Advantages provided by an automation kit for a solid fuel boiler

There are no accidents or coincidences in our world, and people had to automate the process of burning solid fuel in a heating boiler for a reason - there are a number of good reasons for this.

The most important of them is safety. Anyone who uses solid fuel to heat a home probably knows the consequences of overheating the coolant - boiling water in the boiler can even lead to an explosion with serious consequences. First of all, automatic control allows you to control exactly this moment - a person is a forgetful creature by nature, and automation works according to a program, and there is no such thing as “forgetting” for it. In addition, automation of a solid fuel boiler provides a number of other benefits to humans.

- Optimizing the climate inside the house. It eliminates sudden changes in temperature - when the boiler is just loaded and combustion reaches its peak, the house is hot, and when the firebox is empty, the house becomes cold. Automation removes the first rise in temperature towards an increase.

- Fuel economy. This occurs due to the operation of the thermostat. Having brought the temperature of the coolant to the set value, the automation stops burning, switching the boiler to smoldering mode - slow heating occurs, which consumes much less fuel.

- The task of controlling the combustion process is removed from the person. That is, you loaded the firebox full and went about your business - all that remains is not to miss the next loading of the boiler.

This concerns the primary tasks that automation for a solid fuel boiler is designed to solve. In addition to them, depending on its complexity, automatic control of fuel combustion may have additional options that expand the capabilities.

What to consider when assembling the structure

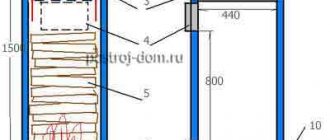

The electric boiler must have a built-in electrical cabinet. It contains input, metering, protection, and control devices for the operation of the heating unit. A function is provided to switch operating modes of the heating system.

The electrical cable from the boiler equipment is inserted into the electrical panel. The boiler is connected to the inlet machine.

Depending on the area of the room, you need to calculate the power of a homemade electric boiler. For 1 sq. m of area accounts for 0.1 kW of thermal power of the heating device. To create a heating system for a house with an area of 100 square meters. m need to make a boiler with a capacity of 10 kW.

Thermal calculations for the house must be done immediately. The cross-section of the wire, elements of the boiler device, and automation depend on the power.

Laying the electrical cable around the house must follow safety rules. If the structure is made of wood, the cable is laid openly or in pipes. For buildings made of stone, brick, foam block, the wire is laid hidden or in boxes.

Homemade boiler

Any twisting, soldering, or welding not provided for by the design of the boiler equipment is prohibited.

The boiler requires strict compliance with safety measures.

How to choose the right boiler connection diagram

In order to keep the house warm, it is not enough to know what heating schemes are available with a solid fuel boiler. Craftsmen who have been creating heating systems for many years give the following recommendations:

- When creating a drawing of a heating circuit for a solid fuel boiler, you should first familiarize yourself with the types and operating principles of such heat generators. This can be a constant or long-burning heater, a pyrolysis or pellet unit, or a buffer. Each of these devices has its own operating criteria, which may be disadvantages for some, and advantages for others.

- To get an ideal heat supply scheme, you need to be able to combine the functioning of the boiler with the tank, since this element accumulates thermal energy. This is justified by the fact that the element heating the water can change its temperature in the range from 60 to 90 degrees. There is no constant indicator. Since solid fuel boilers are inert devices, this distinguishes them favorably from gas, diesel and electric analogues.

- When choosing a heating scheme, you need to objectively assess the risk of power outages. If there are frequent power outages in the area, then a system with a water pump will not only not pay for itself, but may quickly fail. Therefore, it is better to choose a type of heating with natural circulation.

- When choosing a piping, it is worth considering in advance the safety lines between the boiler and the tank. They are located at the points of the inlet and outlet pipes so that they are as close as possible to the water heater. Also, to achieve maximum effect, you need to try to keep the distance between the boiler and expansion tank to a minimum. But it is no longer possible to install safety valves or taps here.

- If a scheme with a pump was chosen, then it is installed on the return pipe, as close as possible to the heat generator. Thus, even if the lights are turned off and the pump stops working, the water will continue to move along the circuit, that is, minimal heat will be retained. The device must be installed along a bypass route. Only then will it be possible to disconnect it from the network (if necessary), and shut off the circuit itself using taps.

- There is such a thing as bypass. These are jumpers with taps that are placed between the supply line and the return pipe. This arrangement facilitates the return of “extra” hot water when the volume changes through the thermostat.

