Device Dimensions

The sizes of indoor units may vary.

The household type equipment used is often rectangular in shape. The design of semi-industrial air conditioners includes a large square or rectangular room module, mainly of the ceiling type, connected to the ventilation duct. The size of the equipment itself is determined by the spaciousness of the room - the volume of air space. Manufacturers of climate control equipment have in their model range both small, medium and large modules. The width of the wall-mounted unit can vary between 70-160 cm, height - 20-32 cm, and depth - 16-20 cm. The larger the size of the indoor unit, the more powerful and larger the heat exchanger is installed. The larger the block, the larger the area it can serve. Maximum area - 70 sq.m.

Semi-industrial air conditioners are less popular due to the specific installation work and cost of such equipment. Still, there are compact cassette devices that are easily installed in a suspended ceiling. The side of a square module can be from 500 mm to 1 m. The power of such equipment can be from 1 to 4 kW. Most of such a block is hidden in the ventilation duct. Only the removable cover of the device and the control panel protrude from the surface.

Types of split systems and types of indoor units

Type is a more general concept applicable to technical climate control devices regarding their purpose for certain buildings. The type has a narrow semantic focus, which means some feature of the structure or design.

Split systems are divided into both types and types. There are two types of two-component installations: domestic and commercial or semi-industrial. The former are installed in apartments or small offices, the latter in shops, hairdressers and other similar establishments.

All split systems are divided into types regarding the design and design of the indoor unit:

- wall;

- cassette;

- columned;

- channel;

- floor-ceiling.

Each manufacturer produces split systems with different types of indoor units, completing them with certain functions and a standard set of operating modes, which include cooling and ventilation of the air available in the room. It is the parameters of this part of the system that justify the choice of buyers.

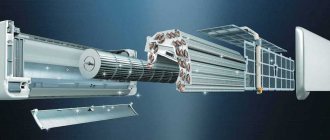

Regardless of the dimensions and external design, any room module consists of:

- heat exchanger (evaporator);

- fan;

- air distribution grille;

- input filter;

- blind guides;

- front panel;

- LEDs;

- temperature sensors.

Fine filters, winter kit and other additional items are available as an option at the request of the customer. The composition may include a mounting plate if the unit is wall-mounted. Operating parameters are set from the remote control. Some models of expensive equipment have the ability to control functionality via the Internet, from a phone or from a central controller.

Operating principle of the indoor air conditioner unit

In general, cooling looks like this: to absorb heat from a room and release coolness, the indoor unit fan draws heated air from the room, after which the process of absorbing heat by the refrigerant begins as it passes through the cold coil.

The refrigerant is a liquid gas (freon), which cools the air. Essentially, it is a heat transfer agent. In the process of transferring cold to the air and taking heat from it, it changes its state, that is, it evaporates. This happens in the heat exchanger of the indoor unit. Here, freon passes from a liquid state into a gaseous state. He took away the heat, the air cooled and flows through the fan back into the room. The process of heat removal is already happening through the outdoor unit.

To put it simply, the role of the indoor module is to take in warm air, cool it and release it back into the room. When the device operates for heating, it, on the contrary, becomes a heat conductor, exchanging functions with the outdoor module. All types of indoor units operate on this principle.

Wall-type indoor units and their sizes

wall-mounted indoor unit

Household air conditioners include wall-mounted models - the most popular among buyers. They resemble a rectangle or square in shape, like LG wall-mounted appliances from the ART COOL GALLERY series. They are hung on the wall in a place convenient for the user so that the treated air does not escape into the person’s permanent residence.

Select the required size of the indoor air conditioner unit relative to the room’s capacity. Each manufacturer has a line of large, standard, and even smaller climate control devices.

The concept of the size of the indoor unit of the air conditioner includes the following values:

- height;

- width;

- depth.

The minimum height can be about 24-25 cm, width - 70-74 cm, and depth - 18-19 cm. For example, the GREE company produces a series of wall splits with an internal block depth of only 18 cm, which significantly expands the possibilities of installing such a device in various points of the room.

The maximum height of a wall-mounted room module can reach up to 30-32 cm, width - 110-120 cm, and depth - about 30 cm. For example, the MITSUBISHI ELECTRIC company produces a series of inverter splits with exactly these parameters.

If the indoor unit of the air conditioner has a non-standard design, for example, it is supposed to be located vertically in the room, then these parameters can vary greatly.

