Innovative surface leveling techniques have been developed to optimize finishing times and reduce labor costs. A fairly young innovation - adjustable floors provide finishers and property owners with a significant number of technological and consumer advantages. With their help, the preparation of the rough surface is carried out quickly, simply, and ideally, which does not require professional skills from the performer.

Universal designs of adjustable roughing bases are used for arranging premises of any purpose, area, configuration. For old buildings with not very reliable floors, for light country cottages made of wood or foam concrete, the ability provided by this technology not to load the floor with a multi-ton concrete screed is an excellent option. For new buildings with low ceilings, this is an opportunity not to reduce the height of rooms that are not very spacious.

Practical adjustable floor with useful technological space

- 2 Two types of adjustable structures

2.1 Installation of floors with leveling plywood

- 2.2 Installation of floors with adjustable joists

Pros of adjustable floors

There are several types of “adjustable flooring” depending on the purpose of the room, the quality of the base and the design height of the floor. To solve the problems of raising the floor level to the required height and placing various communications under it, a floor structure on adjustable DNT joists is used, which provides not only the required levelness of the floor for laying any types of coverings, including wooden floor coverings that require minimal differences in the base, such as parquet , parquet board or laminate (no more than 2 mm per 2 linear meters), but also allows you to make a floor frame if wooden beams are used as an interfloor floor.

Adjustable floors DNT

This design raises the floor to a height of 5 to 20 cm or more, depending on the height of the polymer bolts and the cross-section of the logs, and also allows it to be fixed to a concrete, wooden or any other base.

To solve the problems of leveling the floor base without loss of height, an adjustable floor design using adjustable DNT slabs is used. Its use allows you to prepare a base for parquet, laminate or parquet boards with a difference of no more than 2 mm per 2 linear meters. At the same time, the floor will rise to a height of 2 to 5 cm, which does not exceed the thickness of a conventional screed.

All these designs of adjustable DNT floors allow you to install in the shortest possible time (there are no wet and dusty processes associated with concrete) a flat and reliable floor that has increased sound and heat insulation of the room, the cost of which is no more expensive than traditional types of leveling (concrete screed, semi-dry screed or Knauff floors), and with a floor height of more than 5 cm, it allows you to significantly save on preparing the base for the finishing coating.

Benefits of adjustable screeds

Structurally, progressive floor leveling systems are a solid, dense flooring with mechanical devices that help adjust the floor in the horizontal plane. Main features of this technology:

- Floor systems with adjustment devices can be installed in a couple of days.

- Durable adjustable floors can be installed with your own hands by a person who is installing a floor for the first time.

- A useful technological gap remains between the rough surface and the ceiling, which increases the insulating qualities. In this space, you can lay communications, supplement the insulation by laying synthetic or mineral insulation.

- The floor plane can be raised to a level of up to 20 cm, the thickness of the leveling layer can be reduced to 3 cm, and a multi-level floor can be arranged with one or more podiums.

- Rigid fastening of the leveling system elements to the concrete or wood base is provided.

- It is possible to refuse the underlay traditionally used when laying parquet and a number of other types of floor coverings. This is another economic advantage, reducing the cost of the floor by almost half.

- Once the clean, dry installation of adjustable bases has been completed, there is no need to delay the finishing work, such as waiting for the screed to fully cure.

According to experienced foreign users, adjustable floors will serve faithfully for half a century. The presence of a ventilated cavity will also eliminate the possibility of premature “aging” of the floors, and the floor will not be damaged in case of emergency floods.

An additional layer of insulation can be placed between the joists.

Floors constructed using this technology will not squeak annoyingly or warp, as happens with outdated adjustment of floors along joists, which is done using loose wood chips or sand.

Progressive systems supplied from abroad and produced by domestic enterprises are distinguished by another important advantage - an affordable price; almost a third of the money invested in leveling can be saved by abandoning the cement-sand screed.

The immaculately leveled surface can be raised to any level

Pros and cons of "adjustable floor"

The disadvantages of an adjustable floor may appear if the requirements for proper installation of the floor are not met, which also applies to other methods of leveling the subfloor.

If installed correctly and all material quality requirements are met, the “DNT adjustable floor” is a reliable and durable base for any finishing coating on which you can not only walk, but also drive a car.

