A comfortable microclimate in the house has always been the merit primarily of the insulating materials used. We are talking about insulation, sound insulation, films, protective membranes and additional accessories. All this is designed to keep the living quarters warm, protect from rain outside and water vapor from the inside.

And every year, leading companies work to improve the protective properties of their products and make it easier to work with during the installation process. And the most famous products on the Russian market of insulating materials are Izospan. Let's look at its advantages and types, as well as what the letters A, B, C, D and F mean in the marking of rolls. The main thing is not to get confused!

A little about the manufacturer: why does everyone know about it?

Gexa company is one of the largest manufacturers of nonwoven materials for building insulation. The company itself is relatively young, operating since 1998 and began as a small family company. Today, Gex already employs more than 2,000 employees, and even has its own representative offices in neighboring countries.

Thanks to the availability and thoughtfulness of its products, Hexa quickly captured a large part of the market for similar products, while also developing geosynthetics for road construction and a stable production of disposable clothing for medical workers. Today there are about 15 of its representative offices in Russia.

By the way, Izospan is one of the very first brands of insulation produced domestically. Among builders, all these films and membranes are so well known that they have already received a household name. True, today the company has to actively fight against mass counterfeiting of its films, which differ in quality for the worse and spoil the entire impression of the brand.

Also, Izospan films are well known among the population due to the fact that they are always available. This is a credit to Hex's logistics system. But sometimes you have to look for other brands all over the city; you’re probably familiar with this situation.

In addition, Izospan is constantly working to improve its product; for example, it recently released a three-layer moisture-windproofing membrane with an anti-condensation coating. Another interesting new product is heat-saving insulation based on kraft paper with lamination with metallized lavsan, which we will talk about later.

Quality and range: everything to protect your home

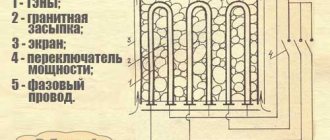

In total, the Izospan line of insulating products has an assortment that is conventionally divided into 4 groups:

- windproof waterproofing vapor-permeable membranes;

- waterproof vapor barrier films;

- universal materials that work in several directions at once;

- heat-steam-waterproofing materials with additional energy-saving effects.

Here is an explanatory illustration of how exactly all these materials differ:

A roofing pie with films from Izospan looks like this:

Series A are windproof materials, and series B, C and D are hydro-vapor barrier membranes. If you are afraid of getting confused in abbreviations, remember a simple rule: the first letter means the insulation class, and the second means the modification.

If there is no second letter, then the material is classic, without additional frills:

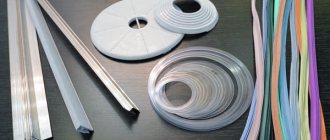

Plus Izospan produces a special tape designed specifically for this product:

This manufacturer also produces special waterproofing materials for flat inversion roofs. The company itself always boasts that it creates all its products in automated production facilities.

And this is evidence that technical control is constantly being exercised over the quality of products. This cannot be achieved with any kind of handicraft production.

Details

Types of roofing materials

Of the very large number of varieties and types of films and under-roofing panels used in arranging a roof in a country house, in utility rooms, and indeed in any room where there are sources of heat and water vapor, the following brands are considered the most popular and frequently used:

A universal material of category “B”, it is used to protect the roof insulation from the ingress and condensation of water vapor, ensuring the unhindered release of steam into the ventilation channels of the under-roof space.- Reinforced version “C”, the tasks and functions are the same, but have a higher degree of strength, stability, and partially block the appearance of a condensing water thin film on the surface when micropores are “choked.”

- Special Izospan brand “D” is used for roofs without an insulation sublayer. The functions mostly include wind protection and waterproofing of roof structures.

- Category “A” has become the most affordable and popular option. Its purpose is wind protection and waterproofing.

Please note that in this case, the classification and division of the protective fabric is made on the basis of technical conditions and parameters of the brand and production.

In addition to Izospan from Hexa, there are many similar materials on the market. its products undergo constant testing, constant laboratory research and production quality control. judging by the number of various awards and recognitions in the TOP list of roofing materials, the quality of Izospan for roofing, which is produced under the control of Hexa - Nonwoven Materials, remains at the proper level. Although in the foreign-type classification, the presence of diplomas and certificates is not recognized as objective evidence of the level of quality.

