Installing heated floors in the bathroom: pros and cons

Do not connect the water circuit to the heating without permission from the relevant authorities.

You can easily install heated floors in your bathroom yourself. In apartments with central heating, it is illegal to change the heating system without the necessary permits.

If you independently, without the knowledge of certain authorities, make warm floors from central heating, then as a result the neighbors will complain that the apartments are quite cold, since the pressure in the pipes will drop. If it turns out that heated floors were made illegally, you will need to remove the system and pay a fine.

Considering these facts, in high-rise buildings it is recommended to begin installation only after the necessary documents and permits have been completed.

Two way valve

An alternative option could be electric floor heating systems.

If a water floor heating system is installed, a connection from a heated towel rail is often used in bathrooms. The main thing in this case is to take care not only of yourself, but also of your neighbors.

They may experience a decrease in battery temperatures. To avoid heat loss from other people, a two-way valve is installed.

Before installation, you should familiarize yourself with the disadvantages and advantages of the system, which are given in the table:

| № | Advantages | Flaws |

| 1 | The system is invisible to the eye and does not take up space like radiators. | The initial cost is quite high. |

| 2 | Taking a bath and being in the room is more pleasant when you stand on a warm floor. | Certain types of coatings cannot be installed with heated floors. But in the bathroom, as a rule, tiles are used, so there should not be any difficulties. |

| 3 | Fast payback of the heating system. |

If you do the installation yourself, the cost will be significantly reduced and you will only get positive emotions from the heating system.

You need to remember about permits that will protect you from paying fines when connecting the system to central heating, as well as from legal proceedings.

How to make a heated floor in the bathroom from a heated towel rail

To avoid troubles during operation, at the preparatory stage of installation the main thing is to choose the right materials. The warm floor from the heated towel rail in the apartment is installed using metal-plastic pipes. This material is able to withstand sudden pressure surges in the system and does not respond to temperature increases.

Reinforced fittings are used for threaded insertion. Experts consider the ideal scheme for a heated floor in a bathroom from a heated towel rail, in which each unit can be independently turned off or the water flow can be regulated using a bypass.

- The first stage of work is cutting into the riser. The taps are installed using union nuts. An adjustment valve is installed on the rack; shut-off valves are more effective if they have a ball design.

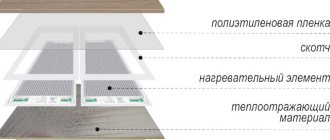

- Before laying the pipes, it is necessary to prepare the substrate. Foam material with a reflective layer is used as standard. In this way, all the heat will go into the room, and not into the floor.

- When laying pipes, you should adhere to a pitch of 15 cm. With a smaller turn, the floor and room will not warm up enough. With more frequent turns, too much pressure inside the system can lead to emergency situations.

- Now all that remains is to connect the warm water floor pipes from the heated towel rail to the system. It is better to do this using couplings, avoiding corner connections. They increase the pressure as the media circulates.

Parallel connection of heated floors

Infrared film heated floor characteristics, calculation, connection diagram and installation

When connecting in parallel, tees are installed at the connection points of the heated towel rail. The underfloor heating circuit pipe is connected to them through shut-off valves. In this case, it is necessary to install one control valve to control the water flow through the circuit.

The disadvantage of this type of connection is the likelihood that an insufficient amount of coolant will pass through the floors. This is due to the fact that the circuit resistance exceeds the hydraulic resistance of the heated towel rail.

To establish high-quality circulation, you will have to limit the water flow through the substation and close the tap at the inlet or outlet of the heating device. This can cause a general decrease in flow through the riser and complaints from neighbors.

As a solution to this problem, you can install a low-power circulation pump. The unit will forcibly pump the coolant, but this will cause a small consumption of electrical energy. The power of the pumps for use in the described case is 50 – 70 W.

