Characteristics of Polynor insulation (POLYNOR)

The new generation thermal insulator under this brand is an alternative solution to the problem of sprayed insulation. Packaging with a small volume allows you to economically consume the required amount of material and process areas of different sizes without wasting insulation.

The cylinders under a pressure of 6 atmospheres contain a one-component composition, which, upon direct contact with oxygen particles in the air, begins to activate, resulting in the process of its polymerization and hardening.

The ease of use of this material is manifested in low labor intensity and simplicity of the process. To get started, you just need to secure the insulation into a special mounting gun with a cylinder holder and press the trigger.

For information, when the first portion of insulation leaves the cylinder, a large outlet pressure is created, which can lead to the release of a large volume of the composition. Therefore, when you press the trigger for the first time, the spraying interval should be short - no more than 1-2 seconds.

The resource of one portion of insulation in a cylinder allows covering approximately 1.15-1.20 m2 with the material, with an insulating layer thickness of 45.0-50.0 mm. As a result of spraying, a cover of a soft but dense structure with open air cells is formed.

Warning! When working with Polinor insulation, toxic components are released into the air during polymerization. Therefore, the manufacturer recommends protecting the respiratory tract, eyes and skin until the insulation hardens.

However, the toxicity of individual components is temporary, and after the insulation suspension hardens, the material becomes absolutely harmless.

Main characteristics of the material

This type of insulation, produced in Norway, appeared on the Russian market only in 2014, but today it is considered very popular and effective due to the possibility of significant optimization of costs during construction and insulation of structures.

Polynor has a unique polyurethane composition, packaged in cylinders under a pressure of about 6 atmospheres. Contacting oxygen in the air, the one-component substance is activated, as a result of which it hardens and polymerizes on any surface. Convenient nozzles allow you to spray material in the most difficult to reach places.

The main qualitative difference between the frozen Polinor and its analogues is the ratio of open and closed cells. In the polyurethane composition, almost 70% is closed, whereas in conventional polyurethane foam it is only 30%. This is what determines such qualities of Polinor as a low level of thermal conductivity, vapor absorption and immunity to moisture penetration.

The approximate consumption of the sprayed composition is 1 cylinder per 1-1.2 square meters. m of surface. In this case, the thickness of the frozen mixture will be approximately 5 mm, which is quite enough for high-quality insulation.

In terms of time costs, Polinor is significantly ahead of other mounting foams, because surface treatment of 100 sq. m with a construction team of several people will take on average only about 3.5 hours.

In this case, the configuration of the room does not matter: the mixture can be applied to the farthest corners, to the joints, to any curved and uneven elements.

Purposes of use

What can be insulated with Polinor:

- residential buildings, country houses, outbuildings;

- industrial buildings, workshops, garages;

- baths, balconies and loggias;

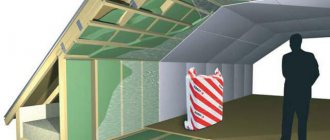

- roofing, floors and walls;

- facades, attics, attics and basements;

- communication structures and systems (pipes, tanks, tanks);

- some types of transport (thermos vans, isothermal cars).

Liquid insulation brand POLYNOR

And the most influential parameter of Polinor’s efficiency can be called thermal conductivity.

The ability to prevent heat loss is a key parameter in all types of insulation. But often the characteristics declared by the manufacturer are leveled out in practice due to the type of insulated surface, the method of installing the insulation and side effects. Sprayed Polynor insulation is devoid of such defects due to reliable adhesion to all surfaces and due to the ability to penetrate into the most difficult to reach places and joints of the house structure.

But returning to the advantages of Polinor’s thermal conductivity, we can pay attention to its priority over other types of thermal insulators.

| Type of insulation | Unit change | Mineral wool | Expanded polystyrene | Penoizol | Polinor |

| Thermal conductivity index | W/(m*deg.) | 0,045 | 0,033 | 0,06 | 0,023 |

To fully perceive all the advantages of this insulation, its other advantages should be emphasized, including:

- Possibility of self-adjustment of the applied layer

- Economical use due to doing the work yourself

- Excellent water absorption rates (0.03 for polynore versus 0.14 for penoizol, 0.20 for mineral wool and 0.02 for expanded polystyrene)

- Possibility of creating a seamless layer

- Effective indicators of noise insulation properties

- Operational period of insulation. This figure is again a record - only 180-200 minutes to insulate 100 square meters of area of any configuration.

The advantages also include the possibility of insulating different types of buildings with different surface textures, as well as the absence of complex technological equipment.

Why is POLYNOR warmer and more profitable?

Polinor looks more efficient than other materials, including sprayed analogues, due to the low thermal conductivity coefficient and the most rational heat capacity indicators. For these reasons, it retains the temperature better and does not let heat out.

This material is more profitable both in terms of process availability, as well as for budgetary reasons.

