Application area

Insulation of walls outside

Insulation from Rockwool Scandic series is most often used to insulate external walls. The best choice is ventilated facade technology, which ensures ideal vapor exchange, which ultimately makes it possible to prevent walls from getting wet and to choose any decorative coating for facades. The good technical characteristics of the material make it possible to use it as insulation for two-layer brickwork. Typically, builders build a wall in two layers using the principle of well masonry, placing material between the layers.

The slabs can also be used in frame construction, laying a layer of insulation between sheet or piece material at the base of a wooden frame. The material will also be useful for those who plan to decorate the walls of a house using the “wet facade” technology; it is used for both external and internal insulation of walls, if necessary. Rockwool insulation from the Light Butts Scandic series is suitable not only for walls, but also for floors and ceilings, for example, for the purpose of insulating basements without heating or cold attics.

With its help, floors on joists or under screed are effectively insulated. The versatility of the material allows it to be used for attics and roofing structures, including for the purpose of insulating pitched and flat roofs. Owners of baths and saunas that require special thermal insulation can use slabs to maintain optimal heat and prevent increased humidity in the walls.

The boards, in combination with additional materials, are suitable for technological equipment and the construction of soundproofing structures.

Application of Rockwool

The new material is clearly aimed at use in private construction and has numerous positive reviews. Rockwool Light Butts Scandic is used to insulate the following external and internal substrates:

- facades - Rockwool thermal insulation does not deteriorate when exposed to moisture;

- walls of interior partitions, ceilings, balconies;

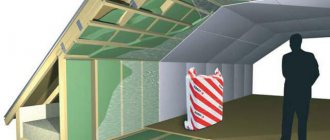

- pitched roofs, attics - Rockwool is easily mounted on inclined surfaces, in addition, their vapor permeability prevents the accumulation of condensation under the roof;

- external doors - mineral wool insulation is very elastic and resistant to temperature changes;

Thanks to its hydrophobic properties, Rockwool has proven itself excellent in cladding saunas and baths. At the same time, ordinary mineral wool has strict restrictions on use in wet rooms or requires serious moisture protection. It should be noted that basalt insulation is not intended to work under load.

What to consider?

If the thermal insulation will be installed with your own hands, it is worth considering the assembly nuances even at the purchase stage. This will allow you to clarify the total dimensions of Rockwool products and not overpay for fasteners.

1. When calculating the insulation consumption, you should know: the free space for placing each slab should be 1-2 cm less than its width.

2. A 5 cm wide flexible (spring) edge is marked at the end of the slab.

3. No special fasteners are needed for installation.

4. When choosing a vehicle for transportation, it is worth first calculating the total volume of packages.

5. The thickness of the insulation is selected taking into account the characteristics of the walls and the climatic features of the region.

6. In order for the thermal insulation to retain its qualities during the standard service life (50 years), you should purchase a vapor barrier film.

Installation features

When installing mineral slabs, experts advise following the manufacturer’s recommendations so that the service life of the material is extremely long.

The insulation must be laid in at least two layers, overlapping the joints. Thanks to the presence of springy edges, the process of placing the slabs is noticeably simplified; they do not need to be cut or adjusted to size. After installation between several rafters or other guide elements, the material expands and fills the empty space. Identifying the marked side is not that difficult since it is marked with a red stripe. Brand slabs must be additionally protected from direct exposure to water and condensation; for this purpose, layers of a special membrane are used, which are laid on top of the mineral wool. Most often, a membrane from the same manufacturer is used, for example, Extra. It must be laid with an overlap, gluing the joints between the layers for greater tightness. The slabs must not be left open, otherwise stone particles and fibers may enter the room. They are additionally covered with a vapor barrier film, siding-type lining, sheets of plywood or drywall.

Rockwool membrane for roofing

During work, personal protective equipment is always used: goggles, respirators, gloves and overalls.

Most often, the slabs are installed as a whole, but sometimes it may be necessary to install fragments; in such cases, the material is cut with a knife. During installation, it is recommended not to compress the slabs over the entire surface; it is better to do this only from one edge, so as not to reduce the effectiveness of the insulation. Each slab is installed on a pre-prepared frame, which significantly simplifies the entire installation process.

For frames, structures made of wooden blocks or metal profiles of standard sizes are used. When installing interior partitions, experts recommend making the frame vertical to reduce noise levels. If the installation work is carried out in accordance with all the rules, the slabs will reliably protect any room from heat loss, noise and sounds, will help reduce the load on supporting structures and extend the life of any structure.

Composition and technology

Light Batts thermal insulation materials are slabs made from basalt wool using the unique Flexi technology. Its peculiarity is the ability of one of the edges of the insulation to spring, reducing its volume when compressed and increasing when the load stops. Thanks to this, the material is much easier to install on wooden and metal frames.

The Rockwool edge, which can change its density, is located on the long side of the slab and is marked for ease of work. When installed, such insulation provides a greater seal to the structure compared to other materials and does not form cracks, due to which drafts do not occur in the room and heat does not escape outside.

The binding component and water-repellent impregnation included in the insulation make it waterproof. Although they leave the possibility of excess water vapor leaving the room without accumulating in the material. And the good thermal insulation properties of Rockwool slabs are due to the chaotic arrangement of fibers, which reduces their thermal conductivity coefficient.

Main technical characteristics

| Parameter | Meaning |

| Type of main raw materials | Inorganic |

| Thermal conductivity | λ10=0.036 W/(m.K)λ25=0.037 W/(m.K)λA=0.039 W/(m.K)λB=0.041 W/(m.K) |

| Flammability group | Non-combustible materials |

| Fire hazard class | KM 0 |

| Water absorption at full immersion, no more | 1.0 kg/m2 |

| Vapor permeability, not less | µ=0.3 mg/(m.h.Pa) |

| Acidity module, not less (ratio between acidic and basic oxides), type A | 2,0 |

| Maximum permissible operating temperature | 200°C |

Review of Rockwool insulation products

In addition to Light Butts Scandic thermal insulation boards for general purposes, the company produces products with special qualities. When finishing facades, the Rockwool Facade Butts line is used, which is characterized by increased mechanical strength and is optimal for applying plaster.