Basic criteria for using different brands

In order not to get lost in the large number of different brands of Izospan and similar vapor insulation films, you need to focus on the indices in the form of letters that manufacturers use to mark their products. Group of analogues “A” category - the canvas is marked with the indices A, AS, AF, AM, AF+, AQ proff. This category includes all film-type analogues that need protection from moisture and gusts of wind entering the roof from the outside. The second category is used for poorly insulated and non-insulated roof types, this is Izospan “D”. Letter indices on the packaging are FX, FS, or FD-FВ. The film for waterproofing contains special layers of aluminum spraying or glued foil with high reflectivity. It is believed that the reflection of infrared waves from the inside of the roof space makes it possible to prevent up to 10% of heat loss through the roof. The third group - analogues “C” and “B”, have a more advanced structure, high price and special requirements for laying material under the roof. In addition to standard films and three-layer panels, there is a category of auxiliary type tapes that is used. This type of coating is used to fasten the joints of individual Izospan panels.

Which material is better

Naturally, the choice of the most suitable type of film for lining directly depends on the arrangement of the roof pie and the method of application of the roof. In a simple case, for roofing insulation from water and condensation that penetrates through cracks in places where different sheets overlap, for example, slate or metal tiles, it is possible to use Izospan type “A”. It is slightly inferior in quality, tensile strength and water resistance to other brands, but in terms of cost and installation it will look more beautiful.

Helpful advice! You can simplify the task of selecting Izospan waterproofing film for your roof if you use a table comparing the parameters of different brands.

Features of using grade “A”

A distinctive feature of this type of material will be very high vapor permeability characteristics. It turns out that this material is best installed on the insulated roof of a room with an abnormally large amount of water vapor, for example, in a summer kitchen, on ceilings, above a bathroom, or covered glazed verandas. Structurally, this material is a two-layer polypropylene film, with a smooth structure on the outside and a matte porous surface on the inside. Modifications of the material due to the presence of an additional 3rd layer have increased strength and conduct steam much worse. They can be laid on the surface of the counter-lattice without an underlayer or rack-type lathing.

Class "B" film

Compared to class “A”, this material has much higher waterproofing characteristics. Izospan, a waterproofing film for roofing class B, is much lighter than canvas “A”, almost 2 times thinner, and therefore has a lower degree of strength. It is more convenient and flexible for creating insulation, both under the roof space and other floors, including vertical walls, ceilings, subfloors, parquet and laminate flooring. In the table you can see that the vapor permeability of “B” is two times lower than that of material “A”. For this reason, it is better to use roof waterproofing “B” - Izospan on broken complex roofs, with a large number of joints and a “playing” coating, where there is a very high risk of waterlogging.

Application of categories “C” and “D”

Approximately half of the roof coverings in private houses are installed without insulation. Utility blocks, garages, bathhouses and unheated extensions to houses most often receive a roof without additional insulation. In this case, Izospan S can be used for a cold roof. In terms of mechanical characteristics, thickness and strength, the material corresponds to category “A”, but in terms of the transmission of water vapor it can be considered moisture-permeable.

Class “C” fabric is distinguished by its ductility and high elongation, and therefore is considered the best lining material for laminate flooring. Canvas “D” is unique in its own way. If you take a closer look at the characteristics, you can see that this is a very durable polypropylene sheet. Which is the best Izospan for roofing? “D” category is used for a large insulated roof on very steep and large slopes, where there is a possibility of damage to the waterproofing layer due to deflection of the rafters or sheathing settlement.

It is essentially a two-layer, durable material with a laminated outer surface that can withstand direct water flow. The stability is so great that class “D” can be used for waterproofing basements, basement elements of a building and even formwork cladding. If there is a need to protect a box made of profiled timber or an unfinished building, then the ideal option would be a temporary roof made of “D” Izospan. It will not be torn by wind gusts, and after construction is completed, the material can be carefully transported to equip the roof or insulate the basement space under the house.

How does Izospan apply to the roof? The quality of waterproofing will fully depend on how well the installation scheme is chosen and how professionally the film is installed. The work of attaching a membrane for waterproofing under the roof is not difficult and is quite accessible even for beginners in roofing.

External protection of house structures from wind and rain: Izospan A

All films of group A protect insulation and roofing elements from the negative effects of the external environment, and all others protect both external and internal at the same time.