As a rule, air conditioners, and not only wall-mounted ones, have a direct relationship between the size of the indoor unit and its internal structure, or more precisely, on the size of the heat exchanger and the space for air blowing it. The smaller they are, the smaller the device, and the worse the performance.

Some manufacturers maintain normal performance while reducing the size by increasing the fan speed, but a new disadvantage appears - increased noise. This is of paramount importance when choosing an air conditioner for an apartment. This trouble can also be avoided by reducing air flow. Although, in any case, a very powerful split cannot have a small internal module.

Today, some manufacturers have turned their attention to the production of non-standard room modules for wall-mounted splits. For example, LG in its ARTCOOL series offers square devices with the ability to change the picture on the case, and CARRIER surprised everyone with the release of a vertical indoor air conditioner unit with non-standard air distribution in two directions, which is more typical for floor-ceiling models. The GREE company has been offering corner appliances for several years now, but they are difficult to find in Russia.

As a rule, buyers prefer both a vertical indoor air conditioner unit, a corner one, and a square one, either because of space saving or purely out of design preferences.

Semi-industrial air conditioners and their sizes

cassette indoor unit

The remaining types of indoor air conditioner units are classified as semi-industrial equipment, but low-power models of such devices can also be installed in ordinary apartments.

The cassette module has a square shape and easily fits into a cell of a suspended ceiling. Its dimensions can be 600x600 mm or 800x800 mm, although some manufacturers produce a series of super compact cassettes with dimensions of 500x500 mm.

duct indoor unit

Along with cassette indoor modules, duct devices are sewn into the false ceiling (or wall), which are a hybrid of an air handling unit and an air conditioner. They not only cool the room, but can also freely renew indoor air by mixing in outdoor air with the help of additional equipment - an air supply unit. For both types of these climate control units, only the distribution grilles are visible from the outside.

The only drawback is that they require at least 30 cm of space between the ceilings for installation.

columnar indoor unit

Column air conditioners look like an elongated cabinet. They are placed in large rooms on the floor where large cooling capacity is required. Their dimensions significantly exceed the dimensions of any wall-mounted model, but this is a necessity, since it is impossible to achieve such power in any other way.

floor-ceiling indoor unit

Floor-ceiling splits are quite compact and at the same time quite productive for rooms up to 100-120 m². Their internal block is shaped like a modern radiator. They are easy to care for and use. The main advantage is that there are two ways to mount such an indoor unit: to the wall and to the ceiling. If the module is hung on the wall just above the floor, then the airflow goes in two directions, covering even the most complex and hard-to-reach areas of the room. That is why floor-ceiling models like to be installed in rooms with complex configurations.

Features of the functioning of air conditioners

It is technically possible to connect up to 7 internal boxes to one outer box. There are no clear connections between the power of the outdoor unit and the number of indoor units. One external person can work in a company with either two or three internal ones.

When calculating the circuit, we proceed from the total power of all indoor units, which must fit into the range of min and max values of the outdoor cooling capacity (+)

Conventional multi-splits differ from expensive and advanced multi-zone installations by the inability of indoor units to operate in a heat-cold pair.

They can function only in one climate direction - either all for cold, or all for heat. If you turn on the units in opposite modes, the equipment will not start.

But you can set different temperatures on each device. But you need to stay within one mode - either cooling or heating.

Why do you need to know the dimensions of the air conditioner?

For those people who care about their health and well-being, it does not matter how much electricity the air conditioner consumes.

In order for the system to work effectively and maintain the temperature at the desired level, it is necessary to select the climate system taking into account its dimensions and power.

It is recommended to install split systems in bedrooms and offices. It has been proven that at temperatures above +26 and below +22 degrees, labor productivity decreases. This negatively affects the work rhythm and psyche. A correctly sized air conditioner will ensure the maintenance of an optimal microclimate in the room.

The size of the air conditioner is especially important for small rooms. Large systems in small rooms will look bulky and spoil the appearance. In addition, when installing them, serious difficulties may arise: the purchased device may not fit in the space allocated for it.

It is important to position the air conditioner correctly. The distance recommended by the manufacturer must be maintained from the ceiling.

As a rule, it is in the range of 60-150 mm. The optimal distance from a perpendicular wall to the system is 400 mm.

