Depending on what material is used as a raw material for the manufacture of natural insulation, the weight of the mineral wool changes. The main indicator that will allow the consumer to determine how much weight they will have to work with when laying thermal insulation material is density, which is defined as the weight of mineral wool in an amount of 1 cubic meter. By and large, the weight of mineral wool slabs used in private house construction and renovation is relatively insignificant and does not affect either the speed of their installation or the ease of performing technological operations.

What determines the weight of the mineral wool used?

In the process of producing insulation, offered to customers under the general name of mineral wool, both basalt rocks can be used, which makes it possible to call the final product basalt wool, and waste from the metallurgical industry - slag, the weight of which is significantly less than basalt, which affects the weight of the insulation.

The weight of mineral wool depends on its density, which influences the choice of material depending on the area of application - loaded or unloaded surfaces. For the most part, this figure can range from 35 to 100 kg/cubic meter. Considering that the size of the insulation boards used is on average 0.6 square meters, the weight during installation is also insignificant. The term “density” in some cases can be replaced by the name “volumetric weight of the minislab”, which fully corresponds to the definition of density and represents the weight of 1 cubic meter of insulation.

How is Archimedes' law related to the issue at hand?

To understand what is heavier - a kilogram of cotton wool or a kilogram of iron, you need to remember that body weight is determined using scales (the type of scale does not matter), and all the bodies around us are in the air, which is the very fluid substance that appears in the law Archimedes. This means that any body that a person encounters in everyday life is subject to a buoyant force directed opposite to the vector of the body’s weight.

Therefore, when measuring with scales, we do not get the true value of the body’s weight, but the difference between it and the Archimedes force. This difference is then converted into mass according to a simple formula:

P - FA = m*g,

where P is weight, and m is the mass of the body being measured.

Thus, it is possible to correctly determine which is heavier—a kilogram of cotton wool or iron—by calculating the FA for these substances.

How much do Rockwool slabs weigh?

The weight of mineral wool from Rockwool, a popular insulation manufacturer in our country, depends on the density of the thermal insulation material that the buyer chooses to perform a certain type of work:

- Weight of Rockwool Acoustic Butts, density 45 kg/cu.m. meter, dimensions 1000 x 600 x 50 mm is no more than 1.35 kg.

- Weight of Rockwool Acoustic Butts, density 37 kg/cu.m. meter, dimensions 1000 x 600 x 50 mm is no more than 1.1 kg.

- The weight of Rockwool Light Butts Scandic mineral wool, density 37 kg/cubic meter, dimensions 1000 x 600 x 50 mm, is no more than 0.75 kg.

The mass of mineral wool can differ radically when using combined types of insulation - Rockwool Fire Butts foil plate, density 110 kg / cubic meter. meter, dimensions 1000 x 600 x 30 mm, weighs within 2 kilograms. The weight also depends on the thickness of the insulation used - Rockwool Light Butts Scandic, density 37 kg/cu. meter, dimensions 1000 x 600 x 100 mm, weighs about one and a half kilograms.

The weight of the insulation does not significantly affect the application features. Of greater importance, of course, is the density of the material. In addition, knowing the density parameter and packaging volume, you can easily calculate the weight of the product.

The density of insulation can vary significantly depending on the brand, composition, and the use of various synthetic elements. For example, with a density of 28-45 kg/m 3, the weight of extruded polystyrene foam (one cubic meter of material) will be 28-45 kg.

The weight of ordinary polystyrene foam is 15-35 kg (one cubic meter)

The density of this material depends on the so-called product classes (their characteristics include not only density, but also strength, water absorption, etc.): 31, 31C, etc. For example, extruded polystyrene foam 35 has a density of approximately 30 kg/m 3 .

The weight of mineral wool (1m3), as a rule, depends on the purpose.

Wall panel, mineral wool

Table 1. Specific gravity of wall sandwich panels with mineral wool .