- A stainless steel valve must be installed in the chimney pipe. Since there is moisture in the smoke, albeit in small quantities, it is this that can provoke the destruction of the internal part.

Tying is a process that deserves special attention. Therefore, they design and install it only if they have complete confidence in their abilities. Nikolay Avramenko, 51 years old

Energodar

Nikolay Avramenko, 51 years old, Energodar

Having read the article, I would like to add my note. The topic of operational characteristics of solid fuel boilers was touched upon here. It was indicated that they have such a feature as high inertia. I would like to say that this phenomenon is not typical for pellet boilers. This is due to the fact that such devices have a burner that receives wood pellets in portions. Therefore, when the supply of raw materials stops, the flame immediately goes out. Although such boilers are not so cheap.

Anton Abramov, 29 years old, Omsk

At one time, I was interested in the work of solid fuel boilers, as they offered me a position related to this area. I would like to leave a few words about the thermostat and its regulatory features. You need to understand that when a certain temperature is set, for example, at 85 degrees, even though the damper is closed, the burning and smoldering continues. Because of this, the water still heats up a couple of degrees, and only then it will be established accurately. Therefore, you should not turn the thermostat back and forth, otherwise this may lead to breakdown of the entire system.

Nikita Karpenko, 37 years old, Arkhangelsk

When we built a house outside the city, we planned to live there all year round. The time came when it came to heating, and I settled on a closed-type system with natural circulation. Firstly, it was quite easy for me to create it with my own hands, and secondly, we were already a little limited in money. I didn’t have any particular problems with the installation, but when the first cold weather arrived, I realized that there was clearly not enough heat for the house. So at school, I was quite good at physics, and I realized that heat is “lost” in areas where the pipes were left open. Taking a roll of mineral wool, I wrapped all the pipes that run in open areas. Literally by the end of the first day, our family felt a significant warming in the rooms. Therefore, you need to remember such moments.

Solid fuel boiler connection diagrams

Expansion tank.

This is due to a certain inertia of fuel combustion, because when the required water temperature is reached or there is a sudden power outage, it will not be possible to immediately stop the process. Advantage: installing such a valve reduces the cost of installing the heat generator piping. The company's products are represented by a wide range of models. When operating a solid fuel boiler, there is always a risk of overheating of the coolant, especially at modes close to maximum power.

It is prohibited: to install any shut-off equipment between the heater, the safety group and the expansion tank; operating the heat generator with open doors; melt the unit without water or other coolant in the system; ignite fuel using fuels and lubricants: gasoline or diesel fuel; flood the unit if there is poor draft in the pipe; leave the operating unit unattended for a long time; leave flammable objects on the surface of the device: paper, newspapers, rags; Small children should not be left unattended near an operating heat generator; in the spring, when you stop heating the boiler, you definitely need to do maintenance: clean it and lubricate the moving parts of the mechanism. The pressure of the latter must be higher so that when working together it has priority over the electric boiler. Tweet on Twitter Connection diagrams for a solid fuel boiler A heating boiler operating on various types of solid fuel differs in operation from gas and electric boilers.

When a solid fuel heat generator is restarted, the reverse process occurs - heating the coolant above a certain temperature leads to the gas burner turning off. But the most popular options are steel or cast iron. Taps are needed for: expansion tank; boilers; pump A heating element is also installed in the boiler.

Basic wiring diagram for a solid fuel boiler

Which heating systems use an electric boiler and a solid fuel boiler together? We connect the fittings to the circuit according to the diagram discussed above. Automation means The solid fuel boiler is equipped with a thermostat, which opens the electrical contacts to control the pump, and its remote sensor is installed at the outlet of the heat exchanger. They have a high degree of protection, and the circuits of electric-gas boilers make them completely safe to use. For safety reasons, it is not recommended to insulate pumps.

It is also possible to use copper pipes, the wall thickness of which is at least 1 mm, indoors. Both boilers are equipped with shut-off thermostats so that they can operate instead of each other. Now, when the unit operates at full power, almost complete combustion of fuel occurs, and the accumulated heat is collected in a buffer tank.