If these requirements are ignored, the operating efficiency of the equipment will be low.

Recently, new approaches to the placement of air conditioners have appeared. Vertical indoor units of split systems are now available for sale. Such devices are equipped with a side outlet of cooled air.

Corner air conditioners do not look as bulky as rectangular ones and take up less space. Such models are the best option for small rooms.

It is important to choose an air conditioner of such a shape and size that it fits perfectly into the space intended for it and looks organically in the interior of the room. Also the unit should not be too noisy

Dimensions of the external unit of the air conditioner

If we consider up to 2.7 kW, then the height of the external unit will be approximately 42-60 cm. On average, this figure will be about 50 cm.

You may need the height of the bracket “foot” - usually 7 cm.

The width (without taps “protruding” beyond the body) is usually 66-80 cm. Taking into account my experience, I suggest taking a distance of 70 cm as the average value.

The depth of small air conditioners is usually

23-30 cm.

Thus, we have obtained the approximate dimensions of the external unit:

- height 50 cm;

- width 70 cm (note that the service taps “protrude” beyond the body by an additional 6 cm);

- depth 27 cm.

I will supplement these figures with the distance between the external block and the wall of the building - on average 15 cm. Taking into account this indentation, the external block will be located at a distance of 42 cm from the wall (cladding) of the house.

For clarity, we present the average dimensions of external units for household air conditioners in the form of a table.

Focusing on these figures, do not forget about the variety of climate control equipment. If you have limited space for the outdoor unit, then before purchasing the device, still check the dimensions for a specific air conditioner model.

Often, during renovations, many people think about installing a split system and plan the design of rooms to fit the size of the air conditioner. The internal unit of this device must be placed in such a way that it is not only correctly positioned, but also looks most harmonious in the intended interior.

The purchase and selection of the air conditioner itself is often planned closer to the end of the repair, and the “power” needs to be supplied now. So, this article was written for such cases. In it we will look in detail at what distances need to be taken into account for subsequent installation, and we will identify the most universal sizes of indoor units (wall-mounted household appliances).

First, we would like to immediately warn you that there are “non-standard” models of air conditioners that may have unique sizes and characteristics. And therefore, this article should not be taken as 100% universal.

Examples of finished sizes

Thus, the Gree company has a room module depth of only 18 cm. The length and width here vary respectively within the range of 70-120 and 24-32 cm.

Mitsubishi air conditioners have the following dimensions: 110-130x30-32x30 cm. These dimensions are taken for a reason: for high-quality airflow, the radius of the cylindrical fan must be at least several centimeters, and its length must be at least 45 cm.

Chinese air conditioners from Ballu are the smallest systems. Model BSWI-09HN1 has a block with dimensions of 70x28.5x18.8 cm. Model BSWI-12HN1 is similar, differing only in a slightly larger external block, the size of which is not particularly important for the internal living space.

But Supra has advanced the furthest: its model US410-07HA has dimensions of the internal unit of 68x25x18 cm. Pioneer is a little behind: the model KFR-20-IW has dimensions of 68x26.5x19 cm. Finally, Zanussi has also succeeded: the ZACS model -07 HPR has an indoor unit with dimensions of 70x28.5x18.8 cm.

Further reduction in the size of the outdoor and indoor units could lead to a decrease in efficiency due to insufficient overall power. No manufacturer has yet presented a rectangular indoor unit whose length would be no more than 60 cm.

How to install an air conditioner: installing external and internal units

First you need to determine the places where the blocks, route and other elements of climate control equipment will be placed. To do this, you need to walk along the entire route with a device designed to detect wiring and apply preliminary markings.

After this, a plate is attached to the wall to fix the indoor unit. This element is placed strictly in a horizontal position, so during the work you must use a building level.

The choice of brackets for mounting outdoor units must be approached very responsibly

Installation procedure for the indoor unit:

The plate is applied to the wall, leveled and the places where the fasteners will be placed are marked. The plate is removed and holes are made at the marked points using a drill. Fastening elements are installed. In wooden houses you can use self-tapping screws; for concrete and brick buildings it is better to use dowels. The plate is put in place and securely fixed

Particular attention should be paid to the latches that hold the unit at the bottom.

All that remains is to check the horizontality of the plate and attach the evaporator to it.

