Today we will tell you on what principle reflective insulation works and which side to lay the insulation with foil. These two aspects simply cannot be separated, because if installed incorrectly, foil insulation simply does not work. In addition, we will tell you about the most important aspects of installation and their impact on heat loss and the microclimate in the room. And naturally, we will conduct our educational program separately for each type of insulation with foil. These include polystyrene foam in sheets, mineral wool in sheets and rolls, foamed polyethylene in rolls, as well as shells for insulating pipes made of polystyrene foam and mineral wool.

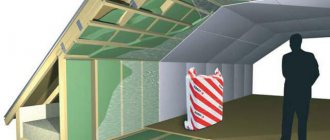

How to properly lay polystyrene foam with foil

Expanded polystyrene mats for floor insulation and subsequent installation of a low-temperature “warm floor” system.

It is necessary to consider which side to lay the insulation with foam foil in the narrow direction of installation of low-temperature heating systems, that is, heated floors. Now you can find on sale special foam mats (sheets), which are covered with foil on one side. In addition, markings are applied to the foil for laying polymer pipes or electrical cables. As you know, heat sources when installing heated floors must be at a certain distance from each other for the system to work correctly.

In this case, the most important role is played by insulation with foil; how to fix it correctly is a key point. The essence of reflective insulation is to reflect infrared rays, that is, heat. Like a mirror, it reflects up to 97% of all IR radiation. Naturally, the reflected rays must return back into the room, so the logical conclusion on how to lay foil insulation suggests itself. Of course, with the reflective surface inward.

Methodology for laying insulation with foil for heated floors:

- the subfloor is leveled;

- foam boards with foil are glued with construction adhesive;

- Cable or pipes are laid according to the markings;

- everything is filled with screed with reinforcing mesh.

Another important point is how to correctly lay insulation with foil: the slabs must fit snugly to the floor. It happens that due to the unevenness of the mats themselves, they lie unevenly on the floor, even if it is perfectly flat. To correct the situation in places where the thermal insulation does not fit tightly, it is simply cut. That is, several smaller ones are made from one sheet, and the operation is carried out locally, after the mats are laid.

Considering the principle by which foil insulation works, figuring out which side to put is as easy as shelling pears. Reflective insulation should reflect IR radiation into the room; accordingly, it is placed with the shiny side in the middle.

Such slabs are used only for floor insulation; they are not used for walls and ceilings, since there are thermal insulation options specifically designed for this. These include:

- mineral wool in mats and rolls with one-sided or double-sided foil;

- foamed polyethylene with foil.

By the way, ordinary foam plastic or its extruded analogue in tandem with penofol perfectly replaces mats for insulating floors and further laying a low-temperature heated floor system. The only inconvenience is the lack of markings.

If you are going to build a private house, then water heating will be the best option for heating it. There are, of course, air, steam and electric heating, but they cannot compete with a liquid coolant circuit.

The two-pipe water heating scheme for a two-story house can be vertical and horizontal. Drawings with explanations here.

Technical characteristics and price issue

It is impossible to name the general characteristics of all foil-type insulation - different materials have different properties. But you can consider the characteristics of the most popular and affordable insulation materials.

Insulator made of foil and polyethylene foam

In most cases, the material is sold in the form of compact rolls. The thickness of the insulation varies from 2 millimeters to 1 centimeter. Foamed polyethylene can be coated on both sides or on one. In addition, self-adhesive material is available on sale, when one of its surfaces is covered with an adhesive layer and a protective film.

The scope of use of polyethylene foil insulation for walls is, as a rule, not limited: they are used for insulation of floors and walls, roofs, ventilation, refrigerators or pipelines. Also quite often, this type of heat insulator is used for installing heated floors, for insulating baths, and as a finishing coating for linoleum or laminate.

To prevent heat from escaping through wall structures, a layer of insulation based on polyethylene and foil is secured behind the heating radiator so that there is about two centimeters of free space between the insulation and it.

Foil-coated polyethylene is often used in shoe production - good shoe insoles are made from this material.

