What is quartz vinyl laminate

The uniqueness of the finishing floor covering lies in its versatility. Quartz laminate is often confused with vinyl tile. The difference in names lies in the form, composition and installation features.

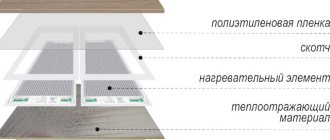

The material has a complex multilayer structure. Each layer performs a specific function and also has different thermal conductivity. The coating class is determined by the thickness of the main and top layers.

Structure and composition of quartz vinyl laminate:

- SPC is the main stone-polymer layer.

Consists of extruded ground stone and vinyl. SPC (stone polymer composite) is the base layer of the product. The composition contains more than 75% natural stone, which provides the coating with hardness, high wear resistance, good thermal conductivity and fire safety. Virgin vinyl performs the function of binding stone chips into a single sheet. Layer density 2000 kg per m³ (identical to the strongest concrete). - Decorative layer.

Made from photo texture with the highest resolution. Most often it imitates natural wood and natural stone in a wide range of colors. - PVC – protective vinyl layer.

Provides durability and wear protection. The class of the product and the permissible load (from 0.2 to 1 mm) depend on its thickness. Thanks to this layer, the coating can be subjected to high loads and used in commercial premises and places with high humidity. - PU varnish is the top protective layer.

High-strength polyurethane varnish gives the surface an even matte shade and protects the coating from UV rays.

All layers are reliably connected to each other using hot pressing. The components are primary, absolutely resistant to moisture, have good thermal conductivity, which is especially important when laying on a “warm floor” system.

What is the difference between quartz vinyl and PVC tiles, porcelain tiles and laminate?

Let's compare the characteristics of several floor coverings to determine the main differences between them:

- PVC tiles. It's vinyl. Does not contain quartz sand, very flexible. The main drawback is unnaturalness.

- Porcelain tiles. A completely environmentally friendly material: hard and wear-resistant, but with a cold-to-touch surface. In addition, tiles or mosaics require grouting.

- Laminate. Externally, it is very similar to quartz vinyl planks, but has less moisture resistance and impact resistance.

We recommend: How many bricks are needed for a stove: calculation, how much is needed for a stove in a house, how to calculate the quantity

It is easy to see that quartz vinyl flooring outperforms other materials in many respects.

Advantages of quartz vinyl coating

Today, quartz laminate has absorbed the best characteristics of floor coverings such as linoleum and traditional laminate.

Read more about the benefits of quartz vinyl laminate:

- Versatility

. The coating can be laid on any surface (floor, walls) and in rooms with high humidity. - Convenient and quick installation.

Quartz laminate has a locking system. The requirements for the base foundation are minimal, the main thing is that the surface is flat (concrete screed, plywood, self-leveling floor). The complexity of installation is similar to laying traditional laminate. - Durability.

The service life declared by the manufacturers is 15-20 years. For example, Fargo quartz laminate belongs to semi-commercial coatings and has a wear resistance class of 33/42, which allows it to be installed in high-traffic areas (cafes, offices, kindergartens). The coating is resistant to falling blunt objects; if you drop a heavy object on the floor, it will not crack, and the coating will not deform under the influence of moisture. - Thermal stability.

Resistance to heat is due to the fact that the composition of the material contains 75% natural stone. The pressing technology is unique as it ensures stability of the coating. The material is ideal for combination with any of the “warm floor” systems. Heating up to 42˚C is allowed. - Electrostaticity.

Does not attract dust. - Resistance to reagents.

Laminate is easy to clean and inert to almost any chemicals. Withstands exposure to alcohol, solvents, gasoline, acid and alkali solutions. Not painted with chemical or natural dyes. Such characteristics allow the use of laminate in medical institutions. - Absorbs noise.

Provides acoustic comfort in the room. SPC board does not emit impact noise. - Environmentally friendly.

Safe for the health of people and animals. Polyvinyl chloride is used to make food containers, drinking water tanks, medical syringes, and children's toys. - Moisture resistance.

