Boiler: making the right choice

Before purchasing and installing gas equipment in a residential area, you should familiarize yourself with the types and functionality of boilers in advance. They come in two options:

- single-circuit - operates only on the principle of providing hot water supply or performs heating functions;

- double-circuit - immediately heats the living space and acts as a boiler, providing hot water.

Boilers also differ in power. Experts recommend choosing models with a power of up to 14 kW if you plan to heat small living spaces and there is no need for hot water supply. For double-circuit models, the optimal power indicator should not be less than 24 kW - this parameter will help provide heat and hot water in a comfortable volume to a private house or townhouse.

Rules for installing heating boilers using diesel fuel

There are a number of requirements for the room in which it is planned to install boiler equipment:

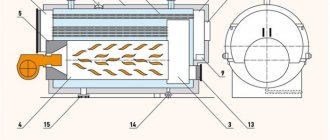

- The boiler room must be located in a separate building. Since all diesel installations are equipped with forced-air burners with a powerful fan, it is recommended to place the equipment in a separate building. In addition, the large dimensions do not allow compact installation of the boiler in a basement or room.

- The ceilings in the boiler room should not be lower than 2.5 meters.

- The walls should be concrete or brick, and their surface should be tiled or covered with mineral plaster. The distance from the walls to the surface of the boiler should not be less than 1 meter.

- The room must be equipped with a supply ventilation system and exhaust hood.

If it is not possible to install a floor-standing diesel heating boiler in a separate building, then the room in the house or workshop should be well soundproofed and protected from fire. In any case, according to fire safety rules, you should not store more than 900 liters of fuel in the tank.

Installation

Only persons with certain qualifications and experience, as well as permits for installation activities, can install gas equipment. Installation work is controlled by SNiP rules, which approve the standards for the functioning of gas distribution systems, the conditions of their operation, taking into account the ventilation of the room.

Installation work is carried out in accordance with the following steps:

- The preparatory stage includes the organization of a working site - a level and safe base with pouring screed and protection with fire-resistant structures.

- Fastening of all elements of the system - pipes, boiler, fittings, etc.

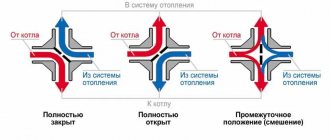

- Installation of shut-off valves and filters for water purification.

- Connecting engineering systems for supplying water to communications and removing combustion products.

- Setting up automatic and technical parameters.

- Assessing the functionality of the boiler in different modes.

As a rule, all the steps discussed above take the master no more than 1-2 days. At the same time, we strongly do not recommend connecting communications yourself, since in the absence of practical experience and knowledge, uninterrupted operation of the devices is possible. Our specialists offer comprehensive services for the selection, design and connection of single- and double-circuit boilers at a competitive cost with a guarantee of high quality.

Choosing a room to install a diesel boiler

Unlike gas equipment, installation of a diesel boiler

does not require preparation of permitting documentation. In view of this, at first glance it can be installed in almost any room of the house. In fact, modern models are equipped with fans that create a certain noise during operation. And the burners are not at all silent either.

Therefore, usually installing a diesel boiler

takes place in a separate room. It must be equipped with exhaust and supply ventilation. If it is impossible to allocate free/non-residential space for the equipment, then the room with it will be equipped with sound insulation.

Cost of services

Contact our organization and we will help you calculate the power of boiler equipment and select it taking into account the client’s requests, develop an installation principle with approval from regulatory authorities, professionally install and optimize the operation of the complexes. The qualifications and decent experience of installation activities of our specialists, the sale of only high-quality and certified equipment is a guarantee of successful cooperation with MirAlex.

How much does it cost to install a turnkey boiler room? The price is determined individually depending on the manufacturer of the technical equipment, the power of the devices, the list of services provided, etc. You can clarify the cost information by calling the phone number listed on our website or using the feedback form.

Advantages

Let's start right away by considering the winning aspects (we'll discuss those that aren't so good later) that characterize heating a country house with diesel fuel. This question is relevant for many owners of private housing, because diesel fuel is not cheap; frankly speaking, a lot of it is required for the heating season.

The rating of this equipment in European countries is quite high, thanks to its advantages. Let's list the main ones.

The efficiency of the equipment under discussion is high, reaching 95% under the following conditions:

- correct installation of the boiler;

- furnace installations in accordance with all rules and regulations;

- high-quality insulation of the house;

- installation of double-glazed windows;

- proper storage of fuel reserves;

- using high-quality fuel;

- timely maintenance;

- competent choice of equipment power, manufacturer, model.

The efficiency can reach up to 98% when using a condensing type boiler, but more on that later.

- Wide range of model range, manufacturers, power characteristics, etc.

- Economical consumption of electrical energy.

- Environmental friendliness, which is a fairly current trend in modern European society. When burned, almost no harmful substances or gases are formed.

- High level of safety compared to gas boilers.

- Autonomous, automatic operation that does not require constant human intervention.

- Inertia is not typical for the design of diesel boilers (unlike solid fuel analogues). Productivity decreases immediately.

- Liquid fuel takes up much less storage space than solid fuel (peat, firewood, coal).

