A heat gun is used to heat various rooms. Usually we are talking about garages, workshops, utility rooms, etc. The fan heater has several undeniable advantages, which is why it is often used in home workshops and garages. Now we will understand the design of the heat gun and talk about the operating principle of the unit. But let’s take a closer look at repairing a heat gun. The matter is not that complicated, so such work can be done with your own hands.

About the operating principle

A heat gun is called a fan heater because it has the same principle of operation, but with slight differences. In any case, the essence remains the same: the air passes through the heating element, as a result of which it reaches a certain temperature. Afterwards it is pumped into the room in a concentrated stream. The design includes a special sensor, so when the optimal temperature in the room is reached, the heat gun turns off, which saves fuel. Of course, diesel is used as fuel, although craftsmen create devices that run on used engine and transmission oil. There are also gas heat guns, but more on that later. So, this kind of heater has a lot of vulnerable spots, so repairs are required periodically. What is it? Usually this is replacing the fan, cleaning the nozzles, etc. In order to understand what the most vulnerable points are, you need to understand the design.

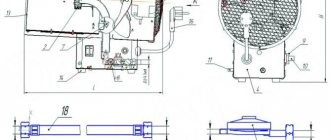

About the device

The heat gun, regardless of the type of fuel and power used, is equipped with a metal casing, which prevents the possibility of any objects falling onto the heating element or blower, which could lead to undesirable consequences, such as fire or equipment failure. A fuse must be present. It will automatically turn off the gun if it overheats. The metal housing houses the burner, as well as channels supplying diesel fuel. A compressor or small pump can be used for supply, and a blower and fan can be used to circulate air flow. Oddly enough, it is the fan that most often fails. This happens for many reasons. We will try to figure out how to prevent damage, and how to fix it.

Causes of malfunctions

There is no need to talk about anything specific here. As practice shows, absolutely any structural element can break, but you can’t tell it right away by eye. This happens for a variety of reasons. Sometimes the user simply does not comply with the rules for operating heating equipment; in other cases, critical components fail due to poor quality of electricity. In the end, any part and assembly has its own service life, after which failure can occur at any time. For example, repairs to a heat gun produced relatively recently are carried out by service departments. This is especially true if the device is under warranty. If not, then you can try to restore the gun yourself. But not everyone buys a new heat gun, but uses an old one, which is not clear how it works.

Repair work of old fan heaters

This is the type of technology that you most often have to deal with. But there is nothing to worry about, because the design of such heat guns is relatively simple, so with minimal knowledge of electrical engineering you can cope with this work. In its simplest design, a heat gun is a metal body, inside of which there are several heating elements (heating elements), as well as a compressor for pumping air. To regulate the temperature, a multi-position switch is used, less often “automatic”. Let's talk in detail about how to repair a heat gun as a whole or any individual elements. As a rule, there is no point in sending old products to a workshop. The cost of restoration work will be high, but their quality is very questionable.

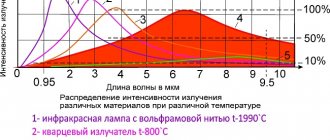

Operating principle of an electric heat gun

The cold air taken by the fan enters the gun and is heated there with the help of special heating elements (heating elements), and after that it is again thrown into the room.

Some features of electric heat guns

- The speed of passage of air masses through the heating system is high, so the heating efficiency directly depends on the power of the heating elements

- The speed of the air flow affects the uniformity of heating. The higher the speed, the more evenly the heat is distributed (while the heating itself occurs more slowly, since the air does not have time to heat up much)

- Electric heat guns are not intended for heating open areas. For these purposes, diesel or gas engines are used.

- During operation of the electric gun, no foreign odors are emitted (in the very first days of operation, a specific smell from the heating elements is possible, which soon disappears)

Diesel heat gun repair

Most often, the cause of the malfunction is the heating element. You can check whether this is true experimentally. If a heat gun does not heat the air or does it ineffectively, then it makes sense to think about it. But since the design includes a group of heating elements, you will have to call each one and determine which one is broken. It is necessary to understand that the air heating element itself cannot be repaired or restored, therefore, if it fails, it will have to be completely replaced.

To ring, you need to use a regular screwdriver with an indicator and a tester. In this case, it is advisable to disconnect the supply wires. Sometimes the heating element plates melt or the outer shell becomes deformed. In this case, replacement can be carried out without delay.

In what cases is diesel gun repair required?

There are also malfunctions of a diesel heat gun - the fuel unevenly enters the combustion chamber. Most often the problem is related to a clogged fuel tank. In this case, thorough flushing of the fuel tank and its supply system to the chamber can help. Before flushing, you need to drain all the fuel, and then purge the entire system and fill the fuel back.