In the case when the heating unit is the only heat source in the house, it is recommended to use the following basic diagram to connect it: Note. Modulating control The multi-stage controller for a simple cascade system uses proportional-integral-derivative PID control to continuously measure the temperature of the coolant entering the system, compare it with the calculated value and determine which burner should be turned on and which should be turned off. They have two circuits and are capable of not only heating the room, but also supplying residents with hot water, without connecting additional gas water heating burners. In order for the boiler to simultaneously heat water in the heating circuit, the DHW system and in the buffer tank, its power must be twice the calculated one. Heating circuit. Heating: TT boiler "Topol-M" + electric boiler "Proterm".

Advantages of gas boilers

Gas heating systems have the following advantages:

- Automation ensures stable operation and ease of operation of the heating unit.

- Gas boilers quickly pay for themselves due to efficient operation and low fuel costs.

- Capable of heating large areas of premises.

- The operating principle is designed for a truly long service life.

- Demonstrate high efficiency indicators.

- Does not force the user to monitor the flame level. Gas is supplied continuously, and if the burner goes out, the automatic system for gas heating boilers reports this to the system and resumes combustion.

- The boiler produces more energy than it consumes itself.

Rules for organizing solid fuel heating

The main difference that a heating system with a closed-type solid fuel boiler has is the type of fuel used. Coal, firewood, peat or fuel briquettes are used as energy carriers. All of them are characterized by high energy intensity and, as a result, intense heat release.

In order to make heating with a solid fuel boiler with your own hands, you will need to familiarize yourself with the rules of its organization. They directly depend on the chosen scheme, the pipe distribution system and the coolant used.

A characteristic feature is the correct installation of heating with a solid fuel boiler. The source of thermal energy and fuel must be located in different rooms, and in addition to the installation rules, safety measures for the operation of heating must be observed.

The basic rules for the design and practical implementation of heating systems using solid fuel boilers and stoves are the following:

- Use of non-combustible materials. When installing a stove or boiler, the floor, walls and ceiling in the chimney area must be fireproof. Those. if exposed to high temperatures, these materials should not spontaneously ignite or smolder;

- Work stabilization. The main danger when operating a solid fuel boiler for water heating is overheating of the water in the heat exchanger. To prevent this, the boiler or stove provides the ability to regulate the air supply necessary to maintain the combustion process of wood. This could be a system of valves connected to a mechanical temperature controller;

- Supply and exhaust ventilation. The classic installation scheme for heating from a solid fuel boiler provides for air exchange in the room where the equipment is installed. When it operates, combustion products will inevitably enter the room. Supply and exhaust ventilation will remove them, thereby preventing CO2 concentrations that are dangerous to humans.

Factory-made or home-made solid fuel heating boilers should be installed in separate boiler rooms. Exceptions are models with low power, which are equipped with a hob. But even in this case, all safety measures must be ensured in the kitchen.

The basic rules for arranging boiler rooms in which double-circuit solid fuel heating boilers will be installed are described in SNiP II-35-76. Before installing the equipment, you should read this document.

Elements included in the heating boiler control system

The main element of the system can be a Sonoff TH10 brand module. This device is manufactured in China, and you can purchase it on AliExpress for some 900 rubles.

We have already talked about Sonoff brand modules here.

An electronic thermometer is connected to the device.

The cables necessary for operation are connected to the bottom of the Sonoff device. All connections are made according to the diagram shown in the lower part of the case. One of the cables is a power cord with a regular 2-prong plug. The second wire connects the Sonoff device to the starter.

The purpose of the Sonoff TH10 device is to supply power to the starter or turn it off, based on a command received from a smartphone. As is clear from its markings, the device can withstand a current of no more than 10 A or a load of 2.2 kW.

This device cannot be used as a normal remote controlled switch. If it is used in this way, then a voltage of 220 V will be applied directly to the gas boiler circuit board, which will definitely burn it out.

To prevent this from happening, the homemade system includes a starter. This simple device costs about 200-300 rubles. And you can buy it at any electrical goods store.

The starter has two pairs of contacts. When the primary contacts are energized, the secondary contacts of the device close. Moreover, there is no voltage on the secondary contacts.

As for the thermostat of a gas boiler, as you know, it closes or opens contacts, supplying power voltage or turning it off.

Want to know about the capabilities of the Sonoff smart home? Click here!

In the proposed system, pressing a button on a smartphone ultimately turns on the boiler. This can be done manually. But maybe in automatic mode. To do this, the corresponding function is activated on the smartphone, maintaining the specified temperature range. This is done using an electronic thermometer included in the system being described. It was mentioned a little above, and it plays the role of a kind of thermostat controlled via the Internet.