If you do not follow the DNT adjustable floor assembly technology, entrusting it to “woe to the specialists”, or use a regular plastic dowel and nail to attach polymer adjustable bolts to a concrete base, the adjustable floor will look like this:

DNT adjustable floor installation technology

Features of adjustable floors

Pros of adjustable floors

- You can install an adjustable floor yourself without the help of a professional. To do this, it is enough to purchase the necessary materials and stock up on simple tools.

- Installing the floor takes very little time: 1-2 days. For comparison, a concrete floor screed must dry for several weeks.

- An adjustable floor allows you to hide communications in the technological space, which means you can save space and remove all visual defects under the base of the floor.

- Using an adjustable floor, you can significantly increase the sound insulation of a room, which is why this type of flooring is often used in concert halls, studios and residential buildings.

- The adjustable floor is quite light in weight. Therefore, you can install it in rooms with weak ceilings - in private houses or on loggias.

- When installing an adjustable floor, virtually no dirty work is carried out. Accordingly, this coating option is ideal for rooms where it is important to maintain cleanliness.

- The adjustable floor can withstand loads of up to 2.5 tons per square meter. This means that this coating can be used for almost any type of premises (residential buildings, offices, shops, warehouses).

Advantages and disadvantages of adjustable floor installation technology

Using adjustable floors

Adjustable floors are suitable for any type of room

Despite all the advantages of adjustable floors, many owners still think about the advisability of installing this type of covering. So, in what cases is it best to use an adjustable floor?

- If the floor surface is difficult or almost impossible to level (there are strong differences or unevenness).

- If it is impossible to use heavy materials to level the floor according to technical specifications.

- If you need to make a floor with different height levels.

- If there is a need to hide communications under the floor.

- If you want to create additional insulation from noise or cold.

Specifications

Conclusion

The process of installing an adjustable floor itself, as you understand, is not particularly difficult; all the work may be familiar to many. Your biggest concern should be the quality of the building materials used in this process. You should not save on this, as you will have to invest in repairs in the future.

In the video presented in this article you will find additional information on this topic.

Types of adjustable floors

Types of adjustable floors

Before we move on to a detailed description of the installation process of an adjustable floor, let's understand its key features. Today there are two types of adjustable floors on the market - floors on joists and adjustable floors on slabs . The main difference between these types of floors is the minimum lift height.

When installing a floor on joists, the rise is 5-20 centimeters or more. For an adjustable floor on slabs, the minimum lift height can be from 3 centimeters.

The process of installing adjustable floors on joists or on slabs is almost identical, but we will still describe the installation of each type in detail so that you can do it yourself at home.

Floor construction with adjustable joists on plastic bushings

Plastic bushings can raise the floor by 5-10 cm. The design itself is very simple.

- Holes are drilled in the joists.

- Plastic pins are screwed into them every 60 cm for wooden floors and plywood, and 30 mm for laying gypsum fiber board sheets and subsequent laying of tiles.

- The logs with studs are placed on the floor and leveled.

- Since the studs are hollow, holes are drilled in the floor from the outside and the studs are attached to the floor with dowels.

Technology for installing adjustable floors on joists

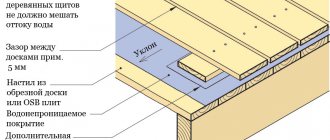

Adjustable floor installation diagram

Floor arrangement diagram

Logs are planed timber. Its dimensions, as a rule, do not exceed 50x50 centimeters. So, before we begin installing the floor on the joists, we will decide on the materials and tools that we will need.

Adjustable floor with insulation

Video - Adjustable logs on homemade racks

Tools

To install the floor yourself, you will need: logs, wear-resistant bolts, a drill, a laser or water level, a hammer, and dowel-nails.

Accessories for assembling an adjustable floor

Plastic stand bolts for adjustable floor installation

You will need similar drills for drilling holes in joists.

Now we will look at step-by-step steps that will help you quickly and efficiently install an adjustable floor on joists.

Complete set of consumables for 4 square meters of floor

Preparatory stage of work

- Clean the floor surface. If necessary, we lay communications that will later be hidden under the adjustable floor.

- We manually screw the polymer bolts into the wooden joists. If the joists have threaded holes, screw the bolts into them. If there are no holes, we make them ourselves. For a log 2 meters long you need to make about 5 holes. You can drill holes using a drill with an extended tip. The holes should be slightly smaller than the diameter of the bolt. This is necessary for the rigidity of the adjustment.