Here we are talking about a wind-moisture-proof membrane that protects the insulation from rain, snow and wind. At the same time, this membrane also removes condensation from the fleecy side. Such films are fixed to mineral wool or polystyrene foam from the outside.

As for newer modifications, Izospan AM and AQ are made of three-layer film, which makes it possible to increase the level of protection of buildings. Also in group “A” there are separate options that are resistant to high temperatures and fires.

Let's take a closer look at the tasks for which Izospan A films are used and what their technical characteristics and properties are:

Izospan AQ Proff

So, the waterproof hydro-windproof membrane Izospan AQ Proff is vapor-permeable and is designed to protect the insulation and roof structure from environmental influences. Namely, from moisture from rain.

Why vapor permeable? The fact is that such a membrane must remove water vapor from the insulation directly into the atmosphere. If it begins to interfere with these vapors, then moisture will begin to linger in the insulation itself and mold will develop.

But at the same time, on the other hand, waterproofing must have a certain water resistance. In a word, on one side it allows water to pass through, but on the other it does not. Izospan suggests using the professional three-layer superdiffusion membrane Izospan AQ Proff for these purposes:

By the way, all Izospan films marked Proff have special markings in the form of a grid with 10x10 cm cells. This is specially made for easy installation; dashed lines along the edges of the film indicate the overlap line. For example, vertical lines are applied in 1 meter increments, making the film easy to cut without first measuring with a tape measure.

Izospan AQ Proff is laid directly on the insulation, without leaving any special ventilation gaps, thereby saving on the installation of sheathing.

This membrane also has excellent light resistance, making it suitable for installation as a temporary roof. It is also highly durable, which allows installation in any weather, even in strong winds.

Izospan AM: protection against heat loss

Izospan AM is a vapor-permeable material that removes water vapor from the insulation directly into the ventilated gap. At the same time, it remarkably protects the thermal insulation from precipitation that accidentally gets under the roofing, as well as condensation:

The film of this brand has high resistance to mechanical loads. Additionally, it serves as a wind barrier, preventing air from passing through the thermal insulation. This, in turn, significantly reduces heat loss.

Izospan AS: as many as three layers

The Izospan AS membrane has two important functions: windproof and moisture-proof. It simultaneously protects both the thermal insulation layer and other roofing elements. To do this, the membrane has three internal layers, each of which was developed for its specific task.

Unlike other films, this membrane can be laid directly on thermal insulation, without a special gap for ventilation. To some extent, this simplifies and reduces the cost of the very design of the roofing pie.

It is also suitable as a component for insulating floors and facades, and lasts for 50 years (as the manufacturer claims):

But remember that the entire Izospan AS line is always installed only on the outer side of the insulation directly under the finishing roofing covering.

Izospan A: instructions for use

Group of materials Izospan A - vapor-conducting windproof membranes that do not conduct liquid water. The exception is Izospan A base. This membrane is only wind protection. It does not interfere with the passage of steam and water. Used in the ceiling above a ventilated facade, stuffed from the underground side. Protects mineral wool from blowing and does not interfere with the removal of moisture from the insulation.

To understand where and how best to use Izospan A, look at the characteristics. Once again: the film is not blown (retains heat), removes steam, and does not allow water to pass through. These properties are needed in the following constructions.

Rules for laying and installing windproof, vapor-permeable membranes

Vapor barrier materials are laid on vertical, inclined and horizontal surfaces. Despite the fact that the designs are different, the installation rules are no different. Here's what to remember:

The basic rule of installation is to make overlaps and carefully glue them

- On pitched roofs and walls, work begins from below. On horizontal roofs - from one of the walls.

- The second layer of material is laid overlapping. That is, one panel overlaps another by no less than:

- 10 cm on walls;

- 15 cm on roofs;

- 15-20 cm in overlaps.

- Vertical joints (if any) have the same dimensions.

- All connections of the canvases are glued using double-sided adhesive tapes.

- The connection to the walls and rafter system is also glued. To adjoin the rafter system, it is recommended to use self-adhesive sealing tape Izospan. For joints - KL, for adjoining the structure KL+.

The task of vapor-permeable waterproofing and windproofing is to allow steam to pass through, but not to allow moisture to enter in a liquid state. Therefore, the strength of the joints is important.