Design and operating principle

The automation that controls the operation of a gas boiler consists of many elements, conditionally divided into two subgroups. The first includes mechanisms that ensure the full and safe functioning of the boiler itself. The second includes devices that make it possible to operate the heating system in the most convenient and user-friendly mode.

Components of a security system

Several modules are responsible for the operational safety of the unit:

Flame controller - consists of two main parts - a solenoid valve and a thermocouple. Shuts off gas promptly and reliably and prevents leakage.

Thermostat - maintains the set coolant temperature and protects the system from overheating

When the coolant cools down to minimum temperatures, the module starts the boiler into operation, and after recording peak-high readings, it turns it off, completely relieving the owners of the need to constantly pay attention to the system.

The draft control sensor is responsible for stopping the gas supply to the burner in the event of a change in the basic position of the bimetallic plate, thus preventing gas leakage.

Safety valve - monitors the amount of coolant in the circuit.

Operating principle and varieties

If you decide to make an electric boiler with your own hands to heat your home, then you can make induction and electrode varieties of such devices. All other types of boilers are modifications of two main types. Since electricity is converted into thermal energy in an electrode device, it is also called ionic.

Electrode boiler

A homemade boiler is quite compact, so it can simply be attached to a pipe. There is no need to allocate a separate place on the floor or wall for it. For safety, it is fixed with two screws, but you can do without them.

Externally, the heater resembles a piece of pipe about 40 cm long. At one end there is a metal rod, and at the other end the device is tightly welded or has a separate pipe for distilling the coolant through the heating system.

If you made a heating element boiler with your own hands, then it should have two pipes for connecting the coolant supply to the system and connecting the return circuit.

In this case, the location of these pipes can be as follows:

- One pipe is installed at the end of the heating pipe, and the other is welded to the side perpendicular to the first.

- Both pipes are attached to the side of the pipe. In this case, both pipe outlets are located parallel to each other and perpendicular to the main heating pipe.

Types and advantages of automatic devices for gas boilers

The automatic control unit for a gas boiler can operate autonomously or from the network

Automation for a gas boiler is traditionally classified according to the degree of its dependence on the energy supply. According to this feature, they distinguish:

- volatile systems that operate only when electricity is available;

- non-volatile electronics that do not require connection to the electrical network.

The second option usually uses a backup UPS. Many users prefer power-dependent systems because they have greater functionality. The second option for powering automatic heating systems is relevant for situations where there are constant power outages in a particular area, and the device itself operates reliably from simple electronics.

The advantages of automatic gas boilers as controlled units include:

- the ability to maintain the temperature in heating circuits at a fixed level without human intervention;

- ability to work in automatic mode for a long time (up to 48 hours);

- the presence of an automatic ignition system for solid and gas fuels;

- limiting operator intervention in controlling a floor-standing or wall-mounted boiler.

The user just needs to set a certain temperature regime, which is constantly maintained within the living space.

An important advantage of gas heating boilers equipped with automatic equipment is independence in critical operating conditions. In case of urgent shutdown, there is no need to wait for it to cool completely.

There is no need to drain the coolant for fear of defrosting the system. Automation will perform all these operations at the command of the owner who is not within the house. Using telephone-controlled electronics, you can set the required operating mode of the gas boiler and, if desired, optimize it.

Step-by-step manufacturing instructions

Tools and materials should be at hand. You can get started:

- Take a cut piece of metal pipe. Cut threads on both sides. On one side, a coupling with electrodes is inserted, on the other, a plug.

- It is necessary to weld the threaded pipes. They will be fastening elements of the thermal communication system.

- Two bolts are welded to the pipe. The first is for the “neutral wire”, the second is for the ground loop.

- For coordinated operation of the resulting product with a common heating system, pipes are supplied to the nozzles.

- The electrode is connected to the phase wire terminal.

- The “neutral wire” terminal and ground wire are connected to the previously welded bolted connections.

- You can begin installing the pressure gauge and fuse system.

- After connecting the automation system, you can begin connecting to the panel.

Boiler installation:

You can make your own electric boiler with heating elements. To do this, select a tank in which heating elements are installed. They are bought in the store. The quantity depends on the case and heating area. More often than not, two or three. The products include a threaded head.