- After manually screwing in, tighten the bolts using a drill with a special attachment.

Floor installation diagram on joists

Video - Adjustable logs preparatory process

Installation phase

- We lay the wooden joists evenly on the base of the floor. The distance between the joists depends on the choice of floor covering. If you plan to cover the floor with linoleum or lay tiles, the distance between the joists should be small. Experts recommend taking a step between lags of no more than 30 centimeters. It is advisable to leave a distance from the joist to the wall of at least 1 centimeter. This will create the necessary ventilation.

- After laying out the joists, we move on to rigidly attaching the bolts to the base. To do this, take a rigid drill and drill a hole in the concrete through the bolt. The depth of the hole should be about 40 millimeters. Next, we insert a dowel-nail into the prepared hole.

- We hammer in the dowel-nail with a hammer, securing the polymer bolt to the base of the floor. Try to drive the nails as firmly as possible so that the entire floor structure does not move in the future. Also, good fastening will avoid squeaks and noise when using the floor.

Log installation process

Log installation process

Floor height is adjustable, protruding bolt heads are removable

Alignment

After the wooden logs are installed around the entire perimeter of the room and tightly bolted, we proceed to leveling. To do this, we need a water (or laser) level and a special tool (key) for adjusting the height.

- We carefully measure the level data. The height difference can be no more than 1-2 millimeters.

- Using a special wrench, raise or lower the bolts, focusing on the level. We try to achieve perfect alignment, since the quality of installation of the final floor covering depends on this.

The final stage of work

Fastening plywood to joists

The process of laying plywood on adjustable joists

- After leveling the joists, firmly secure the nails to the floor using a hammer.

- We cut off the unnecessary remains of the post bolts using a knife or any other cutting device.

- If necessary, we lay materials between the joists for soundproofing or thermal insulation of the room.

- We place the flooring on the upper base of the joists. The choice of decking materials depends on what type of flooring you plan to use. Most often, plywood is used as flooring. It is suitable for further installation of laminite or linoleum. GVL or DSP is also used as flooring.

This is what the adjustable floor looks like from below

Technological vent

Adjustable floor ready for finishing material - After installing the flooring, we lay tiles, linoleum, laminate, parquet or any other covering on the adjustable floor.

Mistakes when installing an adjustable floor

Sequence of installation of logs on steel brackets

For a floor on adjustable joists, complete components are required. In cases where the floor area is small, up to 6-8 m2, it is possible to use a simplified design that is more expensive in terms of materials. Based on a small floor area, the overrun will not be significant.

In this case, the logs are made from dry (humidity up to 8%) timber 60*60 mm. The block must be of high quality and smooth. To install the logs, you will need fasteners in the form of U-shaped brackets with shelves based on the distance along the thickness of the bars, made of metal 2.5-3 mm thick. Holes for self-tapping screws are drilled in the shelves of the brackets for subsequent fastening of the beams.

After marking the floor, install the brackets on dowels, then set the first row of beams on pads, along a stretched cord or laser level.

The beams are attached to the brackets using self-tapping screws and temporary fastening. Then all the joists are aligned using a cord or laser beam and secured with bolts, securing them with self-locking nuts.

Algorithm for creating a floor on slabs

The second type of flooring is done on slabs. It is chosen if the height of the floor should not exceed 3 centimeters. It is difficult to hide communications in such a space between the base of the floor and the covering, but it is quite possible to place cables from the telephone or the Internet here.

The process of installing this type of floor is somewhat reminiscent of installing an adjustable floor on joists.

Algorithm for creating a floor on slabs

Materials and tools

Before installing an adjustable floor on slabs, you need to prepare the following tools and materials: sheets of plywood or other material, bushings, stand-up bolts, drill, self-tapping screws, hammer, water or laser level.

| Type of plywood | Description |

| Plywood FC | moisture-resistant appearance; urea resin is used for gluing veneer sheets. This plywood is intended for indoor use. |

| FKM plywood | has increased water resistance and is made on the basis of melamine resins. This type of plywood is unique, since environmentally friendly melamine resins are used for its production. Due to its environmental characteristics, plywood is used in furniture production and for interior finishing work. |

| Plywood FSF | Veneer sheets are glued together using phenolic resin. This type of plywood also has increased water resistance. It is not recommended for interior decoration, as phenolic resins are harmful to health. Typically used for exterior finishing work |

| Laminated plywood | It is based on FSF plywood, which is covered on both sides with a special film. Laminated plywood is used for the manufacture of formwork. This type can be used repeatedly |

| Bakelized plywood | Bakelite resin is used to glue veneer sheets together. This type of plywood is used in aggressive climates, sea water, aggressive environments, and sometimes for monolithic work. |

| Marine plywood | similar to bakelized, but less durable. Made from foreign wood species |

| Plywood Flexible | foreign version. A distinctive feature is the ability to bend well in the transverse and longitudinal directions |

