correctly, the installation must be carried out in compliance with the general rules listed above and individual nuances for the specifically selected chimney.