The boiler body is a metal pipe. The supply and return pipes are soldered into the side. It is better to install heating elements from above to simplify replacement. There is no need to drain the water. To eliminate the problem of air accumulation, an automatic gas vent is provided.

Nuts are screwed onto the installed heating elements and welded. A pipe for draining water is installed at the bottom of the housing. The pipes are threaded. Allows you to connect heating system pipes to the electric boiler.

The unit is installed on the heating circuit and connected to the electrical network. Connecting the device to the panel or machine is identical. The device power is calculated.

Strapping scheme

A solid fuel unit is usually connected to a boiler that runs on a different type of fuel. This is usually an electrical unit.

An electric one is installed parallel to the solid fuel stove. This is the so-called auxiliary element. Its role is as follows: if, for example, the owners are not in the house for a long time, and the solid fuel boiler has run out of fuel, then the auxiliary element, in this case, the electric unit, automatically comes into working condition. It maintains positive temperatures. More on how it all works.

First, the coolant under pressure from the circulation pump is supplied to the boiler, passing through which it heats up. Next, the coolant enters the radiator, where movement follows the principle of natural circulation. Then it enters a special boiler, inside of which there is a coil that is immersed in water. The coolant, passing through the coil, heats it, as a result of which the water heats up. Thus, the residents of the house are provided with hot water.

After the boiler, the coolant again enters the radiators and underfloor heating coils. But before that, he must pass a special crane. If the temperature of the coolant corresponds to the established norm, then the tap opens and the coolant circulates through the floor coils, and if the temperature is higher than normal, the tap closes.

The manufacturing process of a heating element boiler

Now let's talk about how to make a 220V electric heating boiler with your own hands.

Follow the following instructions:

- First you need to make pipes to connect the device to the heating system of the house. We will need three pipes - two with a diameter of 1.25 inches and one with a cross-section of 3 inches.

- Now we make a container for the tank. Essentially, this is the largest diameter pipe where the coolant will be heated. To do this, holes are cut in the prepared pipe section, the edges of which are carefully cleaned and processed. The pipes that were made at the previous stage are welded to the prepared holes. After this, two circles are cut out of sheet steel, whose diameter is slightly larger than the cross-section of the heating container. The circles are welded to the ends of a large cross-section pipe. Welding areas are thoroughly cleaned and polished.

- A pipe with a cross-section of 1.25 inches is welded to the top of the pipe. Then two holes are made in the bottom of the entire structure, the edges of which are ground. The first heating element is installed in these holes. The second heating element will be attached to the previously welded pipe.

- After this, the boiler is connected to the heating system of the house. To do this, we use pipes that were welded at the preliminary stage.

- After this, another heating element (with less power) is attached to the upper pipe. This heating element must have a thermostat. Now the homemade heating element boiler is ready.

Important! To connect the structure to the electrical network, it is better to seek help from a professional electrician if you have no experience in performing such work.

After connecting, check the functionality of the system. To do this, use a multimeter to measure the temperature of the coolant. It should be within 70°C.

Installation and configuration

The installation process of an automatic control system includes:

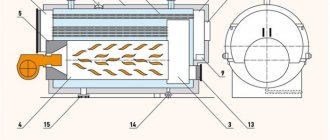

- Connection of the blower fan. As a rule, the turbine is located on the lowest door of the boiler, where the damper is located. But there are models of units where it is installed on the side wall, or in a special place on the top of the boiler, it all depends on the design features. Everything is simple here: the damper is removed, and a fan is put in its place; four bolts are used for fastening. If there are no holes for mounting, they need to be drilled. For fans with a damper, installation is carried out in such a way that the damper is closed when the fan is off.

- Installation of the controller. First of all, you need to decide on the place where the device will be installed. The main requirement is that it should not heat up. On models without a hob, the automation is mounted on top. If the design of the unit allows, you can install the unit on the side wall. Don't forget about the length of the cables.

- Connecting the temperature sensor. A correctly installed temperature sensor will ensure the normal functioning of the entire control unit. If the model does not have a special place for the sensor (hole parameters: diameter 10 mm, depth 60 mm), then it can be mounted on the output metal pipe. A clamp is used as a fastening material; it can be supplied with the device.

- Connecting connectors. To do this, you need to connect the turbine connector to the control unit connector. Finally, you need to connect the device’s network cable. The automation is ready to perform its functions.

Advantages and disadvantages

Automation for solid fuel furnaces has a large number of advantages, and only one drawback. They will be discussed below.