Connecting a heated floor to a heated towel rail

*

The idea of using centralized heating as the main heat source for operating other heating systems in the apartment is not new. Using electric household heaters en masse to create a comfortable temperature in an apartment is a costly task. Insufficient thermal efficiency of residential premises causes high costs for additional heating. In this regard, underfloor heating is the most effective method of heating. For private houses, this heating scheme is realistic and feasible, but for city apartments, the legality of this engineering and technological solution comes first.

The main reason for the ban is that inserting additional heating devices into the centralized heating system can negatively affect the quality of heating in neighboring apartments.

For reference: in a central heating system, the operating pressure differs significantly from the optimal parameters that the pipes of the heated floor circuit have. Don't forget about the temperature of the coolant. For a heated floor, the optimal heating temperature is 35-450C, while in the radiators of a central heating system the coolant has a temperature of 65-750C.

The incompatibility of operating parameters calls into question the combination of a centralized heat supply system with a heating pipe laid in the floor. If we omit the legality of this engineering solution in this situation, heating engineering specialists speak negatively about the idea of using a heating plant to operate a heated floor. The poor quality of the coolant and the high probability of water hammer make this technical solution a problem area in the apartment. It's a completely different matter when it comes to heating a limited area in your apartment.

For example: a bathroom, toilet and other rooms are in dire need of additional heating. Installing a heated floor in the bathroom, which will be connected to a heated towel rail, is a task that you can handle on your own. Calculations and expenses do not play a key role in this case. The small area and insignificant amount of work allow this heating method to be used in a city apartment without harming the neighbors.

Connection diagram for coolant to hot water

How to make a warm floor from heating Warm water floor. Installation of heated floors

Many people are interested in the question of how to connect a heated towel rail to a hot water riser. Of course, here you need to follow certain instructions. All work will consist of several stages, namely:

- Removing the heated towel rail.

- Selecting a new location for its installation and marking the installation.

- Installation of shut-off valves.

- Installation of fasteners for heated towel rails.

Important! It is quite possible to install and connect a heated towel rail to hot water with your own hands. First of all, you should adhere to a certain scheme. So, first of all, experts recommend installing a bypass to the hot water riser, which will act as a jumper

The entire subsequent scheme looks very simple. When connecting a heated towel rail in the bathroom from the hot water supply, it will ensure the circulation of coolant through the heating system. First of all, you need to decide which type and design is best to choose. So, first of all, the coupling is connected. The diameter of the coupling will depend on the outlet to the heated towel rails and the hot water riser. You should also decide exactly how to install this device. So, if the length of the eyeliner reaches about 50 cm, then it is better to choose a horizontal installation.

So, first of all, experts recommend installing a bypass to the hot water riser, which will act as a jumper. The entire subsequent scheme looks very simple. When connecting a heated towel rail in the bathroom from the hot water supply, it will ensure the circulation of coolant through the heating system. First of all, you need to decide which type and design is best to choose. So, first of all, the coupling is connected. The diameter of the coupling will depend on the outlet to the heated towel rails and the hot water riser. You should also decide exactly how to install this device. So, if the length of the eyeliner reaches about 50 cm, then it is better to choose a horizontal installation.

Important! The ideal installation method would be one that allows the coolant to move from top to bottom. This will ensure uniform and high-quality heating.

Among other things, when installing a heated towel rail, it is important to maintain the exact distance from the wall to the pipe. As a rule, it will depend on the diameter of the coolant supply pipe. So, if the diameter is about 40 mm, then the distance should be about 550 mm. Hanging is carried out on special stops. To prevent deformation during the heating process, the fastening must be free. Once you have finished connecting the pipeline to the hot water supply, you can start the system to check its functionality. During the test run, it is important to ensure that all connections are absolutely tight. If there is even the slightest drip, then you will have to fix this leak. As you can see, connecting a heated towel rail to a hot water supply in a private house does not pose any particular problems.

Advice! When working, do not skimp on the quality of all initial building materials. This will allow you to eliminate possible problems when using the towel.