Then you should install the air conditioner yourself from the outside. To do this, taking into account the standards, markings are applied, and metal corners or brackets are installed in accordance with them. As fasteners, you can use stainless steel anchor bolts measuring 10x1 cm. The choice of brackets must be approached very responsibly. These elements must not only withstand the weight of the external unit, but also cope with wind and snow loads.

After making sure that the brackets are installed level, the external unit is secured to them using bolts. The compressor must be lowered to the installation area very carefully, having first tied it with ropes. In the place where communications will pass through the wall, a through hole of the required size is made with a puncher.

Do not install the air conditioner close to the ceiling or side walls

The second stage of installing an air conditioner with your own hands: connecting the blocks

To connect the external and internal units, a cable and copper tubes of two diameters are used. The dimensions of the connecting elements are usually indicated in the instructions that come with the split system. The length is calculated taking into account the placement of blocks. You need to add 30 cm to the resulting value.

Copper tube processing:

- a cut of the required length is made from the bay;

- the edges are straightened and all burrs are removed;

- plugs and plugs are installed at the ends;

- thermal insulation is put on.

After this, the pipes need to be taken out through the hole in the wall and bent in the right places using a pipe bender. Crimp lugs are installed on the cable on both sides, after which it is inserted into the hole and connected in accordance with the instructions.

When installing a split system with your own hands, the drainage pipe is connected to the indoor unit (a special outlet is provided for this) and is brought out to the outside at a distance of about 80 cm from the wall. To prevent sagging, it should be fixed at every meter. Before placing communications in a plastic box, they should be tied into a bundle using metallized tape or ties.

The outdoor unit is installed first, and then the system is installed indoors.

How to connect an air conditioner: connecting copper pipes

First, the tubes are connected to the indoor unit. On its side wall there are two ports with fittings of different diameters. You need to remove the nuts from them. As a result, a hissing sound will appear, indicating that the nitrogen that was pumped by the manufacturer is coming out of the block. It is necessary to protect internal parts from oxidative processes.

Next, you need to remove the plugs from the tubes and check their edges again for defects. The surface must be flat. After this, you can put union nuts on the pipes.

Then the edges of the tubes should be flared. When performing this procedure, you need to hold the product with the hole facing down so that dust and small chips do not get inside. The tube is clamped in the holder so that 2 mm remains outside. Then the roller is installed and the screw is tightened. This is done until the cylinder stops lowering. As a result, a “skirt” is formed on the product.

The tube is connected to the outlet of the indoor unit with a flared edge. A union nut is used as a connecting element, which is tightened with a wrench. There is no need to use sealing materials. The tubes are connected to the external unit in the same way.

Copper tubes are connected to the indoor unit of the air conditioner

Technical characteristics of the indoor unit

To choose the optimal air conditioner model, you should pay close attention to the technical characteristics of the device. Each manufacturer may have its own set of performance characteristics, but the main list of indicators is the same for all and includes the following items:

- Power consumption. Often the general value is indicated for the outdoor and indoor units, where the indoor module consumes only a small part - no more than 100-200 W.

- Heating power.

- Cooling power.

- Air flow. Shows how much air the device is capable of passing through itself per unit of time.

- Device dimensions.

- Weight.

- Recommended area. Makes it easier for consumers to choose by showing for what volumes of premises the device will be optimal.

All this data is recorded in the accompanying documentation, as well as on the information panel on the device itself.

Filters as a marketing ploy

Any air conditioner has a filter through which air is passed to be cleaned. Filter elements must be periodically cleaned and washed. Replacement may be necessary in extreme cases; usually one filter serves as well as an air conditioner. Filter elements are divided into two categories.

Coarse or pre-filters protect the air conditioner from dirt, dust and other foreign elements getting inside. Pre-filters are made in the form of a mesh with small cells that traps particles larger than 2 microns. They are made of metal and plastic, and also differ in the type of weave of threads. The flat version is less effective than the volumetric one.

Fine filters capture particles whose size does not exceed 2 microns. It's not that simple with these filter elements. There are a huge number of them, which are constantly growing:

- adsorbent;

- coal;

- zeolite;

- plasma;

- electrostatic;

- ultraviolet;

- photocatalytic;

- antibacterial;

- antioxidant;

- with vitamin C.

Not all of them turn out to be truly effective. Some, apart from the high cost, are no different from conventional fine filters. Air conditioner manufacturers are actively making money on this topic, throwing dust in the eyes of consumers. Typically, it is the filters that are described most colorfully, while the truly important characteristics are left aside.