Density of mineral wool – 110 kg/m3.

| Building Insulation Materials Foams develop small gas cells or bubbles within the structure; in fabric insulation such as wool, small, variable pockets of air naturally form gas cells. Industrially produced wood fiber insulation was introduced about twenty years ago, after engineers in Europe's timber regions developed new ways to turn waste wood from tunnels and factories into insulation. | |||

| Standard panel thickness, mm | Specific gravity of the sandwich panel, kg/m² depending on the thickness of the cladding, mm | ||

| 0,5 | 0,6 | 0,7 | |

| 50 | 14,61 | 16,26 | 17,93 |

| 80 | 17,91 | 19,56 | 21,23 |

| 100 | 20,11 | 21,76 | 23,43 |

| 120 | 22,30 | 23,96 | 25,62 |

| 150 | 25,61 | 27,26 | 28,93 |

| 180 | 27,81 | 29,46 | 31,13 |

| 200 | 31,11 | 32,76 | 34,43 |

Application

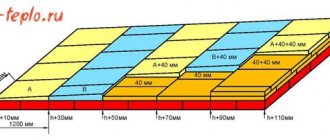

1. Installation of heat-insulating coating in flat roofs and multi-level layers.

2. Thermal insulation of pipeline communications, tanks, gas pipelines and technical equipment in many industrial sectors.

3. Insulation in 3-layer sandwich panels, as well as concrete or reinforced concrete materials.

4. Unloaded insulation in building envelopes.

6. Thermal insulation of ventilated facade structures.

7. Entrance door filler.

Baswool Standard 60

Armor and weapons. How much does 1 cube of ursa weigh, the weight of 1 m3 of mineral wool, how many kilograms in a cube of URSA, how many tons in 1 cubic meter of ursa insulation, kg in 1 cubic meter of mineral wool, tons in 1 m3.

The weight of a volume equal to one cubic meter of insulation, one cubic meter of thermal insulation, one m3 expressed in kilograms kg and in tons tons. Please note that this is not only the number of kilograms in 1 cubic meter of thermal insulation or the number of tons per cubic meter, but also the bulk density of mineral wool or the specific gravity of the insulating material.

What is the weight of 1 cube escarpment, the weight of 1 m3 mineral wool, how many kg in Cuba URSA, how many tons 1 cubic meter escarpment insulation, kg per 1 cubic meter of mineral wool, tn in 1 m3.

Types of mineral wool

All types have good fire resistance. The most popular are glass and mineral wool. The basis of stone mineral wool contains rocks of basalt groups with an admixture of metallurgical substances. The structure of glass wool is filled with glass fiber, using quartz sand and old glass substances.

In 2 cases, phenol-formaldehyde resin is used as binding components. According to research, this substance can harm human health. But in comparison with the popular material chipboard, which contains the same resins, its quantity is 20 times less.

Description of material

This is a world-famous insulation made from mineral wool.

Available in rolls, as well as rigid and semi-rigid slabs. It consists of glass fibers 100-150 microns long, the thickness of which is 4-5 microns. For production, only natural ingredients are used, since mineral wool is environmentally friendly. It can be used both horizontally and vertically. Different types are designed for both indoor and outdoor use.

The insulation is made of quartz sand and broken glass (80% of the total mass). Soda, dolomite, limestone, and borax can also be used. The materials are poured into a hopper, where the process of melting the mass occurs. The filaments are formed when molten glass is blown by steam as it flies out of a centrifuge. Impregnated with an aerosol, they fall onto the rollers and are leveled, forming a “carpet”. At a temperature of 250°C, polymerization occurs. Then the mineral wool is cooled to ambient temperature and cut into mats and rolls.

Prices for Izover insulation

Types of mineral wool

3. Vertically layered.

4. Horizontally layered.

The main component of the material is basalt. It acts as a binder, which can be urea resins, bitumen, phenolic alcohols, clay and starch.

In the process of making mineral wool based on rocks of molten mineral materials, thin fibers of 1–3 microns with a thickness of 50 mm are obtained. To improve strength, molten charge or limestone can be added to the molten basalt fibers. Mineral wool substances repel moisture, thereby protecting the thermal insulation properties.

Roof panel, mineral wool

Table 3. Specific gravity of roofing sandwich panels with mineral wool

Density of mineral wool – 130 kg/m3.

| Standard panel thickness, mm | Specific gravity of the sandwich panel, kg/m² depending on the thickness of the cladding, mm | |

| 0,6 | 0,7 | |

| 50 | 18,34 | 20,18 |

| 80 | 22,24 | 24,08 |

| 100 | 24,84 | 26,68 |

| 120 | 27,44 | 29,28 |

| 150 | 31,34 | 33,18 |

| 180 | 33,94 | 35,78 |

| 200 | 37,84 | 39,68 |

Thermal conductivity coefficients

All durable components are gradually heated, and then cooled, in compliance with the intervals, the temperature regime of the internal structure and surface of the material. The thermal insulation qualities of mineral wool are demonstrated by the thermal conductivity coefficient. Its smallest value ensures maximum preservation of thermal conductivity. Often the coefficient values are pre-specified by the manufacturer. The value of the coefficient is determined in laboratory conditions.