For effective insulation of saunas and steam rooms of Russian baths, the product Sauna Butts is produced. It is pre-equipped with a hydro- and vapor barrier layer that protects the stone wool from excessive moisture

Purchasing this material significantly saves time and facilitates installation, which is especially important if you decide to do the work yourself

For roofing, Rockwool technologists have developed a whole system of intercompatible RockRoof products, including heat-insulating, moisture-proof, vapor barrier materials, fasteners and special accessories. By purchasing a roofing system complex, you ensure that the technical characteristics of thermal protection are maintained for at least 50 years.

Where to buy thermal insulation?

The cost of Scandic Light Butts varies mainly due to transport costs and the thickness of the material. It averages 95-100 rubles per m2.

Reviews of Rockwool products

“My husband decided to do all the roof insulation work himself, although he has no experience. Based on the seller's recommendation, we chose Rockwool slabs. The good thing is that they do not irritate the skin like regular glass wool. And my husband also liked the edge, which can be pressed a little and the slab lies without cracks. And the price of Light Butts Scandic is the same as that of a TechnoNIKOL stove, although there is no such invention. We are happy with the purchase, we bought it from Leroy Merlin.”

Vladimir, Moscow region.

“But I didn’t buy it. They all boast about what’s new, but in reality everything is the same, just to jack up the price. Looks like it’s almost twice as expensive as regular mineral water! It’s better to seal all the cracks with foam, it will be cheaper.”

Yaroslav, Samara.

“For a long time I have been recommending Rockwool products to my clients when insulating their baths. And it doesn’t cake over time, and everything is thought out to the smallest detail, and it’s easy to work with. In short, if you want quality, I recommend not skimping on matches!”

Victor Sergeev, Ufa.

Specifications

The operating parameters of the material are related to the characteristics of the raw materials and production technology. Stone inorganic raw materials provide strength and durability of the fibrous material. Mineral wool has specific properties that determine its advantages and disadvantages. In the manufacturer's catalog ROCKWOOL Light Butts Scandic, the technical specifications are as follows:

- Thermal conductivity coefficient is 0.036-0.039 W/m*K.

- Vapor permeability – 0.3 Mg/(M*h*PA).

- Compressibility coefficient – no more than 30%.

- Water absorption – 1 kg/m2.

- Flammability group - NG.

Mineral wool serves as an excellent sound insulator. When installed correctly, it reduces the noise level by 42-63 dB. The technical characteristics of Rockwool Light Butts Scandic insulation ensure the durability of its operation. The slabs do not lose their properties for about 50 years.

Density

For Rockwool Light Butts Scandic slabs, the density is 37 kg/m3. This is an indicator of a universal insulation that can be used in various areas that are not subject to high loads. Medium-hard fiber boards are the best option for soundproofing rooms. They are characterized by low thermal conductivity and minimal weight. The insulation does not load the supporting structure. Material of low density is cheaper than more rigid analogues.

Parameters and types of Light Butts

It must be admitted that the popularity of Rockwool insulation would be much less if they did not have a lot of unique properties and characteristics that distinguish them from conventional materials.

At the same time, the consumer can choose not only standard Light Butts slabs, but also their improved version - Scandic, which differs in properties during installation and transportation.

Types of materials

Rockwool mineral wool is available in 2 versions:

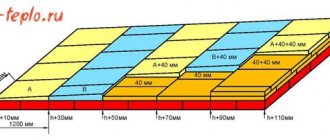

- standard slabs, the dimensions of which are 1.0 × 0.6 m, and the compressibility has a standard value for brand products of 30%, their thickness is in the range of 50–200 mm in increments of 50 mm;

- improved Scandic slabs, having 2 additional standard sizes (0.6 × 0.8 m and 1.2 × 0.6 m) and the ability to compress up to 60%, the thickness of such materials is 100 and 150 mm.

Thus, Scandic insulation is either more convenient than conventional slabs for transportation even in passenger cars (small size), or, conversely, designed to speed up the installation process (larger version). In addition, the material is produced in vacuum packaging, due to the manufacturing technology of which the shelf life of Rockwool boards increases several times.

Table: Comparison of Rockwool Light Butts and Rockwool Scandic

| Parameter | Meaning for Light Butts | Meaning for Light Butts Scandic |

| Images | ||

| Dimensions, mm | Length 1000 mm, width 600 mm, thickness 50 - 200 mm | Length 800 and 1200, width 600 mm, thickness 50 mm, 100 and 150 mm |

| Flammability group | NG | NG |

| Fire hazard class | KM0 | KM0 |

| Thermal conductivity | in dry condition, λ W/(mK), no more: λ10=0.36; λ25=0.37. Calculated values: λА=0.39; λB=0.41. | in dry condition, lW/(mK), no more: λ10=0.36; λ25=0.37. Calculated values: λА=0.39; λB=0.41. |

| Water repellent properties | Sorptive humidity is not more than 1%, and water absorption during short-term immersion in water does not exceed 1 kg/m2 | Sorptive humidity is not more than 1%, and water absorption during short-term immersion in water does not exceed 1 kg/m2 |

| Vapor permeability | µ=0.3 mg/m•h•Pa | µ=0.3 mg/m•h•Pa |

| Compression | no more than 30% | about 70% |

| MORE DETAILS | MORE DETAILS |