Now we invite you to familiarize yourself with common methods and diagrams for installing/connecting a towel. There are several effective ways to accomplish this task. We will look at the most common and popular ones. One way is to connect from below. Everything is very simple here. Hot water comes in on one side and comes out on the other side. A method of connecting from above is also known. For this purpose, a special entrance is used, located in the upper part. It is through it that the power supply will be carried out. Accordingly, on the other side there will be a coolant outlet. Another way to connect diagonally. For example, the water supply will be from above on one side, and diagonally on the other side of the device there will be an outlet at the bottom. Another connection scheme is to carry it out in the center. Special heated towel rails are even sold for this purpose. Their peculiarity is that fastening and installation is carried out on the lower crossbar. This method is especially suitable for cases where the equipment has the shape of a ladder.

Advice! If you have a single-point heated towel rail, then the connection is made at the bottom from one point. But this method is practiced extremely rarely. But some manufacturers offer similar products.

Types of heated towel rails

How to connect a heating cable to the network

A heated towel rail is a special type of radiator in the shape of a coil; the working fluid circulates through a curved pipe. The water model is used complete with fittings that provide connection to the hot water supply system; electric variations have a built-in heating element. The operating principle of both devices is the same: the pipe, heating up along with the energy carrier, dries the air in the room and removes moisture from hanging towels. In the standard version, the battery is fixed to the wall.

Water

It fits into the heating and hot water supply system; this is the most common design option. It is independent of power supply and has the following advantages:

- ease of execution,

- safety,

- unpretentiousness in maintenance,

- loyal price range and variety of models,

- effective completion of the assigned task.

But there are also weaknesses:

- complete dependence on the supply of hot water or heating;

- the formation of a layer of corrosion and scale from the inside, which affects the ability to heat the body.

Water heated towel rail

We must not forget that air pockets often form in such systems.

Electrical

They are full-fledged radiators with a closed circuit. Their dimensions are slightly larger (due to the design features), they can be installed in any area of the bathroom, as long as the cord reaches the outlet. Electric models can be oil-based, they are attractive due to their high heat capacity, and “dry” - they do not contain a working fluid, a cable is laid.

Advantages of the line:

- long service life;

- reliability in use;

- moderate energy consumption;

- The device can be turned on and off as needed.

The downside is complete dependence on the electricity supply; products are sold in a high price segment. Electrical variations can be supplemented with useful options - thermostat, timer, automatic safety equipment.

Electric heated towel rail

On the specialized market there are universal models that combine the positive properties of both categories; they are connected to the electrical network and heating. With the correct installation, the dryer will delight you all year round: in the summer from the mains, and in the winter from centralized heating. The only difficulty is choosing the optimal installation location.

Popular types of heating devices

The modern market of heating devices offers a fairly wide selection of devices designed for heating bathrooms. These include:

- metal water heating radiators;

- infrared heaters;

- convective-infrared heaters;

- oil instruments;

- electric convectors;

- fan heaters;

- cast iron radiators.

To have an idea of the different types, you can consider the characteristics of the most popular models.

Water heating radiators

Popular with users. Such devices have replaced old, cast-iron radiators. Connecting a heated towel rail to a hot water riser is easy.

The advantages of such devices include:

- long service life;

- low price;

- a light weight;

- simplified installation process.

The connection diagram of the device is quite simple; any master can handle connecting the heater. In addition, this device does not consume electricity, unlike other heaters.

Important!

Connecting a heated towel rail to a boiler is also possible; this is especially true for residents of houses with no hot water supply system.

Panel heaters

It is not the air in the room that warms, but the walls and floor. The installation location of the device is the ceiling.

Such heaters do not take up room space; they are advisable to use in rooms with a lack of free space. In addition, such a heater meets the most stringent safety requirements.

The design of such a device is complex; it can function fully in rooms even with extreme humidity levels.

Also interesting: How to install a screen under a bathtub?

The advantage is energy savings - the beams of the device, depending on the need, can be directed in any direction.