Price of Polinor insulation

The amount of costs is one of the significant arguments in choosing an insulating material. And in comparison with other insulation materials, Polynor benefits due to the economical consumption of the structural composition and due to the absence of costs for the purchase of expensive spray equipment.

The recommended retail price for 1 POLYNOR cylinder is from 450 rubles.

To ensure effective insulation performance, a small volume of Polinor is required, which also makes its use economical. In long-term use, savings are achieved by minimizing costs during the heating season.

Reviews about Polinor insulation

Users who have encountered this insulation usually give only positive reviews regarding a noticeable improvement in heat retention, reduced heating costs and ease of use of the insulation.

Some of them were dissatisfied with the polymer smell, which in some cases could last for several days.

In general, this insulation for the walls of a wooden house justifies the costs of its use and is rightly called an innovative means of insulation.

Video about Polinor insulation and its advantages

In the video presenting Polynor insulation, its other advantages are noted that are not mentioned in the description of the characteristics. In this video you can see the effectiveness and appearance of the insulated surface.

Sprayed thermal insulation POLYNOR (POLYNOR) is a one-component polyurethane foam insulation. Norwegian development in the field of heat supply. Easy-to-install insulation for all building structures: floors, walls, ceilings, foundations, air ducts... There are no analogues of the product! 890 ml cylinder, enough for 1.2 m2 of insulated surface 5 cm thick! POLINOR is applied using a spray foam gun and a special nozzle.

POLYNOR insulation has a number of unique characteristics that make it stand out among all other insulation materials:

1. The technology for applying POLYNOR is simple and accessible even to a non-professional performer.

Properties and technical parameters

Polinor insulation has excellent characteristics. Let's look at them:

- On average, the density of the layer that has frozen is 20 kg/m3. Maximum density – 28 kg/m3.

- Moisture absorption is 2%.

- Temperature range is from -25°C to +125°C.

- Initial hardening occurs after 45 minutes, final hardening occurs after 1.5 days.

- The service life is 50 years.

The heat insulator from the manufacturer Polinor is vapor-tight. The insulation is characterized by sufficient chemical and high biological stability. This is another advantage of this material.

Another plus is efficient consumption. One liter is enough to create a layer that is four centimeters thick per square meter of surface. Moreover, you will spend much less money on purchasing this product compared to mineral wool together with additional funds. Additional means are lathing, fasteners, membranes, and so on.

Despite so many advantages, this material is not without its drawbacks. Polinor insulation is a product that has normal flammability and belongs to the civil protection class. At a temperature of 450 degrees the layer melts. A short-term contact with fire is enough for the product, after which it begins to burn for five minutes. The second disadvantage is the irrational use of insulation in cylinders on surfaces that have a large area. But usually this material does not have such a purpose.

Please note the table containing technical specifications:

| Parameter name | Indicator value |

| Density indicator | 18-28 kg/m 3 |

| Water absorption | 2% |

| Thermal conductivity | 0.023-0.025 W/m×K |

| Temperature Range | -25°C to +125°C |

| Material layer thickness | 50-60 millimeters |

| Operational service life | 45-50 years |

| Crystallization rate at 20°C | ¾ hours |

| Final hardening time | 36 hours |

| Compression deformation | no up to 50% |

| Vapor permeability | absent |

| Fire hazard class | GZ |

Judging by the technical characteristics, the product is one of the best among liquid insulation materials (PPU).

Contractor Information Portal

How much does POLYNOR cost?

From us you can buy POLYNOR at a discount depending on volume. Call!

How many cylinders are in a box?

The box contains 12 cylinders with POLYNOR insulation.

Dimensions, weight, volume of the Polinor box?

Dimensions of the box with thermal insulation POLINOR 0.27x0.21x0.34 m (WxDxH)

Volume 0.02 m3, weight 12 kg.

How much does delivery cost?

You can calculate the cost of delivery on the website of the transport company PEC at the link https://pecom.ru

Delivery to TK PEK is free!

What is the consumption of a POLYNOR cylinder?

One cylinder is enough for 1 to 1.2 m2 of insulated surface with a thickness of 5 cm.

Thermal insulation efficiency?

Thanks to the monolithic layer of POLINOR insulation, the possibility of the appearance of cold bridges is eliminated and maximum insulation efficiency is achieved.

POLYNOR has the lowest thermal insulation coefficient among polyurethane foam (0.025 W/m* 0C)!

Insulation 50 mm POLYNOR = 150 mm mineral wool = 80 mm polystyrene foam.

Is this polyurethane foam?

Polyurethane foam is not capable of producing the “torch” necessary for high-quality spraying, which is the main feature of the POLYNOR NPU.