Internal unit dimensions

In the standard version, the unit is a rectangular unit in a plastic or metal casing. The dimensions of the device determine its performance and are selected for the total area of the premises served.

Every serious manufacturer has a line of large, standard and small models.

The sizes of indoor units vary within the following limits:

- Width. 70-120 cm.

- Height. 24-32 cm.

- Depth. 18-30 cm.

Note! If there is a need for devices of different overall dimensions, they will most likely have to be made to order.

The dimensions of the indoor unit determine the space for the heat exchanger and its air flow. The smaller the dimensions, the smaller the element and, consequently, the performance of the device. However, some manufacturers take a different route - a small heat exchanger is placed in a compact case, and performance is increased thanks to a more powerful fan. While gaining in size, such an air conditioner will be inferior to its analogues in terms of noise level.

Tools and Supplies

When performing installation work, it is important to comply with many requirements, and the main one is complete sealing of connections when the blocks are positioned strictly horizontally. To install the air conditioner yourself, you will need a certain set of tools, as well as consumables.

Tools that may be required during installationSource avatars.mds.yandex.net

Tools

The minimum set of tools is as follows:

- drill;

- calibration device;

- sandpaper;

- files;

- perforator;

- pliers;

- flarer;

- drills of various diameters;

- high precision construction level;

- device for bending the pipeline;

pipe cutting device or hacksaw.

In systems up to 6 meters long, you can get by with the listed tools. For longer lengths, a vacuum pump will be needed. It is recommended to use it on short sections to obtain the best quality installation, but on long sections its use is mandatory.

Materials

To install a split system, you will need to use certain consumables. The list of required components is as follows:

- anchor fasteners;

- bolted connections;

- dowels;

- mounting of the outdoor unit;

- copper pipes used in cooling systems;

- plastic protection for communications;

- power cable;

- drainage tube;

- pipe insulation.

All this is purchased in accordance with the specifications required by the manufacturer for the installation of specific equipment.

ConsumablesSource s-climate-s.com.ua

What does the external unit consist of?

Since the street block is exposed to high and low temperatures, it is subject to increased demands on the quality of workmanship. Its shape, which resembles a rectangular parallelepiped, allows you to place a set of the following parts and assemblies inside the case.

- Fan - blows on the condenser, cooling the freon.

- Condenser - in it the freon cools and passes from a gaseous state to a liquid.

- A compressor is an engine that pumps up high pressure of the refrigerant, forcing it to move along the circuit (coil) of the refrigerator.

- Four-way valve - it is equipped with air conditioners designed for heating and cooling modes. This part, upon command from the control panel of the indoor unit, changes the movement of freon and, accordingly, cooling in the summer to heating in the cold season.

- ECU – this module is installed on the outdoor units of inverter air conditioners. They are less sensitive to temperature fluctuations than devices with non-inverter control.

- Bends for connecting tracer pipes connecting the indoor unit with the outdoor unit. Freon flows through these pipes. Like electrical wiring with corrugation, they are protected by a box.

- Retaining grille – protects parts and components of the outdoor unit from large objects, debris and insects.

- A cover that protects the electrical terminals from precipitation.

This is a minimum set of elements, without which the circuit is broken and the operation of the device is impossible. The outdoor unit may also contain the following parts.

- A voltage stabilizer is a protective circuit for electronic and electromechanical elements and components that are particularly sensitive to voltage surges.

- Canopy – protects the outdoor unit from precipitation and reduces icing of the housing.

- A hose through which water condensate flows. Connect it to the sewer or use it for drip irrigation of plantings growing nearby. In winter, when heating and cooling change places, additional heating is used to prevent freezing - the condensate does not freeze into icicles on the body, but drains all away.

To prevent other troubles, install the following on the outdoor unit:

- thorns - to prevent birds from landing;

- reinforcement cage (this is an anti-vandal grille) - to protect against theft, it is not necessary to install it on the balcony and above the 1st floor;

- mosquito net - to prevent poplar fluff and leaves from getting inside the block.

Principle of operation

The general principle of operation of a split system can be described as follows: warm air is removed from the room and discharged outside, cooled air is supplied in the opposite direction, which loses temperature as it passes through the air conditioner and comes into contact with the refrigerant.