The disadvantage is the high price. Bathroom heating mats work on this principle.

Infrared models

The heating element in convective-infrared modular heaters is an element made from a special threshold with a nichrome thread inside.

This device can be hung on the wall; by the way, it does not spoil the appearance of the room at all. The power of the device is adjusted using a thermostat.

You can place the heater not only on the wall, but also on the ceiling, and the device will warm the room equally well.

The heating element is a ceramic panel, which is a radiator.

Once heated, it emits infrared waves. They do not come into contact with air, but affect surrounding objects. Such devices can be used in conditions of high humidity.

The undoubted advantage is that they do not produce unpleasant noise, unlike fan heaters, and act as a source of lighting at night.

When choosing a heating device, you need to start not only from taste preferences. It is important to compare the power of the device with the dimensions of the heated room. A summary table will help you understand these parameters:

| Area (sq.m) | Required power of the device to ensure optimal heating (W); |

| 5-6 | 500 |

| 7-9 | 750 |

| 10-12 | 1000 |

| 12-14 | 1250 |

| 15-17 | 1500 |

| 18-19 | 1750 |

| 20-23 | 2000 |

The use of insufficiently powerful appliances in large bathrooms is unjustified; this will lead to energy costs, but the heat generated will not be enough to fully warm up the room.

Fact!

The internal part of the heater warms up to 150°C, but the body temperature does not exceed 60°C.

Oil appliances

They are one of the most popular devices. An electric spiral, which is placed inside the device, heats up the oil, due to the boiling of which the body is heated, and after which the air in the room warms up.

Presented in a metal case with a ribbed structure. They are installed using special anchors that come with the device.

Advice!

Such fittings may not be of very high quality, so it is better to purchase a set of anchors separately. The heating element of such a device is a heating element, and the coolant is oil.

The design is resistant to corrosion, as the surface is covered with enamel. The thermostat protects the device from overheating, which also affects energy consumption.

The device turns off automatically after the air in the room warms up to the required temperature. An oil radiator can be used to dry clothes.

The advantages also include:

- high maximum temperature;

- operational safety;

- no noise;

- automatic shutdown when overheating;

- wheels for ease of movement.

Also interesting: Loft style in the bathroom and the sophistication of urban everyday life

Preference should be given to devices with a built-in air ionizer, because oil heaters dry out the air in the room.

You should not purchase cheap models, because during operation they can emit an unpleasant odor.

Electric convectors

Used for space heating. The device consists of a metal body and an internal heating coil. The air passes through the heating part and warms up.

It is worth noting that the efficiency of such heaters improves if such devices are located below.

When choosing heaters of this type, you should pay attention to:

- devices with a ceramic heating element do not burn air;

- for use in the bathroom, preference should be given to devices with high protection against moisture;

- the advantage will be the presence of wheels for free movement of the device;

- room heating speed.

The disadvantage of devices made according to this scheme is that they have a built-in fan, which often acts as a source of excess noise.

Fan heaters

They are the simplest heating devices, and many users choose them for heating bathrooms. The power of such devices is quite high.

They are quite compact, so they can be installed on the floor or other flat surface.

A fan heater is a simple device consisting of a plastic housing, a fan and a heating coil.

Among the advantages are:

- low cost;

- ease of use;

- device mobility;

- ability to quickly warm up the room;

- ease of operation;

- small sizes;

- modern appearance.

The device has certain disadvantages, for example, it makes annoying noise and emits an unpleasant odor.

Operating principles of the heating system

This connection option does not pose any technical difficulties. A heated towel rail is a heating device installed in almost every city apartment. From a constructive point of view, this is an external element of communications through which hot coolant or hot water of the DHW system circulates. Such elements are often installed as a compensating loop of the heating system, playing the role of an additional source of heat in rooms with high humidity. The name of the element speaks for itself, hence the serpentine shape, thanks to which you can effectively use the heated circuit.