Polynor, like polyurethane foam, is polyurethane foam. However, Polynor's properties and characteristics differ from polyurethane foam:

Low water absorption - according to this indicator, POLYNOR is among the leaders (0.01-0.03 per day from the initial volume for POLYNOR; 0.2 for mineral wool; 0.02 for expanded polystyrene; 0.14 for penoizol). Does not support combustion. The lowest thermal insulation coefficient among polyurethane foam (0.025 W/m* 0С) Predominantly closed-cell structure (70% of the cells are closed)

Properties

The main goal of Polinor is to effectively insulate a structure from noise and maintain the required temperature in it.

Being a high-class sprayed insulation, the material has the lowest thermal conductivity among analogues presented on the domestic market. So, if mineral wool has a heat saving of 0.045 W/m*deg, penoizol - 0.06, and polystyrene foam - 0.033, then for POLYNOR this figure is 0.023 W/m*deg.

It is important to note that the lower the thermal conductivity, the higher the thermal insulation characteristics, i.e. material consumption will be significantly less.

In addition, POLYNOR does not require additional treatment with a protective film and does not require the purchase of accessories for installation.

Advantages

Polyurethane material has the following obvious advantages:

- High degree of adhesion to building surfaces of various qualities (possibility of using Polinor in combination with any popular building materials: brick, plastic, stone, concrete, wood).

- Reduced ability of the material to ignite.

- Low labor intensity, simplicity and ease of installation (no additional frames or special skills required).

- Environmental friendliness and low degree of toxicity of the mixture (after complete drying it does not emit substances harmful to human health into the atmosphere).

- Durability (official warranty from the manufacturer is 45 years, while the insulator serves without crumbling or sagging).

- The material, due to its lightness and airiness, does not create additional load on the frame and load-bearing elements of the building.

- The elasticity of the mixture makes it resistant to cracking and any mechanical vibrations during the repair process.

This sprayed insulation is biologically passive, that is, it does not attract rodents and is significantly resistant to the appearance of fungi, mold and other harmful microorganisms on the treated surface.

Flaw

It is important to understand that during the process of spraying and polymerization, the material releases harmful chemical compounds, the effects of which can be protected by using protective gloves and a respirator mask.

After the mixture hardens, it loses its toxic properties, but a faint polymer odor may persist for several days.

Sprayed insulation Polinor

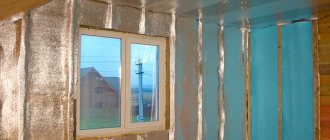

For thermal insulation of flat surfaces (for example, walls, partitions, etc.), rolled or flat materials are usually used - felt, mineral wool, basalt slabs, etc. But what kind of thermal insulation should be used for hard-to-reach places (cracks near windows, pipes, between building blocks and slabs)? Sprayed thermal insulator POLYNOR will help you here .

Description

Polinor is produced in liter aerosol cans containing a homogeneous polymer mass sprayed using a special gun. Polyurethane foam, interacting with oxygen molecules, swells and creates a fine-celled, dense coating without cracks or gaps, that is, it works like polyurethane foam. The drug, having a liquid structure, easily penetrates into hard-to-reach places and small crevices, thereby ensuring complete sealing of the surface being treated.

Polinor is far superior to other similar thermal insulation materials in a number of indicators.

Advantages and disadvantages of Polinor insulation

Advantages

- High performance. A liter can is enough for 1-1.5 m2 of area, with a layer thickness of 4 cm. In addition, the price of sprayed insulation is an order of magnitude lower than the total cost of mineral wool along with lathing, fastening, film and other auxiliary means.

- Durability. Polinor does not crumble or sag over the years. The manufacturer guarantees its service life - 35-50 years.

- The thickness of the applied layer is independently regulated and depends on the force of pressing the trigger of the spray gun.

- High water absorption rates are 0.03, while mineral wool has 0.20, and penoizol has 0.14.

- The treated surface can be painted or plastered.

- Ease of use. Compared to mineral wool and expanded polystyrene, it does not require installation of a frame. Thus, even a child can carry out high-quality installation work.

- Good adhesion. Polinor is fixed on almost all types of coatings: wood, concrete, metal, brick, etc.

- Efficiency. The energy saving indicator is an order of magnitude higher than that of mineral wool.

- Biostability and lack of condensation.

- High speed of application and ease of installation. One person can easily handle the thermal insulation of a room with an area of 100 m2 in just 3-4 hours of work, and without any preliminary preparation.

- Possibility of thermal insulation of buildings with different surface textures.

- Carrying out insulation work does not require the use of expensive complex equipment.

- Economical packaging, allowing you to purchase only the amount of material needed for the job.

- Environmental Safety. During operation, sprayed insulation does not emit any substances harmful or hazardous to the environment and human health.

Flaws

- Does not tolerate direct sunlight;

- destroyed by water;

- When applied, it requires strict adherence to temperature conditions (15-20 degrees above zero).