When switching the split system mode to heating, the reverse process occurs. The external unit takes in cold air from outside and raises the temperature to the desired level. The indoor unit supplies heated air to the room.

KKB works due to the physical properties of the refrigerant, which transfers energy when the state of aggregation changes.

The outdoor unit of the air conditioner works as follows:

- The working substance in a gaseous state is supplied from the container to the compressor.

- From the compressor, the refrigerant flows under high pressure into the condenser, where it turns into liquid, giving off heat.

- Having lost some of the energy, freon enters the main line.

- From the main line, the working substance passes into the throttling device, where it loses pressure and cools.

- The cold liquid is transferred to the evaporator, where it actively circulates through the tubes.

- The evaporator is blown with warm supply air using a fan.

- Cold air is supplied to the room.

- Warm supply air heats the heat exchanger as it passes through it before being supplied to the room.

- The heat exchanger heats the refrigerant, which turns into gas.

- Freon, turning into a gaseous state, gives off cold to the air. From the heat exchanger, the refrigerant gas flows back into the compressor, where the process is repeated.

- A closed work cycle is created.

How to disassemble?

Disassembling the air conditioner requires caution. The most common question is how to open the indoor unit of a wall-mounted air conditioner.

Unplug it and do the following:

lift the cover of the indoor unit, remove and wash the mesh filters; under the curtains of the air conditioner blinds and near the filters, unscrew the screws and slightly open the lower part of the housing; pull it towards you and unclip the clips; remove auxiliary parts from the body (if any); dismantle the drain pan into which the condensate is drained, to do this, unscrew the screws and unclip the lock, remove the blind motor, remove the tray and the end of the drain hose; Unscrew and remove the left part of the coil with the radiator; Loosen the screw inside the shaft a couple of turns and carefully pull it out.

In a more complex design, the ECU board and shaft motor are removed. If you are not very sure, call the specialists. Clean and rinse the fan shaft and radiator with coil. You may need a Karcher high-pressure washer running at low speed. Reassemble the indoor unit of the air conditioner in the reverse order, turn it on and test it in operation. Cooling speed and efficiency should increase significantly.

To learn about the types of indoor air conditioner units, see the following video.

Components of the device

Under the neat square or rectangular front panel of the indoor unit of the air conditioner there are many parts hidden, the operation of which allows you to transfer cold or hot air into the room. The internal unit of a household split system includes:

- Housing and removable plastic panel, designed for convenience during repair and operation.

- Filter system. The design of the device includes a coarse filter. Some models can use carbon and electrostatic types of filtration systems.

- Evaporator. This is the radiator into which the coolant flows.

- Fan. Its operation allows the circulation of cooled or heated air.

- Control board and indicator panel. Electrical equipment that allows the device to operate in the mode specified by the user.

- Blinds (horizontal and vertical types). Used to change the direction of air flow in a direction specified by the user.

On the back side of the indoor unit there are fitting connections that are necessary to connect the device to the external part of the split system. Depending on the manufacturer and model of the device, they may be located on the left or right side of the device.

Freon line length

Users of climate control equipment often argue about the distance from the external unit of the air conditioner to the internal one, and then experiment with the installation. They can be understood - sometimes the features of the interior or the location of rooms require an increase in the length of the pipeline.

But professional installers know for sure that it is impossible to increase or decrease the length of the pipeline without permission. Indeed, deviation from the required parameters immediately affects the performance of the air conditioner.

Let's find out what the installation standards should be and why they cannot be changed.

Distance standards between blocks

Installation standards are set by the manufacturer. If you take the instructions, in the installation section you will find diagrams and operating parameters that you need to focus on during installation.

As a rule, the maximum length of the highway is indicated, nothing is said about the minimum. But complete with the blocks you will find copper tubes for connecting them - they should not be shortened under any circumstances.

The length of the pipeline depends on the model.

For household split systems with an internal wall unit, the following standards apply:

- the maximum distance between blocks is 15 m or 20 m (less often – 10 m);

- the minimum distance between blocks is 3, 4, 5 m (according to the length of the pipe included).

The exact data is indicated in the technical documents for the specific model.

Based on the parameters indicated in the table, it is clear that when extending the route, additional filling of the circuit with freon is required.

