There are several types of systems that provide floor surface heating. They can be classified into water systems and electric ones, which in turn are divided into: heating cable, heating mat and thermal film.

All of the above heating systems have their own advantages and disadvantages, but it is the heating system based on the use of thermal film that is the easiest to install. This feature allows you to make a film heated floor with your own hands, regardless of the intended location and technical characteristics of the thermal film.

Application area

Thermal film

Floor heating systems based on the use of thermal film can be used in all types of premises as the main or additional source of thermal energy.

Film heated floors can be installed in residential and public buildings, offices and childcare facilities, industrial enterprises and agricultural buildings.

In addition, thermal film is used for objects located outdoors, such as parking lots, sports grounds, airports, railway stations and other areas where it is necessary to ensure the absence of snow and ice cover.

Principle of operation

The operation of thermal film is based on the principle of secondary convection, when the heating element emits infrared rays, which, similar to solar rays, affect the internal structure of things and building structures located in the room where such a system is installed.

Under the influence of IR rays, all objects, including the floor surface, heat up, after which they give up their heat to the surrounding air, but it should be noted that the IR rays themselves do not affect the surrounding air.

Currently, the industry produces two types of film heated floor systems, differing in the method of installation (installation), these are:

- External installation - the film is mounted directly on the heated surface.

This type of thermal film consists of three layers, the middle layer is carbon-resistive, placed between layers made of lavsan film.

- Internal installation - the film is laid under the finishing floor covering.

This type of thermal film consists of four layers, the top and bottom are made of polyurethane film, and layers of copper and aluminum are placed between them. At the point of contact of the inner layers, a bimetallic contact is formed, which is a heating element of the structure.

Characteristics of thermal film

To make thermal film, thin polypropylene or polyethylene is used. The film is two-layer. Between the layers there is a graphite or carbon mixture. It is applied to the surface in stripes. The top layer reliably protects the heating element from moisture.

Film thickness 0.33 mm. When installing infrared heated floors, the strips are left in their original form. The film can be cut only according to special markings that are applied to its surface.

The current reaches the strips along the heating busbars. They are made of copper and silver and are located at the edges of the film. To organize high-quality heating, manufacturers suggest using film flooring of various capacities.

- Infrared flooring under laminate is used with the ability to heat up to 27 0C.

- An infrared floor under tiles can heat up to 50 0C. Thermal film is used for heating loggias and utility rooms.

- There is also a universal material. It can withstand low and high temperature. Such systems include a coating with continuous application of a heating substance.

The carbon layer can be applied to the film not in separate strips, but in a continuous layer. This gives great opportunities to set up heating in rooms with any geometry. The fabric can be cut in any area. The advantage of this material is its resistance to external influences.

We recommend: How to install Devi heated floors?

You can install stationary furniture on infrared heated floors. Soft and hard materials are used as cladding.

- Depending on the type of room, thermal film of varying strengths is chosen. Systems with a low power of 130 W/m2 are used as additional heating. They are installed in rooms with little load on the floor: bathroom, toilet.

- In the kitchen, in the hallway, for rooms with tiled cladding, infrared heated floors of medium power, up to 170 W, are chosen.

- In garages, workshops, and bathhouses, it is recommended to use thermal film with high output, more than 220 W.

The heating system is regulated automatically by the control unit. The mode is set initially. The heating turns on or off as the floor warms up. This mode allows you to reduce energy consumption. The system operates from 220 V.

The thermal film warms up quickly, in 2 minutes; begins to transfer heat to the floor covering. An infrared heated floor in a residential area with normal temperature consumes 50-70 W/m2 of energy per day; with additional heating 20 W/m2..

Electricity consumption is quite high, so in cold regions the systems are used only as additional heating. When creating a normal microclimate in the room, the film should occupy up to 70% of the surface of the floor base

In Moscow, they use infrared heated floors under linoleum and under wooden coverings of the “heat pro” brand, made in Malaysia. The company produces both thermal film and a system with a continuous heating layer. The “warm floor” heating system “stem energy”, manufactured in Korea, has proven itself well.

Advantages and disadvantages

Film heated floors are simply installed.

Any technical device, including engineering equipment systems, has its own advantages and disadvantages specific to them. In this regard, film heated flooring is no exception; the advantages of its use are:

- Ease of installation work.

- There is no need to make a concrete (sand-cement) screed.

- The volume of the room where such a system is installed does not decrease.

- Economical to use based on IR radiation.

- No or low levels of electromagnetic radiation.

- During operation, the air in the room in which this system is installed does not dry out.

- When the device operates, air ionization occurs, which has a positive effect on human health.

- Possibility of installation both in a horizontal plane (on the floor) and in a vertical plane.

- For devices with an external stacking system – mobility.

There are also disadvantages to such a system:

- The system only works when there is power supply.

- After installation, with an internal installation system, it is impossible to move the strip without removing the finishing floor covering.

- When used as the main source of thermal energy in large areas, the costs for the electrical energy used are quite high.

- Some objects and furniture negatively perceive constant direct influence from a heat source, which leads to the need to install them on special pads that provide an air gap between them and the floor.

Floor covering

Thermal film or rods can be laid under any covering. When using tiles, a layer of glue must be applied to the heating circuit, but the thickness of the layer should not exceed 2 cm. Otherwise, heating will be ineffective. It will take a lot of energy to achieve the required temperature in the room.

We recommend: What is the pipe consumption for underfloor heating per m2?

For porcelain stoneware, a heating system with increased power is used. Before applying the glue, it is recommended to cover the film or rods with waterproofing material.

If linoleum or laminate was chosen as the cladding, then the thermal film is covered with a backing. In a room with a heavy load, the film is covered with sheets of plywood. In this case, stationary furniture can be installed on it. For a system of rods, it is recommended to make a screed from a concrete mixture.