Scope of use

Sprayed insulation Polinor is used for heat and sound insulation:

- City apartments, country houses and country cottages.

- Heating systems, water supply and other engineering and technical communications;

- Foundations, attics, balconies, facades, basements, verandas, etc.

- Isothermal wagons, thermos vans and other similar vehicles.

- Garage and warehouse doors.

Specifications

- In appearance, Polinor is a homogeneous viscous mass of gray, red, pink, beige, orange or white.

- The thermal insulation density is at least 18-28 kg/m3;

- thermal conductivity coefficient at average temperature 50

- ° 0.023-0.025 W/m2;

- the material has a medium-fine cellular structure;

- since the insulation is an elastic foam, damage during shear or compression is insignificant;

- actual heat loss from Polinor is 1.5-1.7 times lower than normal;

- The heat insulator is resistant to various chemicals (soap solution, sea water, gasoline, kerosene, alcohol, etc.).

Scope of application

I’ll probably call this insulation “folk”. Why? Because working with it does not require special knowledge, and therefore, no search for third-party performers. If we are talking about small “private” volumes of insulation, then you can handle it yourself.

Polinor is used for insulation:

- External and internal walls of residential and non-residential premises built from almost any building material;

- Floors with a so-called non-load-bearing structure and cavities between the joists;

Gun with nozzle - pitched roof;

- Basement, basement, foundation;

- Garage and other non-insulated doors (from the inside);

- Heating pipes, water supply, sewerage and other communications;

- Containers, baths, cisterns;

- Loggias, balconies, attics, verandas and attics;

- Transport kungs, wagons, insulated vans, painting booths, etc.

Just in case, let me clarify - it (Polinor) has an orange-pink color.

Application Features

Before using POLINOR to insulate a particular area, it is necessary to prepare the surface by carefully removing dirt, dust, grease and oil stains from it. Before starting work, the PU foam cylinder should be left for some time in a room with an air temperature of +18 °C. This is done so that the substance does not harden - then the applied layer will be more uniform.

To prepare POLINOR for use, install a special nozzle on the cylinder, which is included in the kit. Having put it on until it clicks, you need to remove the cover from the cross and attach the mounting gun, which is purchased separately. All actions must be performed while holding the packaging in a vertical position. At the beginning of work and as it progresses, the container should be shaken well.

The insulation is applied to the surface by spraying by pressing the “trigger” of the mounting gun. The maximum layer thickness should be no more than 500 mm. At the end of the work, the gun must be disconnected from the cylinder and its parts must be cleaned with a liquid solvent. Each package includes instructions for using the material with clear recommendations and explanations.

Customer Reviews

Three years ago, when the composition first appeared on the domestic market, many experts treated it with some caution. Today, most buyers leave only positive reviews about this product:. “I was considering liquid insulation in cylinders as an option for insulating floors in the basement of my country house

I chose POLINOR and it turned out to be absolutely right. I decided to do the whole process myself and, to be honest, I didn’t even expect such a result. Imagine as much as 120 m2 of high-quality insulation in just four hours of work! I would especially note the good adhesion of the material to the concrete base"

“I was considering liquid insulation in cylinders as an option for insulating the floors in the basement of my country house. I chose POLINOR and it turned out to be absolutely right. I decided to do the whole process myself and, to be honest, I didn’t even expect such a result. Imagine as much as 120 m2 of high-quality insulation in just four hours of work! I would especially note the good adhesion of the material to the concrete base.”

Evgeniy, Samara.

“I insulated a standard 3.5 square meter balcony in just an hour, and spent three times less money than on the mineral wool that my neighbor suggested installing. POLINOR has only one drawback - certain conditions are required for its application. The air temperature should be at least +15 °C; if it’s colder outside, it foams worse and consumption increases.”

Fedor Fedorovich, Ufa.

“We planned to order a team of specialists with equipment, but we thought about it, did the math and decided to do everything ourselves. Believe it or not, you saved twice as much! We insulated the garage (the walls between it and the house), spent a long time choosing materials and, after reading reviews on the Internet, decided to buy sprayed POLYNOR. It turned out very well, and most importantly – quickly and inexpensively.”

Ekaterina, Moscow region.

Pros and cons of insulation

Concluding the review, we need to once again list all the advantages of the innovative insulation of the POLINOR brand:

1. Efficiency. The energy saving indicators of the material are higher than those of its analogues.

2. Ease of use. POLINOR does not require installation of a frame structure.

3. Cost-effective. The insulation is packaged in small cylinders - this allows you to purchase the exact amount needed for work.

4. Environmentally safe to use and harmless during operation.

5. High performance. The insulation can be sprayed over an area of 1 m2 in just 15 seconds.

6. Durability. The service life of the material is at least 50 years.

7. Affordable price. POLINOR in cylinders costs 2.5 times cheaper than visiting a team of craftsmen with special equipment for standard insulation.