If the split system is equipped with a 5-meter pipe, it cannot be shortened. What to do if the distance between the blocks is only 3 m, and the tube is 5 m? You just need to carefully wind it up in large rings, without breaking or twisting, and hide the remaining 2 m in one of the blocks.

Pipeline too short

If manufacturers do not indicate the minimum length of the freon line in any of the available sources (paper or electronic instructions, video), rely on the generally accepted value - 3 m. The route cannot be made shorter.

If we remember how the process of transition of a refrigerant from one state to another occurs, we will understand that a short pipe is simply not enough to completely transform the substance. Freon, which has not had time to turn into gas in the evaporator, will enter the compressor in the form of a liquid, which should not be allowed.

The consequences of installing a pipeline that is too short are different:

- breakdown of air conditioner parts;

- transition of vibrations from the outdoor module to the wall module;

- noises uncharacteristic for an air conditioner - gurgling of freon in the pipeline.

The listed troubles can only be eliminated by increasing the length of the pipeline. As you can see, a small installation nuance turned out to be very important.

Distance longer than standard

As you already know, the maximum length of the freon line is limited to 20 meters. This value is relevant for home models with an average productivity of 2.5-3 kW. But for semi-industrial units from 8-9 kW, other limits are used - the pipeline length increases to 50 m.

We can conclude that the parameters of the distance between the blocks of split systems are directly related to such technical characteristics as productivity.

The most dangerous thing that can happen if the pipeline is too long is a decrease in pressure. Moreover, both sections – gas and liquid – expect negative consequences.

If the gas pressure drops before it enters the compressor, it also becomes lower at the outlet. As a result, temperature parameters decrease and freezing occurs.

There is no special line heating function, so the compressor overheats and breaks due to the load. You discussed the features of compressor diagnostics and the method of repairing it in the article: How to lay an air conditioner route: specifics of the communications device

A decrease in pressure in the pipeline section with liquid freon leads to an increase in the proportion of gas. A high gas content increases the speed of movement of the refrigerant, which leads to an even greater drop in pressure. In such conditions, normal operation of the air conditioner is simply impossible.

But there is one way out: to reduce pressure losses in the line, increase the diameter of the copper pipe. To do this, use the formula:

Professional installers advise increasing the length of the freon line only in horizontal sections.

In order to avoid complex calculations, it is recommended to increase the diameter of the gas pipe (it is slightly thicker) by 1 size: that is, replace 3/8 with 1/2, 1/2 with 5/8, etc.

We do not recommend doing the usual installation of an air conditioner or replacing pipes yourself. Experienced specialists know better what to do in difficult cases and avoid problems.

What determine the dimensions of the outdoor unit?

The dimensions of the block body, of course, are determined by the dimensions of the component parts. The largest parts of the external unit are the capacitor (radiator) and. The size of the blocks depends on their performance. The more powerful the air conditioner, the greater the “capabilities” and dimensions of its main components.

It's no secret that air conditioners come in different cooling capacities. In most cases, there is a direct relationship between the cooling capacity and the dimensions of the unit (especially one line). But when comparing different brands or models, you may get different numbers!

Of course, the more powerful the air conditioner, the larger its parts, the larger the dimensions of the units. But now “splits” with inflated characteristics are appearing. To reduce the price, they are assembled from budget components, which hardly provide the declared cooling capacity. This is also why different brands may have significantly different dimensions for the same power.

Installation Recommendation

It is better to entrust the installation of expensive, complex climate control equipment to professionals. At the same time, it is worth familiarizing yourself with its main stages if you plan to purchase a multi-split system with a common outdoor unit for 2 rooms.

The outdoor module is placed on an external wall or roof. In this case, each room module is located in the corresponding room. Pipelines are laid between the internal elements. They contain refrigerant, electrical supply wires and control cables.

The installation process itself usually includes the following steps:

- installation of a street block;

- installation of electrical wires;

- installation of communication systems;

- laying pipes;

- cabling;

- filling the line with refrigerant;

- checking the tightness of the work;

- installation of indoor units;

- connecting all elements of the system;

- equipment operation testing.

See the following video for installation of a multi-split system.

How to choose an air conditioner (split system)

Summer is coming, and the presence of air conditioning in the room (especially if it is located on the south side of the house) becomes the key to comfortable work and restful sleep. When it’s +30 outside the window, the fan is no longer able to provide the desired coolness.

And, although the hot weather in most of Russia lasts for five weeks at most, do not underestimate the damage that exposure to high temperatures can cause.