Infrared heating is used for heating in country houses, but one must always remember that heating will depend on electricity. If there are frequent interruptions in the network, it is recommended to consider an alternative heating system. In city apartments, thermal film and rod systems with infrared radiation are often used as additional heating for cold areas.

YouTube responded with an error: The request cannot be completed because you have exceeded your quota.

- Related Posts

- How to install heated flooring in the kitchen?

- How to choose a wire for a heated floor?

- How to install PErt pipes for heated floors?

- How is polystyrene foam used for heated floors?

- How does a flow meter for a heated floor collector work?

- How to install an electric heated floor?

How to choose a film heated floor

When choosing a thermal film used to create underfloor heating, the selection criteria are:

- Electrical power, measured in W/m2.

- Film thickness.

- Manufacturer's brand.

- Price.

Knowing the selection criteria and the location of the intended installation of the film heated floor, you can always choose exactly the product that will provide the required heating parameters, regardless of what heat source the installed system will act as.

In addition, thanks to the Internet, you can always find reviews from users who are already using one or another model of a film floor heating system.

Do-it-yourself installation of film heated floors

Laying a heated film floor

When a decision is made about the need to install a floor heating system, and the choice fell on thermal film, then several questions arise that need to be resolved before starting work, these are:

- How to do it?

- How to connect this?

The simplest, but more expensive way is to contact a specialized organization, whose specialists will select the required system and install it.

If the user wants to carry out the installation himself, then the work is performed in the following sequence:

- The type of film is selected - in accordance with the selection criteria, the location of the heating system and its purpose (main or additional heating source).

- The base is being prepared.

The base on which the heating system will be installed must be level, without bumps or holes. The permissible size of irregularities is 2.0 – 2.5 mm.

If the base is concrete, then it is sanded; if it is wooden, it is sanded. There should be no debris or foreign objects on the surface.

- Laying film heated floors.

Before starting installation, you must read the instructions included in the delivery kit, which reflect the conditions for installation and connection of a specific model of the heated floor system.

It must be remembered that when laying thermal film, the gap between its edge and the wall should be no more than 100 mm, and cutting it can only be done in places marked on the surface of the product.

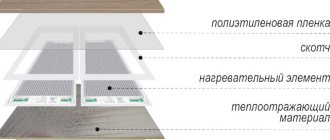

A heat-insulating gasket is placed on the prepared base, with the smooth, metalized side facing upward. The gasket strips are connected to each other with tape; its surface should be smooth, without folds or bulges.

Thermal film is being laid. To prevent the film strips from slipping, they are connected to each other and to the lining using tape or other adhesive tape. The film strips are laid close to each other, which further ensures uniform heating of the floor surface.

- Connecting thermal film.

After all the strips of the film used are laid, they must be connected into a single chain.

To do this, use special clamps included in the delivery set, with the help of which the bus bars mounted in the film with connecting wires are connected.

By means of connecting wires, all strips of film are connected, as well as the end connections are brought to the system control panel.

Electrical wires (terminals) are led out to the wall, where they are subsequently inserted under the baseboard.

The temperature sensor is being installed. The location of its placement is determined in each specific case individually, but taking into account the length of the wires that ensure signal transmission to the control panel. As a rule, this is no more than 50.0 meters.

The control panel (temperature regulator) is being installed. Its location should be convenient for making adjustments to the heating system.

All electrical wires are connected into a single circuit and connected to the power supply network, after which the functionality of the assembled circuit is checked.

- Laying the finishing coating.

After completing the installation of the thermal film, you can begin to carry out the final work, and if a laminate is used as the finishing coating, then it is enough to lay a layer of solid polyethylene film, and then install the coating.

If carpet or linoleum is used, it is necessary to lay plywood, OSB sheets or other sheet lumber that provides the required protection over the surface of the thermal film.

When using ceramic tiles as a finishing floor covering, it is necessary to lay a layer of polyethylene film over the surface of the thermal film, on which a reinforcing mesh is laid, onto which the tiles are installed using tile adhesive.

When installing a film floor, you must remember that:

- Do not bend the thermal film used at an acute angle.

- Installation work is not carried out at low ambient temperatures and high humidity.

- It is prohibited to use nails and self-tapping screws when securing elements of the heated floor system and its finishing.

- The length of the laid underfloor heating strips should not exceed 10.0 linear meters.

- Installation near other sources of thermal energy (fireplaces, stoves, heating radiators) is prohibited.

- You cannot check the performance of thermal film in the transport position (on a roll).

Rod systems

Infrared film flooring is easy to install. You just need to connect all the parts correctly. Installing the rod circuit is also not difficult. Rod flooring is produced in rolls: width from 70 cm to 1.5 m; roll length 25 m.

The graphite or carbon mixture is enclosed in individual rods. They are insulated with a protective sheath made of polypropylene. The rods are located in increments of 10 cm from each other. At the edges they are connected by copper wire, which is protected by insulation. If one rod breaks, the system continues to operate. Heating stops only in a certain area.

We recommend: What are the advantages of Gulfstream underfloor heating?

If the side wire breaks, the system shuts down completely. Installation of rod heating is carried out under tile adhesive or under a screed. With additional heating, energy costs will be minimal.

What are the consequences of installation errors?

The base must be made level

When installing a film heated floor, done by yourself, you can make a number of mistakes that can lead to negative consequences, such as:

- Failure to match the electrical power of the underfloor heating system with the power of the electrical network through which the connection is made will lead to failure of the protection devices or supply line wires, and as a result, a short circuit and fire.

- Incorrect preparation of the base or selection of underlying materials can lead to damage to the tires mounted in the film, and as a result, to failure of the heating system element.

- The absence of a thermal insulating gasket will reduce the efficiency of using a floor heating system.