For aesthetics, heated towel rails are usually made of stainless steel or plated with nickel. The design itself and the method of connecting the heated towel rail to the centralized communication make it possible to connect a water floor pipe to it without much difficulty. As a rule, small diameter pipes are used for heated floors. For a bathroom, the area of which rarely exceeds 4-5 m2 in a city apartment, only 15-20 meters of pipe will be required.

There are two types of heated towel rails:

- a coil that is connected to a centralized heating system;

- a coil that is connected to a centralized hot water supply.

In the first case, with the onset of the heating season, water fills the heated towel rail and accordingly enters the heated floor circuit, heating the floor surface.

The first option only works during the heating season. The rest of the time your heated floor will be inactive. A coil connected to the DHW system looks preferable. Such a floor in the bathroom will always work, providing a good microclimate and comfortable temperature.

Heated floor design instead of a heated towel rail

High-quality work directly depends on a properly installed substrate. It consists of 5 main components:

- insulation from possible leaks;

- metal mounting mesh;

- thermal insulation;

- damper tape compensating for various expansions;

- one type of screed (dry or wet).

On average, the thickness of such a substrate is 5–15 cm.

The essence of the design is that metal-plastic pipes are fixed together into fragments, placed on a substrate and fixed to the collectors. The coolant circulates through the latter, and the return is returned. Warm floors are a low-temperature design, because their heating does not exceed 45 °C.

Reference! For improved heating of the room, it is better to use ceramic tiles or concrete screed as a floor covering.

Advantages

- No interference with finishing the room;

- preservation and saving of heat consumption. This is especially true for rooms with high ceilings;

- Absolutely environmentally friendly. This design does not have a negative impact on human health.

Flaws

- Expensive installation of heated floors;

- administrative ban on installation of this structure;

- increase in floor weight due to layering of the substrate in the bathroom.

How to lay infrared film?

Preparatory work is carried out as in the version with cables. Sheets of film are laid parallel to the thermal insulation material, retreating approximately 20 cm from the wall. A distance of 30-50 mm is left between the strips of infrared fabric.

Laying sheets of infrared film overlapping is prohibited.

Next, a thermostat with a sensor is installed, then their functionality is checked.

Carefully cover the device with infrared film with a reinforcing mounting mesh so as not to touch the contacts, and secure it with self-tapping screws. The structure is filled with cement screed.

You need to wait until the concrete mortar has completely dried, then lay the tiles on the adhesive, which will be the finishing coating.

Specifics of installing a heated towel rail

The general principle of connecting any type of heated towel rail remains unchanged: water is supplied at one end, and it flows out at the other. Installation of a substation requires mandatory consideration of points dictated by the installation features.

When connected to a hot water or central heating system, it becomes part of the pipeline. If the connection is made incorrectly, then the problems that arise will affect not only the individual apartment, but also all the others located along this riser.

The heated towel rail is connected to centralized and autonomous heating or hot water supply systems, hung on the wall and/or installed on the floor

To avoid electrolytic corrosion, it is recommended to use parts made of the same material. The exception is plastic pipes; plumbing fixtures made of any material will fit them.

For our water supply system, it is better to choose a heated towel rail manufactured by domestic manufacturers and that complies with regulatory documents. You need to be careful with imported models - most of them are designed for different standards.

The range of heated towel rails includes rotating options, the connections of which are equipped with movable mechanisms with sealing seals. Models can be loaded up to 5 kg

A ladder-shaped heated towel rail is connected to the pipeline using several methods - vertical, diagonal, lateral. The main thing is to maintain an interaxial distance of 50 cm.

When connecting to an existing system, you need to take into account its parameters. The distance from the riser to the newly installed unit should not exceed 200 cm, otherwise significant heat loss cannot be avoided.

Ideally, the pipes of the system and the heated towel rail are the same in diameter, but if they still differ, then the connection is made through adapters.