Thermal water values vary around 0.032 W/(m*K). The latter indicator is found only in high-quality insulation materials.

Mineral wool [MV], rub. per m².

The insulation density is 110 kg/m³ with metal cladding 0.5 .

| Thickness | 50/60 | 80 | 100 | 120 | 150 | 200 |

| Wall up to 150m² | 1280 | 1350 | 1400 | 1460 | 1560 | 1730 |

| Wall 150-500m² | 1260 | 1330 | 1380 | 1440 | 1540 | 1710 |

| Wall from 500m² | 1240 | 1310 | 1360 | 1420 | 1520 | 1690 |

| Roofing up to 150m² | 1340 | 1420 | 1460 | 1530 | 1630 | 1780 |

| Roof 150-500m² | 1320 | 1400 | 1440 | 1510 | 1610 | 1760 |

| Roof from 500m² | 1300 | 1380 | 1420 | 1490 | 1590 | 1740 |

Mineral wool sizes

Manufacturers present 3 types of mineral wool, each of which has its own type of raw material, namely

3. Basalt mineral wool.

Sheets

Mineral wool rolled into rolls is produced in the form of a large piece, pre-cut and completed. The dimensions of the material are indicated on the packaging, since many manufacturers have different sizes. Thickness can vary from 40 to 200 mm, width from 565 to 610 mm, length about 1170 mm. The thickness of rigid slabs for hydro and thermal insulation varies from about 50–170 mm, the width of the product is about 1190 mm, and the length is 1380 mm.

Roll material

Mineral wool in this format is ideal for thermal insulation of large areas, since the rolls contain a large amount of material. As a rule, the width of the materials varies between 50–200 mm, the length of the sheet is about 7000–14000 mm, and the width is approximately 1200 mm. The material is easy to cut and adjust to the size of the room.

Mineral wool in cylinders

Designed for waterproofing hydraulic lines. The basis of this type of mineral wool includes: foil, fiberglass mesh and basalt. The structure can withstand high temperatures up to 250 C. The width of the product generally varies between 12–324 mm, length about 1200 mm, with a thickness of 20–80 mm. The exact dimensions are indicated on the packaging of the material. Mineral wool in cylinders is intended for thermal insulation of heat exchange systems and heating communications. Diameter, thickness and length are selected in accordance with the size of the pipes

The mass of mineral wool varies depending on the substances filling it. To determine what weight the builder will be dealing with, you should pay attention to the density of the material, which can also be found as the mass of mineral wool per 1 cubic meter. This figure can vary from 35 to 100 kg per 1 cubic meter. The average weight of insulating boards is 0.6 cm. In the process of performing technical operations, weight does not play a significant role.

Manufacturers' products have different weights, on average this figure varies from 37 to 45 kg with sizes no more than 1.35 kg, and depends on the density of the thermal insulation material. Its weight changes significantly with a combined approach to insulation. In this case, the thickness of the insulation used is decisive.

Rockwool insulation in rolls

Rockwool lamella rolls.

Types of Rockwool insulation in rolls are divided into two categories:

Solid rolls are long strips of insulation without joints. They are presented in a line called:

- Tech Mat – 43 kg/m. cube, 0.034 W/m*S. Used for thermal insulation of pipelines and technological equipment, can be with foil;

- Wired Mat – 50 kg/m. cube, stitched with galvanized wire;

- Domrock, Megarock, Multirock.

Lamella rolls are narrow rectangular pieces of thermal insulation that are attached to a foil base. This approach allows you to roll denser materials. These include Klimafix and Lamella Mat. The dimensions of Rockwool insulation differ only in length and thickness, and the standard width for all is 1 m.

Regardless of whether Rockwool thermal insulation is produced in mats or rolls, the entire line is quite versatile. The main characteristics are approximately the same, only the density of the material and the presence of foil or reinforcement differ. There are also two-layer and single-layer insulation, of course, different sizes.

The characteristics of physical bodies make it possible to determine their functionality, predict the duration of their operational life, and identify their features. With regard to materials for thermal insulation based on mineral wool, one of the main quality indicators is density, which is also the specific gravity of the insulator.

The unit of measurement for density (volume weight) is kg/m3. The scope and performance of the material directly depends on this indicator.