Indoors, the risk of overheating of household appliances and computers increases, and people also lose the desire to work. In addition, high temperatures have a bad effect on people with heart disease - when the body overheats, the risk of a heart attack increases many times over. And finally, the air conditioner does not necessarily have to remain idle throughout the cold season: an air conditioner with a heating function is also useful in winter, and some models can additionally operate in ventilation or dehumidification mode.

Connecting blocks

In general, there are no special secrets here. We connect the communications stretched through the hole in the wall to the appropriate connectors. There are no problems with connecting the cable - you connect wires of the same color to the terminals that are already connected to them. In this case, you definitely can’t go wrong.

If the height difference in the installation of blocks exceeds 5 meters, it is necessary to make a loop to catch the oil (we lay copper pipes in this way) dissolved in freon. If the difference is lower, we do not make any loops.

Laying a route between the indoor and outdoor units of the split system

Drainage

There are two ways to drain drainage from a split system - into the sewer or just outside, outside the window. The second method is more common among us, although it is not very correct.

This is the drainage outlet of the indoor unit (at hand)

Connecting the drainage tube is also easy. A corrugated hose is easily pulled onto the outlet of the drainage system of the indoor unit (a tube with a plastic tip at the bottom of the unit). To keep it securely, you can tighten the connection with a clamp.

The same applies to drainage from the outdoor unit. Its exit is at the bottom. Often they leave everything as is, and the water just drips down, but it’s probably better to also put on a drainage hose and remove moisture from the walls.

Outdoor unit drainage

If you are using a polymer pipe rather than a hose, you will need to select an adapter that will allow you to connect the air conditioner outlet and the pipe. You will have to look on the spot, because situations are different.

When laying the drainage pipe, it is better to avoid sharp turns and certainly not allow sagging - condensation will accumulate in these places, which is not at all good. As has been said more than once, the tube is laid out with a slope. The optimal is 3 mm per 1 meter, the minimum is 1 mm per meter. Throughout its entire length it is fixed to the wall, at least every meter.

Freon circulation system

It is somewhat more difficult to connect copper pipes. They are laid out carefully on the walls, avoiding kinks and creases. For bending, it is better to use a pipe bender, but you can get by with a spring bender. In this case, sharp turns should also be avoided, but in order not to bend the tubes.

The ports on the outdoor unit look like this. It's the same on the inside.

From the beginning we connect the tubes in the indoor unit. We unscrew the nuts from the ports on it. As the nuts are loosened, a hissing sound is heard. This is nitrogen coming out. This is normal - nitrogen was pumped in at the factory so that the insides do not oxidize. When the hissing stops, take out the plugs, remove the nut, put it on the tube, and then begin rolling.

Rolling

First, remove the plugs from the pipes and check the edge. It should be smooth, round, without burrs. If the cross-section becomes not round during cutting, use a calibrator. This is a small device that can be found in any store. It is inserted into the pipe, scrolled, leveling the cross-section.

The edges of the tubes are carefully aligned over a distance of 5 cm, after which the edges are flared so that they can be connected to the inlet/outlet of the blocks, creating a closed system. The correct execution of this part of the installation is very important, since the freon circulation system must be sealed. Then you will not need to refill the air conditioner soon.

Flaring copper pipes for air conditioner installation

When flaring, hold the pipe with the hole facing down. Again, so that copper particles do not get inside, but spill out onto the floor. It is clamped in the holder so that 2 mm sticks out. Exactly like that, no more, no less. We clamp the tube, install a flaring cone, and tighten it, applying considerable effort (the tube is thick-walled). Flaring is complete when the cone goes no further. We repeat the operation on the other side, then with the other tube.

This should be the result

If you haven’t rolled pipes before, it’s better to practice on unnecessary pieces. The edge should be smooth, with a clear continuous border.

Port connection

Connect the flared edge of the pipe to the corresponding outlet and tighten the nut. There is no need to use any additional gaskets, sealants, or the like (prohibited). This is why they take special tubes made of high-quality copper so that they provide sealing without additional means.

The principle of connecting a copper tube to an air conditioner port

You need to make a serious effort - about 60-70 kg. Only in this case will the copper flatten out, crimp the fitting, and the connection will become almost monolithic and completely airtight.

The same operation is repeated with all four outputs.