Video - Which plywood is better

Preparatory stage of work

- Just like when installing an adjustable floor on joists, installing a floor on slabs requires certain preparation of the working surface of the floor. Be sure to remove excess debris and correctly distribute communications that you plan to hide under the floor. Remember that the maximum lift height will be about 3 centimeters.

- Carefully place the sheets around the perimeter of the room. The distance between the sheets should be 2-3 centimeters on each side of the sheet.

- Mark the points for drilling holes. With a sheet size of 1.5 by 1.5 meters, 9 holes will be enough. One hole should be located in the middle (center of the sheet), four holes can be at the corners of the sheet and four more should be located in the central part of each side of the sheet. This arrangement of holes will ensure reliable fastening of the sheet.

Instructions for installing an adjustable floor on slabs

Installation of sheets

Fastening plywood

- After we have marked the holes, we begin drilling. We take a drill with a special attachment with an extended tip.

- We insert stand-up bolts into the drilled holes. We attach the bushings to the underside of the bolts using small self-tapping screws.

- Once the bolts are inserted and secured into each hole on the sheet, we turn the sheet over and place it on the subfloor.

- We drill holes in the concrete base through the post bolts and insert dowel nails into these holes.

- Hammer the nails exactly halfway.

Installation process

Adjustment

- After preparing and installing the sheets, we proceed to their alignment and adjustment. To make adjustments, we use a special key, as well as a water or laser level.

- After carefully adjusting the height of the sheets, we carefully cut off the extra centimeters of the post bolts.

- Using a hammer, drive the dowel nails all the way to the base of the floor.

Instructions for installing an adjustable floor on slabs

DIY adjustable floors

First and second layers of plywood flooring

First and second layers of plywood flooring

Final stage

- If necessary, we place thermal insulation or sound insulation of the floor on top of the sheets.

- After installing the sheets, we also lay out laminite, tiles, parquet, linoleum or any other selected floor covering.

Alignment of logs to a single horizontal level

- After placement, the logs need to be secured to the base floor. For this purpose, special holes are made in the post bolts. Using a drill and a long bit, drill holes through the bolt in the subfloor. Insert fasteners into the drilled hole: a dowel-nail or a dowel with a screw. Screw the fasteners, but not all the way - the adjusting bushings (bolts) must rotate to adjust the height.

- After securing (not completely) the bolts of the racks, you need to align all the joists in a single horizontal level. The permissible deviation is no more than 1 mm per 1000 linear mm of floor.

- If necessary, install soundproofing sheets on special hangers.

Secrets to successfully installing an adjustable floor

Adjustable plywood and joists

After completing installation work, be sure to thoroughly clean the floor surface before installing the flooring. Excess debris, sawdust, and pieces of plastic can create squeaking and noise after laying the top layer of the floor.

Carefully hammer and tighten all floor fastenings. The reliability of the entire structure depends on this.

If you are making a high floor, it is advisable to place soundproofing material between the joists. This will avoid unnecessary noise when using the floor. Don't skimp on the quality of materials. It is more profitable to immediately choose more expensive materials for installing the floor, instead of completely redoing the entire job after a short time.

If, after installing the floor, you need to move communications, you can simply remove several strips of the adjustable floor in the right place. After completing the necessary work, you can easily put the floor back in its original place.

We hope that our tips, as well as step-by-step instructions, will help you install an adjustable floor in your home, cottage or office yourself, quickly and without any difficulty.

Conclusion

The process of installing an adjustable floor itself, as you understand, is not particularly difficult; all the work may be familiar to many. Your biggest concern should be the quality of the building materials used in this process. You should not save on this, as you will have to invest in repairs in the future.

In the video presented in this article you will find additional information on this topic.” width=”640″ height=”360″ frameborder=”0″ allowfullscreen=”allowfullscreen”>