In building materials stores you often find such names of materials as Ecofol, Izolon and Penofol. The price of one roll is directly dependent on the thickness of the material. For example, a roll of thermal insulation with foil 2 millimeters thick will cost about 1,700 rubles. With a thickness of 1 centimeter, the cost will be about 3,500 rubles.

Mineral wool with foil

In this type of heat insulator, only one side is often covered with foil. It is sold in two different formats: rolls and slabs. The thickness of the thermal insulation layer is from 4 to 10 centimeters. It is made on the basis of basalt wool or fiberglass.

The use of foil mineral wool is limited, since the material is harmful to human health, it causes lung diseases and releases phenol into the surrounding space. It is mainly used for external insulation of buildings and non-residential premises. Basalt wool is not subject to combustion; it is installed if resistance to high temperatures is required: on fireplaces, stove pipes, etc.

Properties such as moisture absorption, density and others depend on the brand and type of wool, as well as the characteristics that were included in the material by the manufacturer. The good waterproofing properties of this insulation make it possible to use it in showers, saunas and baths.

The most popular brands are Izover, Parok, Ursa and Rockwool. The cost of the material is approximately 1,300 rubles per 0.25 cubic meters.

Foiled polystyrene foam insulator

This is a high-strength thermoplastic, which is obtained by melting polystyrene granules. Produced only in the form of individual slabs. Such material can be used in places that are subject to significant mechanical stress and moisture - strong polystyrene with foil is not susceptible to rotting and mold or mildew. Therefore, it is often used when installing a warm water floor. The average cost is 90 rubles per slab.

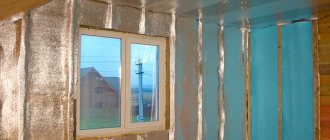

Which side to attach polyethylene foam with foil

When the question arises about how to attach foil insulation to a wall, most often we are talking about penofol. This is insulation that consists of two layers. The first layer is polyethylene foam, and the second layer is foil. In addition, there are products in which the foil is on both sides. The reflective surface can be glossy, like a mirror, or crumpled (embossed). It is believed that the relief allows you to slightly increase the reflection area, but not critically, so there is not much difference.

Unlike mats for floor insulation, regarding penofol, the answer to the question: “Which side should we attach the insulation with foil?” sounds like this: with a base (foamed polyethylene) to a wall or other insulation.

The thing is that this material is used for both internal and external insulation. It turns out that during thermal insulation of the facade, it will not be possible to put penofol with the shiny side inward; it will look outward. What will this give us:

- Such insulation will not reflect heat from the room, since there is no ventilation gap between the foil and polyethylene;

- the insulation will not let summer heat into the house.

Two-layer reflective insulation, where polyethylene foam acts as a damper and reinforcement.

It is precisely because of the absence of any significant shifts towards increasing the thermal insulation qualities of the room that experts do not use penofol for external insulation. How to properly lay foil penofol insulation:

- should be placed from inside the room with the shiny side facing the heat source;

- there must be an air buffer zone (ventilated gap) between the foil and the finish;

- the material is laid end-to-end;

- secured either with nails or staples;

- The joints are glued with aluminum (not ordinary, but aluminum) tape.

These manipulations are performed in order to create a sealed reflective screen, which additionally acts as a vapor barrier, since it does not allow steam or moisture to pass through. Why, when answering the question of how to properly lay insulation with foil, do we focus on the ventilation gap? The fact is that without it the material will not perform its functions. The air space allows the foil to repel IR radiation from structures in front (plasterboard, lining, siding, whatever).

If there is no air gap, then heat will be transferred to the foil not through IR rays, but through direct contact of the materials. Aluminum's thermal conductivity is exceptionally high, so the process of transferring heat outside the room will even speed up in this case. A thin layer of foamed polyethylene does not create a special barrier to heat loss, and its main function is different: it acts as a damper and reinforcement for the foil, everything else is indirect.

This will cause an undesirable side effect – condensation. The foil does not allow steam to pass through, and it settles on it in the form of condensation. If there is a ventilation gap, then micro droplets of moisture simply evaporate. In the absence of a buffer air zone, moisture collects and is absorbed into the finish, causing fungus to appear. This is what can lead to not knowing which side to put insulation with foil on.