Quartz vinyl laminate is 100% moisture resistant. Suitable for finishing bathrooms, pool areas, balconies, outdoor terraces. The material is resistant to changes in humidity and flooding, and does not lose its shape over many years of use.

Caring for quartz vinyl coating is quite simple. It can be washed with any household cleaning products.

How to install?

Before installing the flooring, you should prepare a tool kit, which includes the following accessories:

- pencil;

- roulette;

- marking cord;

- sharp knife;

- metal square;

- putty knife;

- roller;

- sponge;

- construction level.

Stages of laying square quartz vinyl tiles:

- Before the installation process, you need to let the material sit for several days in the room where it will be used.

- Marking. This is done using a regular coated cord: the surface is divided into four even parts.

- Then you should apply the glue and give it half an hour to dry. The glue is applied with a special notched trowel. It is correct to start laying from the entrance to the room and move towards the center.

- Control over the installation process must be exercised using previously drawn clear lines.

- Laying tiles and fixing them using a pressure roller. In this case, it is necessary to remove excess glue and air bubbles.

- For tiles with a pattern, there are signs from the manufacturer on the back side to help you understand the laying order.

- The tiles must be placed tightly, square to square.

- When the work is completely done, you need to use a sponge soaked in ethyl alcohol to remove any remaining glue.

You can walk on the new floor immediately, but placing heavy objects (furniture) on it is allowed after a few days. It is recommended to wash the floor from excess dust later: after 5-6 days.

Video on how to glue tiles to the floor?

In order to glue quartz vinyl to the base without errors, it is worth familiarizing yourself with some of the subtleties that are covered in this video:

We recommend: How to disassemble a boiler with your own hands - step-by-step disassembly instructions

What determines the environmental friendliness of quartz vinyl coating?

The material is absolutely harmless, since it contains only primary natural materials. The finished product does not contain solvents or toxic substances.

To understand why quartz vinyl is an environmentally friendly material, consider the method of its production.

To make the main base layer, mix the following ingredients in a mixer:

- Crushed stone mixture (powder) from rock particles;

- Primary vinyl, PVC (materials used in the food and medical industries);

- Plasticizers, stabilizers, natural dyes and lubricants (less than 0.01%).

The mixture enters the extruder and melts under high temperature. The melting process ensures homogeneity of the mass. Next, the homogeneous mass is squeezed out through a sleeve in the form of a sheet and fed into the calender. With the help of drive shafts, the mass is shaped, cooled, hardened in special baths and takes on the appearance of a canvas. Using a guillotine, elements of the required size are cut.

The production process produces a very dense and stable material. Decorative and protective layers are applied by hot pressing.

When combined with a “warm floor” system, quartz vinyl coating does not emit any toxic substances. Recommended for use in children's and medical institutions.

Quartz laminate and heated floor

A distinctive feature of quartz vinyl coating is its versatility of installation on any surface, including walls. Buyers are often interested in whether it is possible to lay quartz laminate on a “warm floor” system.

Many people strive to maximize the comfort of their living space, and it is always associated with warmth under their feet.

At what temperature does a person feel most comfortable? Its optimal value is 27-28˚C for a cozy home environment

In fact, its indicator must be below body temperature, otherwise the person begins to experience discomfort.

Quartz - Vinyl flooring is suitable for any heated flooring system.

Let us consider separately the combination with each “warm floor” system.

Water underfloor heating system under concrete screed

In city apartments and private houses, a water underfloor heating system under a concrete screed is most often used.

Installation features:

- A layer of waterproofing material is laid on the base.

- The water circuit is installed.

- The structure is filled with concrete screed.

- The final coating is a leveling screed.

- Laying the substrate.

- Laying decorative covering.

After the finishing leveling screed has dried, the floors are completely ready for laying quartz vinyl covering. As decoration, you can use either laminate with a locking joint or adhesive-based tiles.

Electric underfloor heating system under concrete screed

Electric underfloor heating is the most common heating option in city apartments.