- Possibility to use used engine oils, which are cheaper. At the same time, the issue of recycling waste material, which is completely burned in a diesel unit, is resolved. Again, a reference to environmental friendliness.

Don't miss: Stem, 3 and 4 way faucets

Fuel storage

In the boiler room it is allowed to install a tank for diesel fuel with a capacity of no more than 0.8 m3. This volume may not be enough to heat a large house. Therefore, simultaneously with performing such an operation as installing and connecting a diesel boiler, a fuel storage facility is usually installed. Its location is selected taking into account fire safety rules. It is installed outdoors, most often underground. According to the standards, 20 cm of free space is required to be left between the walls of the pit and the fuel container. The bottom of the pit is covered with a concrete pad.

When installing and connecting a heating boiler using liquid fuel, mistakes cannot be made. Otherwise, the operation of the equipment may be unsafe. Therefore, the installation of such a boiler is usually entrusted to specialists. You can order this service from us at a low cost. Our highly qualified employees will make all the necessary calculations, advise on the choice of the most suitable equipment and carry out its installation with high quality.

Main stages of work

Installing a diesel boiler has its own nuances. It is more complex than gas or electric equipment, and is also more expensive. However, in a situation where no other type of fuel is available, it has to be done.

The main difficulties are caused by the equipment of the energy storage facility, as well as the performance of work related to its supply to the burner. Therefore, the installation work of such equipment also includes issues related to these aspects.

So, the procedure for connecting and installing a diesel boiler consists of the following steps:

- Selecting a room and preparing a podium for the device, usually it is made of concrete or in the form of a metal frame 15-20 cm high

- Installing the boiler with leveling it

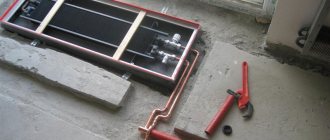

- Installation of supply and return pipes, with the installation of a dirt filter on the latter, protecting the equipment from foreign particles entering it

- When choosing a dual-circuit device, you will need to connect the hot water supply

- Installation of a fuel tank, with laying a pipe and a pump to supply energy to the unit

- Carrying out chimney connection work

- Launching equipment and testing its correct functioning in various modes

However, each of the listed points must be fulfilled taking into account all requirements. So, there are certain requirements for the rooms in which the boiler will be located. They relate to area, ceiling height and the presence of emergency exits. For example, a device with a power of up to 60 kW can be installed in the kitchen, although you are unlikely to want this.

For more powerful units, it is necessary to choose rooms with a height of at least 2.5 m and a volume of more than 15 m³. At the same time, they must have ventilation and lighting, and surface finishing is allowed only with fire-resistant materials.

If your boiler room is located in the basement, then an additional fire exit will be required. But for boilers with a power of over 350 kW, you will have to build a separate room, at a distance of at least 1 m from the door and window openings.

Having chosen a room and installed all the necessary equipment in it, proceed to connecting or piping the boiler. This process must be approached very seriously, since the operation of the entire system as a whole depends on it. To ensure that everything is connected in accordance with the requirements, you should create or find a wiring diagram online. It can have different options, depending on the power of the device, the characteristics of the boiler room and the installation of protection elements.

If you have the necessary skills, it is possible to install diesel boilers yourself. But since in the future you will have to contact specialized companies for warranty maintenance, it is better if they carry out the installation. This will allow you to receive a future guarantee for the uninterrupted operation of the boiler and free maintenance in the future.

Pro tips and recommendations for installing a diesel boiler

In order for your heating system to work properly, the process of equipping it must be approached very responsibly. In this case, experts recommend correctly installing a diesel heating boiler, connecting to the chimney, and commissioning. And also remember about all the official documents that need to be carefully studied before performing installation work.

When designing a chimney, you need to take into account that its pipe should only stand vertically and be without ledges. Its cross-section must be no less than that of the boiler smoke outlet pipe. As a material for a chimney, steel with high anti-corrosion qualities and a thickness of at least 1 mm may be suitable.

Since soot deposits appear on the pipe walls during operation of the system, special cleaning channels are required.

For fire safety, all chimneys in contact with flammable surfaces of the house must be specially protected. materials. The height of the chimney is calculated for a specific building, taking into account all its parameters. At the same time, the installation of the pipe must follow all the necessary rules and it is better if it is done by a professional.

After installing the diesel boiler and chimney, proceed to installing the burner and fuel filter. It is important to know that its power must correspond to the dimensions of the boiler. And the last step is commissioning work, and certainly in the presence of specialists.

Share on social media networks

0

Tweet

What is needed to install the boiler?

Before you begin connecting equipment for the heating system, it is necessary to carry out preparatory work. These include preparing the room in which the boiler room will be located and choosing a location for fuel tanks. They must meet the requirements of SNiPs.

In addition, you will need the equipment itself:

- Diesel unit with burner

- Fuel container

- Diesel supply kit (grade corresponding to the specific project)

- Automation

As well as fittings, pipes, shut-off valves and tools for performing installation work, and always the correct connection diagram for a diesel boiler. We should not forget about performing thermal engineering calculations. It will help you decide on the choice of boiler power.