Despite the fact that there is plenty of information about heating a house from sip panels, many can still decide on the method of heating a house made from this material. Although there are quite a lot of approaches that have a lot of advantages and benefits.

You can find all the necessary information about convector heating at home with photos and video files on our website by following this link.

Properties

The materials used in production are most often environmentally friendly, safe for health and the environment.

Related article: Which is better, carpet or linoleum? answer the question

Advantages:

- light weight;

- durability;

- resistance to loads;

- protection against moisture penetration;

- high rates of heat saving and sound insulation;

- resistance to temperature changes;

- ease of installation;

- high reflective properties.

Such insulation can be used in any premises. In addition to the described qualities, it is capable of reflecting radiation.

What to glue mineral wool with foil to

Mineral wool with foil is produced in rolls and sheets. It is attached with universal construction adhesive.

Mineral wool with one-sided and double-sided foil is produced in rolls and sheets of different thicknesses. Mineral wool refers to all its varieties: from glass wool to basalt wool. It, like polystyrene foam, is glued to the wall and is additionally reinforced with dowels. What to glue insulation with mineral wool foil to? For work, use a universal plaster-adhesive mixture, which is suitable for both cotton wool and expanded polystyrene.

When choosing what to glue foil insulation with, you need to consider only high-quality mixtures from leading manufacturers:

- Knauf;

- Ceresit;

- Weber vetonit;

- Eunice.

If the surface on which the insulation is heated is flat, then apply the adhesive in a 3 cm layer with a notched trowel along the entire perimeter of the thermal insulation sheets. If the cotton wool is glued to an uneven surface, then the glue is applied with a thickness of 4 cm in cakes, the diameter of which is at least 10 cm.

In addition, before laying insulation with foil, you need to clean and prime the working surface for better adhesion. Again, we remind you about the ventilation gap and that the reflective foil should face the inside of the room. This material is not used for external insulation, as it is impractical. Mineral wool with foil is suitable for baths, as it is resistant to high temperatures, but it is afraid of moisture, so it must be protected with a vapor barrier. This does not apply to stone wool, since it practically does not absorb moisture.

Real thermal insulation characteristics

At the beginning of the publication, we mentioned the overestimation of the performance parameters of the material by unscrupulous sellers. Common myths about the properties of an insulator look like this:

- Innovative insulation "Penofol" has the best thermal insulation characteristics. The thermal resistance R of a 4 mm thick sheet reaches 1.2 m² • °C/W, which is comparable to 0.67 meter red brick masonry or 46 mm polystyrene foam.

- The Penofol layer serves as excellent sound insulation.

- The insulation can be freely filled with cement-sand screed, turning the foil up.

Material with an adhesive layer on the back side (type C)

The heat transfer resistance of one insulating layer can be easily calculated using the classic formula from the building thermal physics course:

- R – the value of the thermal resistance of the material, m² • °C/W;

- δ – insulation thickness, m;

- λ – coefficient of specific thermal conductivity, W/(m • °C).

Substituting the manufacturer's data into the formula (we take the optimal option), we get R = 0.004 mm / 0.037 W/(m • °C) ≈ 0.11 m² • °C/W. Knowing the thermal conductivity of the foam (λ = 0.043), it is easy to determine the appropriate layer thickness: 0.11 x 0.043 = 0.0047 m = 4.7 mm. Roughly speaking, 5 mm of polystyrene foam and 4 mm of polyethylene foam will retain the same amount of heat; there is no talk of 46 mm.

Closed pores do not allow Penofol to become a full-fledged soundproofing material. Sound waves are only partially absorbed by the soft surface of the polymer.

To soundproof the floors, a special membrane made of 3 layers of polyethylene foam is used

For effective sound insulation, acoustic building materials with an open structure are needed:

- mineral wool;

- cork lining;

- foam rubber sheets;

- cellulose ecowool.

It is strictly not recommended to lay Penofol under a cement screed for heated floors for the following reasons:

- Under the weight of the solution, the soft polyethylene foam is crushed, air (or inert gas) is squeezed out of the chambers, and the insulation becomes twice as thin. Thermal resistance is reduced to a minimum.

- Aluminum foil embedded in concrete does not reflect infrared waves.

- Monoliths thinner than 6 mm shrink and crack along with the tiles.