Installation features:

- Laying the electrical circuit on the base.

- Pouring cement-polymer screed.

- Laying the substrate.

- Laying decorative covering.

The electric floor heating system is the most popular, since its connection does not cause technical difficulties, unlike water heating. After the cement-polymer screed has dried, you can begin laying the quartz vinyl coating.

Film heated floor under quartz laminate

The easiest and fastest way to install a “warm floor” system for any residential and commercial premises.

Installation features:

- A “warm floor” film system is laid on a concrete base.

- Laying the substrate.

- Installation of quartz vinyl laminate.

When installing a heated floor on a film base, you cannot use adhesive-based vinyl tiles as a decorative covering. In this option, only quartz laminate with a locking connection is used.

Composition and structure of the coating

This material is environmentally friendly because it consists of almost 70% quartz sand. The product consists of:

- polyurethane layer providing abrasion resistance;

- decorative coating, the pattern of which imitates different textures;

- a base layer of polyvinyl chloride with quartz chips, which gives the product strength;

- a layer of glass fiber, which increases the load-bearing capacity of the product;

- a base layer of PVC that ensures adhesion of the tiles to the floor.

The photo clearly shows the structure of quartz vinyl floor film.

Useful tips for installing and operating heated floors under quartz vinyl coating

Despite the fact that quartz vinyl coating is considered a universal decorative material, certain rules should be followed when installing it.

What you need to know:

- Quartz vinyl should not be laid on foam surfaces.

- The operating temperature of the heated floor should not exceed 42˚C.

- In rooms with a “warm floor” system, the installation of furniture without legs and any shelters that impede the free circulation of air is unacceptable.

Quartz vinyl coating itself creates a comfortable feeling of warmth and coziness. If you do not need additional heating, then there is no point in the additional costs of installing a “warm floor” system. It is enough to choose the right decorative coating and enjoy perfect floors.

Which type is better to choose

Regardless of the choice of the type of heated floor, it is not laid under furniture without legs.

Laying quartz vinyl tiles can be carried out in conjunction with any heated floors. But several conditions must be met:

- quartz vinyl must be laid on a solid base;

- the warm floor should not cause heating of the final coating above 40 degrees;

- The heated floor system should not be installed under furniture without legs, since the heated air will have nowhere to escape.

If the tiles are laid on an adhesive solution, the heated floor should be turned on no earlier than a day later, when the glue has completely dried. When using the dry tile installation method using a click joint, the underfloor heating system can be turned on the same day.

Water

Quartz vinyl tiles are laid on a heated water floor mounted in a screed.

Quartz vinyl tiles are laid on a warm water floor mounted in a screed. This method provides an even base for the finishing material, and also protects pipes with coolant from mechanical stress. The disadvantage of this method is that the screed takes a long time to dry and the system is difficult to repair. Therefore, installation must be carried out immediately correctly using high-quality materials.

The principle of operation of a water floor is to lay the contours in a “snail” or “snake” pattern. Heated water circulates through the pipes and releases heat evenly. To ensure that all the thermal energy goes upstairs into the room, foil material is laid on a clean and level concrete base.

Electric

Layout of heated floors with quartz vinyl coating

Electric heated floors are often installed in apartments, since it is difficult to obtain permission for water heating for them. The heat carrier is electrical cables filled with screed. Monolithic concrete pouring reliably protects cables from mechanical damage.

Laying is carried out on a previously cleaned, repaired and level base. The cables are laid out on top of the insulating foil material, connected to the thermostat and the operation of the system is checked. Only after this the screed is poured.

The peculiarity of the installation is that electric heated floors are installed only in open areas of the room. Where furniture is located, cables are not installed. The disadvantage is obvious - in such a room it is impossible to rearrange the furniture without losing the efficiency of electric heating.

You can quickly install an infrared heated floor. It is available in film form. It is laid out on a flat base and connected to the control unit. You can lay tiles on top. In this case, installation is carried out dry, using a locking connection.