So, the advantages:

- Automatic temperature adjustment. Previously, a person had to set the damper at the right level to increase and decrease the temperature in the boiler. Now, modern solid fuel stoves will take care of this themselves. A person only needs to adjust the temperature and that’s it! During operation, the boiler will check the temperature and, using special devices such as a fan or pump, will limit or increase the air supply. If the temperature inside the boiler rises, the air supply is automatically limited, and if the temperature is below the set norm, the air supply is increased.

- Independent operation of the boiler. Previously, if the owner needed to go somewhere for several days, he had to completely turn off the boiler, that is, take it out of the operating phase. With modern units everything is different. Thanks to automation, you can set the minimum parameters for the stove before leaving, and when you arrive, the house will be warm and cozy.

- Ignition of fuel. Now there is no need to ignite the fuel. The system will do this automatically.

- Safety. Modern units have the highest level of safety. The system is equipped with special devices that are capable of detecting the breakdown or failure of one or another element. This will be indicated by a sharp jump in temperature, change in pressure, etc. If this is detected, the system automatically stops operation and makes a sound, so the owner can quickly find out about the malfunction and call a specialist.

- Electricity reserve. If the power supply is suddenly interrupted, the unit will continue to operate for some time.

- Self-loading of fuel. Modern boilers have a special tank in which firewood or other types of fuel are stored. Automation is capable of automatically loading fuel into the combustion chamber. Now the ash pan is also cleaned automatically without human intervention.

- Control system. There are types of automation where a person, by clicking on special screen elements, must set certain values. But there are also options where a person does not need to approach the system and can simply control the remote control, and the signal is picked up at a fairly large distance.

These are the advantages of automation. It must be said that all this is aimed at making human life as comfortable as possible and the boiler as safe as possible. Automation has only one drawback - energy dependence.

How to make simple automation with your own hands: tips and tricks

It’s not difficult to set up the simplest automatic control of a solid fuel boiler with your own hands. The most important thing here is to buy the right equipment. You understand that you will not be able to make all the necessary devices, and the equipment itself, by and large, does not cost that much. That is why, when talking about homemade automation for a solid fuel boiler, in most cases we mean buying ready-made equipment and installing it yourself. Do-it-yourself installation is quite simple, and you can imagine this whole process in the form of the following sequence of work.

- Fan installation. This is the most difficult part of the work, especially if the boiler design does not provide for automatic control. In such a situation, you will have to make a hole for air injection yourself and install a turbine on it. In principle, this is not difficult for a technically competent person - the main thing here is not to forget about the heat-resistant seal between the fan and the door, and everything else is trivial. The fan is screwed into place through pre-drilled holes in the blower door.

- Connecting the controller. There is also nothing complicated here - when purchasing an automation kit, you are buying some semblance of a construction set, which is assembled according to the scheme. No exception is the switching of wires, which, among other things, are equipped with connectors that cannot be confused.

When the automation is assembled, there is only one thing left to do - install a temperature sensor. As a rule, in almost all models of modern solid fuel boilers a special place is provided for it. If this is not available, then you can attach the sensor directly to the supply pipeline - in the simplest version, this is done using metallized heat-resistant tape. The sensor is simply wound onto the pipe.

Homemade automation for a solid fuel boiler photo

This concerns the electronic control of a solid fuel boiler. But besides this, there are also mechanical systems that regulate the intensity of fuel combustion by simply opening and closing the boiler ash door. How such automatic control works is, one might say, quite simple. A mechanical thermoelement is installed in the boiler (in a specially designated place) - when heated, the plate built into it changes its shape and configuration, which sets a special lever in motion. In turn, this lever is connected to the ash door by a cable or chain, which transmits the movement of the lever directly to the door, as a result of which it opens and closes, depending on the temperature of the coolant in the boiler.

Which automation is better for solid fuel boilers? Mechanical or electronic? Both principles of controlling fuel combustion in a boiler have their drawbacks. Electronic systems do not work without electricity - in order to ensure the operation of the boiler during power outages, you will additionally have to purchase an uninterruptible power supply unit. The mechanics often jam. In addition, the choice of one or another automation system for a solid fuel boiler can also be influenced by its cost - mechanics will cost less.