The fuel does not ignite. Defects in the spark plug can cause this problem. To fix this, you need to pull out the spark plug and clean it mechanically, creating a gap between the electrodes.

The diesel gun works intermittently. The most common cause of the problem is a clogged air filter. The only thing that will help in this situation is a new filter, which you need to buy and stop.

The heat exchanger does not heat up well, the fire in the combustion chamber is small:

- You should look at the injector, most likely it is clogged.

- You can clean it yourself by rinsing it from dirt and then thoroughly blowing it with a powerful stream of air.

- If it still doesn't light up, the master will help.

The gun becomes very hot during operation. Most often the problem is with the thermostat. The defect can be eliminated by cleaning the thermostat parts or completely replacing them with new ones. The heat gun can be easily repaired at home if the cause of the breakdown is correctly identified. To carry out the procedure you don’t even need any special tools or skills.

Electric motor repair

If we are dealing with a failure of the fan motor, then the situation becomes somewhat more complicated. It is quite simple to determine this breakdown - there is no directed flow of warm air. At the same time, it is necessary to understand that there is a risk of heating elements breaking down, since they are not cooled and can easily overheat.

Repair work should begin with checking the voltage at the terminals. If necessary, the contacts must be cleaned. Next you should move on to checking the continuity of the motor winding. However, a screwdriver with a tester will not help much here, so it is better to use more accurate devices, such as a multimeter or an analog tester. In this case, the winding insulation is additionally checked. If the core fails, then in this case it is easier to replace the entire electric motor. In any case, it will be faster and easier.

Heat gun repair

An electric heat gun or heat fan is one of the types of household electric heaters, which is often simply irreplaceable for heating both large areas (construction sites, workshops, warehouses, etc.) and small ones (dacha, room in an apartment or private house, garage etc.).

Like any electrical device, a heat gun can fail during operation. There can be a lot of reasons for malfunctions of a heat gun: from violations of operating rules or poor quality of electricity to wear and tear of its electrical equipment, which has a certain service life (working life). If your modern heat gun breaks down, i.e. purchased quite recently, the breakdown can be repaired by contacting the manufacturer’s service center. In addition, if it is under warranty, then the malfunction can be eliminated by warranty repair.

But what to do if your old heat gun, which has always been a lifesaver, has stopped working? After all, the cost of repairs in a specialized workshop and spare parts for it may exceed the cost of your household heater. But at the same time, in this situation, you shouldn’t rush to throw it away and buy a new one. An old-style heat gun is a household electrical appliance, which, in principle, is not particularly complex in its electrical circuit and design. That is why, having at least a little knowledge in the field of electrical engineering, in some cases, you can independently eliminate the malfunction that has arisen.

A simple electric heat gun consists of a metal case, inside of which there are heating elements (heating elements) and a fan (electric motor), which pumps the air heated from them into the room. The heating level is regulated by turning on or off groups of heating elements using a multi-position switch or conventional circuit breakers.

Heating elements. The most common cause of malfunctions of heat guns is the failure of one or more heating elements. This will be noticeable if the fan begins to pump cold or barely warm air into the room. The malfunction of the heating elements can be determined by the unevenness of the air temperature at the outlet of the heat gun by placing your palm in front of the air flow. Air heating elements are not repaired or restored, therefore, if a heat gun fails, there can only be one repair - replacement of faulty heating elements. You can determine which of the heating elements are faulty by “ringing” them with an electrical tester or “breaker”. For an accurate examination, it is necessary to disconnect the supply wires from the heating elements being tested; otherwise, the heating elements sitting in parallel will also ring. In some cases, checking the heating element is not required - sometimes a burnt heating element can be seen without any “continuity” - when the outer metal shell is mechanically deformed or even the plates of its radiator are melted.

Electric motor. Quite often, the electric motor of the gun fan also fails. The operating mode of a heat gun, when the heating elements are working properly, but the motor shaft does not rotate, is an emergency mode, because, in addition to the lack of heat flow, it poses a real threat to the heating elements - as a result of the lack of cooling of the heating elements in the form of blowing, they will very quickly fail. First of all, in this case, you should make sure that there is supply voltage at the motor terminals, and if everything is in order with the power supply, then, after removing the voltage, ring the motor windings. For measurements, it is better to use instruments - a digital multimeter or an analog tester, as well as a “breaker”. In addition to checking the winding(s) itself, you should check their insulation (checking the insulation resistance) - the “continuity” of the motor windings with the shaft or housing.