The pipes of the device may be larger in diameter than the pipes of the existing circuit, but in no case smaller. This will prevent the creation of excess hydraulic pressure and ensure normal coolant circulation in the system.

A selection of photos will familiarize you with the features of connecting a substation to hot water systems:

Image gallery

Heated towel rails connected to the risers of centralized hot water supply networks are used as clothes dryers and bathroom heaters.

They are made from seamless steel pipes in the form of stairs with rungs or coil-shaped structures

The devices are made from materials that are resistant to standard operating conditions for bathtubs and showers. External coating protects pipes from rusting

Heated towel rail devices manufactured for connection to hot water risers can be used as radiator types and are allowed for connection to heating circuits.

To ensure that the device, if necessary, can be easily dismantled and moved to another wall, detachable couplings with American-type internal threads must be used to connect it to the riser. It is necessary to strive to reduce the number of adapters, because... Leaks may form at the places where they are installed.

The joints should be sealed with special compounds or winding, and you should not save on this. Connections with regular metric threads are sealed with flax winding. It is better to seal tapered threads using FUM tape. Tightening should be carried out with a slightly noticeable tension; excessive force is unacceptable.

When selecting taps and fittings, inquire about their electrochemical compatibility so that they do not create a galvanic couple upon contact. A connection made of steel and brass has this property. Rapid corrosion occurs and the unit becomes unusable.

The use of an adapter called American allows you to fix the structure when the diameters of the taps and pipes in the system do not match

If the plumbing fixture is part of the riser, then no shutoff devices can be installed on it. To make it possible to turn off the heated towel rail without shutting off the entire riser, it is necessary to include a bypass in the system - a jumper connecting the outlets from the riser towards the device.

Ball valves are installed after this jumper. When the connection pipes are embedded in the riser, it itself acts as a bypass.

In order for the device to be dismantled for repairs without turning off the system and draining water from it, it is better to include a bypass in the installation diagram of the heated towel rail

Self-installation

The concrete base must be leveled before laying the pipeline

After all preliminary issues have been resolved and permits have been obtained, you can begin installing the underfloor heating system.

Before purchasing material, it is advisable that a diagram be developed that indicates the exact length of the pipeline, the diameter of the pipes and the location of the supply and return. It will roughly look like this:

Connection diagram of the water circuit to the heated towel rail

Related article: How to glue wallpaper for painting: the right approach and 9 materials

Don’t forget about waterproofing, which, in the event of a pipe break, will protect your neighbors from flooding.

As mentioned earlier, heated floors connected from the water circuit of the heated towel rail are laid directly on a concrete base, which must be well cleaned.

The next step is to lay thermal insulation on the surface. Only after this can you begin laying and connecting the pipeline.

This is done as follows:

- The structure is assembled depending on what material was purchased. The polypropylene pipe is connected using special fittings, the metal sheet is laid out so that there is a minimum number of connections. Copper or stainless steel are mounted with corners of a similar composition.

- Fixation to the floor surface is carried out with clamps.

- The insertion into the system occurs using a coupling. In this case, it is recommended to avoid sharp turns of the pipeline and use only high-quality materials.

Metal reinforcement will increase the strength of the screed

- A reinforcing mesh is laid out on top of the pipeline, designed to provide greater strength.

- At the intersection of the walls and the floor, a damper tape is glued, which is necessary to limit the enclosing structure from the cement mixture.

- The mixture used to fill the screed is poured along the exposed beacons.

- Over the course of several days or weeks (depending on the thickness of the poured layer), the composition will harden; it is recommended to periodically moisten it with water. This will prevent the surface from cracking due to drying out. To learn how to connect the water circuit to the battery, watch this video

After the screed has hardened, you can lay the finishing floor covering: tiles, linoleum, self-leveling floor.

Warm floor from a heated towel rail, how to connect, diagram

To make a warm floor from a heated towel rail, you do not need to install a circulation pump.

The fact is that the area of the room is quite small, so the length of the pipeline will also be insignificant.