On a pitched roof, on top of insulation

The vapor barrier is laid on top of mineral wool and covered with any roofing material. Let's see how everything works. Here it is necessary that the steam that gets into the insulation from the attic is removed. At the same time, condensation and possible leaks did not enter the insulation. So you need to remove steam and not let water through. This is what Izospan A does.

Application of Izospan A in an insulated pitched roof

The membranes are turned with the logo facing towards you. It is better to lay it not under tension, but with sagging. In this case, condensation, which cannot be avoided on the roof, will flow into the center, and then into the gutter of the drainage system. This way it will dry out faster even in damp times, moisture will be retained less, and there is less chance of it getting into the insulation.

On top of the vapor barrier, slats are placed along the rafters, and then across the sheathing for installation of the roofing material. With this device and the presence of ventilation holes in the roof, the vapor barrier will be blown and dried.

In frame walls on the street side

Typically, indoor humidity is higher than outdoors. And no matter how much we protect the walls, steam leaks into them. These are the laws of physics. And since he hit the wall, he needs to be taken out. So the task here is the same - to let off steam. This can only be done from the street side. So Izospan A in frame walls is also placed on the street side. Here you can use all types of Izospan A, except for the “base”.

Izospan A - instructions for use in a frame wall

When using Izospan A “in its pure form”, it does not matter which side it is laid on. We unfold all other modifications - AS, AQ, AM - so that the logo is facing out.

When insulating walls with mineral wool and for ventilated facades

With external insulation of walls, in ventilated facades, the situation is almost the same as with the frame. Some moisture is seeping into the wall from the room. Then it penetrates into the insulation. Since wet mineral wool is a poor insulator, care must be taken to ensure that this steam is quickly removed. At the same time, it is necessary to protect the cotton wool from getting wet and retain heat as much as possible. That is, the problem is solved by the same vapor-permeable membranes of the Izospan A group.

Application of Izospan A for external wall insulation and in the system of ventilated facades

Any vapor barrier for use in the case of external wall insulation, except Izospan A with OZD, AF+ and base. The installation rule is the same - turn it with the logo facing you. For use in ventilated facade systems, Izospan AF+ is recommended. If a metal structure is used, its strength will ensure that the vapor barrier will not break. If the ventilated facade is covered with wooden blocks, Izospan AM, AS and AQ in any of the options may well be suitable.

Ceiling over a ventilated subfloor

The floor insulated with mineral wool over a ventilated base has its own characteristics. First and most important, for the scheme to work, the subfloor must be ventilated. This means that there must be vents in the foundation. And they must be open even in winter, otherwise you will have wet insulation and cold in the house.

How does this pie work? From the side of the house, moisture and steam seep into the insulation. If you simply line the insulation with mesh or slats, the wind blowing underground will do an excellent job of removing moisture. But at the same time, it will carry away heat and gradually remove mineral wool particles, reducing its thickness. To get rid of heat and insulation from escaping, Izospan A base vapor barrier is used. It allows steam and moisture to pass freely in both directions, but does not allow wind to pass through.

Izospan A: instructions for use in the ceiling above a ventilated subfloor

The following objection may arise. Moisture from the soil will evaporate and enter the insulation. Under certain conditions, it condenses on the membrane, causing the insulation to become wet. Maybe it’s better to use a vapor barrier with waterproofing properties? No. This won't work. If the membrane does not conduct moisture, then the moisture that condenses or gets into the insulation will remain there. Because it will not heat up enough to evaporate and be released as steam. In a couple of years you will have bags of water hanging from the ceiling and completely wet and unusable insulation.

And in order to reduce the evaporation of moisture from the soil, a dense film is placed in the underground, a layer of sand (any kind, but without clay and dust) is poured on it in a layer of 5-10 cm. The film retains most of the moisture, and the sand works as an adsorbent, absorbing fallen condensate. It (the sand) is also dried by the passing wind.

Interfloor and attic floors

In ceilings, steam enters from below and must be discharged from above. Therefore, a vapor barrier is placed at the bottom to protect against moisture, and a vapor-permeable wind barrier is placed at the top. In this case, it also additionally protects against the penetration of mineral wool particles into the room. You need to put Izospan in the same way - the logo should be facing you.

Izospan A for flooring - in interfloor and attic floors

In the interfloor ceiling, to reduce the cost, vapor-permeable Izospan can be replaced with non-woven material (any type of geotextile). Its main function here is to protect against the penetration of small mineral wool particles into the air. But you can do this only if the flooring is sheet material in two layers, with the seams spaced apart. Otherwise, moisture may seep in and then simply the non-woven material will not protect the insulation from getting wet.