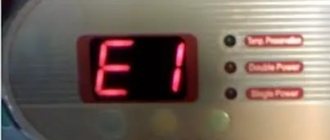

In addition to the main elements of the heat gun device - the electric motor and heating elements, they also contain switching devices - automatic switches and, in some cases, magnetic starters. Malfunction of heat guns can be caused by the usual lack of contact in the terminal of the machine, starter or malfunction of these switching devices. Therefore, during repairs, you should definitely pay attention to this, check the serviceability of their operation and the quality of the contacts. Of course, not all problems can be fixed on your own. Many modern models of heat guns have electronic heat level regulators, which, like any device, are subject to malfunctions. If they fail, in the absence of knowledge in the field of electronics, it is best to contact specialists.

Heat gas gun repair

These types of heaters are equipped with special burners. This is often where the reason lies. For example, if a mixture of gas and oxygen does not ignite, then most likely the problem is in the injectors. They must be removed, blown with compressed air or washed under pressure, and then inserted back. The absence of a spark indicates a faulty piezo ignition. In this case, it is necessary to clean the contacts or simply replace the piezo. If the problem is a malfunction of the circuit breakers, then they can be removed from the structure altogether, but in this case the unit will be turned off manually. I would like to note that old heat guns are repaired somewhat easier than new models. This is due to the absence of a large number of electronic components. For example, if Master heat guns are being repaired, you will need special equipment to test electrical circuits.

Gas heat gun malfunctions

Most often, the following structural elements can break in a gas heat gun:

- blower fan;

- control and protective units;

- fuel supply device.

Heat gun repair

We will look in detail at what problems you may encounter during the process of gas heat guns and how to deal with them:

- The first problem you may encounter is the lack of flame, in other words, the gas refuses to ignite. Usually the cause of such a problem is a failed piezoelectric element. It is necessary to clean the igniter and adjust the gap between the electrodes. If after these manipulations no changes occur, then the piezoelement must be completely replaced.

- The next problem may be due to the fact that gas is connected to the heat gun, but does not enter the combustion chamber. Usually this problem occurs due to the burner becoming clogged. It is necessary to clean this element using a compressor. In simple terms, you need to blow out the burner with a powerful stream of air.

- The appearance of an unpleasant pungent odor of carbon monoxide. This phenomenon is usually caused by a leak in the gas hoses. In order to get rid of an unpleasant odor, you should tighten the fastening clamps or cut off the ends of the hose. If the described actions are not successful, then all that remains is to replace these main hoses. You can check suspected areas where a leak has occurred using a soap solution. If gas leaks, it will blow soap bubbles in this place.

- The heat gun starts to turn off on its own. This problem indicates that the electronic valve that regulates the fuel supply has failed. In this case, you should replace this element completely.

- The device operates stably, but has begun to consume too much gas. This defect is associated with a gearbox malfunction. To save fuel, you can replace this element.

- The burner burns, but no warm air comes in. The problem here is with the fan. Initially, you need to check the power supply and the entire contact group. If no defects are found, the fan should be replaced completely.

To calculate the required power of a heat gun, you can use our calculator.

About replacing the fan

Now we have already figured out a little about what a heat gun is. A master can repair such equipment for a relatively small amount of money, but in most cases this is a feasible task for anyone. Most often you have to deal with the fan, since this element is most subject to intense wear. Since in most cases we will be dealing with wire burnout and oxidation, repair is possible, but a malfunction such as mechanical damage or critical wear requires replacing the electric motor. In this case, it makes absolutely no sense to carry out repairs. The Kraton diesel heat gun or any other is equipped with low-power fans. They must be selected based on the performance of the equipment. In any case, there are no special requirements; you can even use a small household fan, if, of course, you can fit it into the case.

When is diesel heat gun repair needed?

Most often, the fan in diesel heat guns breaks down, because it is the one that wears out the fastest.

This happens for the following reasons:

- The insulation melts or burns out quite often. In this situation, you should change the wires. However, if the wire has completely worn out or it has been damaged mechanically, the fan will have to be replaced.

- Most diesel heat guns are equipped with low-power fans, so if necessary, it can be easily replaced, because this part is available in any gun equipment store.

- You need to choose a fan based on the performance of the gun.

- You can replace the fan yourself, or if you are unsure of your own abilities, call a specialist.

Any breakdown of a diesel gun can be repaired without calling a technician; most often you just need to buy and install a new part. Of course, each heating installation requires a special approach, but if you find time for repairs, you can do everything yourself.