However, before installing pipes, it is advisable to completely dismantle the old floor covering.

The room should only have a concrete floor. Moreover, it is recommended to thoroughly clean it from dirt and bullets.

Features of the work

It is worth noting that the installation of heated floors is carried out using accurate data and diagrams.

If you assemble the pipeline autonomously without mathematical calculations, you can run into a number of problems. The main ones are presented below:

- If the heated towel rail is heated excessively, the floor surface will also be very hot, which can cause burns to your feet. It is recommended to make a temperature regulator for the dryer, otherwise it is better to abandon the plan.

- Installation errors may result in disruption of hot water supply.

- High internal pressure will lead to damage to the integrity of the pipes, depressurization and leakage.

- Professional craftsmen do not undertake such work without first providing permitting documentation from the competent authorities.

It is recommended to proceed with installation only after all the advantages and disadvantages of installing a heated floor with a connection from a heated towel rail have been weighed.

Self-installation

After all preliminary issues have been resolved and permits have been obtained, you can begin installing the underfloor heating system.

Before purchasing material, it is advisable that a diagram be developed that indicates the exact length of the pipeline, the diameter of the pipes and the location of the supply and return. It will roughly look like this:

As mentioned earlier, heated floors connected from the water circuit of the heated towel rail are laid directly on a concrete base, which must be well cleaned.

The next step is to lay thermal insulation on the surface. Only after this can you begin laying and connecting the pipeline.

This is done as follows:

- The structure is assembled depending on what material was purchased. The polypropylene pipe is connected using special fittings, the metal sheet is laid out so that there is a minimum number of connections. Copper or stainless steel are mounted with corners of a similar composition.

- Fixation to the floor surface is carried out with clamps.

- The insertion into the system occurs using a coupling. In this case, it is recommended to avoid sharp turns of the pipeline and use only high-quality materials. Metal reinforcement will increase the strength of the screed

- A reinforcing mesh is laid out on top of the pipeline, designed to provide greater strength.

- At the intersection of the walls and the floor, a damper tape is glued, which is necessary to limit the enclosing structure from the cement mixture.

- The mixture used to fill the screed is poured along the exposed beacons. Over the course of several days or weeks (depending on the thickness of the poured layer), the composition will harden; it is recommended to periodically moisten it with water. This will prevent the surface from cracking due to drying out. To learn how to connect the water circuit to the battery, watch this video

After the screed has hardened, you can lay the finishing floor covering: tiles, linoleum, self-leveling floor.

Main disadvantage

Warm floors from a heated towel rail are a complex structure, the quality of which depends on a number of reasons.

For example, if there are frequent hot water outages in the house, the floor surface will be cold at such times.

With low pressure in the pipeline, the water will cool inside it, which is also considered a significant drawback. Separately, it should be said about the situation when a pipe burst occurs. If such an accident occurs, you will need to not only remove the floor covering layer, but also damage the integrity of the concrete screed. In addition, if a leak is not detected in a timely manner, there is a danger of flooding the neighbors below.

If you decide to make a heated floor with a connection from a heated towel rail, before pouring the concrete screed, be sure to check the integrity of the system by filling it with water and performing a test run.

In addition, it is desirable that the diagram and the actual layout of the pipes are identical. This will help in further operation and accurate detection of leaks.

How to make a heated floor from a heated towel rail?

First you need to get rid of the old floor covering and thoroughly clean the dust and dirt from the surface of the concrete base.

The installation site is leveled and high-quality waterproofing is carried out, which will be an excellent insurance against water breakthrough in case of damage to the structural elements of the water heated floor. Further installation of thermal insulation will prevent heat leakage downwards.

Polypropylene pipes are connected using fittings. To connect metal-plastic pipes, you need ones that create as few joints as possible during installation. When using copper products, corners made of the same material are used.

The necessary elements are fixed using clamps. Using couplings, the finished circuit cuts into the system without sharp turns of the pipeline. To increase the strength of the screed, a reinforcing mesh is laid as the next layer.