The alkaline base of cement destroys thin aluminum in literally 4-5 weeks.

Under the monolith, ordinary “Penofol” quickly loses its foil due to the aggressive effects of Portland cement, which is clearly demonstrated in the video below. The manufacturer suggests placing a special type of insulation under the screed - Penofol ALP, laminated with a protective polymer film. True, the issue of compression and destruction of closed pores from the weight of the monolith remains unresolved.

Conclusion. Foil-coated polyethylene products are not inferior to Penoplex and sprayed polyurethane in terms of thermal insulation properties. The weaknesses of Penofol are its small thickness and soft structure. The material must be used in certain places, following the technology and manufacturer’s instructions.

How to lay insulation with foil for pipes

Shells for insulating communications are made of polystyrene foam and mineral wool.

In addition to thermal insulation for floors, horizontal ceilings and walls, there is also insulation with a reflective layer for pipe insulation. These are shells that are made of polystyrene foam or mineral wool. The former are lighter and are not afraid of moisture, while the latter can withstand high temperatures, which is appropriate when insulating chimney pipes. Considering the fact that the material is already produced in the form of a pipe, the question of whether to put the insulation with foil on the outside or inside is not worth it. There is a shell that you put on the pipe and that’s it, you can’t turn it inside out.

At the same time, there is always a choice when purchasing, since they are also produced with one (outer) or two (outer and inner) layers of foil. Such shells are used for:

- laying pipelines by air;

- laying highways underground;

- laying pipelines in unheated rooms;

- insulation of chimneys.

In some cases, they are used to insulate pipes so that the coolant does not lose its temperature even in heated rooms. For example, in industries where the first and last heat exchanger of one circulation ring are installed at a great distance from each other.

Features of using foil insulation

The use of materials with foil for insulation depends on a couple of indicators: the properties of a particular heat insulator and the place where it will be used. In general, with the help of such thermal insulation, floor structures are insulated, the heat transfer of heating radiators is increased, and air ducts and pipelines are finished. Thermal insulation of entrance doors of verandas, loggias, porches and balconies also gives excellent results

When installing foil-type insulation, you need to acquire all the necessary tools for the job:

- Construction stapler.

- Small carnations with large heads.

- Nail puller and hammer.

- Construction tape with foil coating.

- Direct insulation with foil.

The most common mistake many builders make is incorrect installation of the material with the foil surface facing outward. Due to the fact that the foil is a reflector, it is designed to return heat to the room. But if you place the insulating material on the wrong side, you won’t be able to achieve this effect.

When laying foil insulation , it is recommended to enclose it in a wood sheathing.

Slabs, rolls or sheets of material must not be laid overlapping. They must be installed strictly on the same plane, secured with nails or construction staples.

Material with an adhesive surface does not need to be secured with additional fasteners, but to increase service life it is still better to use small nails. In the absence of an adhesive coating, rubber or acrylic adhesive can be used to fix the material on the surface.

After installing and securing all layers of heat insulation, the joints between them must be treated with foil tape. This completes the installation.

When installing a heat insulator on vertical surfaces that have mold, wallpaper or dirt on them, they must first be cleaned, otherwise the fixation will be very unreliable, and the material will simply fall off over time. In addition, it is recommended to treat the surface with antiseptic agents.

Let's sum it up

So, we found out that there are several types of foil insulation:

- polystyrene foam in sheets for flooring;

- mineral wool in sheets and rolls;

- penofol;

- shells for insulating pipes made of foam plastic and mineral wool.

All types of insulation, except shells, with a reflective layer are intended for internal insulation. The foil should be placed in the middle of the room. Such materials are suitable for external insulation, since the concept of reflecting IR radiation is reduced to nothing. Therefore, there is no point in paying for something that will not bring results.

Foam and mineral wool slabs must be glued using a special plaster-adhesive mixture from trusted manufacturers. The latter include the same Knauf or Ceresit. Laying on the walls is carried out from the bottom up, the sheets are additionally secured with dowels. And the most important thing is the presence of a ventilated gap in front of the reflective surface. If it is not there, then instead of reflecting heat you will get even more heat leakage and, in addition, mold on the finish.