In the attic floor, such a replacement is not considered at all - here it is also necessary to protect the heat from weathering. So wind protection is necessary here.

Also note that the vapor barrier is attached to the beams with counterbattens. And the flooring is already laid on them. Counter rails are needed to create a ventilation gap, which is a prerequisite for moisture evaporation. It is important.

Line of vapor barrier materials: Izospan B

Izospan B is a vapor barrier with universal properties, suitable for any task and any room (except perhaps for saunas, they have their own line). This film perfectly protects walls from water vapor and can withstand temperatures from -60 to +80 degrees. One of its sides is rough, designed to hold condensation and slowly evaporate it.

It is made from polypropylene non-woven fabric and another additional polypropylene film. These two materials are securely glued together and never delaminate.

By the way, it is with this type of film that most questions arise about which side to mount Izospan on: rough or smooth? Indeed, there is a difference. But you can easily find the right side by touch, don't worry.

Additionally, this film prevents the penetration of small volatile insulation fibers directly into wall or roof structures. This is extremely important, especially if mineral wool insulation was used. In simple terms, in order not to breathe “prickly” air in a cozy attic:

Working with this material is not difficult, because... With Izospan B films there are always detailed instructions for use and calculation of the material.

But the slightly improved Izospan B Fix has special adhesive tapes directly on the film.

Two sides of one film: Izospan S

Izospan S is another type of hydro-vapor barrier. It differs from simple films primarily in that it also has a double structure - smooth on the inside and rough on the outside.

This film is also denser and more durable, and therefore suitable not only as a vapor barrier, but even as additional insulation. And its rough part is attached inside the building.

It is recommended to fix such a vapor barrier to the roof using galvanized nails:

Izospan C is also often used as a waterproofing agent during the installation of cement floor screeds in rooms with high air humidity.

For non-insulated roofs: Izospan D

The next type is Izospan D. These are materials based on polypropylene fiber, even more durable and reliable. They are even allowed to be used as shelter for up to four months. But, first of all, Izospan D serves as a vapor barrier for wooden roofs and cold walls. Sometimes it is also used as a layer for cement screed, like Izospan S. This is what this insulation looks like on the spread:

Let's make a short digression that will explain to you why all these details are so important, and why there are so many types of all these films, although it was possible to release one universal one. The quality of the vapor barrier directly affects the service life of both the roof and the house itself. That is why experts always advise giving preference to materials only from a well-known manufacturer who is concerned about its reputation.

After all, even with high-quality material it is usually difficult to create an absolutely sealed insulating layer, let alone thin and short-lived films. And during its operation, the insulation, if it begins to accumulate moisture, will quickly lose all its properties, thereby nullifying all efforts to construct the walls and roof.

Just imagine for a moment that you spent a lot of time and money on building a house, and within six months you began to notice the smell of mold. This is very very bad.

Another common problem is the leakage of the vapor barrier layer at the joints. Namely, poorly glued sheets. To solve precisely this problem, the Hexa company began to produce new products in 2021 - Izospan B Fix and Izospan D Fix.

Their difference from previous products is that there is already special adhesive hair pre-applied to the canvas. They not only facilitate the installation process itself, but also truly ensure reliable fastening of the canvases to each other.

When working with such material, you no longer need to worry that the construction tape will touch this particular area, pull and tear off a piece, or lie unevenly, or simply turn out to be of poor quality and easily peel off.

By the way, the D line also has a subtype - DM, films with a special anti-condensation coating that perfectly retains random droplets of moisture:

Recommendations and tips

So, when installing Izospan of any type, it is necessary to check the “polarity” of the installation, namely, that each panel should lie with the smooth side up, and the fleecy or porous side down. Moreover, the material does not require much tension; firstly, the installation is carried out on a wooden frame, which is subject to shrinkage and deflection, and can easily tear the material off the roof. Secondly, if there is a suspicion that the film may tear off the staples, you can always use cardboard heel pads or seal the attachment point with tape.

Izospan for roofing is in ever-growing demand. For this reason, the biggest problem that you will have to face when using waterproofing film is the presence of a large number of fakes of branded material on the market. It is better to purchase roof film yourself, because even most construction companies do not hesitate to use counterfeit material.