Author of the article Alexander Kulikov

How to connect and configure

Installation of any automation for a solid fuel boiler is approximately the same. You need to follow a number of simple steps:

- Place the automation unit in a place inaccessible to overheating. It is not at all necessary to install the automation unit very close to the boiler or on its body. It is much more important to define it in such a way as to avoid overheating, even taking into account possible emergency situations. The maximum distance is determined by the permissible length of cables for connecting the fan, circulation pump and sensors, which can range from 2 to 10 meters.

- Connect a fan to supply air on the combustion door instead of the ash damper or in a separately prepared hole. For older boiler models, you will have to manually cut and prepare a hole for the fan. In modern boilers, installation is carried out in a prepared place.

- Install the coolant temperature sensor. It is best to measure the water temperature directly in the boiler heat exchanger or inside the main heat storage tank. For this purpose, boilers often provide a special seat or hole up to 60 mm deep. If it is not possible to fix the sensor on the heat exchanger, then it is transferred to the boiler outlet pipe through which the hottest coolant flows. More often, the manufacturer advises using a clamp with a thermal pad for better contact.

- Connect all equipment to the controller using power and signal wires. For the fan, circulation pump and sensors, corresponding pairs of terminals are allocated, mounted on the body of the automation unit. Their markings and position should be checked with the instructions from the manufacturer.

- The initial settings are set: target coolant temperature. The maximum and minimum volume of air supplied by the fan to the combustion chamber. Limits of permissible change in water temperature in the boiler.

The programming algorithm and settings of the automatic control unit for solid-fruit boilers are established by the manufacturer and are described in detail in the instructions.

Main characteristics of the controller

Automation prevents freezing of pipes in the heating system

The characteristic indicators of electronic controllers built into the boiler include:

- the ability to control the intensity of fuel supply to the unit responsible for its combustion;

- implementation of all protective functions provided for such systems (against overheating or freezing of pipes, pump stops);

- number of control objects and the possibility of their priority selection;

- the presence of a GPS unit that allows you to control the boiler automation remotely;

- the ability to update software at certain intervals.

The best known manufacturers and models: characteristics and prices

ATOS + WPA 120

One of the best and most common automation kits for solid fuel heating boilers.

The ATOS controller is distinguished by extremely wide functionality, a considerable number of customizable operating parameters and an affordable price. In addition to standard functions, there is: protection against freezing of the heating system; notification of temperature drop or overheating, lack of fuel; LED indicators of circulation pump and fan operation; adjustable hysteresis. It is also known for its reliability due to operational practice. Manufacturer: KOM-STER, Poland.

Blower fan M+M WPA 120 is also the most common, time-tested Polish model. Designed to work with boilers with a power of 25-50 kW. There are other versions on the market for more or less powerful boilers.

Cost of the set: 8,900-10,000 rubles.

COMFORT-ECO + NWS-100

The controller is another Polish model: with almost the same functionality and reliability for an even more modest price. Functionality implies the presence of all safety functions, the ability to connect a room thermostat and outdoor sensors, control of a circulation pump (but not DHW). It features a fail-safe filter and an overload fuse.

The Nowosolar NWS-100 turbine is a simple Polish aluminum model, one of the most inexpensive on the market. It has an unremarkable standard design, known for high-quality assembly and reliability. The model is designed for installation in boilers with a power of 30-50 kW.

Cost of the set: 8,500-9,800 rubles.

Tech ST24 + WPA 120

The controller is a hassle-free, simpler model, equipped only with standard functions: control of the boost fan speed, control of the circulation pump, LED indication of the operation of the elements. Installation of external sensors and automatic feeding systems is also not provided. An excellent choice, but at a price comparable to more functional models. The fan is the most common model already described above.

Cost of the set: 9,200-10,500 rubles.

KG Elektronik CS-18S + DP-120

The Polish controller KG Elektronik CS-18S is one of the most modern and functional on the market. It is distinguished by the presence of a touch screen control, the ability to control the fan, circulation pump, hot water supply, and automatic supply system. The DHW pump can be made a priority; there are also special modes adapted for each type of fuel: wood, wood and coal, coal, sawdust. All existing protective mechanisms are also provided: against overheating and freezing, stopping the circulation pump.

The KG Elektronik CS-18S + DP-120 fan is also one of the best. It features an asynchronous motor and high performance with a relatively low noise level of up to 63-65 dB. It has a metal damper at the outlet that blocks the reverse flow of exhaust gases.

Cost of the set: 11,000-12,500 rubles.