A compensation damper tape must be glued along the perimeter of the walls to avoid cracking of the concrete screed, as it expands when drying. Beacons are set before pouring the solution so that the surface can be leveled using them.

Depending on the thickness of the concrete mixture, it will take about two weeks to dry; from time to time it is necessary to moisten the surface of the screed with water to prevent it from drying out.

After connecting the circuit to the heating radiator, the system is checked and the finishing lining is laid - tiles, self-leveling flooring, linoleum.

When installing heated floors in the bathroom on your own, it is recommended to work together with an experienced specialist.

- Related Posts

- How much does underfloor heating cost?

- What characteristics does Warmstad underfloor heating have?

- How is a heated floor connected?

- How to fill a heated floor?

- How to choose a pump for underfloor heating?

- How to check a heated floor?

Connection to individual heating

Another connection method is to use an individual heating system. In this case, everything is much simpler, because you do not need to obtain any permits. This scheme has virtually no disadvantages. As a rule, such a scheme may include the following elements:

- Thermostatic valve. It receives a signal from the installed temperature sensor to turn the heating on and off.

- Balancing valve. Thanks to this, idling of the coolant in the circuit is completely eliminated. If the coolant is not supplied, then it starts heating in a small circle without a boiler.

- Circulation pump. This device allows you to achieve a uniform temperature over the entire floor area.

- Safety thermostat. Its installation is carried out on the feed. It controls the temperature of the coolant in the entire underfloor heating system.

- Electric drive. It is used to control the valves of each circuit.

- A collector that distributes coolant flows across different circuits.

- Remote temperature sensor. The heating floor sensor is connected to the entire control unit.

Features of the work

If you install the floor without a temperature controller, the floor will be as hot as the heated towel rail itself

It is worth noting that the installation of heated floors is carried out using accurate data and diagrams.

If you assemble the pipeline autonomously without mathematical calculations, you can run into a number of problems. The main ones are presented below:

- If the heated towel rail is heated excessively, the floor surface will also be very hot, which can cause burns to your feet. It is recommended to make a temperature regulator for the dryer, otherwise it is better to abandon the plan.

- Installation errors may result in disruption of hot water supply.

- High internal pressure will lead to damage to the integrity of the pipes, depressurization and leakage.

- Professional craftsmen do not undertake such work without first providing permitting documentation from the competent authorities.

It is recommended to proceed with installation only after all the advantages and disadvantages of installing a heated floor with a connection from a heated towel rail have been weighed.

Features of use

A warm floor from a heated towel rail in a bathroom is, rather, not commonplace, but an exception to the rule. However, such a heating system still exists, and therefore deserves attention.

Let us remind you that this water heating system will directly depend on how the centralized communications network functions. And, for example, a pressure drop in the general system or a deterioration in the quality of the coolant will affect the permeability of the water circuit.

How to install a warm water floor in an apartment using a heat exchanger. You can read about this in this article.

Don't forget about possible emergency situations. If a pipe ruptures due to a water hammer, the resulting leak will need to be repaired immediately. It will be necessary to remove both the tiles and repair the screed area. It is even possible that in an accident you will flood your neighbors.

Remember that a hot towel dryer can be your problem. If there is no thermostat, it will be difficult to achieve the optimal temperature in the bathroom. A floor that is too hot can dry out a small bath space too much. After all, instability of hot water supply in apartment buildings is not a rare phenomenon. In some cases, a collector and thermal control sensor can help, but then, naturally, the heating system will require large financial investments.

You can read about the types of thermostats for heated floors.

A warm floor in a bathroom is, of course, comfort and warmth, which is so lacking in the cold season. Connecting the system to a heated towel rail is one of the options for creating these favorable conditions.

You can install underfloor heating from a heated towel rail yourself, but only if you have the appropriate skills. If you have no experience, rely on the skills of qualified workers.